Chimney damper

One of the main conditions for the efficiency of a heating system is the quality of draft. To regulate air flows, a damper is used - a simple-shaped metal valve mounted in the smoke exhaust duct. The damper is considered a mandatory element of the chimney and is sold along with it, but for homemade stoves the damper can be purchased separately. In addition, it is not difficult to make and install a gate valve on your own if you familiarize yourself with the technology in detail.

Is a valve needed in a sauna stove?

Definitely needed. Good draft in the bathhouse is the key to successful construction of the stove. According to experts, it all depends on the design of the sauna stove. If there is a chimney, then there is no doubt about the need for a damper.

The oven damper is used in all types of ovens. The principle of their operation is a little similar, so you shouldn’t bother. A gate is definitely needed. If combustion is only carried out thanks to the supply air, the valve is not installed. The gate will help you save on fuel, getting the most out of every run. The fuel will not be wasted.

How is traction adjusted?

The damper plate follows the cross-section of the chimney and, when closed, almost completely blocks the chimney. A small hole in the valve does not allow the pipe to be hermetically sealed, which meets fire safety requirements. By changing the position of the damper, you increase the air flow, and, accordingly, the flame in the furnace burns hotter. Reduce the gap - the draft decreases, the fire burns weaker. When the flame in the firebox dies out, the damper is closed to retain heat. If you don't do this, the oven cools down much faster.

The latest modifications of stoves are equipped with deflectors that automatically regulate draft. All other heating devices require the installation of gate valves.

Gate prices

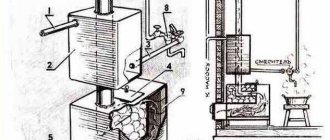

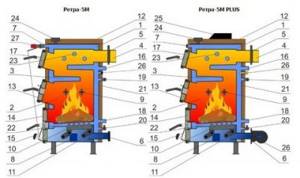

How to use a gate valve on a solid fuel boiler

- Coal.

- Pellets.

- Wood waste.

- Firewood.

The Stropuva universal solid fuel boiler, according to research and consumer reviews, can be classified as one of the most economical types of heating equipment produced by the Stropuva company.

The use of wood waste only is not permitted. With each fire, you will need to add a small amount of high-quality solid fuel. Stropuva universal dual-fuel coal-wood boilers require regular maintenance.

Types of gate

Retractable

The retractable type gate is considered the most convenient and reliable to use. This is a smooth plate with a small longitudinal hole that moves along grooves in the chimney. It is mounted in a horizontal position, the traction force is regulated by the movement of the plate, which reduces or increases the cross-section of the pipe. This type of valve is intended for brick stoves, although it can also be used in chimneys made of steel pipes.

Prices for retractable gate

Rotary (throttle)

Rotary gate. The plate that regulates traction is visible

The rotary gate is a metal plate with a guide welded in the center. It is installed inside the chimney, with the end of the guide necessarily leading out. The traction is adjusted by rotating the plate around its axis. This design is less reliable, since over time the welding fastening weakens and the damper comes off. The rotary damper is used in steel chimneys.

The material from which the valves are made is no less important.

Cast iron

Cast iron is a very strong and durable material, traditionally used for the manufacture of furnace valves. A cast iron gate has only one drawback - it is heavy.

Cast iron damper for sauna stoves, fireplaces

Stainless steel

High quality steel gate unit

Stainless steel is not afraid of corrosion, lasts a long time, weighs little and does not reduce the efficiency of the furnace. The smooth polished surface of the stainless steel valve prevents the accumulation of soot, making cleaning easier. Such dampers can be of any design and can be installed in both brick and steel chimneys.

Steel gate in a brick kiln

Why do you need to install a damper?

The installed valve ensures the most efficient operation of the heating equipment. It acts as a regulator damper, the use of which provides partial blocking of the chimney cross-section. So, a gate valve makes it possible to close the smoke channel after the firebox.

The draft is adjusted in this way: by closing the damper, you can reduce or increase the diameter of the chimney.

A gate valve is needed to control combustion in the fireplace insert. Its installation ensures regulation of flue gases and air flows in the chimney of structures.

Types of chimney dampers

- Retractable system. It is made in the form of a horizontal plate; due to its movement, the cross-section of the chimney pipe decreases or increases, regulating the draft. The smooth valve is equipped with a small diameter hole, thanks to which easy and tight movement is carried out in the guide grooves. This type of damper is more common and is used in chimneys whose pipes are made of brick or steel.

- Rotary system (double-wall, throttle). This structure, rotating around its axis, blocks or opens the smoke channel. It is made in the form of a smooth plate, divided in half by an axis and fixed on it. Adjustable by turning both parts in a circle. Used in cases where for some reason it is impossible to install a retractable damper. The disadvantage of the rotating design is that during use, the welding that rotates the plate can break or burn out.

Damper materials can vary, but most often they are stainless steel or cast iron. They are durable, strong, resistant to high temperatures, and the main difference is weight. Cast iron gates are very heavy, which complicates their installation, so gate valves are only inserted into brick pipes. Stainless steel dampers, on the contrary, are universal, lightweight and are used in various types of heating devices.

Making a gate valve with your own hands

Both a retractable and a rotary gate can be made independently if you have a welding machine and a grinder. Assembling both structures is not difficult, the main thing here is the accuracy of the measurements. If the valve fits too tightly into the pipe, it may jam when exposed to high temperatures. If you leave a large gap between the plate and the pipe, this will make it difficult to adjust the draft.

Manufacturing of a retractable gate

The design of the gate consists of the valve itself and the guide frame. First you need to measure the internal cross-section of the pipe or brick chimney. According to measurements, a rectangular valve is cut out of sheet steel 4-5 mm thick. On one side, a longitudinal fold 20-30 mm wide is made to make it easier to pull out the flap. All cuts are carefully polished, simultaneously reducing the size of the product by 1-2 mm on each side. This will ensure free movement of the damper inside the chimney.

If the damper is installed in a brick chimney, the frame can be made of thick steel wire, for example, with a diameter of 6 mm. To do this, the wire is simply bent in a U shape to fit the hole.

If the chimney is steel and has a rectangular shape, the frame is made of a steel strip 2 mm thick and 30-35 mm wide. The strip is bent lengthwise, leaving a gap along the thickness of the plate, then cut in two places at an angle of 45 degrees and given a U-shape. The gaps in the places of the cuts are butt welded. The ends of the homemade profile are connected with two pieces of metal, positioned so that the valve blade passes freely between them. You should get a rectangular frame with grooves for the gate. In this case, the internal perimeter of the frame must be equal to the cross-section of the chimney.

Manufacturing of gate valves

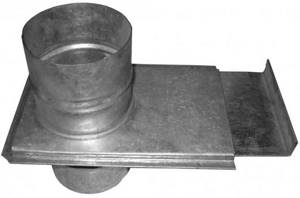

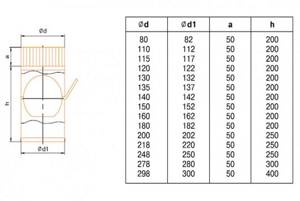

Ready-made damper design for a round chimney

For a round chimney, the damper is made a little differently: take 2 identical metal sheets 2 mm thick, cut round holes in the center according to the diameter of the pipe, and cut out the valve plate separately.

Now the sheets need to be connected by welding on three sides around the perimeter so that the holes for the pipe coincide, and there is a gap of 4-5 mm between the top and bottom sheets. After this, all that remains is to insert the valve and secure the gate to the pipe.

How to make a chimney damper with your own hands?

Many owners are interested in the question: how to make valves in round pipes? For a round or square chimney, you can make a valve yourself. For round structures, a rotary valve is best suited, however, you can also use a horizontal one.

You can make a gate valve yourself, as its design is very simple. Independent production of this shaped element of the chimney structure is relevant if the nearest stores do not have a valve of the required cross-section.

The step-by-step process for making a chimney valve looks like this:

- First of all, it is necessary to prepare the frame in which the retractable plate will be located. It is recommended to make the frame from heat-resistant stainless steel. The width of the steel corner shelves should be from 3.5 to 4.5 cm. The corners are joined using welding equipment.

- At the second stage, you need to make a hole for the axle. It is worth remembering that if you need to make a bolt with a “straight” rotation, then it is recommended to drill a hole at a point that corresponds to the center of the parallel sides of the frame. And for devices that rotate at an angle, the hole is made diagonally.

- Next, you need to install special bushings, which can be made from ordinary pipes. The size of the sleeve should be approximately half an inch, which corresponds to 1.25 cm. To install the tubes, you must use welding equipment. Bushings should not interfere with the movement of the rod axis.

- Then the workpiece is selected for the gate plate. To do this, you will need a stainless steel sheet of appropriate thickness, from which you need to cut a part that fits the cross-section of your chimney. It is worth noting that the thickness of the damper can be higher than 1 mm (for example, 2 or 3 mm).

- At the fifth stage, the finished plate is inserted into the frame and welded to its axis. Experts advise leaving a small gap between the frame and the plate (at least 1 mm).

- The restrictive element is secured, which is necessary to hold the gate plate in the desired position.

- And finally, all that remains is to attach the handle to the axis, which is necessary to regulate the position of the valve.

What is it and what is it for?

Damper (from the German Schieber - damper) is a device for completely or partially blocking the movement of gases in the chimney. It has been used since the appearance of the first Russian stoves. Made from cast iron or steel. In modern engineering it has found application both in smoke exhaust structures and in ventilation systems.

- Regulating draft and maintaining heat in the room.

The chimney is closed after use to prevent warm air from being drawn from the room into the chimney. Using a damper, you can reduce or increase the working cross-section of the chimney.

The valve can be used to regulate the intensity of oxygen flow to the flame, and accordingly increase or decrease the efficiency of the heater.

This statement is true only for furnaces and boilers without blowers and forced air supply devices.

Chimneys for a gas boiler in a private house: how to make them correctly with your own hands

When installing a gas boiler, the question always arises about the removal of gas combustion products from the room where the boiler is installed. This device must comply with current safety regulations.

Firms designing a gas heating boiler for a private home develop drawings taking into account the requirements of the gas service. Only if the chimney is made correctly will it be allowed to use gas for heating purposes in a private house.

How the gate works

Structurally, the gate is a locking device with an adjustable valve. It is thanks to the displacement of the valve that the movement of gases in the chimney is regulated. Can be installed in chimneys of round, square and rectangular cross-section. It is a metal plate that moves inside the smoke channel in a certain way.

Gate valves can be of two types:

- Retractable. Moves in one plane back and forth.

- Rotary. Regulates air access by rotating around its axis.

In addition, valves can be manual or equipped with an electric drive. The cost of the latter is an order of magnitude higher and they are not used in chimneys.

Differences between retractable and rotary gates

So far we have been talking about the retractable type of damper on a stove chimney, although there is another type - a rotary one. Let's look at how they differ.

The purpose of both types is the same - to partially or completely block the flow of flue/heated gases. The differences relate to the design.

A retractable model is a metal plate that is fixed in a frame and moves along guides in a horizontal position. There are no strict requirements for the dimensions of the device, since they must correspond to the cross-section of the chimney and completely depend on its parameters.

Thus, the valve consists of two main parts:

- frame , which is fixed in the smoke exhaust duct and is motionless;

- plate moving inside the frame.

Typically, both parts are made from the same material to maintain performance when heated or cooled.

A properly designed and installed damper should never completely block a stove chimney. A small gap is necessary for fire safety purposes.

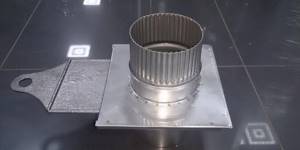

The design of the rotary (throttle) gate does not extend, but rotates along an axis, as the name suggests.

A round or rectangular plate (depending on the cross-section of the chimney) is fixed on a metal rod, the free end of which extends beyond the channel and serves as an adjustment tool.

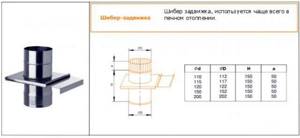

The simplest model of a rotary gate with a diameter of 120 mm. Manufacturing material – stainless steel. The smoke exhaust channel is closed by turning the handle with a curved end

Gate valves are considered more reliable and wear-resistant devices. The weak point of the rotary devices is the connection between the rod and the plate, which becomes loose over time and renders the valve unusable.

Types and designs

The chimney damper is available in several versions.

Retractable

It is a round or rectangular frame with a plate. The plate extends and retracts, thereby adjusting the cross-section of the chimney.

This option is most often used with brick and ceramic channels. To ensure incomplete sealing and avoid carbon monoxide poisoning, a small hole is made in the plate. The main advantage of this option is ease of installation.

Rotary throttle

A rotary or throttle valve (also known as a hog valve) is a plate made of steel or cast iron that rotates around an axis. The axis is a metal rod welded inside the chimney. Used in steel chimneys.

It is less reliable - over time, the welding fastening of the plate and axle weakens. You should avoid installing a rotary damper in the bathhouse - even when closed, this type of damper partially allows steam to pass through.

In addition, gate valves differ in material (the most common are stainless steel and cast iron) and the method of adjustment.

Differences between retractable and rotary gates

The retractable damper allows you to adjust the working cross-section of the chimney, while the rotary damper only allows you to open or close the pipe. Of course, some tricks are possible - such as securing the hog in an intermediate position in different ways, but the factory equipment does not provide for this. In addition, the rotary gate complicates mechanical cleaning of the pipe.

The hog is often installed in metal chimneys, and the retractable one is installed in brick chimneys.

Purpose and types of these devices

The chimney valve, or, as it is also called, a damper, is designed to regulate the draft in the chimney. The operation is performed as follows. During combustion, the valve closes a certain section of the chimney channel. By reducing or, conversely, increasing the damper area, you can control the air flow in the chimney and, accordingly, the flame strength in the heating device and draft. After the combustion process stops, the valve closes so that air currents do not carry away heat from the room. However, even in this state, the damper should not completely block the chimney: this is contrary to safety standards. The systems must be installed on almost all types of heating devices except the latest models, where the draft is adjusted automatically using a deflector.

In their shape, chimney valves must very accurately reproduce the cross-section of the pipe. There are two different design options for gate valves:

Retractable. The simplest and most reliable design. Moves only in the horizontal direction. It is most often installed in steel or brick chimneys. It is a smooth plate with holes that easily moves in the guide grooves.

Rotary or throttle.

The device rotates around its axis, as a result of which it can open or close the smoke channel. Installed in cases where the retractable damper cannot be used for various reasons.

Retractable option. During the combustion process, the gate valve opens. The ability to regulate the overlap area of the smoke channel allows you to adjust the draft. After the fire goes out, the damper closes

The throttle gate valve rotates around its axis, closing or, conversely, opening the smoke channel. Installed in cases where the use of a retractable damper is not possible

The required system option is selected based on the design features of the chimney. In addition to the type of device, the material also plays an important role. Most often used:

- Cast iron. It produces very strong, reliable and durable products. Traditionally used to make devices. The main disadvantage is their heavy weight, so such valves can only be installed on brick pipes.

- Stainless steel. Lightweight, durable and corrosion-resistant material. It does not affect the heat transfer of the heating device, therefore it allows you to achieve maximum efficiency of the stove. Steel gates are usually polished to provide a smooth surface that prevents soot from settling. Installed on any pipes.

Make it yourself or order it

The choice between a homemade or a ready-made damper should be based on the type of chimney and the degree of its readiness. So, you can install a self-made retractable structure into a ceramic or brick channel.

If we are talking about a stainless chimney that is in the process of assembly, in this case it is better to choose a finished product. The damper is usually included in the chimney system and is mounted using pipe-to-pipe technology, which I will talk about later.

In addition, it is not always possible in the store to select a product specifically for your chimney shape.

Optimal location options

There are several ways to install a gate, each of which has both pros and cons. An important factor is what the chimney is made of. But modern masters prefer to use the three most common options:

- Installation in a fireplace insert.

- Fastening using the “pipe in pipe” method.

- Installation in a ventilation system.

If you install a damper in the furnace of the stove itself or on the outlet pipe, the damper will be located on that section of the pipe that is as close as possible to the heating boiler. It is worth noting that in this case the valve will be built into the main structure of the chimney. This method has its advantages, since the damper will be easier to use. This is due to the fact that the gate handle will not touch either the cladding area or the portal itself.

The damper can be installed in the ventilation system

If the master has chosen the “pipe-to-pipe” installation type, then he will not need to use special fasteners to securely fix the damper with the fireplace elements. The location of the damper in the ventilation system completely eliminates the possibility of overheating of the fan motor during active operation.

Modern manufacturers offer ready-to-install chimneys that are equipped with all the necessary devices (the slide damper is no exception). In this case, the part must be used in strict accordance with the recommendations established by the manufacturer. Otherwise, you can make a chimney damper with your own hands and at a more affordable price.

Making and installing a gate valve with your own hands

Required materials and tools

To independently manufacture and install any type of stainless steel gate, we will need the following tools:

- Bulgarian;

- Abrasive wheels - cutting and grinding;

- Drill;

- Tap and thread lubricant;

- Hammer;

- Pliers;

- Vise;

- Welding and electrodes;

- Kern;

- Roulette;

- Compass;

- Marker.

- Stainless steel sheet (preferably domestic brand 12×18n10t, or imported AISI304, they are more expensive, but last an order of magnitude longer).

- Stainless steel tube 6mm;

- Bolts 8mm -2 pcs;

- Metal rod for the frame.

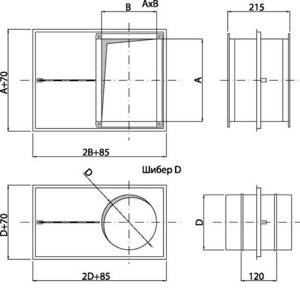

Drawing and diagrams

Before manufacturing, it is necessary to draw a drawing or diagram of the future valve.

I will give some example diagrams below:

Size calculation

You need to take measurements very carefully; a gap of even a few millimeters can cause the chimney to malfunction.

- Using a tape measure, measure the dimensions of the internal section of the channel;

- Add 20-30 mm to the obtained result - you get the outer size of the frame;

- Do not forget to make an opening in the finished valve to release gas;

- The position of the welding holes should be accurately marked.

We summarize the dimensions for the rotary gate in the table:

How to make a gate valve with your own hands

Let's look at how to make both types of chimney valves - retractable and rotary. Each of them has its own manufacturing and installation nuances. Let's start with the retractable view.

Preparation of materials and tools

To create the simplest model of a retractable gate, galvanized steel is suitable. It is lightweight, thanks to its smooth surface it is easy to clean from soot, and if necessary, the moving part can be easily replaced.

Millimeter steel will not work, as it bends easily, and if deformed, it will be difficult to slide the plate into the chimney. The minimum sheet thickness is 1.5 mm, and preferably 2-2.5 mm

The main tools are a welding machine, electrodes, a grinder, metal scissors (choose depending on the thickness of the sheet), a drill with a grinding disc, metal drills, and a file. It is better to carry out work on a workbench with a vice. Among other things, you will need a sheet of paper for a template, a tape measure, and a marker.

Drawing up a diagram (drawing)

Removing dimensions must be taken seriously, since even a few millimeters can cause the chimney to malfunction. To find out the dimensions of the frame, you should use a tape measure to measure the cross-section of the smoke exhaust duct - it will coincide with the dimensions of the inside of the frame. To this value you should add 20-30 mm on three sides and calculate the outer side of the frame.

Drawing of a damper with a wire frame. A wire frame is more difficult to secure to brickwork than a profile with flat wide sides

In order for the latch to slide out easily, without effort, its width should be slightly narrower than the width of the frame (taking into account the outer sides). To simplify the calculations, it is necessary to draw a design diagram and indicate all possible dimensions, so that in the future, when working with metal, you can navigate by them.

For metal pipes, a flat damper design is usually combined with a chimney fragment located perpendicularly.

Design dimensions for a rectangular pipe. The valve must completely block the chimney, but at the same time have small holes for air penetration, drilled with a drill, or a gap

For brick chimneys, a flat frame made of wire or profile with a valve moving along guides (two parallel sides) is sufficient.

Marking and cutting out parts

Having determined the exact dimensions, we cut out the frame for the gate. If the chimney is small (for example, in a bathhouse or in a summer kitchen), you can use thick wire, bending it in the shape of the letter P.

A more comprehensive frame is a durable corner profile. To make it, we cut out a strip from sheet steel and bend it lengthwise at an angle of 90º. To give the profile the desired shape, in the places where the corners are marked, we cut one of the planes. When folded, we get a frame. We weld the bends.

Next, we cut out the damper itself. It should be approximately 5-10 mm narrower than the width of the frame. We adjust the length so that when closed, only a small fragment of the valve peeks out. It can be decorated in different ways: in the form of an ear with a hole or simply a folded edge.

We clean the edges of the cut gate with a disc so that the closing/opening process is easy and silent. Parts cannot be painted.

Gate valve installation steps

The photo shows the stages of installing a factory-made gate. A homemade device is mounted using the same principle.

Image gallery Photo from In accordance with the furnace diagram, we determine the installation location of the gate valve and mark the bricks that need to be trimmed

We take out the bricks that serve as the basis for installing the damper and cut them to the size of the gate frame with a grinder

To fix the valve we use masonry mortar. We apply it to the installation site, and then to the edges of the frame from above.

The valve “stands” on the same level as the rest of the bricks, so there are no obstacles to further masonry; it is carried out in the usual manner - according to the ordering scheme

Step 1 - determining the installation location

Step 2 - cutting bricks around the perimeter of the hole

Step 3 - planting the gate on the solution

Step 4 - brickwork above the gate

The installation height of the damper largely depends on the design of the stove; in sauna stoves it is lower, in home heating stoves it is higher. The minimum height is 0.9-1 m from the floor, the maximum is about 2 m.

Installation features

- When installing the gate at the stage of laying brickwork, the frame is placed at a height of 6-8 rows from the base of the pipe;

- The frame should stand straight, without blocking the outline of the chimney;

- In stainless steel chimneys, the valve is installed using the “pipe-to-pipe” technology. It is necessary to coordinate its dimensions with the diameter of the channel;

- An important nuance - the damper is installed on an uninsulated section of the chimney;

- The height from the firebox to the damper should not exceed 1 m (for metal channels);

- Pipe height from the floor to the valve - 1.8 - maximum 2 m (for brick);

- The damper in the grooves should move freely;

Basic Installation Recommendations

If the chimney is made of brick, then it is better to install the damper at a distance of one meter from the surface of the stove. This detail is installed at the stage of laying the fireplace itself. Only in this case can the damper frame be properly embedded. A small part of the gate assembly must remain outside. To prevent the novice technician from making mistakes, experts divided the installation process into several main stages:

- You need to start with laying the chimney (the first 7-9 rows).

- At this stage, the top layer of brick is covered with a small amount of mortar.

- Now you can safely place a pre-prepared frame, which should stand as straight as possible so as not to block the chimney.

- A layer of working mortar is applied to the installed product, and the masonry itself continues according to the existing scheme.

At the final stage, all that remains is to seal all existing cracks so as not to disturb the traction force and prevent carbon monoxide from entering the room.

Frequent errors and problems during installation

- Installation of a valve in an insulated area. Under the influence of thermal expansion, the damper may jam;

- Installation of a cast iron part in a metal chimney (cast iron weighs a lot);

- Using too thin steel or stainless steel with a low nickel content for the manufacture of valves. Such a product quickly deforms under the influence of hot gases and can burn out;

- Installation of a gate with a non-smooth surface;

- Installation of a valve without a hole for carbon monoxide release;

- Installation of handles that do not allow monitoring the position of the valve (applies to rotary elements).

Features of wood burning

To ensure high-quality heating, you need to know how to heat a solid fuel boiler with wood efficiently and economically. For kindling, chips are laid down, on top of which you need to place 3-5 firewood with a diameter of up to 15 cm. It is recommended to lay crumpled paper between the chips so that the wood flares up faster.

After the first fire has ignited, the firebox is filled with large firewood. To achieve the most complete and efficient burning of wood, you can place 1-2 large logs in the firebox at intervals of 30-40 minutes. In addition, this method will help reduce firewood consumption.

When the firebox is completely filled with large firewood, an ordinary modern solid fuel boiler is capable of maintaining fairly intense combustion for 3-4 hours. Long-burning boilers operate on one burner even longer. It is generally not recommended to burn such models with small wood, which does not burn completely due to increased gas emission. The optimal size of logs in diameter is 15-30 cm.

If you figure out how to properly heat a TT boiler, then the choice of firewood is of great importance. Wood moisture content should not be higher than 20%, otherwise the efficiency of the equipment will be lost. In some cases, to increase the burning time, damp wood is specially placed in the firebox, which takes longer to burn. However, it must be taken into account that this leads to increased release of tar, which settles on the walls of the firebox and on the chimney, and this causes deterioration in draft. As a result, the boiler has to be cleaned more often. In order for firewood to have an optimal level of humidity, it must be dried under a canopy for approximately 1.5-2 years before use.

If you want to increase the burning time of one bookmark, then you should not use damp firewood, but set the correct position of the gate valve and thermostat. These provisions for each TT boiler model are determined experimentally.

Features of gate maintenance

The gate, made of stainless steel, is usually polished to perfect smoothness. Soot settles on it poorly, but still settles. Therefore, it must be cleaned periodically.

The horizontal valve can be cleaned simply by pulling it out to the maximum and applying a special solution. Rotary - cleaned through the chimney with a special plastic brush. You should also ensure that the damper moves freely along the guides. It is allowed to periodically lubricate them with an anti-corrosion compound.

Features of the operation of modern solid fuel boilers

Solid fuel boilers of the modern generation are equipped with a pressurization system and an automatic control unit.

Electronics controls the temperature of the coolant using a sensor installed in the heat exchanger. Depending on the temperature conditions, the automation gives commands to turn on and off the blower, which supplies air to the combustion chamber and facilitates the effective removal of combustion products through the chimney. This regulates the intensity of the fuel combustion process depending on the temperature of the coolant. Thus, the user takes the minimum necessary participation in the operation of the equipment. His concern about how to fire a TT boiler comes down to adding fuel at a certain frequency. After this, the boiler switches to intensive combustion mode. As the temperature rises, the combustion intensity weakens, and when the temperature reaches its maximum, the boiler goes into smoldering mode. After the coolant temperature drops below the set value, the boost is turned on again.

Timely loading of fuel into the TT boiler is the main task of the user, which cannot be automated. The number and frequency of fillings is determined based on the boiler power and the required temperature conditions. If you miss the start date, the boiler will only be able to operate in smoldering mode for a limited time, after which it stops.

It is of great importance how to heat a solid fuel boiler. Today the following types of fuel can be used for this purpose:

To achieve maximum efficiency, you need to know how to effectively heat a solid fuel boiler with different types of fuel.

Expert advice

Where to install the damper on the chimney

There are 3 options for placing the damper relative to the chimney:

- Placement in the firebox of a fireplace or stove;

- Fastening according to the “pipe to pipe” principle;

- Installation in a ventilation pipe.

Let's consider the first 2 options:

- By placing the valve in the furnace firebox or in the outlet pipe

In this case, the damper is located at a height of no more than 1 m from the firebox, on an uninsulated section of the pipe. This location is convenient for adjusting the damper.

Applicable for metal chimneys. This installation option does not require additional fasteners. When purchasing a ready-made system, you should install the valve strictly according to the manufacturer’s instructions.

How to adjust traction

Adjusting the draft using a slider is quite simple. By changing the position towards increasing the gap, we increase the flow of air to the fire and the flame flares up stronger. Reduce the gap - traction decreases. The valve is closed after the flame has completely died out - this way the oven cools down much faster.

The latest boiler models are made with built-in automatic baffles. All other heating units require the mandatory installation of a damper.

Technical characteristics of the gate

The gate valve is a thin metal plate that is manually adjusted using a special handle. The latter is located outside the chimney pipe so that the user can manually adjust the position of the plate.

Depending on the design and type of damper, it is installed using a special metal frame, or is inserted inside the pipe and fixed with an axial rod.

The damper in the chimney performs the following functions:

- increases traction force in difficult weather conditions;

- increases the intensity of combustion in the furnace due to increased oxygen flow;

- reduces draft when there is a strong hum in the chimney during strong winds;

- saves fuel by reducing combustion intensity;

- prevents heat loss after the heater has warmed up.

To understand the purpose of this part for the chimney structure, you need to understand what a damper in a stove is. The damper provides a change in the traction force in the unit by adjusting the combustion of fuel in the firebox.

This element has an important advantage - it has low resistance relative to the remaining gas bubbles, which must be removed outside the room. When the chimney is inoperative, then the damper is completely closed. For the manufacture of gate valves for stoves and fireplaces, stainless steel is most often used - steel that is least susceptible to corrosion processes

The thickness of the metal should be one millimeter

For the manufacture of gate valves for stoves and fireplaces, stainless steel is most often used - steel that is least susceptible to corrosion processes. The thickness of the metal should be one millimeter.

This device allows you to control and regulate the draft into the smoke exhaust system. Translated from German,

gate (“schieber”) means a part that is made of a certain metal.

To eliminate these dangerous and unpleasant moments, a slide damper is installed in the smoke exhaust system. It prevents the fission of gas bubbles that should not be separated.

It is recommended to install a slide damper when heating with gas, coal, or solid fuel.

Being the main draft regulator inside the chimney, the damper regulates the combustion of fuel. To reduce the draft and reduce the intensity of the flame in the firebox, it is enough to close the slide valve. To increase traction, on the contrary, it is necessary to open it.

In fact, a gate is an ordinary metal plate that allows you to regulate traction.

It can be installed both in single-wall and double-wall boiler systems.

As a rule, the valve is installed at the initial section of the chimney (on the first meter), since this particular section remains uninsulated.

But on the contrary, it is not recommended to install a valve on a section of a well-insulated chimney pipe. Especially when it comes to double-circuit pipes. When the metal of the inner and outer pipe expands, the gate valve may jam.

So, the main tasks of a gate valve are:

- Function of the draft regulator in the chimney.

- Partial blocking of the chimney channel section.

- Regulator of flame burning intensity in the firebox.

Design features of the device

The design of a gate valve or “knife” valve is quite simple. It consists:

- From a body that is a tee with a central extension and hollow branches. Can be equipped with a lid.

- Sedel. These elements perform a guiding function and ensure the tightness of the shutter.

- Locking unit (damper). This element is located perpendicular to the flow of the medium and regulates the throughput of the valve.

- A rod in the upper part of the housing, responsible for moving the damper.

- Control mechanism - screw, lever, drive.

- A stuffing box assembly that ensures the tightness of the rod-housing pair.

Gate valve design advantages and disadvantages:

The main advantage of the fittings is their simplicity of design, low hydraulic resistance and the ability to be used for transporting media with solid inclusions.

Disadvantage: low tightness, high construction height. Such products cannot be used to carry hazardous substances, the leakage of which could be critical.

Gate valve installation

Installation of any type of damper is carried out at the first stages of installing a heating system. Installing the structure on a chimney pipe is not at all difficult. This can be done in three ways:

- Near the fireplace. The device is connected to the chimney pipe at a distance of one meter from the heating devices. This convenient installation of the damper allows you to easily monitor the operation of the gate.

- "Pipe to pipe." This method involves attaching a slide damper to a chimney pipe without the use of additional clamps. The valve is held securely due to its tight connection to the chimney pipe.

- In the ventilation duct. This installation option is mainly used to cool the fan motor.

When constructing stoves and fireplaces, the damper is most often installed using the first method. Gate valves are used for both round and square chimney pipes. Products with a rotating plate are most often installed in chimneys with a cross-section in the form of a circle.

Installing a damper in a brick oven

The gate valve is quite often used for brick kilns. It is installed during the construction of the chimney. Place the valve on the first meter of the pipe. This arrangement of the gate makes it easy to adjust the draft. To install such a gate you need:

- two rows of chimney bricks are laid;

- in the second row an opening of the required size is cut;

- a damper is installed;

- in any brick of the same row a recess is made for a rotary handle;

Next, the next rows are laid

In this case, you should pay attention to the tightness of the fit to the place where the gate is installed. All cracks should be sealed with mortar.

When using such a damper, all safety precautions must be taken into account. During operation of the furnace, under no circumstances should the gate valve be closed. This action will lead to carbon monoxide entering the room. Some models have a special fixing element that prevents the pipe opening from being completely closed.

Why do you need a chimney damper - what is a damper, types, installation rules

A damper is a damper, a valve for a stove chimney, designed to improve draft in it. This part is made of metal. It is installed at the stage of construction of the chimney pipe and ventilation passage.

Draft is of great importance for the functioning of the heating unit. When it is strong enough, the fuel burns completely, resulting in reduced costs. When the draft is poor, a fire can occur at any moment, and to prevent this, install a damper for the stove or fireplace.

You can install a damper for a fireplace or heating unit in one of three ways:

- The damper is installed directly in the fireplace insert. It is placed at a distance of 100 centimeters from the heating device, which makes it easy to control.

- Combining the damper with other elements of the heating structure without the use of additional fasteners. This installation method is called “pipe to pipe”.

- The damper is installed in ventilation pipes. It is used to prevent the fan motor from overheating during operation.

Since there are a variety of models of stove units and fireplaces and heating using them is carried out in different ways, each of them requires its own type of valve.

For example, for a stove operating on gas, you will need a classic rotary-type throttle valve or a rotary automatic damper, since they are capable of blocking the chimney pipe completely and then the flame will not be able to escape outside.

At the same time, rotary valves should not be installed when installing a sauna stove, since when closed they will allow steam to pass through, and in the open position they are very difficult to clean.

As a rule, a damper for a fireplace or stove unit is sold as a complete set along with a chimney. But there are smoke exhaust structures without a damper, so you can make one yourself by buying elements for it at a hardware store. The main thing to do before purchasing them is to decide on the required sizes.

t one row of bricks. The gate plays one of the main roles in the chimney, the purpose of which is to regulate draft. Good draft means that the efficiency of the entire heating system will be excellent and fuel savings will be obvious.

Before making the design and installing it yourself, consult a specialist who will calculate the draft level of your stove. For this, professionals use a special formula. Take care of yourself!

How to install?

How to properly install a valve on a stove and how to install a valve on a chimney? It's simple, let's consider 2 cases.

Installing the damper in the furnace

When installing the damper in the furnace, you need to take into account that this is done during brick laying. It is placed at the beginning of the pipe, about a meter from the surface of the furnace itself. The frame fits tightly into the chimney structure, and the damper is installed after.

Installing a valve in a furnace can be done in three steps:

- Reach the 6th row of brick laying.

- Apply the solution in the desired location and carefully install the frame there. Sometimes you need to cut grooves in the brick for convenience and easier retraction.

- Align the frame so that it lines up with the bricks. Then you can continue laying bricks.

All cracks that may form when installing the plug must be sealed with mortar. Otherwise, there will be loss of thrust and combustion.

Video instruction:

Pipe installation

The damper is also installed at a height of 1 meter from the firebox

It is important that this is the uninsulated part of the pipe. Then there will be no temperature difference when the valve operates

Installation on the pipe is also simple. First, the first part of the pipe is attached. The joints are lubricated with sealant (temperature-resistant). A gate is tightly placed on top of the structure (the first nozzle). The second part of the pipe is attached to the gate on top. This entire structure is connected to an insulated chimney.

Thus, there is no need to further secure the structure.

It is worth saying that homemade gates can be attached to the pipe a little differently. This already depends on the design. An example of installation of a homemade rotary gate, we reviewed the manufacturing instructions above:

- We make a mark on the chimney pipe.

- Let's try on our preparation.

- We insert the gate into the pipe and screw it into the structure with a thread.

Design Features

The gate device is influenced by various factors: temperature, pipe dimensions, flow conditions. During manufacturing, the design is based on a sheet of metal of different thicknesses, moving along a slot pocket and guide corners.

Depending on the base, the gates are either locking or reversible. Serve to restrict the movement of air flows.

There is a classification of devices according to the principle of operation, depending on the type of drive: manual, pneumatic, hydraulic, electric. Gates come in straight and oblique designs. The first option is a classic damper. Designed for supply and exhaust ventilation systems operating under forced influence. The second type of structure is used in systems related to industrial aspiration and transport powered by pneumatics. The gate received this name as a result of its placement at an angle of 45 degrees.

How to regulate traction using a gate valve

The firewood burns completely, and very little soot is produced only if the thrust corresponds to the “alpha” value, that is, it is in the range of 2.0-2.5 (there is a special formula for calculating it). An important condition for the existence of good draft is to ensure the supply of air to the combustion zone.

It is necessary to remember the following point well: if you close the damper, carbon monoxide will still seep into the bathhouse, and you may not see smoke or smell the burning. Carbon monoxide is very dangerous, because in a few hours you can become completely burned out. The damper can only be closed at the very end of the firebox, when absolutely all the wood has completely burned out and is slightly covered with ash.

Video “Traction regulator”:

https://youtube.com/watch?v=MH6WfxT2n_E

Video “Homemade chimney damper”:

Be careful, do not risk your health and your life! Take care of yourself!

Drive types

To regulate the operation of the mechanism, different types of drives are used. This is due to different pipe capacities and different densities of the working medium.

- With the manual method, the valve is adjusted using a handle or lever. It is mounted on pipelines carrying liquids and gases of low density without solid inclusions.

- Electric drives allow you to adjust the position of the damper without physical impact. Such valves are used in large enterprises to regulate the flow of viscous, granular media with solid inclusions.

- Valves with pneumatic actuators have the most complex design. They provide the best tightness and are mounted on pipelines with remote adjustment and allow manual control.