To provide warmth in your home or country house, your own autonomous heating system is installed all year round. A long-burning solid fuel boiler (TCDG) can be an effective source of thermal energy . It is capable of operating for a long time on one load of fuel, which is facilitated by special technology.

Such equipment from leading domestic and foreign manufacturers is widely represented on the Russian market.

The question of how to choose the optimal model deserves special attention.

Rating of the TOP 10 best long-burning solid fuel boilers of 2020-2021

Long-burning solid fuel boilers are becoming indispensable in regions where there is no need to think about natural gas yet. They have proven to be very effective.

You can choose a model for a specific fuel type or choose a universal model. When choosing, you should take into account the main criteria.

The rating of the best models allows you to choose the best option.

| Place | Name | Price |

| TOP 5 best long-burning solid fuel boilers with a water circuit | ||

| 1 | Stropuva S30 30 kV | Find out the price |

| 2 | Stropuva Mini S8 8 kW | Find out the price |

| 3 | Teplodar Cooper Expert 15 | Find out the price |

| 4 | Teplodar Cooper Expert 22 | Find out the price |

| 5 | ZOTA Carbon 50 | Find out the price |

| TOP 5 best long-burning solid fuel boilers without a water circuit | ||

| 1 | Teplodar Cooper Expert-45 | Find out the price |

| 2 | TermoKRoss TKR-08D | Find out the price |

| 3 | Aremikas Candle 35 kW | Find out the price |

| 4 | Stropuva S40 40 kW | Find out the price |

| 5 | Stropuva S15 15 kW | Find out the price |

Device classification

Boilers are divided into several types according to the type of fuel combustion:

- Pyrolysis - equipped with a pair of combustion chambers. In the first, smoldering occurs and gas is formed, which is mixed with oxygen in the second compartment and burned. Such equipment emits a small amount of pollutants into the atmosphere and is considered environmentally friendly. Also, after fuel combustion, little soot remains. Automatic models are additionally equipped with a power regulator.

- With an overhead combustion compartment . Easy to maintain devices, with a minimum of automatic functions required for operation. They can operate autonomously, without access to the power grid. But as a result of work, a large amount of ash accumulates, and not all types of fuel are suitable for them. For example, sawdust and fine chains cannot be used.

- Pellet boilers are boilers for which special compressed briquettes are used for lighting. Such equipment is economical, durable, environmentally friendly and efficient in operation. The disadvantages of the devices are high cost, demanding fuel storage conditions. Pellets are stored only in a dry room.

What long-burning solid fuel boiler is installed in your home?

Pyrolysis Pellet

What to look for when choosing?

When choosing a TKDG, the main attention should be paid to the following characteristics:

- Type of fuel . The units can be designed for a specific fuel or be universal. Main options: coal, firewood, peat, pellets.

- Boiler power . It determines the heated area. For domestic needs, usually does not exceed 100 kW.

- Number of circuits : single-circuit or double-circuit.

- Loading chamber volume . The duration of operation without new fuel loading depends on it.

- Cost-effectiveness , i.e. fuel consumption. The main indicator is efficiency.

- Durability or service life.

- Control systems : electronic or mechanical.

- Safety . Critical protection systems must be provided.

- Price.

You should also pay attention to the material of the body and combustion chamber, loading method (manual, automatic, semi-automatic), volatility, weight and dimensions.

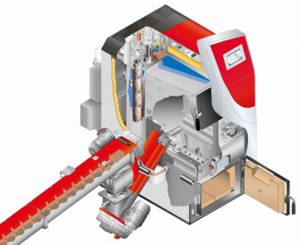

The best pellet boilers with hopper

Buderus Logano S181

German single-circuit solid fuel boilers Buderus Logano series S181 are presented in three models with a power of 15, 20 and 27 kW. They are used to heat low-rise residential and industrial buildings with an area of up to 216 sq.m. The equipment is designed to work with fine fractions of coal or pellets.

Watch the product video

Design features

Structurally, the products consist of two blocks installed in direct contact:

- the boiler itself with a combustion chamber, heat exchanger and control unit;

- a spacious bunker for storing fuel reserves with the ability to dose it into the combustion chamber.

To activate the mechanisms and operate the automation system, a power supply of 220 volts is required. The boiler is capable of heating the circulating coolant up to 80o C.

The heat exchanger is designed for a pressure of 3 bar. In case of overheating, automatic protection is triggered. Human participation in regulating the combustion process is almost not required. The efficiency of models in this range is 88%.

ACV TKAN

The lineup

The line of solid fuel boilers of the Belgian ACV brand is represented by household and industrial units with a power from 60 to 300 kW. They have one heating circuit for coolant circulating through the building’s heating system. The installed electrical equipment requires connection to an alternating current network of 220 volts.

Watch the product video

Design features

The unit consists of a housing with elements located inside it: a combustion chamber, an ash pan and heat exchange equipment. A spacious hopper with a supply of pellets is attached to the side. The heat exchanger is made of copper. This material conducts heat excellently, is not afraid of corrosion and is almost resistant to the adhesion of layers of scale and dirt. The equipment can withstand a pressure of 3 bar and heats the circulating water to 80o C.

Such boilers are designed for long-term operation without human control. Their efficiency reaches 90%.

Zota 15S Pellet

The lineup

Pellet boilers of this Russian brand are represented by a long range of heating devices with a power from 15 to 130 kW. They have one heating circuit and are used exclusively for heating rooms. Maximum parameters of the circulating coolant:

- pressure 3 bar;

- temperature 95o C.

In case of overheating, a lock is triggered. The device is distinguished by the presence of a large bunker designed to store a supply of pellets and feed them into the firebox. It allows you to leave the boiler for a long time without direct human control.

For the automation and transport line to function, the unit must be connected to a household electrical network. On the rear wall there are fittings for connecting a chimney with a diameter of 150 mm and heating pipelines of 2".

Watch the product video

Design features

If there are no pellets, you can switch to using regular firewood. To do this, you will have to install the additional grate included in the delivery set and disconnect the secondary air supply tubes. Boilers of this brand are not only simple and unpretentious, but also achieve an efficiency of 90%.

The best solid fuel boilers with a water circuit

Based on consumer reviews and expert opinions, we have compiled a rating of TKDGs from different manufacturers.

Below is the TOP 5 best models with a water circuit.

Stropuva S30 30 kV

Among the best models, TKDG Stropuva S30 stands out. The unit is capable of heating a room with an area of 200-300 m2.

Firewood and pellets are used as fuel. Combustion occurs according to the “top-down” principle. The boiler does not require electrical power. Traction is provided by a special bimetallic regulator. Mechanical control.

The heat exchanger is made of stainless steel. Has a floor-standing design. Despite its considerable dimensions, the boiler has an ergonomic design. An air distributor for firewood and pellets is provided.

There is a valve for maintaining pressure up to 2 bar.

Specifications:

- thermal power - 30 kW;

- fuel capacity – 342 dm3;

- burning time on one tab – 31 hours;

- volume of water in the boiler – 51 l;

- Efficiency – no less than 85%;

- water temperature – 75 degrees;

- dimensions – diameter – 68 cm, height – 185 cm.

- weight – 280 kg.

pros

- simplicity of design and control;

- affordable price;

- long burning on one tab;

- energy independence.

Minuses

- not designed for coal;

- mechanical control;

- no display.

In the budget category, this model especially stands out for its reliability and durability.

Stropuva Mini S8 8 kW

The Stropuva boiler line is adequately represented by the Stropuva Mini S8 model. The device is designed for heating

rooms up to 80 m2.

Fuel - firewood and wood briquettes.

It consists of 2 cylindrical chambers made of stainless steel. Top combustion of fuel is ensured. Air is supplied to the firebox through a telescopic pipe. Automatic adjustment of its supply is provided. The boiler maintains a cyclic operating mode. Mechanical control.

Fuel loading is manual. The water temperature is changed by a bi-thermal draft regulator. The control is based on a very simple design but reliable automatic valve. Installation - floor.

Specifications:

- thermal power 8 kW;

- burning time on one stack is 30 hours (48 hours on briquettes);

- Efficiency – no less than 85%;

- water temperature – up to 90 degrees;

- dimensions – diameter – 55.5 cm, height – 136.5 cm.

- weight – 145 kg.

pros

- small dimensions;

- European quality certificate;

- optimal heat removal;

- energy independence.

Minuses

- the rough surface of the body makes cleaning difficult;

- Difficulty loading.

This model is ideal for small houses and cottages, as noted by most consumers.

Teplodar Cooper Expert 15

Teplodar Kupper Expert 15 is a Russian-made heating TKDG, designed for premises

area 100-150 m2.

Firewood, briquettes and coal can be used as fuel.

The design additionally includes a built-in heating element to maintain the coolant temperature. There are 4 operating modes: fast warm-up, Classic, Medium and Maximum. For ease of maintenance there are 2 cleaning hatches. Combustion is ensured from top to bottom.

The fuel loading door is protected by a stainless steel screen. Heat exchanger material – stainless steel. Control is mechanical. Installation - floor.

Specifications:

- thermal power - 15 kW;

- burning time on one tab – 24 hours;

- Efficiency – 90%;

- water temperature –60-95 degrees;

- dimensions – 51.3x88x77.5 cm;

- weight – 148 kg.

pros

- different operating modes;

- adjustable coolant temperature over a wide range;

- convenient cleaning;

- affordable price.

Minuses

- lack of built-in expansion tank;

- energy dependence when using heating elements.

The model is popular because combines price and reliability well.

Teplodar Cooper Expert 22

The Kupper series is represented by the high-power TKDG Teplodar Kuppe Expert-22. The boiler is capable

heat a house up to 220 m2.

Structurally, the model is largely similar to the previous device. To maintain the temperature, a 6 kW heating element is installed. The long process is ensured by top combustion.

Efficiency is increased due to a developed heat exchanger and 3-zone air supply. You can set 4 different operating modes. You can lay coal, firewood, pellets. The chimney carries combustion products back. Control is mechanical. Installed on the floor.

Technical specifications:

- thermal power - 22 kW;

- firebox volume – 45 l;

- burning time on one tab – 31 hours;

- volume of water in the boiler – 90 l;

- Efficiency – 90%;

- water temperature – up to 95 degrees;

- dimensions – 51.3x88x88.3.

- weight – 165.5 kg.

pros

- possibility of quick heating;

- large area of the heated house;

- availability of economy mode;

- Ease of Management.

Minuses

- energy dependence;

- mechanical control;

- lack of a built-in pump.

Widespread use for heating large houses is explained by its affordable price and high quality.

ZOTA Carbon 50

One of the best TKDG is the ZOTA Carbon 50 model, which can heat houses and industrial

premises with an area of more than 400 m2.

The unit is designed for coal fraction 10-50 mm.

A special air supply control system ensures long-lasting fuel combustion. The body is made of high-strength boiler steel. Top coal loading and a three-pass gas duct are provided.

You can additionally install a heating element to maintain the temperature during fuel combustion. The kit includes an adjustable chimney pipe. The ash pan is located on the cooled surface. The movable grate makes cleaning easier.

Specifications:

- thermal power - 50 kW;

- fuel capacity – 87 dm3;

- burning time on one tab – 30 hours;

- volume of water in the boiler – 102 l;

- water temperature – 90 degrees;

- dimensions – 91.5x69.5x117 cm;

- weight – 303 kg.

pros

- high-strength body;

- large combustion chamber;

- convenient cleaning;

- high thermal power;

- high working pressure.

Minuses

- lack of a built-in pump;

- increased price.

Consumers note that the high cost of the unit is consistent with its power and reliability.

Solid fuel boilers: advantages

Solid fuel boilers have recently become in great demand due to positive aspects, including:

- equipment cost and fuel efficiency;

- Beautiful design;

- autonomous work;

- ease of installation and maintenance.

Firewood will not cost that much, and will burn for a long time. Manufacturers also took care of the appearance of the equipment. Solid fuel boilers and fireplaces are available for sale. These models do exactly the same job as regular models and add an attractive look to your home.

Long-burning devices can operate for a long time even without power supply.

This indicator is very important in places where the electricity supply is intermittent.

Anyone can install the equipment; no special skills are required. There is also no need to purchase special tools. There should be no issues during operation and maintenance. Each model has instructions, after studying which it becomes clear how the boiler works.

The best solid fuel boilers without a water circuit

Below is the TOP 5 TKDG models without a water circuit, especially distinguished by their quality and reliability.

Teplodar Cooper Expert-45

The top five TKDG includes the Teplodar Kupper Expert-45 model, capable of heating a room of

200-450 m2.

The boiler can operate on almost any type of solid fuel.

Heat exchangers and grates have a large contact area with heated gases, which increases the efficiency of heat removal. Operation can be provided in 4 modes, incl. on economical and maximum.

The tilting door and special tray make loading easier. The fast heating mode allows you to heat the coolant in 30 minutes. A simple but reliable draft regulator is provided. There is a built-in heating element. Installation method: floor.

Specifications:

- thermal power - 45 kW;

- burning time on one tab – 24 hours;

- Efficiency – at least 75%;

- water temperature – 95 degrees;

- dimensions – 103x65x81.5 cm;

- weight – 207 kg.

pros

- increased power;

- the presence of a mode of increased combustion duration;

- economical fuel consumption;

- ability to work on any solid fuel.

Minuses

- mechanical control;

- energy dependence when installing heating elements;

- lack of built-in expansion tank.

The boiler is designed for large houses, and under these conditions it shows itself to be very effective.

TermoKRoss TKR-08D

The TermoKRoss TKR-08D boiler receives many positive ratings. This is a single-circuit type unit with a firebox

closed type. Combustion occurs from top to bottom.

It can heat a room up to 80 m2. Air is supplied through a special valve directly into the combustion zone. Designed to work on firewood and wood briquettes, coal and pellets.

Mechanical control. The heat exchanger is made of stainless steel. You can additionally install a heating element to maintain the temperature when the wood burns. The chimney diameter is 160 mm. Overheating protection is provided.

Specifications:

- thermal power - 8 kW;

- burning time on one stack of wood – 35 hours, coal – 170 hours;

- volume of water in the boiler – 38 l;

- Efficiency – 91%;

- water temperature – 95 degrees;

- dimensions – diameter – 56 cm, height – 140 cm.

- weight – 175 kg.

pros

- compactness;

- simplicity of design and control;

- increased operating time on one load;

- energy independence in the absence of heating elements.

Minuses

- mechanical control;

- reduced power.

The boiler is fully adapted to Russian conditions and has an affordable price.

Aremikas Candle 35 kW

Among the leaders stands out the solid fuel single-circuit boiler Aremikas Candle 35 kW, designed for

heating a house with an area of up to 300-350 m2.

It has a floor-standing design. When burned, only the surface layer of fuel up to 20 cm thick burns. Firewood and wood briquettes are used as fuel. Mechanical control.

The firebox has a cylindrical shape. The heat exchanger is made of stainless steel. There is an automatic draft regulator that allows you to change the temperature of the coolant.

Specifications:

- thermal power - 35 kW;

- fuel capacity – 400 dm3;

- burning time on one tab – 34 hours;

- Efficiency – at least 80%;

- water temperature – 90 degrees;

- dimensions – diameter – 70 cm, height – 207 cm.

- weight – 315 kg.

pros

- significant thermal power;

- possibility of connecting a boiler;

- large firebox volume;

- economical fuel consumption.

Minuses

- the use of coal is not provided;

- significant weight;

- increased cost.

The boiler allows you to heat large volumes of premises, which compensates for the high price.

Stropuva S40 40 kW

The Stropuva S40 40 kW model is noted among the leaders of high-power TKDG. The unit has one circuit and can

heat an area of up to 400 m2.

You can connect an external water heater.

An open combustion chamber is used. Firewood is recommended as fuel. Mechanical control. Floor installation in a separate room. The heat exchanger is made of stainless steel.

Protection is provided by a safety valve. There is a special device for air distribution. The maximum water pressure in the circuit is 1.5 bar. A chimney with a diameter of 200 mm is provided.

Specifications:

- thermal power - 40 kW;

- burning time on one tab – 31 hours;

- Efficiency – 92%;

- water temperature – 60-95 degrees;

- dimensions – diameter – 68 cm, height – 212 cm.

- weight – 291 kg.

pros

- simplicity of design and maintenance;

- significant power;

- Possibility of cascade connection;

- complete safety.

Minuses

- lack of expansion tank;

- significant height of the unit;

- increased cost.

Great possibilities for heating huge houses compensate for all the shortcomings.

Stropuva S15 15 kW

One of the best representatives of the Stropuva family is the single-circuit solid fuel boiler Stropuva

S15.

It copes with heating rooms up to 150 m2.

The design includes 2 steel cylinders that fit inside each other, with external thermal insulation. The heated coolant is directed into the space between the cylinders. Air is supplied through a telescopic pipe. Fuel – firewood and wood briquettes.

Installation - floor. The parameters are regulated by a bithermal draft regulator. Mechanical control. No electricity required to operate. The safety valve ensures complete safety.

Specifications:

- thermal power - 15 kW;

- burning time on one stack is 30 hours (48 hours on briquettes);

- Efficiency – no less than 85%;

- water temperature – 90 degrees;

- dimensions – diameter – 56 cm, height – 172 cm.

- weight – 200 kg.

pros

- compactness;

- high reliability and safety;

- energy independence;

- economical fuel consumption.

Minuses

- reduced power;

- lack of expansion tank and built-in pump.

The boiler is designed for heating relatively small rooms where large thermal output is not required.

Why is a wood boiler sometimes the best option?

Of course, gas units are recognized as the best option both in terms of ease of use and cost of energy. But, unfortunately, not all populated areas of the country (and this is especially true in rural areas) are covered by gasification. In addition, supplying gas to a house, even if there is a central pipeline, is a rather difficult and costly task associated with the preparation of numerous documents. Obtaining all permits and approvals, drawing up a project, as well as purchasing everything necessary for connecting an individual gas supply line will require a lot of time, nerves, and money.

Gas equipment for heating a private home - alas, not everyone has the opportunity to take advantage of its convenience

Electric heating units, it would seem, can be used to heat any building to which electricity is supplied. Such boilers are easy to install, adjust and operate. However, their use also has its pitfalls.

You may be interested in information about what characteristics an electric boiler has for heating a private home

An electric boiler is quick and easy to install, but not everyone can afford the cost of such heating.

For example, to install high-power devices (above 7÷9 kW), a three-phase power line is required. And this is again trips to the authorities, drawing up a project, its approval, approval and other “joys”. Another factor that cannot be ignored is the high cost of electricity, and it is growing every year. Therefore, paying for heating using an electric boiler can become an unbearable burden for the family budget.

In addition, it is necessary to remember that if during an emergency there is a power outage, the house will be left not only without light, but also without heating.

The logical conclusion is that if it is impossible to use gas, a solid fuel boiler is more reliable and profitable for heating a private home. Moreover, heating homes with wood has been traditional for many decades, since there is no shortage of this fuel. Particularly problems do not arise in regions rich in forests, where there is always enough dead wood. And purchasing ready-made firewood for the heating season will cost much less than paying for electricity.

That is why, even after installing gas heating equipment, many owners of old houses are in no hurry to get rid of stoves and fireplaces, which are maintained in working order “just in case.”

However, a stove is not an option that can heat large areas of the house. Therefore, in order to achieve comfortable temperatures, several stoves had to be installed in the building, which were heated several times a day. Of course, this is not only difficult, but also extremely uneconomical.

A solid fuel boiler is a modern, powerful unit capable of providing heat to a very large residential building.

This discomfort is eliminated by creating a full-fledged heating system powered by a long-burning solid fuel boiler, which allows the entire house to be supplied with heat from one place. Unlike a conventional stove, such units are capable of operating from one load of fuel for up to 12 hours or even more. Thus, such a boiler will require attention twice a day, when the required amount of firewood is put into the firebox.

By the way, there are also models of solid fuel units that can operate on one load of fuel for a day or more.

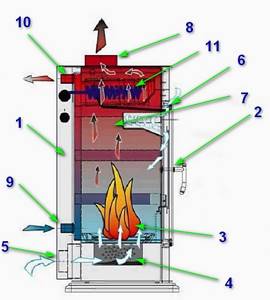

The structure of one of the models of a long-burning solid fuel boiler and the types of fuel used.

The advantage of solid fuel boilers is that almost all models can operate not only on wood, but also on other types of solid fuel. For this purpose, pellets, peat briquettes, as well as so-called “euro firewood” are produced from wood waste on an industrial scale.

Some types of coal are also used as fuel for these units, however, not all models are designed for it. Therefore, if you plan to use coal for heating, you should choose the appropriate model after studying its characteristics when purchasing.

Operating principle of TKDG

Long-term combustion in a TKDG furnace can be ensured in 2 ways:

- Top combustion principle . In the combustion chamber, the fuel does not burn, but smolders with limited access to oxygen. The cylindrical firebox is located at the top of the unit and has a cylindrical shape. The gas released during smoldering enters the afterburning chamber, where a supply of atmospheric oxygen is ensured for its complete combustion. As a result, almost complete combustion of the fuel occurs with the active release of thermal energy.

- Pyrolysis principle . The combustion chamber is located at the bottom. Active smoldering of fuel also occurs here with limited access to oxygen. The combustible gas rises up and reaches the second chamber, where, enriched with oxygen, it burns completely.

Thus, the duration of combustion is ensured by the two-chamber design of the unit, when the fuel slowly smolderes in the firebox, and the released combustible gases burn in the second chamber.

Design and operating principle of long-burning heating boilers

To understand how the boiler functions, as well as to facilitate the process of its future maintenance, you need to familiarize yourself with the design and principle of operation.

The principle of long burning is that, firstly, such boilers have a very voluminous firewood loading chamber. And secondly, that fuel combustion does not occur immediately, but is broken down into two stages.

- Firewood (or other solid fuel acceptable for this model) is placed in the combustion chamber. This compartment should be filled to almost its entire volume. Only at the very loading window do they try to lay out thin logs, wood chips, branches, etc. – to facilitate initial ignition.

Long-burning boilers are always distinguished by a very capacious fuel chamber, which is tightly filled with firewood “to capacity”

- Next, using a torch or paper, the fuel supply is ignited. At this stage, a sufficient amount of air is supplied to the chamber, necessary for intense combustion to occur.

- Once the fuel is ignited, the supply of air to this primary combustion chamber is reduced to a minimum. Thanks to this, the usual active burning of wood stops and goes into the stage of thermal decomposition, in other words, smoldering.

- Under such conditions, smoldering wood, during its decomposition, releases very significant volumes of combustible gases with high energy potential. This process is called pyrolysis, and the gases themselves (which are dominated by methane) are accordingly often called pyrolysis.

- If in conventional furnaces the resulting pyrolysis gases simply go into the chimney, then in long-burning boilers they enter a specially designed afterburner chamber. Here, under the influence of high temperature and excess supplied oxygen (air), the gas mixture ignites and completely burns out with a very significant release of heat. As a result of the full cycle, there is practically no waste left from the firewood, since its solid component is destroyed by smoldering to the smallest ash, and the gaseous component burns out intensively in the afterburner. This in total determines the high heat transfer of the boiler and its high efficiency.

It is the formed pyrolysis gases that are the main source of thermal energy, and it is their afterburning chamber that accounts for the main part of the water circuit heat exchanger. Although, of course, heat extraction begins in the primary combustion chamber.

You may be interested in information about what characteristics solid fuel has for briquette boilers

To make it more clear how such boilers are approximately arranged, you can consider the following diagram:

One of the options for a long-burning boiler

1 – boiler body with a reliable layer of thermal insulation.

2 – firewood loading window with a tightly closing door.

3 – chamber of primary thermal decomposition of wood (pyrolysis).

4 – ash pit in which unburnt waste is collected.

5 – channel for dosed supply of primary air necessary to ensure smoldering of firewood

6 – channel for supplying secondary air, necessary for complete afterburning of bleached pyrolysis gases.

7 – afterburning chamber of pyrolysis gases.

8 – pipe for connecting the boiler to the chimney to remove combustion gases.

9 – pipe for connecting the return pipe of the heating circuit.

10 – pipe for connection to the heating circuit supply pipe.

11 – additional heat exchanger, which is often used to connect the indirect heating boiler of a home’s hot water supply system

Of course, such a scheme is not at all some kind of dogma. The number of models offered for sale is large, and the layout can have very significant differences. In particular, the structure of the loading chamber, the direction of combustion of the fuel fill, and the location and design principle of the secondary afterburning chamber of pyrolysis gases may differ. Each model has its own “water jacket” design or additional heat exchangers. But the principle of operation of the boiler still remains similar.

Before you start using the selected model, you must carefully study the diagram of its design, which is necessarily included in the documentation accompanying this heating device.

You may be interested in information about the advantages of autonomous gas heating in an apartment

Advantages and disadvantages

Advantages of the boilers under consideration:

- high efficiency exceeding 90%;

- accessible and fairly cheap fuel;

- ease of installation, management and operation;

- almost complete combustion of combustion products;

- increased durability;

- affordable price.

Some disadvantages of TKDG should also be noted:

- the need for a separate room for installation;

- the need for periodic ash removal;

- arrangement of a storage facility for fuel supplies.

In budget designs, fuel is loaded manually, which can also be attributed to the disadvantages of such equipment.

Efficiency of different types of boilers

The effectiveness of traditional fuel combustion engines is limited by the cyclical nature of the combustion process. When the boiler is ignited, heat transfer is minimal. After complete ignition of the entire stack, maximum draft occurs, preventing the complete removal of heat from the flue gases. The relatively stable phase begins when only smoldering embers remain.

All three stages, lasting 3–4 hours, must be visually monitored, changing the intensity of air flow manually in time using dampers or the ash chamber door. Under such conditions, the maximum possible efficiency does not exceed 60%, and most often much less. Ensuring a stable temperature of the heating system coolant is also difficult. The only way out is to constantly stay near the boiler, add small portions of firewood or coal, and control the intensity of the flame.

It is possible to obtain the highest possible efficiency of 85% using solid fuel only when using fully mechanized pellet boilers. Despite their high cost, they are becoming increasingly popular.

With appropriate bunker sizes, non-stop operation is possible until the fuel supply runs out. Automatic ash removal and soot cleaning from the surface of the chimney does not require third-party control.

Pyrolysis fuel boilers are affordable, easy to use and efficient - they have an efficiency of 70–75%. The time for complete combustion of fuel is 6–20 hours. Heat transfer is relatively stable, since the change in thermal power does not exceed 20% during the entire burning time of one load of firewood.

This type of TC has a number of other advantages:

- possibility of using large unsplit firewood;

- the presence of a smoke exhauster allows you to automate control and adjustment;

- two-stage combustion guarantees the highest possible efficiency.

Pyrolysis TC is not without its drawbacks. The smoke exhauster creates unpleasant noise during operation, so it is recommended to install the heat generator in a utility room.

Prices for various types of solid fuel boilers

solid fuel boiler

Water circuit

To ensure autonomous hot water supply, in addition to the heating system, TKDG with a water circuit or double-circuit boilers are installed. Such units have 2 independent circuits for water circulation. An additional heat exchanger acts as a boiler and is intended only for heating water.

If the TKDG is connected to the water supply network, then water circulation through both circuits is ensured without forced supply, i.e. due to pressure in the water supply. When there is no centralized coolant supply, a storage tank is needed. It contains the necessary supply of water to meet demand.

The tank is usually installed above the boiler. A number of unit models have a built-in expansion tank. Forced water supply is provided by a circulation pump.

Selection of coolant

When choosing one or another heating system with a water circuit, it is important to think about what coolant will be used. In winter, country houses and country houses are not often visited, and heating is necessary only when the owners arrive

Therefore, owners give preference to non-freezing liquids, the consistency of which does not change with the onset of severe frosts. Such fluids eliminate the possible problem of pipe rupture. If water is used as a coolant, then before leaving it must be drained and refilled before use. The following can also be used as a coolant:

antifreeze is a special liquid that prevents freezing. The heating system uses 2 types of antifreeze - propylene glycol and ethylene glycol.

When choosing this method, it is important to know that ethylene glycol is extremely toxic, so it must be handled appropriately. coolant based on glycerin. Considered more effective and safer (non-explosive and non-flammable)

Glycerin liquid is expensive, but since the oven only needs to be filled with it once, it makes sense to invest in the purchase. In addition, glycerin freezes only if the temperature drops below -30 degrees. saline solution or solution of the natural mineral bischofite. The standard ratio is 1:0.4. This water-salt solution does not harden down to -20 degrees.

How to choose a coolant

Detailed instructions for choosing a coolant for heating systems and technical characteristics can be found here

Installation

Installation of a furnace with a water circuit can be carried out according to two schemes. The first scenario involves the circulation of liquid in this way: cold water goes down and warm water rises up

Then, when installing the stove, it is important not to disturb the correct height difference

The second scenario is used when fluid circulation is not naturally possible. Then pumps are installed to ensure an artificial water circulation.

For convenience, the installation of the heating system takes place in several approaches. First, a wood-burning stove or fireplace is installed and the chimneys are removed, observing fire safety rules. Later, a water circuit is installed throughout the house.

Features of furnaces with a water circuit

Before rushing to purchase equipment, it is important to familiarize yourself with the features of the heating system. Advantages:

Advantages:

- The ability to efficiently heat several large rooms.

- Even heat distribution.

- Safety of use.

- They can be autonomous heat sources or work together with a centralized heating system.

- Using a temperature sensor that allows you to monitor the operation of the device.

- Autonomy (independence from sources of electricity and gas communications).

- Relatively low cost of maintenance.

- The stove operates on coal, peat, wood and coke coal.

- Economical and environmentally friendly heating system.

- Modern design and fits any style and interior.

Flaws:

The boiler reduces the useful volume of the firebox

To eliminate this fact, it is important to consider the required width of the boiler and the stove itself when laying the firebox. Long-burning stoves can also be used. Low level of automation

Only manual control is possible. The thermal energy obtained as a result of burning wood is spent on heating the boiler and the liquid in it, and the walls of the firebox heat up more slowly and to a lesser extent. In severe frosts, the coolant may freeze. There is a risk of freezing if permanent residence is not planned in the house. To prevent this, special additives should be added to the purified water to protect the system. Experts also recommend using antifreeze - a universal coolant that freezes only at very low temperatures.

The use and maintenance of heating furnaces with a water circuit is not particularly difficult. We have attached a video for further explanation.

Having decided to purchase a heating stove with a water circuit, study in advance the models offered by foreign and domestic companies. They are distinguished by size, design, cost and auxiliary equipment. For a small country house, a brick stove with water heating, low power and without design frills is quite enough. The owner of a large mansion is unlikely to be satisfied with such a model. A spacious living room can be decorated with a stylish foreign-made stove.

How is the boiler power selected?

Accurate calculation of the required boiler power for heating a house is quite complicated. A simple technique is usually used: to heat an area of 10 m2, 1 kW of thermal energy is needed.

For unforeseen cases, a reserve of 10-15% of power is created. When using a water circuit or installing an additional boiler, additional energy of about 25-30% is required.

Climatic conditions make their own adjustments. In cold regions, where the air temperature can drop below minus 30 degrees, TKDG is selected at the rate of 1.6-2 kW per 10 m2 of room area. For the southern regions of the country, the requirement can be reduced: 0.8-0.9 kW per 10 m2.

How to choose the right boiler

To select a suitable heating system, the owner of a private housing construction needs to determine in advance the characteristics of the purchased heat generator. Then it will be easy to understand the wide range of boilers offered by modern manufacturers: Viessmann, Olimp, Atmos, Dakon, Opop.

Based on the functions they perform, TCs are divided into two types:

- single-circuit - used only for heating;

- double-circuit, a hot water boiler is connected to them.

When choosing, you should decide which option is the most profitable, whether the unit uses a convenient type of fuel: firewood, coal, peat, pellets. For a pyrolysis fuel boiler, only dry firewood is suitable; for storing pellets you will need a bunker next to the boiler; a coal or peat shed should be located in a place convenient for unloading from a dump truck.

The most important characteristic of a pyrolysis fuel chamber is the volume of the loading chamber. Its size will determine how often the boiler will have to be filled with firewood. The useful volume of the top-loading chamber is larger than others, and fuel storage is more convenient.

TC can be equipped with automatic control and regulation means, a smoke exhauster, a fuel feeder, ash removal and soot cleaning mechanisms. All these devices require continuous power supply. Stable operation of the heat generator can be ensured by an emergency power supply. Moreover, it does not have to be a generator with a gasoline engine.

In case of a sudden power outage, a 300 Ah car battery is suitable. This is enough for 12 hours of continuous operation of mechanisms with a total power of 200 W.

An inverter will help convert direct current into alternating current by increasing the voltage from 12 to 220 V. It must be connected through an electronic unit, which automatically activates reserve power. Then the heating system will work regardless of power supply problems.

Kholmov's solid fuel boiler is an advantage over traditional installations. This topic can be found here.

How to calculate the performance of a heating unit

Use the initially simplified formula: per 10 square meters of building area, 1.2 kW of thermal power is required. For example, for a house with an area of 200 m2, a heating system with a rated power of 24 kW is suitable. To provide the cottage with hot water, multiply the final figure by 20%. For an accurate calculation, use the methodology from the “Building Norms and Rules” (SNIP).

Then you need to consider:

- climatic conditions;

- design characteristics of premises;

- size of heated area;

- the number of external walls, their orientation to the cardinal points - south, east, west, north;

- outside air temperature during the coldest week of winter;

- thermal resistance of external walls, depending on the thickness and thermal conductivity of the material;

- ceiling height;

- what is below and above: a heated or cold room, an attic - insulated or not;

- degree of floor insulation;

- presence of a basement;

- number and size of windows;

- type of window structures: wood or metal-plastic, double or triple glazing;

- the presence and size of doors to the street or balcony.

Calculations must be carried out for each room separately. Then sum up the heat loss, and then it will be possible to obtain the required power of the heat generating unit.

The best manufacturers

It is recommended to choose TKDG only from proven, reliable manufacturers. These include:

- : boilers of the Ochag series with power from 5 to 35 kW.

- Krasnoyarsk Heating Equipment Plant : Zota, Dymok and Topol series.

- SibEnergoTerm : boilers of the Prometheus brand with a power of up to 46 kW.

- TeploDar : Cooper series.

- Bosch (Germany). Supplies boilers for heating houses with an area of more than 500 m.

- Buderus (Germany). The boilers operate on coal and pellets. Power – up to 30 kW.

- Junkers (Germany). The most popular are TKDGs with a power of 25-35 kW.

- Stropuva (Lithuania-Ukraine). TKGD series Buran with power up to 42 kW stand out.

- "Logika" (Poland): boilers with a power of up to 220 kW.

Leading manufacturers are widely represented on the Russian market, which makes it possible to choose the optimal model for specific conditions.