Column device

How to understand the location of water heater components? Don't worry, the diagram will help you. It is created based on columns.

External device:

- Metal casing;

- Control window;

- Gas flow regulator;

- Water regulator;

- Digital temperature display;

- Cold water connection (thread G 1/2);

- Hot water outlet pipe;

- Pipe for connection to the gas main (cylinder);

- A pipe for removing combustion products is connected to the chimney;

- The basis;

- Back wall;

- Installation holes;

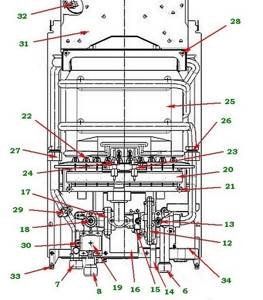

Internal equipment:

- 6, 7, 8 - continuation, pipes, as indicated above;

- 12 — water unit;

- 13 — water adjustment rod;

- 14 - drain plug;

- 15 - microswitch;

- 16 — control unit;

- 17 — gas unit;

- 18 — fuel adjusting rod;

- 19 — solenoid valve;

- 20 - collector;

- 21 — manifold mounting screws;

- 22 — burner nozzles;

- 23 - spark plug;

- 24 — ionization sensor;

- 25 - copper heat exchanger;

- 26 — output to the water unit;

- 27 — output to the gas unit;

- 28 — mounting bolts;

- 29 — thermal relay;

- 30 - thermometer;

- 31 — gas outlet device;

- 32 — traction sensor;

- 33 — brackets for installation;

- 34 — battery compartment;

Having understood the design, you can begin troubleshooting.

How to install and configure?

Receiving 10 liters of hot water in 60 seconds means that only a single water point can be served. The minimum requirement for starting is a liquid pressure of 0.15 atm. The diameter of the chimney provided for in the diagram is 12 cm; the water and gas supply channels are connected through pipes with a ½-inch cross-section. Gas supply is allowed only through bellows-type hoses. The recommended design of the smoke channel is with aluminum corrugation.

Neva 4510 is equipped with a chamber with natural (gravitational) thrust. Therefore, it must be installed strictly in rooms of at least 8 square meters. m. Carefully designed ventilation is a prerequisite. This ventilation must use materials that are resistant to significant heat. Another essential requirement is to be equipped with devices that guarantee safe use.

Malfunctions and their elimination

No spark discharge when opening hot water

- Insufficient water pressure in the water supply network (with the tap fully open, less than 2 liters per minute). It is necessary to call the service to eliminate the causes of low pressure in the pipeline.

- Check the functionality or correct installation of the batteries in the battery compartment (if the polarity is correct). If the elements are discharged, they must be replaced.

Battery pack

- Check whether the hot water tap at the inlet in front of the column is open enough. If necessary, open it completely.

- Or the problem may be insufficient water flow when the water pressure adjustment knob is selected - switch it to the required mode.

Repair and maintenance of gas-water unit

The design of the gas water heater water reducer has a simple internal structure. Everything is easy to understand. If desired, you can repair the geyser frog or carry out preventive maintenance without calling a technician.

How to remove a frog from a gas water heater

First you need to turn off the water and gas supplies. After this, work is carried out in the following order:

- drain the water from the heat exchanger - for this purpose it is better to use a tap or mixer located significantly below the water heater;

- disconnect the gas and water supply pipelines (an adjustable wrench will be required);

- Now you can remove the water unit of the gas water heater; if everything is done correctly, the frog should be easily dismantled.

The design of the gearbox may differ depending on the model of the flow column. In order for the removal of the water block to be successful, it is necessary to unfasten all parts and pipes suitable for the main structure. The housing can be easily removed; no physical effort is required.

Cleaning the water unit of a gas water heater

Held at least every year. There are several fixation bolts on the frog cover. When unscrewing, care must be taken not to damage the folds. After removing the cover or disassembling the gearbox into two parts (depending on the model of the column), the internal space is cleaned and the structural parts are serviced:

- when cleaning the gearbox, scale and solid residues settled at the bottom of the unit are removed, and at the same time the coarse mesh on the inlet pipe is cleaned;

- the rod can be lubricated with castor oil or grease;

- The gasket can also be coated if it feels rough to the touch and has lost its elasticity.

Regular maintenance of the frog will extend the life of the instantaneous gas boiler and ensure its smooth operation.

Which components should be replaced?

The gearbox contains several elements that are constantly exposed to mechanical pressure and poor quality water. At each service, the functionality of the following components is checked and replaced:

- rod seal - replacement of the seal is necessary on average every 3 years to protect the gas valve from moisture;

- membrane - replacement of the gasket is necessary when it ruptures, as well as when microcracks appear;

- rod and components - the spring that brings the rod to its original position fails after intensive use after 4-5 years.

For maintenance, it is better to use ready-made branded gaskets for the gearbox. The membrane is usually sold separately, but if you wish, you can purchase a factory repair kit with all the components that need to be replaced.

How to adjust the reducer on a gas water heater

Setting up the water unit will help optimize gas flow and water pressure at the outlet of the column. Adjustment of the water reducer of an instantaneous gas water heater is carried out using bolts located on the back side of the unit. Usually they are set in factory conditions, which is sufficient for normal operation of the column.

If you need to adjust the water pressure, the bolts are loosened a little. The DHW pressure at the outlet should increase. Adjustment of the gas water heater reducer is not carried out unless absolutely necessary. It is better to have the work performed by a gas service representative.

After the maintenance is completed, the water unit is installed back. Check for water and gas leaks. The column is launched and used as usual.

Error codes Neva Lux

The display allows the user to see the fault code. Column self-diagnosis provides a digital value if there is a malfunction.

E0

The boiler turns off

No fuel enters the system. Check the gas valve; the supply may have been turned off for a short time.

E1

The control board does not receive a signal from the flame sensor. More than a minute passed.

What could have happened:

- Air in the gas pipeline. This happens when you turn it on for the first time or when the device is turned off for a long time. Open and close the hot water several times until the burner lights up.

- The fuel supply valve is not fully open. Turn off the tap.

- Insufficient pressure in the gas line.

- The cylinder has run out of fuel. The cylinder needs to be replaced.

- Broken wiring between the water unit and the flame sensor, solenoid valve. Inspect the cable for damage to the insulation.

- The electrode has moved out of place and does not reach the burner. Return the part to its original place.

- The electrode and flame sensor are covered with soot. You can clean the parts with a brush.

- The contacts between the spark plug and the high-voltage wire have come loose.

- The nozzles are clogged with soot.

The burner must be removed for cleaning. Disconnect the wiring and unscrew the pipe nut.

Unscrew the two manifold bolts, and then do the same with the burner mounts. After dismantling, the holes are washed with a brush and soapy water.

After rinsing and drying, reassembly is carried out.

Code E3

The solenoid valve actuated before the signal from the flow sensor was received. The valve is faulty.

A new element is being installed. The electronic unit is broken. Diagnosis is carried out by a specialist.

Error E7

After 7 attempts to ignite the appliance still does not light up or goes out. Open the fuel valve all the way. The ionization sensor has moved or soot has accumulated on its electrode.

It should be in the flame zone, near the burner. Cleaning is done with a brush. Electric valves have failed. The water or gas block has boiled. Replacement of elements.

Error E8

The traction sensor has tripped. Reasons: The sensor is broken. Check to see if the contacts fit tightly and change the part.

The chimney is clogged with debris or soot. If you cannot clear the passage with your own hands, contact utility services.

Design and types of water block

The material used to make the water reducer varies and is therefore divided into several types:

- Brass. Alloy of copper and zinc.

- Plastic. The practical device is not subject to corrosion.

- Polyamide. Reliable device with fiberglass composition.

The column regulator or “frog”, as the block is also called, has protective functions. It serves to automatically turn on the device when water is supplied. It also protects against overheating when pressure in the line decreases.

How the gearbox works:

- Base and cover with bolts.

- Rubber membrane with a disc on the rod.

- Flow device.

- Temperature switch.

- Flow sensor.

- Venturi tube.

- Filtering device for hot water.

See diagram:

The water pressure regulator cover can be held together with steel screws or plugs. Since the parts do not come into contact with water, there is no risk of corrosion. By unscrewing the screws, you will remove the cover behind which the membrane is located. The device is quite simple.

When you turn on the water, pressure is created on the membrane. It pushes out the rod, which operates the gas valve. Fuel is supplied to the burner and heating begins. When the mixer closes, the pressure drops - the parts return to their previous position.

An important part of the gas-water unit is the Venturi nozzle. What is it for? For example, in the Neva technology, the tube is located at the bottom. The location in the “Oasis” and “Astra” columns may differ. The part serves to reduce the pressure of the working medium. This is how the gas supply is adjusted.

When you close the tap, the tube equalizes the indicators, causing the membrane fitting to return to its place. After this, the device turns off.

The water part is also susceptible to breakdowns, so we will list the main faults and ways to repair them yourself.

What to do if the flame in the Neva column does not light up

If the column is under warranty, it is better to invite a specialist. Let's look at some reasons and solutions when a water heater does not ignite.

As soon as you pulled it back a little, excellent traction appeared, the smell of gas stopped, and the automation stopped turning off the column. I turn on the water, hear and see how the piezo discharge works, but the column does not turn on. BUT! What I noticed is that before it ignites there is a CLICK (like some kind of relay). Therefore, ignition occurred when gas rushed in and hit the spark. And it was even worse that out of five times, one time she wasn’t allowed in at all. Column 4511 at first glance is super for such money (5200), installed by my mother-in-law, everything is super. Soft switching on and off. Heats the water to the fullest, keeps the set temperature more or less normally.

But in summer the water temperature rises by several degrees, so the column needs to be screwed down. As a result, the water heater turns off almost immediately due to overheating.

Unfortunately, the burners in the Neva and Oasis gas water heaters (as in many others) are susceptible to blockages. It needs to be removed, for which the column is disassembled and the burner itself is removed from it. If your gas heater does not light and you decide to clean it, do it on the balcony or in the open air.

Recommendations for use

A lot depends on how correctly the system is used. If technical standards are properly followed, the display, microswitch and other parts will not be subject to failures or will become subject to them less frequently. Neva 4510 is very sensitive to the characteristics of heated water. The supply of rusty liquid significantly accelerates the contamination of internal ducts and leads to a drop in pressure. It is important to remember that, despite the manufacturer's instruction about 15 regulatory positions, gas injectors are usually placed in one of three positions.

Do not open hot and cold taps at the same time unless absolutely necessary. In such a situation, the automation often gives a false alarm and mistakenly stops the device. It is imperative to maintain a limited water temperature in the outlet circuit. Otherwise, a very large amount of mineral salts and scale will likely accumulate.

Cleaning the burners and heat exchanger, although not a particularly pleasant procedure, is the only guarantee against premature failure.

At least once a year it is worth inviting a gas mechanic or another specialized organization. It is recommended to ventilate the room before each use and after switching it off. You cannot light the heater if the draft in the chimney has not been checked or the reason for its absence remains. The use of inlet magnetic filters on water pipes sharply reduces the risk of scale formation. This risk can be reduced by never heating the water to more than 40 degrees.

In general, the system meets the same requirements as developed Western European designs. If freezing of water is detected, it must be drained.

Normal operation of the dispenser with a working gas pipeline is not accompanied by the appearance of a mercaptan smell in the room. Having discovered it, you should immediately turn off the device and do not use any electrical appliances. Further actions must be taken by gas service employees.

For information on repairing and replacing the membrane in the Neva 4510-4511 geyser, see the following video.

Turning on the speaker with extraneous claps

Most often, this problem is caused by clogged ventilation; it may also happen that the supply batteries have expired or the fuel is supplied too intensively. Sometimes characteristic pops occur when the nozzle is clogged. In any of these cases, you need to contact a specialist. The only exception is replacing batteries or cleaning ventilation ducts.

Model range of geysers Neva

Gas water heater Neva 4510

One of the popular models is the Neva 4510 geyser. The unit is equipped with an electronic automatic ignition system. The productivity of water heating equipment is 10 l/min.

The column turns on at a minimum pressure of 0.29 atm, the power is 17 kW, and the weight of the device is 10.4 kg. The model is characterized by low fuel consumption. Thus, Neva 4510 consumes 0.77 m³/hour of liquefied gas, and natural gas - 1.95 m³/hour. Device dimensions: 648×356×218 mm.

Gas water heater Neva Lux 5514

Neva Lux 5514 is one of the best models of household gas water heaters, which in terms of basic technical indicators is not inferior to well-known brands. The design features of the unit include:

- presence of a traction sensor,

- reliable combustion chamber equipped with a water cooling system,

- automatic maintenance of the set water temperature,

- integrated piezo ignition,

- hydraulic flame intensity modulation control system,

- automatic gas pressure level limiter.

The water heater power is 28 kW, productivity is 14 l/min, and the device weighs 12 kg. These indicators are quite enough to ensure uninterrupted operation of the unit to supply hot water to two intake points simultaneously. The column turns on automatically when the water tap is opened.

The water heater has dimensions: 650×350×299 mm. The product has a stylish modern design. On the front part of the screen of the Neva Lux 5514 unit there is a rotary regulator, thanks to which the operating parameters of the equipment are adjusted.

The presence of an electric ignition system ensures economical consumption of consumed gas, which makes paying utility bills at a fairly low price. The Neva Lux 5514 geyser is characterized by stable, silent operation, and the occurrence of unit malfunctions is quite rare.

Gas water heater Neva 4511

If you need a powerful instantaneous water heater, you should pay attention to the Neva 4511 model. It has an attractive design, high-quality assembly and high performance - in 1 minute of operation the unit manages to heat 11 liters of water, the power rating is 21 kW

You can read about how to properly connect the device to the water supply system, gas mains or liquefied gas cylinder in the operating instructions. According to user reviews, the Neva 4511 gas water heater copes well with several points of consumption simultaneously. The weight of the water heater is 11 kg, the dimensions of the device are 565 × 290 × 221 mm. The model is equipped with automatic electronic ignition and has a water-cooled combustion chamber.

Video: “The Neva 411 column does not light up - a method for troubleshooting”

Gas water heater Neva 4513

The Neva 4513 household gas water heater is equipped with an automatic electric ignition system. The rated power of the model is 25 kW, the unit productivity is 13 l/min. With a weight of 15.8 kg, the dimensions of the product are 665 × 390 × 237 mm. The column has a water-cooled combustion chamber.

Neva 4513 is easy to operate, has a long service life and a high degree of safety. The power of the unit is quite enough to supply hot water to several consumers at the same time.

Technical characteristics of the gas water heater Neva 3208

The Neva 3208 instantaneous gas water heater model can operate at a minimum pressure of 0.15 atmospheres. With a rated power of the equipment of 23.2 kW, its productivity is 6.5 l/min. The column is installed in a vertical position, the supply lines are from the bottom.

The device weighs 19.5 kg and its dimensions are 730x390x280 mm. The column is equipped with an electric ignition system. If the Neva column does not light up, most likely the breakdown is due to a malfunction of the heat exchanger. It can be eliminated by flushing the pipeline.

Gas water heater Neva Transit

Let's look at the operating features of the Neva Transit family of dispensers using the example of the VPG-EM model (there are also VPG-E I, VPG-E, EMT with a power of 12−24 kW and a capacity of 6−12 l/min). Flow units maintain the specified liquid heating temperature in automatic mode.

The column has a gas modulation device: by changing the position of the rod, you can reduce the amount of fuel consumed and increase the heating efficiency. In addition, the amount of deposits in the heat exchanger pipeline is reduced, thereby significantly increasing the operating life of the unit.

Repair of geyser Neva

Most models of Neva geysers have proven themselves to be simple and easy-to-repair water heating devices. They are far from the reliability of European models, but repairing them is much cheaper, and you can almost always do it yourself.

Failure and subsequent repair of a spark plug is considered by the rules to be an atypical case of breakdown, therefore, after performing repair work, it would be correct to look for the cause of the defect. Most often, plastic burnout occurs due to condensation flowing through the ventilation system onto the body of the gas burner.

How to repair a heat exchanger union nut

One of the most common defects of Neva geysers for almost all models is the low quality of the metal of the heat exchanger. According to the rules, the heat exchange circuit through which water moves should not come into contact with aluminum parts, for example, a gas burner or a control unit. Any such contact can cause electrochemical corrosion of the copper walls, and then repair will simply be useless.

In addition, the rules for tightening the union nuts that secure the heat exchanger to the regulator and outlet pipe are not always followed. With each heat exchanger removal and repair, the nuts cut a thin, barely visible path into the copper wall. Ultimately, the flared end and part of the copper pipe simply break off the tenth time of twisting.

In this case, you have to trim and level the area of the breakdown, install a new nut with an external thread, and connect the heat exchanger to the control unit with a regular flexible hose. Any other repair option, as practice shows, turns out to be short-lived.

Repair of a microswitch in the geyser starting system

A situation similar to the Oasis with dead batteries also happens with the Neva gas water heater. When you try to start the Neva, the indicator board lights up, but the gas burner does not ignite. Sometimes the column can be turned on 4-5 times.

In this situation, repair of the microswitch is required due to premature wear of the part or improper adjustment of the unit.

The switch is located next to the water pressure control unit. When the column starts, the membrane on the block pushes out the rod, which unlocks the switch contact. Unlike the Oasis, all parts of the unit, including the rod, are made of brass, so there is no corrosion; the microswitch itself must be repaired and replaced.

To perform repair work, you need to disconnect the connector, unscrew two M3 screws and remove the switch housing from the strip, as in the video

Replacing the microphone is easy. You can buy an original part for 400-500 rubles. in a specialized salon or purchase an analogue for 50 rubles. in any radio parts store. There is no difference for repairs; in both cases they will sell a part from Chinese consumer goods.

In order to carry out the repair, you will need to unsolder two wires with a connector from the switch legs, put on a heat-shrinkable tube and solder them to the contacts of the new part.

At the final stage of repair, the switch is screwed with old screws onto the mounting strip on the block. Next, you need to adjust the position of the microswitch body so that the rod completely releases the contact when moving. This is done using mounting screws. One of the screws bends with a radius; accordingly, by rotating it, you can move the switch body in the desired direction.

Soot has accumulated on the heat exchanger

If you open the cold water too much, the lit column will simply go out. Make it a rule to turn on the hot water supply first, and only then the cold water supply. It’s best to adjust the degree of heating using the appropriate controls.

The main burner may burn partially if there is dirt.

One of the options we have already mentioned is a pilot burner.

If there is no pressure even in a cold water tap, all that remains is to complain to the authorities responsible for water supply - the pressure must correspond to the standards established in the country. If no one is going to do anything, we install a pressure-increasing pump - it will raise the pressure to the required limits and help ignite the gas in your column.

All this is a consequence of the burner being clogged with dust and the nozzles of the nozzles on the manifold becoming overgrown. The collector is also first cleaned from above of dust and deposits with a damp cloth. It is better to unscrew them (head 8) and blow them with a stream of air, for example, with a car pump. If the owner is a motorist, then he may have an aerosol in the garage for cleaning the carburetor channels: in this case, such a solution can be very useful.

The following situation is possible: the column turns on, but for some reason the water flows barely warm; and after a short period of time the column suddenly goes out. The reason lies in a faulty mixer that “unauthorizedly” mixes cold water with hot water. In this case, the water in the column overheats and it turns off. If water comes out of it, then the mixer needs to be replaced. The draft must take place even when the column is not working; in this case, the chimney works as a ventilation duct.

Lack of draft will require an inspection of the flue gas collector and the chimney itself. If there are blockages here, they can interfere with the normal passage of combustion products. Unfortunately, you will be able to independently check only the part of the chimney that is visible before entering the wall - further work must be carried out by specialists.