The efficiency and safety of a stove, fireplace or heating boiler directly depends on how competently the chimney was installed in a private home. If earlier this depended on the professionalism of the stove maker, today it is a matter of wise choice of the owner of the house. Sandwich chimneys, which can be installed independently to any type of heating equipment, are in great demand, and deservedly so. It is important to choose the right pipes and install them, observing all the necessary conditions.

Choice of shape and material

The chimney cap was invented quite a long time ago . It solves several practical problems:

- protects the chimney from external factors: rain, snow and wind;

- acts as an additional roof decoration.

It is important to provide, first of all, protection from wind and precipitation, otherwise the walls of the chimney will be destroyed under the influence of weather conditions.

The cover should be selected in accordance with:

- channel type;

- hole diameter.

Based on these indicators, select:

- a cap made of chrome and nickel if the house is heated with gas;

- a removable product if the apartment is heated by a fireplace, solid fuel boiler or wood stove.

The main types are models with a round and square base, stationary or folding, made of tin - chromium-nickel or black. Many modifications are unfounded. They are fixed directly to the chimney duct.

Today, chimneys made of galvanized or stainless steel and copper have appeared. It is also possible to select modifications so that the shade of the cap matches the color of the roof. The selected option must correspond in functionality to the specific type of pipe. It should also match the style of the building.

The following colors are available:

| RAL 1014 | RAL 5005 | RAL 7024 |

| RAL 1015 | RAL 6002 | RAL 8017 |

| RAL 3005 | RAL 6005 | RAL 9003 |

| RAL 3009 | RAL 7004 | RAL 9004 |

| RAL 3011 | RAL 7005 | RAL 9006 |

| RR 32 | RR 11 | RR 29 |

Other colors and coatings are available upon request

If you choose a color from stock items, then the planks (additional elements and flashings) can be picked up the next day. We make fence caps and chimneys within 5 working days. If the color is custom-made, then the production time is individual, but in any case it increases by 1-3 weeks due to the delivery of materials.

Powder painting is possible in any RAL color, including with additional effects.

The main purpose of the chimney (wind vane) is to close the mouth of the chimney pipe from precipitation. But protection from rain and snow is not the only advantage of this cap: with it, the roof becomes simply beautiful and takes on a finished look. Many chimney designs allow for increased draft.

Architectural form

As for the architectural shape of the cap, a multi-slope weather vane can perfectly protect against precipitation and snow. This chimney looks very impressive, especially if you place figures of any animals made of metal on top.

Models with a flat surface are more often used. There are caps with an opening lid, which are also popular. They are convenient for preventive maintenance and unhindered maintenance of the chimney. The deflector, which has a ventilation hole in its body, significantly improves traction.

But the smoker is not always used. There is virtually no need for it in areas where there is rarely precipitation and virtually no wind. But for Russian latitudes it is a necessity.

What types of chimneys are there depending on their shape?

The variety of shapes of modern chimneys is very large. Here you can find almost any options. Let's look at the most popular of them, which have an unusual geometric shape and can decorate any pipe:

- a weather vane of a standard shape: it looks like a house with a hipped roof;

- chimney in the Art Nouveau style: designed like a standard one, but additionally has a flat top;

- European style chimney: has an unusual appearance due to the semicircular top;

- caps with a gable roof, which has four slopes (a very functional design that is well ventilated and at the same time protects the pipe from snow);

Cap with gable roof.

- weather vane with weather vane;

- weather vane equipped with a detachable lid.

Wind vanes with a weather vane are distinguished by the fact that a special damper is located inside the structure, allowing combustion products to calmly exit the chimney even in the windiest weather. And an additional opening lid provides easy access to the chimney channels for cleaning.

Depending on the shape, chimney roofs are divided into the following categories:

- tent;

- gable;

- hipped;

- semi-cylindrical (or vaulted);

- flat;

- spire-shaped;

- four-pincer.

However, in most cases, this parameter does not affect the functionality of the device and serves solely for aesthetic purposes, providing the chimney pipe with a unique appearance.

The chimney is an important element of the smoke removal system in the house.

Chimney umbrella

A chimney hood can be installed for several reasons:

- it is capable of partially closing the mouths from blowing wind, due to which the draft is prevented from overturning;

- the chimney prevents small debris from getting inside;

- mesh design provides protection from nesting birds;

- such a product extends the service life of the head of a brick pipe, which can be destroyed under the influence of precipitation;

- A weather vane of this type has good decorative qualities, and therefore is able to complement the architectural appearance of the building.

The height of the chimney according to the standards and the level of elevation of the chimney above the roof relative to the ridge

To understand why it is important to correctly calculate the height of the chimney and the amount of its elevation on the roof, let’s start with questions from portal users.

A_B_E_LFORUMHOUSE Member

I have a cast iron heating stove in my house. I wondered if the chimney height of 3.5 m would be enough for her? How will the stove behave with such a chimney length and could any problems arise?

VdaForumHouse Member

I have a gas boiler. The chimney and ventilation are made of an asbestos pipe with a diameter of 16 cm, insulated with basalt wool with a galvanized casing. Pipes pass through the second floor, attic floor and roof. The total height of the pipes is about 8 meters. The roof is gable with a slope of about 45 degrees, the height is about 4.5 m. The pipes are located about 1 m below the ridge and at a distance of about 2.5 meters from it. In winter there were no problems with draft, but now, with strong gusts of wind, the boiler blows. What should I do, extend the pipe above the ridge?

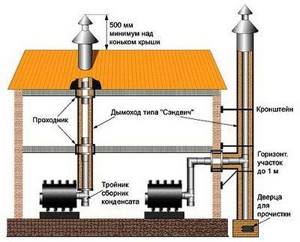

There is a rule - the height of the chimney must be at least 5 m , if we count the distance from the firebox grate to the top of the chimney head.

The calculation does not take into account the height of elements protruding above the pipe - caps, weather vanes, spark arresters, etc.

The second rule regulates the height of the chimney above the roof.

Yuri KozakSchiedel specialist

The pipe, located at a distance of up to 1.5 m from the ridge of the house, must rise at least 0.5 meters from the ridge to the smoke exhaust level. Please note: not to the top of the umbrella, but precisely to the level where the annular part of the pipe ends. If the pipe is located at a distance of more than 1.5 and up to 3 m from the roof ridge, the mouth of the pipe should be at the level of the ridge. If the chimney is mounted at a distance of 3 or more meters from the ridge, then a 10-degree decrease in the elevation level of the pipe relative to the ridge is allowed.

When installing a chimney on a flat roof, the amount of snow cover should be taken into account and the height of the pipe elevation of at least 50 cm should be measured from it.

These requirements are mainly related to the aerodynamics of the roof under wind influence (support). On the windward side, a “mound of excess pressure” is formed, and on the reverse, leeward side, turbulence through the ridge (like a springboard) can create breakthrough blowing with an angle of attack from top to bottom. Therefore, even with constant wind directions, the chimney outlet levels are chosen equally on all sides of the roof. As a rule, deflector umbrellas help prevent blowing on the leeward side. But the wind also has “landscape” turbulence, and the “wind rose” can also change. And for carbon monoxide poisoning, due to the overturning of the draft in the chimney, just one time is enough.

Installing the hood

Here you should focus on safety and practicality. The last thing you need to think about is the external attractiveness of the structure. It is important to consider the following recommendations:

- Round steel pipes cannot be covered with traditional shaped structures. They remove smoke from highly efficient boilers whose efficiency exceeds 85%. It is better to use conical nozzles made in the form of an open nozzle. They will not become covered with a crust of ice in freezing temperatures.

- A brick chimney, devoid of inserts, connected to a high-efficiency heat generator, can be equipped with a cap-shaped nozzle. A pipe passes through it.

- It is advisable to install an umbrella on stoves with vertical channels. This shape performs a protective function on the chimney. But to make this possible, it is advisable to place a stainless steel plate inside.

It is recommended to install hip or gable hoods on smoke exhaust blocks made of brick and equipped with side vents. Due to this, the upper part of the masonry will be protected from precipitation and wind. In this case, contact with the gas duct openings on the sides will be excluded.

To protect a brick block, where chimney and exhaust pipes are open at the top, you can make a box with several through pipes. They, in turn, are inserted into the specified channels. Conventional mushroom-shaped caps are installed on top of the ventilation terminals, while conical nozzles must be installed on gas terminals.

Advantages and disadvantages

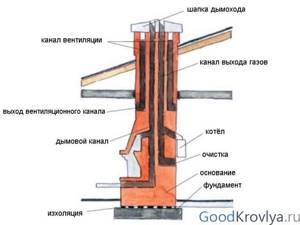

Brick chimneys have the following advantages:

- relative cheapness, in comparison with modern materials used for it (now popular “sandwich” panels);

- long service life, can reach up to 30 years;

- brick chimney as an architectural element is ideally combined with many roofing materials.

But due to the fact that brick still belongs to the “old-timers” of construction, it has many disadvantages in comparison with its modern analogues:

- the significant weight of the brick structure requires the creation of a reliable foundation;

- erecting a pipe takes longer than when using a “sandwich”;

- for a chimney, the ideal cross-section is round, and the brick is rectangular in shape; square structures are better made from it;

- The inside of the pipe, even after applying plaster, remains rough, which is why it quickly becomes covered with soot, which impairs traction.

Making a visor

You can make a cap for the chimney pipe with your own hands. The drawings will help you navigate this, but it is important to follow all the parameters specified in it. First of all, you need to determine the external dimensions of the head. The umbrella will be attached here. Following this, you need to sketch a sketch depicting the future structure. To do this correctly, you need to consider the following points:

- the diameter of the product must be 10 cm larger than the dimensions of the pipe so that the edges protrude on all sides up to 50 mm;

- slope angles should vary from 30 to 45 degrees;

- from the chimney cut to the fungus, the minimum height should be 100 mm.

An umbrella is a traditional solution . There are other design options:

- rotating weather vane;

- deflector.

The latter makes it possible to increase traction through wind pressure. Thanks to it, a vacuum is created in the cylindrical body, into which the smoke channel passes. In calm weather, this device retains all its positive qualities. At the same time, it reduces the traction force in the pipe, which results in increased resistance at the exit of combustion products.

A semi-cylindrical weather vane is often popularly called a “sycophant” because it turns with the wind. It is mounted on a special bearing and consists of several components. This is one of the best options, but there are doubts about the reliability of the bearing, and the price of this design is high. It is especially good to install such a model on a round chimney, as it protects the mouth of this device from precipitation and blowing out.

To make a chimney for a canopy with your own hands, it is better to use painted or galvanized metal, the thickness of which is at least 0.5 mm.

Disadvantages of a chimney made outside the house

If the heat generator and chimney are installed close to one of the external walls, then the chimney must be inside the thermal circuit.

Another frequently asked question is whether it is possible to install a brick chimney outside the house.

Projects of houses with an external location of a beautiful stone chimney are often found abroad.

Regi-naFORUMHOUSE participant

I want to install a cast-iron fireplace stove in the house, and make a brick chimney with a liner on the outside, instead of an expensive metal sandwich, and then cover it with stone. How will such a chimney behave in a harsh winter?

The short answer is that such a chimney can be made, but is it necessary in relation to Russian winters?

Yuri KozakSchiedel specialist

Even if a well-insulated chimney is located in a cold zone on the street, then, in our harsh climate and long heating period, in winter favorable conditions are created for the chimney to cool and freeze. This can lead to:

1. to increased condensation formation; 2. to accelerated soot accumulation; 3. to difficulties with lighting the heat generator; 4. to deterioration of traction, up to its capsizing.

Do not forget about the complication of construction and installation of a long chimney located close to the edge of the roof slope. A rising structure, for example, a regular sandwich chimney, needs to be given additional static stability by making braces.

A tall chimney will have to withstand increased wind and snow loads.

Outdoor placement of the chimney, especially at the edge of the roof slope, will lead to additional costs during its design and installation:

- Under a heavy brick chimney you will have to make a reinforced foundation.

- The chimney, due to the increased consumption of materials, will cost more.

- The chimney will have to be well insulated along its entire length.

- An external chimney does not heat the house, for example, transferring part of the heat to the second floor, but the street.

Important: when smoke ducts are located outside buildings, the thickness of the walls made of brick must be at least 38 cm at an estimated outside air temperature of -20 °C. If the temperature in winter is lower, then the thickness of the chimney walls will have to be increased even more.

So, difficult decisions to avoid:

- Installing a chimney “in the valley” will most likely lead to leaks.

- Installation of the chimney close to the edge of the roof slope or on the “street”.

The best option is to place the chimney in the ridge, or next to the ridge, with the narrow side parallel to the axis of the roof.

If the width of the chimney exceeds 80 cm, then you will have to arrange a valley or slope so that rainwater and snow do not accumulate in this place.

Making a Simple Round Umbrella

To perform such work, you need to prepare tools: a drill, metal shears, a hammer and equipment for installing rivets. Once the size of the fungus is determined , work is performed in the following order:

- Screw two self-tapping screws into a wooden plank, maintaining a distance between them equal to the radius of the product + 15 mm. It turns out to be a homemade compass, with which you can make a mark on the metal, marking the central part of the circle. Its outline is also drawn.

- The workpiece is cut with scissors, after which a sector is drawn, the arc length of which is 120 mm. The resulting figure is somewhat reminiscent of a piece of cake.

- The indicated wedge is cut out, and then the outer edges of the figure are aligned with force. Fix them with a vice.

- Drill three holes along the resulting line and connect the ends of the part with screws or rivets. The upper part of the weather vane can be considered ready.

Using steel strips, legs for the fungus and a clamp encircling the pipe are created. They take thin sheets that are bent several times. These parts are similarly secured to the umbrella with rivets.

Conditions for normal operation

The design should:

- effectively remove gaseous waste from fuel combustion;

- be safe and comfortable for home;

- have good traction;

- withstand high temperatures;

- be protected from moisture and condensation;

- be resistant to external aggressive environments.

Chimneys can have a square or cylindrical shape, the latter is considered optimal, since it is less susceptible to the accumulation of soot and soot.

Other parameters that are also indicated by building codes:

- alloy steel parts made for the installation of chimneys are distinguished by anti-corrosion qualities and have a thickness of 0.5 cm;

- the diameter of the pipe should be the same size as the furnace pipe or be slightly larger;

- a chimney arranged for a brick stove is equipped with pockets, which are located in the lower part of the chimney channels and have a depth of 20-25 centimeters. Doors are installed on them, through which soot deposits are removed;

- a metal chimney cannot have more than 3 turns;

- the turning radius of a metal chimney cannot be greater than the diameter of the pipe;

- the pipe must have a height of at least five meters.

All these conditions will help create normal draft in the chimney and effective removal of combustion products hazardous to health.

Gable model

To make a gable weather vane, you need to use a machine called a sheet bender.

Just as in the previous case, first measure the outer surface of the brick chimney. Calculate the pattern and make the corresponding diagram. Next, the cap is assembled using a simple algorithm.

You need to cut the metal and bend it following the dashed lines. The resulting parts must be connected with rivets. The function of rigid racks is performed by ready-made corners made of painted metal , the thickness of which varies from 0.5 to 0.7 mm.

How to calculate chimney parameters?

In order for the aerodynamic process to achieve optimal processes, it is necessary to correctly calculate the main parameters of the pipe. Experienced specialists recommend selecting a chimney for a boiler and stove based on their power.

The surface inside the structure must be perfectly smooth without any flaws. This will increase the traction force, which will affect the rate of removal of harmful gases during the combustion process. That is why many often choose a square pipe shape into which metal structures are placed.

European cap

This model is more designed to prevent the formation of condensation and has a rounded appearance. A chimney of this type can be made independently using a steel sheet and hand-made holders.

How to make a European cap:

- Take a standard metal sheet and carefully bend it around the pipe, or directly along the contour of the chimney.

- They remake the spoons that will hold the cap directly on the pipe. It is best to do this with a special machine or ask a welder you know. You can also make transverse cuts that do not go all the way and carefully bend the strips using pliers.

- These cuts do not have to be transverse. It is permissible to use longitudinal strips if the piece of metal is quite long. A rectangle is cut out along the edges and the tails are left in the center. After this, roll the sheet in the shape of a semicircle and press the tails with a clamp.

- Gently bend the legs.

It is permissible to use a regular chimney pipe clamp to mount such a cap on the pipe.

To make a European cap, all you need is a piece of sheet metal and a grinder disc.

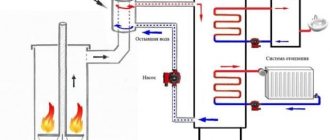

Chimney for metal stoves and boilers

Chimneys for cast iron stoves are simpler in structure and come in two types:

Two options for prefabricated metal chimney

- The first of them, shown in the figure, is more complicated than the second in execution, since it passes inside the building through all the ceilings. The procedures for arranging it in the roof and waterproofing the seams around the pipe will be especially labor-intensive.

But the advantage of this chimney is that it retains more heat in the rooms and that it can also heat the second floor or attic through which the pipe will pass.

- The second option for a chimney for a metal stove is a design that runs almost entirely along the street. Only part of it remains inside the house, which is fixed horizontally. This is a branch section from the heating device, which can be straight or in the form of a so-called elbow. It exits through the wall onto the street and enters a vertical chimney that rises parallel to the wall. Such a device is safer, and the pipe will not take up excess space in the room. Its arrangement will not cause trouble with waterproofing on the roof and its passage through the ceilings.

But when making such a design, the pipe for it must be selected with a thicker thermal insulation layer, which can reach a thickness of up to 10 cm. Without such insulation, the smoke in the pipe will quickly cool down, the draft will decrease, and condensation may also form, which is extremely undesirable for the stove .

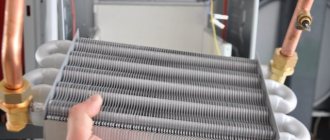

Parts for metal chimney

If earlier in order to make a decent chimney you had to tinker a lot or spend a considerable amount on ordering a tinsmith, today manufacturers of ventilation and heating systems produce ready-made parts of various configurations.

Prefabricated Metal Chimney Details

Such chimneys are available in different diameters, heights and insulation thicknesses. In addition, other accessories necessary for installing a smoke exhaust system on the wall and protecting it from moisture getting inside are also sold. An approximate list of parts intended for this purpose:

- Pipes of different lengths, equipped with special locking grooves for fastening them to other structural parts.

- Metal corner transitions made at different angles.

- Crimp clamps in various sizes.

- Mounting brackets

- Floor, wall and ceiling stands and pipe passages.

- Tees also made at different angles.

- Deflectors, fungi, spark arresters and thermal fungi.

- Connecting elbows with the required angle range.

- Other small parts required for chimney installation.

Basic requirements for chimneys ↑

The chimney is designed to remove combustion products and create draft during the operation of heat generators. It must be resistant to high temperatures, moisture and sulfuric acid formed when flue gases come into contact with condensate. The walls of the pipeline should be smooth so that less soot accumulates.

Requirements for the installation of chimneys are regulated by special state regulations: SNiP 41-01-2003; VDPO (Rules for the performance of work, repair of furnaces and smoke ducts); SP 7.13130.2009.

The main ones are the following:

- the cross-sectional area of the chimney or channel must be greater than or equal to the area of the heat generator outlet pipe;

- at the base of the channel it is necessary to arrange a pocket 250 mm deep for cleaning and/or a pipe for removing condensate;

- you cannot use more than three turns;

- the pipe must be rotated with a radius of rounding no larger than the diameter;

- connections of elements at intersections of building structures are prohibited;

- the length of the horizontal section is allowed a maximum of 1 m;

- bends and tees should not bear the load from the elements located above them;

- if the roof structure contains flammable materials, a spark arrester with a cell no larger than 5x5 mm must be installed on the head of the pipe;

- When working with a natural gas heat generator, the head must always be open without umbrellas or other coverings.

Gas exhaust system design

Checking the chimney before use ↑

After completing the installation of the chimney, be sure to check the presence of draft. This is a very important point, regardless of whether the chimney was installed in a private house with your own hands or with the help of specialists. Violations made during installation can lead to poor traction or even reverse traction. This is fraught with the accumulation of carbon monoxide in the room, which poses a direct threat to the life and health of residents.

- The draft can be checked using a mirror by placing it in the area of the smoke hood and pointing it towards the chimney. With good traction, it does not fog up.

- It is convenient to use a flame from a burning match, paper or candle. If the flame deviates in its direction when approaching the chimney, then everything is in order, otherwise operation is unacceptable.

To check the tightness of the joints and the absence of dangerous heating of structures adjacent to the chimney, a test firebox is carried out. At the beginning of operation, there may be an odor and slight smoke due to the evaporation of residual oil and crystallization of the sealant.

During further operation, its condition should be checked at least once a year and cleaned before the heating season.

It is important not to forget about cleaning

To summarize, we should once again dwell on when and which chimneys are best to use:

- for wood stoves and fireplaces when building a house - brick or ceramic;

- for wood-burning stoves and fireplaces in an inhabited house - ceramic in a steel casing;

- for gas, liquid fuel and pyrolysis boilers - system (ceramic or steel pipe inside a brick channel) or insulated steel sandwich type.

Almost every man can install a steel chimney like the one in the photo in a house with his own hands if he takes a responsible approach and follows the above recommendations. A preliminary consultation with a specialist is guaranteed to protect you from dangerous mistakes.

Chimney built into the wall

This option is usually built into one of the main walls so that some part of it extends outside the house. It is important to pay attention to the insulation of the chimney, otherwise moisture will accumulate inside the chimney due to the temperature difference, and this will significantly affect its operation.

It is worth noting that this variety is also widespread due to its significance for the appearance of the house. Such a chimney will definitely diversify the appearance of the building.