Very useful tips

Threaded connections must be tightened with a wrench and not by hand to ensure the required tightness.

To connect fittings, protective devices and the pumping station itself, it is better to use pipes whose diameter is slightly larger than the calculated one in order to compensate for the load increased due to bends in the line. To protect the pump from idling, you can install a recirculation line. To do this, tees are placed on the supply and suction pipes and the free pipes are connected with a return line.

A valve should be placed on it to control the intensity of the reverse flow. This addition will improve the pressure, but will slightly reduce the performance of the device.

A bracket can be used as a base for the pumping station, but it must stand level on shock-absorbing pads to minimize vibration.

About once every three months you need to check:

- condition of joints for leaks.

- condition of filters for timely cleaning.

- relay settings for their correction;

- the condition of the hydraulic tank to determine the location of leaks.

Possible malfunctions and methods for eliminating them

Despite the high reliability of such devices, they, like any technical element, have operating features and can also break down and fail. Most often the check valve stops working:

- If debris and stones get into the housing;

- If the spring is damaged;

- When the surface of rubber or plastic seals wears out;

- Gradual aging and loss of elasticity of plastic and rubber;

- Exposure to water and chemicals dissolved in it.

Traditionally, if the valve operates unsatisfactorily, it is simply replaced, since the cost of replacing individual parts and assemblies far exceeds the price of a new one. But it is quite possible to extend the service life of such a device; to do this, it is enough to install a regular, simplest mesh filter at the inlet. Such a simple device is quite enough to almost double the service life of the valve.

Types of constipation

Locking mechanisms placed in front of the meter are classified according to different criteria. First of all, these are design features.

The following types are considered the most common:

Devices with disc and double-leaf locking elements are considered separately. The first type of device consists of a flat disk held in place by a spring. Under the influence of water, the spiral contracts, and the water begins to flow away. When the pressure drops, the disk is pressed against the hole, and the reverse outflow of liquid becomes impossible. Double-leaf devices operate on the principle of closing the doors, fixed on an axis. Such devices are not installed in multi-storey buildings. The valves cannot withstand impacts from coarse particles circulating in the water supply.

Rotary valve

Locking mechanisms of this type are capable of operating for a long time in extreme conditions and withstanding collisions with large particles. Rotary models are mounted on pipes of any cross-section. This is explained by the features of the device. The shut-off element is a hinged flap that allows flow in the desired direction. When casting back, the part closes, fitting tightly into the socket.

In a rotary check valve, a disc acts as a shut-off element.

Ball valve

This type resembles disc devices, but the closure component is spherical in shape.

The element is driven by a stretched spring, stopping the flow of water. Ball devices are mounted only on pipes of small cross-section.

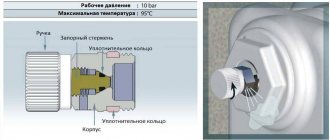

Lift valve

Such devices are installed only on horizontally located pipelines. The locking device has the form of a disk, fixed by a spring and placed in a vertical position.

This component has the following features:

- installed after the meter, which eliminates the need to remove the device;

- used in both domestic and industrial environments;

- characterized by high tightness;

- sensitive to contaminated liquids.

Operating principle: when a stream hits, the shutter rises, allowing water to flow into the pipe. When the pressure decreases, the disc lowers, preventing the reverse outflow of fluid.

How to fix a water seal failure

The problem of pushing back and breaking the water seal in a pipe requires special attention. This is one of the most common problems in modern apartments, since the reasons for this problem lie either in atmospheric pressure or in the filling of the water seal tank with wastewater.

Causes of water seal failure in the sewer system:

- Changing pipe sizes established by technical regulations. This is often the case during renovations, when adjusting important sewer facilities to the interior design, for example.

- Blockages in the sewer system also contribute to an increase in pressure inside the pipes and, as a result, displacement of the water seal, filling the sewer with wastewater.

- In especially old houses, the valve breaks due to icing of the sewer in the basement or attic of the house.

Most often, when repairing water seals with your own hands, they resort to chemicals that allow you to clean the pipes efficiently. Depending on what stinks - the bathroom drain hole or the kitchen sink, you will need the appropriate product.

If the cause is actually icing of the pipes, you need to resort to centralized cleaning of ice from the sewer system. This is done quite simply - hot water is poured into the water supply system in the place where ice accumulation is detected. A separate case is a pipe in an apartment, which simply does not have an elbow where a water plug would form in the form of a water seal. In this case, you can bend the pipe yourself, or better replace it with a more suitable one.

This is interesting: How to choose the best film for a greenhouse: we outline the essence

Varieties and selection options

Check valves installed in water supply systems are available in several types:

Disk devices are distinguished by their compactness. The principle of operation of the device is simple - under the pressure of the liquid, the disc valve moves, freeing the channel. When the pressure decreases, the disk returns to its original state due to the action of the spring; in this position, reverse flow of water is impossible.

Double-blade valves, which are large in size, are installed in complex water pipelines. As an example, we can imagine the water supply systems of individual houses equipped with a pump - if it breaks down, there is a high probability of reverse movement of water under pressure. The principle of operation of a two-bladed device is also not complicated: the shut-off element folds in half under the influence of liquid, and when the reverse current flows, the valve unfolds, completely occupying the passage.

A ball can be used as a shutter, moved to the open position by the action of a fluid flow. When the pressure decreases, the element returns to its original position, closing the working passage. Such valves, like taps, are called “ball” and are installed in water pipelines made of pipes of various diameters.

Lift valves use a shut-off bowl (spool). Under the pressure of the liquid, the bowl rises, freeing up space for the flow to pass through. When the pressure decreases, the spool moves to its original position, closing the passage. Such devices can only be installed on horizontally located pipes.

In petal-type devices, the shutter consists of petals that move apart under water pressure and open the channel. When the liquid moves in the opposite direction, the petals move.

When selecting a valve, you should pay attention to the material it is made of: high-quality devices are made of CW617N brass.

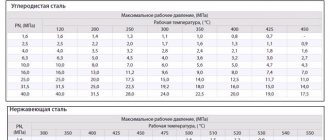

You also need to consider special markings:

- The designation of permissible pressure is carried out with the letters PN or RU and the numbers following them. For example, RU-20 means the device’s ability to operate under pressure up to 20 bar. In central water supply systems, the standard pressure is up to 6 bar for cold water and up to 50 bar for hot water.

- The diameter of the passage is marked with the letters DN or RU, for example, RU-20. Based on this parameter, the valve is selected taking into account the passage size of adjacent elements to prevent increased loads and decreased pressure.

Possible malfunctions and methods for eliminating them

Despite the high reliability of such devices, they, like any technical element, have operating features and can also break down and fail. Most often the check valve stops working:

- If debris and stones get into the housing;

- If the spring is damaged;

- When the surface of rubber or plastic seals wears out;

- Gradual aging and loss of elasticity of plastic and rubber;

- Exposure to water and chemicals dissolved in it.

Traditionally, if the valve operates unsatisfactorily, it is simply replaced, since the cost of replacing individual parts and assemblies far exceeds the price of a new one. But it is quite possible to extend the service life of such a device; to do this, it is enough to install a regular, simplest mesh filter at the inlet. Such a simple device is quite enough to almost double the service life of the valve.

Installation features

Experts recommend installing 2 drains with check valves for the water meter. They are installed after the ball valves of both risers of the apartment.

Installation is carried out as follows:

- If a mesh filter was not previously installed after the locking device, install it first. A part that prevents the backflow of water is placed after the meter.

- Install the metering device. Observing the correct direction, place the valve. If you install the device backwards, it will not solve the assigned tasks. Some meters are equipped with built-in mechanisms. In this case, the described stage of work is skipped. Small check valves are inserted into the fitting hole or placed in a fitting located after the meter.

- The resulting structure is connected to the pipeline.

Compact built-in devices look like a plastic circle with a cross inside. Due to their small size and poor build quality, these products fail and require replacement. Therefore, it is recommended to mount 2 devices at once. There are water direction indicators on the surface of the universal parts.

The body consists of 2 components: the base and the nut that screws onto it. The fixing element is screwed clockwise and dismantled counterclockwise. When installing and removing the device, hold the nut on which the pointer is drawn.

You might be interested in:

Procedure for installing a water meter in an apartment

Installation of a gas meter in an apartment, relocation

Gas meters for private homes: types, installation rules

Source

Thermal insulation of external water supply

The location of the pipes below the freezing level of the ground allows you to avoid measures to insulate the main line. However, not all areas can boast a sufficiently low groundwater level, which completely eliminates the possibility of digging deep trenches. In this case, the solution to the problem is to lay pipes at a shallow depth and properly insulate the external water supply.

Relatively recently, the only way was to wrap external communication pipes with thermal insulation material and plastic film to protect them from water.

Modern methods, materials and technologies make the insulation process simpler and significantly increase the efficiency of heat conservation. Modern methods of insulation include enclosing pipes in a hard polystyrene foam shell at one of the production stages.

A heating cable stretched along the main and attached to the pipe is the most effective option for a water pipe with a diameter of 32 mm. However, this option has one significant drawback - the need to connect to the power supply network

This problem is not of particular importance for owners of suburban housing who constantly live off-grid. In case of a power outage, they have an alternative option - a generator running on gas, gasoline or diesel fuel.. https://www.youtube.com/embed/nnE3BYTgh70

Rules for installing a check valve ^

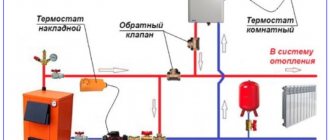

There are two options for installing a check valve on a water supply system if it involves a pumping station:

- in front of the pumping station;

- immediately after the ratchet on the suction pipe.

The second option is considered the most optimal, because installing a check valve in front of the station can lead to a limitation in the volume of water required to be discharged into the suction pipe and subsequently captured by the pump when it is turned on.

In this case, along with the working medium, the pump can capture a portion of air. This leads to noise in the pipeline and the expulsion of the air plug when the water tap is opened.

Mechanism objectives

The working mechanism of most water meter devices is a multi-bladed impeller that does not have a locking element and rotates in both directions.

Some consumers, refusing to install a valve, pursue a selfish goal - rewinding the water meter readings. To rotate the impeller in a different direction, perform the following actions:

- the supply of liquid flow to the mixer is shut off;

- the remaining water is drained;

- Air is supplied through the hose of the vacuum cleaner connected to the mixer.

Despite the apparent simplicity of the procedure, there are several nuances that do not meet the expectations of consumers:

- manipulations take a long time;

- requires significant energy consumption;

- too little air pressure will leave people living in the house without water for the whole day;

- too much pressure can damage the impeller;

- To connect, you need to find a Soviet-made vacuum cleaner; most modern devices cannot supply air outside.

Whether a check valve is required on a water meter follows from the law of connecting vessels. Water supply systems (cold and hot) organized in apartment buildings converge many times in mixing devices. It is almost impossible to maintain the same pressure level in pipelines.

When the taps are opened simultaneously, both flows are mixed, the liquid flows from the system with increased pressure into the pipeline of lower pressure. The hot water meter can also determine the flow rate of cold water, which will affect the size of the water bill. In a situation where a “cold” water meter begins to determine the flow of hot water, there is also no benefit. Its elements are not intended for use in a hot liquid environment; the water meter will quickly fail.

An equally important factor explaining why a water meter with a check valve is needed is the operating conditions. The service period specified by the manufacturer is achieved only if the measuring chamber is constantly filled with water of proper quality.

Primary purification of the liquid from large particles is carried out using a mesh filter. In a flowmeter with a check valve, the chamber is not completely emptied.

A non-return valve is installed in faucets, but when the water supply is temporarily interrupted, a situation often arises when an impatient consumer opens the valve in the hope that it will turn on soon. The water located in the gap between the shut-off valve and the mixing device flows into the sewer pipe. If a water meter with a check valve is installed, only liquid will flow from the area from the mixer to the valve. The reason is that the valve turns on only under the required pressure. It doesn’t matter if the shutdown was short and the residents managed to turn off the water in time. If the water supply is interrupted for a long time, not only the water meter may be damaged, but also the neighbors will be reimbursed for repair costs - there is a risk that the pipe will burst.

What material should the valve be made of?

This type of product can be from:

- Brass. Does not corrode, does not oxidize, does not rot. The material is strong, durable, but belongs to the expensive segment. At the same time, the alloy is brittle, subject to mechanical stress and is used mainly by professionals.

- Cast iron. It is used extremely rarely in everyday life, since at low cost it is a fragile material. It is subject to aging, works for a long time, but becomes overgrown with limescale, which is undesirable when organizing a water supply system.

- Stainless steel. The alloy can withstand mechanical loads. No corrosion spots appear on it. Does not rot, is resistant to aggressive environments, inert to water and chemical compounds. The only negative is the high cost.

When choosing a check valve for a pumping station, you need to remember that the markings indicate the materials from which all elements are made. If, say, the body is brass, then this does not exclude that the internal elements are made, for example, of plastic. This is how manufacturers try to reduce the cost of the design. The consumer, not being a professional, does not buy the best modification.

How to choose a valve for your home pipeline

When purchasing a protective device for installation on a pipeline, you need to take into account several features, then the device will delight the owner with its technical features. We invite you to consider a few simple rules.

- Before purchasing, carefully study the design of the connecting elements of the device. It is very important that the diameters of the pipeline and the check valve match. In current living conditions, most people prefer to use coupling options, since most plumbing systems are assembled using this connection method.

- Analyze the principle of operation of a check valve. If you lack knowledge, consult the seller, or refer to the documentation if the product is branded. If any malfunctions or violations are identified, it is better to refuse the purchase.

- If you need to purchase a ball, flange or wafer mechanism for a pump or other technical needs, be sure to compare their capabilities with the characteristics of the environment in which they will operate.

- The material from which the structure is made must be selected based on the technical characteristics of the water supply system: plastic is suitable for polypropylene structures. If the check valve must be installed on a hot pipeline, the best option would be to choose a device made of durable metal, since most propylene structures are unstable to high temperatures.

- Brass products are an ideal alternative to all fragile structures. Products made from this material are well protected from various temperature and mechanical deformations; moreover, most designs have a ball-type action.

Attention! All devices for protecting against water hammer in a pipeline must be purchased wisely, when choosing, taking into account a number of functional features, and not just selection rules.

The best vibration pumping stations

The working mechanism of such models is based on a special membrane. Under the influence of electromagnetic vibrations, it is deformed and allows water to pass through at different pressures. Vibration pumping stations are distinguished by high performance and low energy consumption.

DAB E.sybox Mini 3 (800 W)

5

★★★★★ editorial assessment

100% of buyers recommend this product

Features of the model are ease of operation and high performance. Low noise level and absence of vibration under heavy loads contribute to the comfortable use of the unit in residential buildings. The pump can be installed in any position relative to the floor or mounted on the wall.

The wide LCD screen can be rotated at an angle of up to 90°, the Russified menu makes it easy to configure the main operating parameters. The complex uses a number of built-in protection systems, including against dry running, overheating, voltage surges, short circuits and blocking of the pump shaft.

Advantages:

- ease of installation;

- Ease of use;

- productivity 4.8 m³/h;

- pressure up to 50 meters;

- durability.

Flaws:

high price.

DAB E.sybox Mini 3 is the best option for home use. Maintaining constant pressure and high productivity of the complex contribute to the efficient operation of water supply to a large number of consumers.

Metabo HWW 4000/25 G

4.9

★★★★★ editorial assessment

95% of buyers recommend this product

The pump body is made of cast iron, the boiler is made of steel. Thanks to the mounting holes, the unit can be securely fixed to the surface, which eliminates vibration under high loads. The device is equipped with a filler hole that allows you to independently replenish the water level in the tank.

The lifting height is 46 meters, the engine power is 1100 W. A pressure switch, protection against overloads and overheating, and a system of mechanical sealing rings help increase the service life of the unit in any conditions.

Advantages:

- ease of maintenance;

- durability;

- productivity up to 4000 l/h;

- powerful engine;

- hole for filling water.

Flaws:

short cable.

Metabo HWW can be used for site irrigation, clean water supply or groundwater pumping. The carrying handle and large tank make it easier to solve various household tasks.

BISON US-T5-1100-S

4.8

★★★★★ editorial assessment

90% of buyers recommend this product

The model has a 24-liter reservoir, which helps to increase the interval between turning the device on and off and softens the water hammer when the pump is turned on. The 1100 W motor has overload and overheat protection and is highly efficient.

The throughput capacity of the unit is 4.2 cubic meters per hour, the maximum pressure is 45 meters. The anti-contaminant filter and check valve ensure clean water flow and prevent it from returning to the pump.

Advantages:

- durable body;

- durability;

- powerful engine;

- high performance;

- check valve

Flaws:

short network cable.

BISON NAS-T5-1100-S is resistant to high loads and external influences. The station is worth purchasing to ensure operation and maintain pressure in the water supply system of a private home.

Aquarobot M 5-10 (B)

4.8

★★★★★ editorial assessment

89% of buyers recommend this product

The main features of the model include compactness and ease of installation. The volume of the hydraulic accumulator is 5 liters, the throughput is 1.6 cubic meters. m/hour. The complex is used for pumping clean water; the content of impurities and solid particles in it should not exceed 100 g/m³.

Thanks to the 245 W motor power and the ergonomic design of the unit, an increased pressure is achieved - up to 75 meters. This makes it possible to ensure a stable water supply to houses located at a great distance from a well or well.

Advantages:

- compactness;

- high performance;

- ease of maintenance;

- ease of installation;

- low price.

Flaws:

shallow suction depth.

Aquarobot M is suitable for providing water to small residential buildings. A reliable solution at an affordable price, especially if the well or well is located far from consumers.

Materials and components for installation

The steel mains of the central water supply, supplying dirty and rusty water to our homes, are forever a thing of the past. To install water supply for a private house from a well or borehole, use modern HDPE polyethylene pipes PE-100 with a wall thickness of 3 mm, which can be easily laid and brought into the house with your own hands. In the vast majority of cases, a diameter of 32 mm is sufficient for external wiring.

To supply water according to the first scheme (with submersion of the pumping unit) from a well you will need:

- head or well adapter;

- suspension cable with a diameter of 3 mm;

- the pump itself, equipped with a check valve;

- hydraulic accumulator with a capacity of 25-100 l;

- pressure switch type RDM-5 and “dry” running;

- coarse filter and dirt trap;

- pressure gauge;

- ball valves, fittings;

- electrical cable and circuit breakers rated 16 A.

If a scheme with a pumping station is more suitable for you, then you do not need to buy a relay and a hydraulic accumulator separately, since they are included in the installation kit. How to correctly calculate the minimum volume of the storage tank and pump power, watch the video:

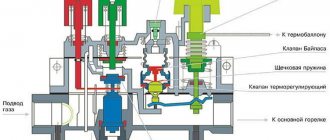

Types and purpose of check valves

The dimensions of the check valve are small, but without this little detail it will be impossible to maintain the pressure in the water supply system. It belongs to the category of pipeline fittings whose main task is to prevent a reverse change in the flow of water in the pipes of the water supply system.

Household pumping equipment is not designed for its movement in an abnormal direction.

A check valve is used to allow water flow to flow in only one direction, completely blocking its path back (+)

There are models of pumping stations on the market, the manufacturers of which include a check valve. Such options are supplied with a suction hose with a built-in check valve. But in most cases, you have to purchase this fittings yourself.

Such valves are installed both on the suction line and at the entrance to the internal water supply system immediately after the pump with a hydraulic accumulator or in front of the pumping station.

Depending on the installation location in the water supply system diagram, check valves are divided into:

- Bottom. They prevent the reverse movement of water raised from the source when the pumping equipment is turned off. They create conditions for operating the unit without constant filling with water before starting it and the suction line.

- Pipeline. These include axial and valve varieties. Prevents a drop in the operating pressure in the system.

If there is no check valve at the end of the suction pipe of the pumping station, then when the pump stops, water will begin to flow back under the influence of gravity. As a result, air pockets will form in the line, and under “dry running” conditions, the seals will begin to collapse. As a result, water will penetrate into the electric pump and cause it to burn out.

Not only the starting point of the suction line can be equipped with a check valve. To ensure pressure support, it is installed on the pipeline in front of the pumping station or in front of the hydraulic tank when it is located separately

Most modern pumps are protected against such processes. But water for starting will have to be poured into them after each stop of the unit.

In some pump models, it is possible that the impeller spins up completely, which can lead to its failure. Installation of this fittings on the liquid intake line from the source is mandatory, otherwise no electronic protection will help the water pumping unit.

When connecting several pumping stations into a single unit, check valves protect the switched off unit from the pressure of operating devices

With a pipeline check valve the situation is somewhat different. Here it no longer protects the pump, but the water distribution system inside the house. By locking the water in the pipes, preventing it from returning back to the accumulator, the check valve helps maintain the required operating pressure in the system. Without it, water will rush back into the storage tank, causing it to work abnormally.

Check valves increase the efficiency and reliability of the pumping station, while protecting the pump, plumbing and water system from water hammer. Overall, it is an indispensable device. But the water has to expend effort to open the valve, which reduces the pressure of the flow after its passage by 0.1–0.3 atm.

Variety of species

Check valves are divided into several types:

- The spring type has the smallest dimensions. This element includes a special shutter - a disk or plate that is pressed by a spring. In operation, the disc, coming under water pressure, is wrung out, thereby providing free passage for water flows. If the pressure decreases, the spring presses the plate, blocking the outflow of water. The dimensions of this type of check valve vary from 0.15 cm to 0.20 cm.

- Double doors are usually used in large and complex systems. For example, if a pump stops in the hydraulic system of a house, a strong water flow will occur, which will cause significant damage to the entire system. The principle of operation of a double-leaf check valve is based on the fact that under the influence of a strong flow of water, the shut-off element is folded in half. Strong water currents return the element to its original position, pressing it.

- In the petal device, the shutting element is the spool. With strong water pressure, the spool tilts, opening the path of liquid. As soon as the pressure drops, the spool falls and closes access to the passage channel.

- The operating principle of a ball-type check valve is slightly different. The locking element is a ball with a spring. In case of low pressure, it presses down, blocking access to the outflow of water. This type of check valve is used in plumbing elements where the pipes have a smaller diameter than in the general pipeline.

- The lift-type check valve device includes a special element - a lift spool. High water pressure will raise it, thereby opening the path for coolant. As soon as the pressure decreases, the spool will fall and prevent backflow. It is worth noting that this type of valve is mounted only on horizontal pipes.

Installation procedure and details

Before installing a shut-off element after the pump, it should be taken into account that the power of the device will decrease due to overcoming the resistance of the spring or valve. But the pump does not have to pump up pressure in the system all the time; it is created once and then only maintained. Thus, the operation of the unit becomes more rational.

If the device is installed on an already installed water supply system, the installation location is selected between the pump and the pumping station. It is necessary to make a break in the pipeline, install a valve on one edge of it and connect it with a pipe to the other edge. A device is installed in sewer pipes to prevent the backflow of waste water and waste. This way you can avoid leakage of liquid through the toilet when the general sewer is clogged. Installation is carried out on a horizontal or vertical section in an existing or new sewerage system, in places where there are pipes of the required diameter. The diameter of the shut-off valve here can be from 50 to 100 mm. The connection is made using an adapter from cast iron to plastic. To cut into a cast iron pipe you will need an angle grinder.

There are parallel movement systems where a pump is used along with the natural flow of water. In this case, installing a valve is necessary.

To install a shut-off element on a water supply and heating system, you need tools for cutting into a pipe: a grinder for metal pipes, and a regular hacksaw is suitable for plastic pipes. On metal pipes for connection, it is necessary to make a thread using a thread cutting tool. A check valve is installed using an adjustable wrench and a gas wrench. After this, the pipe to which the device is screwed is connected to its other part by a pipe using the required key. Special adapters are used to connect plastic pipes.

If you know a little about plumbing and have some free time, installing the unit yourself will not be difficult. Non-specialists in this matter can always delegate the work to an experienced master.

roma100471.ru

Design and principle of operation

Answering the question why a check valve is needed, it is worth saying that this device does not allow the water raised by the pump to return back to the well or well. Another advantage of using this valve is that you do not have to wait for the liquid to displace the air in the hose. If the hose has already been filled with water, the flow will begin immediately.

What elements does the water check valve device include:

- a collapsible metal body, which consists of two parts, each of which has a thread;

- metal or plastic shutter with gasket;

- a spring designed to support the bolt.

The operation of the valve is not complicated. The principle of operation of a water check valve for a pump is as follows: after water stops flowing from the pump into the pipeline or hose, the valve is pressed by a spring and is in the closed position. When sufficient water pressure appears in front of the valve to depress the spring, the valve opens, allowing water to flow into the pipeline.

When the pump is turned off, the water pressure drops, the valve is again pressed by the spring and becomes in the closed position. In addition to the spring, water pressure is created on the valve from the side of the pipeline, preventing it from opening. The most popular type of check valve is for domestic use.

Important: all valves operate on this principle, regardless of whether they are used with or without a pump in the pipeline.

Choosing an installation location

Pumping stations are installed near a water source - a well or a well - in a specially equipped pit - a caisson. The second option is in a utility room in the house. The third is on a shelf in the well (this number will not work with a well), and the fourth is in the underground.

Installing a pumping station in the underground - the noise from its operation may be too audible

How to Determine Suction Depth

When choosing a location, they are primarily guided by the technical characteristics - the maximum suction depth of the pump (from where the pump can lift water). The thing is that the maximum lifting depth of pumping stations is 8-9 meters.

Suction depth - the distance from the water surface to the pump. The supply pipeline can be lowered to any depth; it will pump water from the level of the water surface.

Wells often have a greater depth than 8-9 meters. In this case, you will have to use other equipment - a submersible pump or a pumping station with an ejector. In this case, water can be supplied from 20-30 meters, which is usually sufficient. The disadvantage of this solution is expensive equipment.

Suction depth is a characteristic that determines the installation method

If you are just a meter short of being able to install conventional equipment, you can install the station in a well or above a well. In the well, a shelf is attached to the wall; in the case of a well, the pit is deepened.

When making calculations, do not forget that the water level “floats” - in summer it usually drops. If your suction depth is on the verge, there may simply be no water during this period. Later, when the level rises, water supply will be restored.

Security Considerations

Another point that must be taken into account is the safety of the equipment. If you plan to install a pumping station near a permanent residence, there are fewer problems - you can choose any option, even in a small shed. There is only one condition - it should not freeze in winter.

Installing a pumping station in a barn is suitable for permanent residence and insulation/heating conditions for the winter

If this is a dacha where people do not live permanently, the matter is more complicated - you need to arrange a room that does not catch the eye. The safest way to install a pumping station is in the house. Although they can take it away in this case too.

The second place where you can install a pumping station is a buried camouflaged caisson.

Installation diagram of a pumping station in a well

The third is on a shelf in the well. Only in this case there is no need to make a traditional well house. You need a steel lid that can be locked with a reliable lock (weld hinges to the ring, make slits in the lid on which to hang the locks). Although, a good cover may also be hidden under the house. Only the design needs to be thought out so that it does not interfere.

Convenience and operating conditions

Installing a pumping station in the house is good for everyone, except that the equipment is noisy during operation. If there is a separate room with good sound insulation and this is possible according to the technical characteristics, no problem. Often a similar room is made in the basement or on the ground floor. If there is no basement, you can make a box in the underground. Access to it is through the hatch. In addition to sound insulation, this box must also have good thermal insulation - the operating temperature range starts from +5°C.

To reduce the noise level, the station can be placed on thick rubber to dampen vibration (created by the cooling fan). In this case, it is even possible to install it in the house, but the sound will certainly still be there.

Caisson made of concrete rings

If you choose to install a pumping station in a caisson, it should also be insulated and also waterproof. Usually, ready-made reinforced concrete containers are used for these purposes, but a caisson can be made from concrete rings (like a well). Place the ring with the bottom down, and the ring with the lid on top. Another option is to build it out of brick and fill the floor with concrete. But this method is suitable for dry areas - the groundwater level should be one meter below the depth of the caisson.

The depth of the caisson is such that the equipment is installed below the freezing level. Insulation foam polystyrene. Better - extruded. Then at the same time you also get waterproofing.

For a caisson made of concrete rings, it is convenient to use a shell (if you find a suitable diameter). But you can also slab polystyrene foam, cut into strips and glue it. For rectangular pits and structures, slabs are suitable that can be glued to the walls using bitumen mastic. Coat the wall, apply insulation, you can additionally secure it with a pair of nails/dowels.