Who is the manufacturer

The international company Protherm was founded in 1991 in the Czech Republic. The initial production line was located at a plant in Prague and specialized in the production of electric boilers.

Proterm produce quite a few modifications of boilers

The high popularity of the products forced the company's management to increase production, so the company moved its workshops to the Slovak city of Skalica.

A year later, Proterm begins production of boiler units operating on liquid fuel and using two types of gas: liquefied and main gas. In 1997, the company acquired the European quality certificate ISO 9001 and began exporting boiler equipment to England and Germany.

At the same time, the company is launching a production line for the production of solid fuel and condensing boilers, as well as boilers for heating and storing hot water. In 2013, Protherm began manufacturing solar collectors.

Since 2010, the Protherm brand has been part of the group of red brands of the trading company Vaillant Group, which has thoroughly redesigned the corporate identity of the boilers.

Manufacturer Protherm

The Protherm company is primarily a well-known European manufacturer of heating equipment. Many years of experience and successful sales of equipment characterize it as a reliable manufacturer of high-quality products.

Protherm sells in many countries on different continents and thanks to its guaranteed high quality and affordable prices, this brand has gained the trust of consumers.

The product range includes more than 95 items, among them there are classic solutions such as gas boilers, electric boilers, boilers, solid fuel boilers, as well as innovative products such as condensing boilers.

A distinctive feature of the company’s activities on the Ukrainian market is the provision of professional services throughout Russia. Service maintenance is carried out both by our own service department and with the involvement of partner companies, whose specialists are required to undergo special training on Protherm products.

The plant in Skalitsa is the main site for the production of Protherm heating equipment; it produces and supplies over 4,000 products to markets in more than 25 countries around the world. The assortment assembled at the plant is varied: wall-mounted and floor-mounted gas boilers, solid fuel boilers, industrial boilers, electric boilers, water heaters, buffer tanks, etc.

history of the company

1991 – Founding of the company in Prague. Start of production of electric boilers in Zličín, Prague.

1992 – The rapid growth in sales of electric boilers served as an incentive to organize their mass production. Transfer of production to a new large plant located in the city of Skalitsa.

1993 – The Protherm brand conquered 65% of the electric boiler market, uniting over 800 trading and service partner companies in the Czech Republic and Slovakia.

1994 – Development and launch of production of wall-mounted gas boilers.

1995 – Expansion into foreign markets: first deliveries to Germany and Ukraine.

1996 – First deliveries of products under the Protherm brand to Russia. Signing a strategic partnership agreement with the Anglo-French manufacturing group Hepworth - Saunier Duval.

1997 – Certification of heating equipment production in accordance with ISO 9001 standards.

1998 – Launch of assembly lines for wall-mounted gas boilers of the TIGER series and floor-standing gas boilers of the BEAR series.

1999 – The company’s products passed the procedure for assessing compliance with European Union standards, CE certification.

2000 – Large-scale modernization of the plant, production lines and research center. Launch of production lines for the assembly of boilers of the PANTHER and LEOPARD series.

2001 – Merger with the largest German manufacturer of heating equipment – Vaillant Group. Presentation of the condensing boiler LEV. Record production rates of heating equipment: 732 boilers are assembled in two production shifts per day.

2002 – Increase in the number of assembly lines.

2003 – Active international expansion: export of products to more than 20 countries in Europe, Asia and Africa.

2004 – Creation of an extensive service network of 1,750 service offices in the Czech and Slovak Republics.

2005 – Opening of a representative office of Protherm in Russia.

2006 – Introduction at the enterprise of a new high-tech production process One-Piece-Flow, i.e. “one boiler - one master” made it possible to bring products to a higher level of quality. Obtaining ISO 14001 certificate.

2007 – The next stage of production modernization: the organization of 5 production lines for the assembly of floor heating equipment, the transition from the traditional assembly of wall-mounted gas boilers to assembly on the principle of one boiler - one master, updating the KLOM and KLZ series of the Bear family, launching the production of Bober solid fuel boilers.

2008 – Update of boilers of the Panther and Lion series. The Protherm brand becomes the leader in sales of condensing boilers on the Slovak market.

2009 – Active expansion into Asian regions. Consolidated leadership in the segment of gas condensing boilers.

2010 – Modernization of the assembly lines of wall-mounted gas boilers Panther, Cheetah, renewal of the assembly line of wall-mounted electric boilers, launch of a new assembly line of condensing boilers, presentation of solar technology of the HELIOSET series. The Protherm brand has become part of the red Saunier Duval Brand Group of the Vaillant Group, significantly changing its corporate identity.

2011 — Fifteen years of successful sales in Russia

2015 — Reorganization of assembly lines to increase the production of condensing equipment in connection with new environmental standards introduced in the EU

2016 — Twenty years on the market of Russia and the CIS countries

2017 — Update of the line of floor-standing gas boilers Bear KLOM and Bear KLZ with a cast iron heat exchanger

Factory in Skalica, Slovakia

Since its opening in 1992, the Vaillant Group plant in Skalica, Slovakia, has been the main production site for the Protherm brand. Today, over 400 plant employees annually produce over 350 thousand boilers, supplied to 25 countries around the world. The range of products manufactured by the plant includes wall-mounted and floor-mounted gas boilers, condensing boilers, solid and liquid fuel boilers, heat pumps and industrial heating boilers. The production quality management system is organized in accordance with the ISO 9001 standard and is annually audited by Bureau Veritas Quality International.

Depending on the type of product being manufactured, the assembly line can be arranged according to the conveyor principle (for example, for large-sized and heavy floor-standing boilers) or according to the “one piece flow” principle, where each boiler is assembled from the beginning and to the end by one master who bears personal responsibility for the result and quality of work. Each production line carries out final quality control, checking safety elements and the control unit of each boiler.

A testing laboratory is located on the territory of the plant, which allows for constant testing of products, testing of new structural elements and technologies. In addition to our own research and testing, Protherm brand products undergo annual testing by foreign testing laboratories.

Quality control in production

The assembly technology of boilers and spare parts for heating and hot water systems of the Protherm brand is organized with special care and German scrupulousness. In addition to complying with its own requirements for the quality and reliability of equipment, Vaillant Group regularly audits production sites to ensure that internal production processes comply with international standards for quality management at the enterprise.

Protherm brand products have won the hearts of Russian consumers with their price-quality combination. The quality of the product, the safety of its use and the durability of its operation are the result of a scrupulous approach to all production processes, including the quality control process. The production quality management system is organized in accordance with the ISO 9001 standard.

The worker who assembles the equipment is personally responsible for the quality of his work. If a problem is detected in the boiler, you can always determine when the boiler was assembled, on what shift, and who assembled it.

Moving from one assembly station to another, a plant employee assembles the boiler step by step under the control of the AMS system, moving between assembly stations. The assembly process control system collects information from all assembly stations, analyzes the data obtained and makes a decision to interrupt or continue the assembly of each boiler individually. If there were problems at the previous stage or the assembler did not perform some necessary actions, the AMS system will not allow the assembly process to continue further and will inform about where the error was made, thereby allowing it to be corrected. Thus, every manipulation of the master is under control, which almost completely eliminates the possibility of incorrect assembly of the equipment.

Additionally, finished products from each batch are selected at random and undergo additional testing. If additional testing reveals a manufacturing defect, then the entire batch of boilers is sent for testing.

Such a complex process of quality control in production allows millions of owners of our boilers to rely on its reliability in difficult operating conditions and allows us to rightfully occupy a leading position in the Russian market.

Range of gas boilers Proterm

Proterm gas boilers today are presented in a fairly wide range. As consumer reviews show, each model of such equipment has its own characteristics, advantages and some disadvantages. To make your choice, just familiarize yourself with the technical characteristics of each model. Of course, you should also read reviews about the selected boiler.

“Panther” boiler series

This wall-mounted heating equipment has a bithermic heat exchanger. Thanks to this, Protherm boilers of this model range allow you not only to heat a living space, but also to quickly heat water for household needs. It is worth noting that such units are ideal for heating private houses, apartments and country houses. Also in the reviews there is information that gas boilers of the “Panther” model range can be used as a backup or the main source of heat and hot water.

"Cheetah" series

This is another main model range of gas boilers from Proterm. To be more precise, Cheetah is the most popular line of gas heating equipment. Judging by the reviews, the cost of such units fully corresponds to their quality.

Series "Lynx"

Proterm boilers, belonging to the Lynx model range, are equipment that provides autonomous heating. Boilers of the “Lynx” series are placed on the wall, which allows you to significantly save space. Such equipment can be placed even in a small room.

Series "Leopard"

Proterm gas boilers from the “Leopard” series are no less relevant among consumers. Reviews of such products are usually positive. It is very rare to find a negative opinion about such units. Often such reviews arise due to incorrect configuration of the equipment or as a result of incorrect installation. Gas boilers Proterm "Leopard" work perfectly even when the gas pressure decreases. In addition, the heating equipment of the series guarantees fast heating of water. It is also worth noting that the units of this model range are equipped with sensitive automation.

Series "Bear"

This is a series of floor heating equipment. Boilers of the “Bear” series differ from others in their ease of operation. In addition, such units do not require special care. Each model is equipped with convenient automation. If a malfunction occurs in the operation of the equipment, the boiler turns off. It is worth noting that the units of the “Bear” series are a new generation of products, which are made of cast iron, which is characterized by high strength.

As reviews show, the main advantage of such equipment is the function of automatically turning off the heating of residential premises during the warm period. At the same time, a fully hot water supply is maintained.

Prevention recommendations

Maintenance by service center

Every year, preferably before the first turn on after the summer break, it is recommended to invite a specialist from a certified service organization to inspect and test the boiler. During a preventive inspection, the condition of the gas burner is checked, the power is adjusted, and the burner nozzles and heat exchangers are cleaned. A particularly important part of the inspection is checking the operation of the emergency thermostat and the combustion chamber thermostat.

Boiler user maintenance

Cleaning the unit lining without removing the protective casing. Must be carried out after disconnecting the device from the network. Power supply is allowed only after complete drying.

The water pressure in the heating circuit must be checked weekly. If necessary, top up after the unit has cooled below 400°C.

It is necessary to regularly, at least once every three months, check the tightness of the connections of the chimney system, the cleanliness of the filter and mud pan, and remove dirt if necessary.

If a gas leak is detected, the device must be immediately turned off, the gas valve closed and a service specialist must be called. It is not recommended to repair the unit yourself. For example, the instruction manual for the Cheetah wall-mounted double-circuit gas boiler manufactured by Proterm does not recommend trying to fix faults yourself, so as not to lose the company’s warranty.

Popular models

The company's product range includes electric and gas heating equipment of various capacities. Among the most popular modifications:

Cheetah

The wall-mounted version is equipped with a stainless steel heat exchanger. This is a 23 kW model. The operation of the system is automated and can be carried out using a temperature sensor. The compact housing allows the unit to be installed in apartments and cottages. The Cheetah boiler is available with forced and natural removal of combustion products.

Bear

The Bear series consists of several modifications:

- TLO is a low temperature boiler with a cast iron heat exchanger. The model does not need to be connected to electricity; it is equipped with piezo ignition.

- KLOM is a floor-mounted stationary unit with a modulating burner. The boiler has an electronic ignition system and operates according to a given temperature schedule.

- PLO - the unit is equipped with an injection burner to change the water temperature. There is a step switch on the panel. The display shows the temperature and pressure in the heating system.

- KLZ - the boiler has a built-in 90 liter boiler and electronic burner ignition. The power can be adjusted from 70 to 100%. The equipment has a self-diagnosis function.

Wolf

Single-circuit boiler with steel heat exchanger. The model is attractive due to its energy independence and affordable cost. It is recommended for private houses and cottages. A piezoelectric element is provided to ignite the burner.

Bear

Wolf

Cheetah

Tiger

The double-circuit unit with a built-in boiler is equipped with a function for controlling temperature and water supply speed. Models are available with a power of 12 and 24 kW. Equipment power 24 and 28 kW. Mode selection, operation control and possible errors are displayed on the LCD screen. Seasonal programming allows you to save fuel.

Lynx

A gas boiler is suitable for rooms where there is no chimney. It is equipped with a system for forced removal of combustion products. The series is distinguished by its compact design and affordable price. The unit operates in two modes: “Comfortable” and “Economical”. It has a hot water preparation function. The heating equipment is equipped with a circulation pump and an expansion tank.

Panther

The series is intended for heating systems with forced circulation of coolant. These are mounted boilers made of durable composite materials. The power of the models ranges from 12-35 kW. Panther comes with an open and closed combustion chamber, condensation and convection type. The water heats up to the set temperature in a few seconds.

Tiger

Panther

Lynx

Scat

Scat

An electric boiler is a reliable heating equipment for a home, cottage or apartment. Skat models are characterized by high performance and ease of maintenance. New for 2021 – built-in storage boiler. The single-circuit boiler has a self-diagnosis function; it is completely protected from overheating and pump jamming.

"Leopard"

These devices also have high efficiency. They operate in economical mode. This model range includes devices that differ in the design of the combustion chamber. It can be open or closed.

The maximum area that the boiler can heat is 220 m2. Power adjustment and operating mode are carried out using an automated control system. Speaking about the advantages of this design, it should be noted that the equipment is capable of operating even at low pressure in the gas line.

If necessary, the devices can be easily converted to operate using bottled gas. To do this, the valve and nozzle are changed. The heating device includes a protective module. It automatically shuts off the gas supply in the following situations:

- if the temperature inside the fuel compartment exceeds the permissible values;

- if traction is impaired;

- when the electricity is turned off;

- when the burner goes out.

Boiler maintenance Proterm Medved

After acceptance tests and issuance of permission to operate the boiler by the regional branch of the gas supply organization, the owner of the equipment begins to operate the boiler.

The new boiler is under warranty, so repair and adjustment work is carried out by specialists. The user can only independently monitor the proper operation of the boiler and control its operation using the control panel.

It is better to entrust servicing to certified specialists

During operation of the equipment, monitor the boiler readings and monitor the absence of gas contamination in the room, noise and vibration in the installation body. Service work is divided into three types:

- Routine maintenance to diagnose the technical condition of the boiler and eliminate possible failures, prepare it for operation during the heating season, including cleaning the boiler heating surfaces and the smoke exhaust system, is carried out annually.

- Maintenance upon request of the subscriber, depending on the technical condition of the boiler or failures identified by the diagnostic system.

- Overhaul is an event to eliminate malfunctions of the main elements of the boiler, carried out as necessary.

High-quality maintenance of the boiler unit allows you to extend the operation of the boiler beyond the period specified by the manufacturer, usually 10 years.

In addition, timely cleaning of gas surfaces from soot and internal surfaces of the heat exchanger from scale increases the efficiency of the boiler and significantly reduces the owner’s expenses for heating the house.

Specifications

The main technical characteristics, for ease of comparison and to speed up the search for the necessary information, are summarized in Table 1.

| Model | Panther | Jaguar | Cheetah | Tiger | Lynx |

| Characteristic | 25 KOV, 25 KTV, 30 KTV | 11 JTV, 24 JTV | 11 MOV, 11 MTV, 23 MOV, 23 MTV | 12 KOZ, 12 KTZ, 24 KOZ, 24 KTZ | 18/25 MKV 25/30 MKV |

| The combustion chamber | T – closed O – open | closed | T – closed O – open | T – closed O – open | closed |

| Exhaust temperature, °C | 35-85 | 30-85 | 30-83 | 45-85 | 30-85 |

| DHW temperature, °C | 38-60 | 30-64 | 38-65 | 40-60 | 30-64 |

| Extension tank, l | 7,0 | 7,0 | 5,0 | 8,0 | 8,0 |

| DHW expansion tank, l | — | — | — | 2,0 | 5,0 |

| DHW capacity, l/min | up to 17.0 | up to 10.7 | until 11 | up to 12.6 | up to 14.2 |

| Natural gas consumption kg/hour | 2,84 – 3,44 | — | 2,73 | 1,41 – 2,84 | — |

| Liquefied gas consumption, kg/hour | 2,08 – 3,21 | — | 1,9 | 0,91 – 2,08 | — |

| Natural gas consumption DHW cubic meters/hour | — | 2,73 | — | — | 1,39-3,08 |

| Consumption of liquefied domestic hot water gas, kg/hour | — | 1,02 | — | — | 1,02-2,26 |

| Natural gas consumption OB cubic meters/hour | — | 1,39 2,73 | — | — | — |

| Liquefied gas consumption, kg/hour | — | 0,55 1,02 | — | — | — |

| Storage tank, l | — | — | — | 45 | — |

| Weight, kg | 34 – 41 | 29 – 30 | 31 – 34 | 70 – 71 | 35 – 36 |

| Dimensions, mm | 800x338*440 | 700x280x410 | 740x310x410 | 900x410x570 | 700x280x390 |

| Price, thousand rubles | 45 – 53 | 27 — 32 | 34 – 39 | 50 – 130 | 54 – 56 |

Abbreviations: OH – heating water, DHW – hot water supply.

Explanation of the code in the model name:

- a two-digit figure corresponds to the rated power consumption in kW;

- the first letter - in combination with the third, indicates the model;

- the second letter is the type of combustion chamber: O - open, K, T - closed;

- the third letter is the type of boiler: V, Z – double-circuit, O – single-circuit.

In addition to the parameters indicated in the table, all wall-mounted double-circuit boilers have a number of other characteristics. In particular, they have the following protection systems:

- safety valve for releasing coolant when pressure in the system increases;

- protection of the circulation pump from jamming;

- protection of water pipes from freezing;

- gas control – stops the gas supply to the burner if the flame suddenly goes out;

- air venting – ridding the heating system of trapped air;

- protecting the boiler from overheating using a thermostat.

The electronic control system for gas boilers performs the following functions:

- microprocessor control;

- automatic control of the unit operation;

- device status monitoring;

- regulation of indoor air temperature;

- display of current temperature readings and fault codes.

Advantages and disadvantages

The advantages of Protherm gas boilers include:

- High quality manufacturing and assembly of all components and parts.

- Large selection of design and configuration options.

- The presence of many modifications that are optimally suited for working in difficult conditions.

- Environmental cleanliness, equipment safety.

- A self-diagnosis system is used that monitors the condition of all units of the unit.

- Economical consumption of gas and electricity. Non-volatile models are available.

There are some disadvantages:

- Dependence on the availability and correct connection to the power supply network, sensitivity to power surges or surges.

- High cost of spare parts, difficulties with supply in some regions.

- Low level of professionalism among technical personnel of service organizations.

IMPORTANT!

Complaints about the lack of training of service workers should not be understood as a design flaw in Protherm boilers, since the problem is of an organizational and administrative nature.

Advantages of Protherm heating units

The advantages of heaters include the following characteristics:

- ability to work on various types of fuel;

- Protherm gas boilers have a wide range of models. Manufactured devices have different power;

- Products are easy to install and maintain;

- the equipment has a high level of fire safety;

- During the combustion process, practically no harmful substances are released;

- the body is made of low-temperature cast iron;

- Using a special temperature sensor, you can control the combustion process and influence it.

The main advantages of Proterm boilers

As you know, you can heat a house not only with gas, but also with diesel, etc. And if at the moment you need a diesel boiler, but in the future you plan to switch to gas, then it is not necessary to buy two heating devices, because Protherm gas boilers are sold today.

Of course, each model has a different power, but they still compare favorably with other boilers in this parameter. The fact is that they can be used to heat rooms with a total area of 270 square meters. In addition, all products of this brand are easy to use and install, and this is an ideal option for those who value safety first. And it’s not surprising, because all boilers of this brand fully comply with European and world standards.

Note! It is worth adding that all Proterm heating devices have another amazing characteristic - unusual fuel combustion. Even experienced experts are surprised how environmentally friendly this process is in this case.

Low-temperature cast iron is used in the manufacturing process. And this, who doesn’t know, is a material that extremely effectively minimizes heat loss during heating. Another feature of boilers can be called special mechanisms, thanks to which the owners, even independently, without anyone’s help, will be able to create the most favorable microclimate in their home. And with the help of a special temperature sensor - a kind of magic wand - you can change the heating power. In a word, all the advantages of the products described are very significant, so the choice, frankly speaking, is quite obvious.

What determines the gas consumption of the Bear boiler from Protherm?

In addition to the characteristics of the heating boiler, heating efficiency is affected by:

- insulation of the house;

- wall material;

- characteristics of the attic and basement;

- ceiling height;

- number of windows and doors;

- errors during installation and configuration of boiler equipment;

- other potential heat losses.

The better the house is insulated, the less thermally conductive its walls are, the less gas needs to be spent on heating the room. An abundance of windows and doors helps to cool the house and requires an increase in heating intensity.

The boiler and type of heating system should be selected during the process of building a house. In this case, you can achieve maximum efficiency and reduce gas consumption.

On average, heating 10 m2 of a house with standard height ceilings (~2.5 meters) requires 1 kW of boiler power. However, you need to make an allowance of 10-15% for heat loss.

In terms of efficiency, the most economical fuel is main gas. If it is not possible to gasify the house, then the boiler can be converted to use liquefied gas in cylinders. Heating costs in this case will increase, but will be lower than when using electrical energy.

Protherm floor-standing boilers

Let's not beat around the bush - let's move directly to the characteristics.

Model "Bear"

Excellent cast iron equipment that can be used not only as the main, but also as an auxiliary heat source (for example, in addition to a solid fuel boiler). It is known for high-quality cast iron, thanks to which the service life is significantly increased. The advantages also include uninterrupted operation and ease of operation.

Special parameters of gas boilers:

- traction control;

- if you install a semi-turbo superstructure, then a chimney is not needed at all;

- operating modes “Winter” and “Summer”.

The approximate cost is from 40 to 117.2 thousand rubles.

Model "Bison"

Reliable and durable boilers that operate not only on gas, but also on fuel oil and diesel fuel. Increased efficiency, large power range. They are used where power is required, which is measured in megawatts.

Main advantages:

- impressive efficiency;

- environmental friendliness;

- ease of care and use;

- consumption of alternative fuels;

- long service life of the heat exchanger;

- DHW is heated in a separate tank.

The approximate cost is from 55 to 130 thousand rubles. So we looked at the main Protherm gas boilers. Warm winters and good luck at work!

Protherm Grizzly boiler catalog

The table below shows the main technical data and characteristics of Proterm Grizzly .

Series: Gas cast iron boiler PROTHERM Grizzly

| The PROTHERM Grizzly boiler is a new series of powerful cast iron boilers with a wide range of application possibilities. The series is distinguished by simple installation, the possibility of cascade connection to achieve power measured in MW, and ease of maintenance. The most interesting features of Grizzly boilers include: equithermal regulation of a cascade of boilers, automatic switching of winter-summer modes, preparation of hot water in combination with a PROTHERM indirect heating boiler. |

| Type | 65 KLOR | 85 KLOR | 100 KLOR | 130 KLOR | 150 KLOR |

| Fuel, inlet pressure | natural gas, 18 mbar | ||||

| Power 1st and 2nd stages, kW | 49 / 65 | 59 / 85 | 70 /99 | 91 / 130 | 105 / 150 |

| Gas consumption 1st and 2nd stage, m3/hour | 5.7 / 7.5 | 6.8 / 9.8 | 8.1 / 11.3 | 10.4 / 14.9 | 12.2 / 17.2 |

| Removal of combustion products | down the chimney | ||||

| Chimney diameter, mm | 180 | 200 | 220 | 220 | 250 |

| Volume of water in the boiler, lit. | 27.7 | 34.3 | 40.9 | 50.8 | 57.4 |

| Boiler efficiency | 91 % | ||||

| Boiler weight without coolant, kg | 317 | 369 | 421 | 499 | 550 |

| Gas connection | G 1″ | G 3/4″ | |||

| The connection will heat. contour | G 11/2″ | ||||

| Dimensions, H x W x D, mm | 1195x850x960 | 1195x1010x960 | 1195x1170x960 | 1195x1410x960 | 1195x1570x960 |

A little about the company

The Proterm organization was opened back in 1991. At this time, the production of the first floor heating equipment that ran on gas was established in Prague. Proterm boilers appeared on the Russian market in 1996 of the last century.

The products manufactured by this company are of fairly high quality. This is explained by the introduction of the One-Piece-Flow program into high-tech production. In other words, a separate master assembles the entire unit: from the very beginning until delivery of the equipment. It is this specialist who is responsible for any malfunctions during the operation of the unit, but only during the warranty period.

This became a good incentive to ensure a sufficiently high quality of manufactured products. In many reviews, owners noted not only this advantage of the product, but also its long service life. It is worth noting that the Proterm company occupies one of the leading positions in the global market. It produces a little more than two thousand boilers of various types per year.

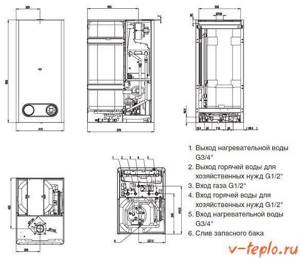

Description of the Proterm double-circuit boiler

Boilers that have the function of heating domestic water are called double-circuit because they heat water for two systems - the heating circuit and the hot water supply system (DHW).

The DHW system in such boilers, if necessary, can operate separately from the heating system. This mode is necessary to supply the house with hot water in the summer.

Wall-mounted double-circuit models are presented in a wide power range - from 11 to 30 kV, which allows the buyer to choose the best option depending on the heated area.

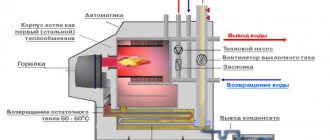

Wall-mounted boilers have a mechanism for releasing the combustion chamber from exhaust gases. This is done in two ways. The first is the forced removal of residual gases using a fan; such a combustion chamber is called closed. The second option is that the gases are given the opportunity to independently exit the room through the chimney; this chamber is open.

All Proterm products are equipped with the most modern automatic monitoring, control and protection systems.

"Panther"

The heating device has a special function that makes it possible to quickly heat water. Power control is carried out using a built-in microprocessor. For ease of operation, the boiler is equipped with a LCD monitor and electronic ignition.

These heaters can be used to heat a room and create a hot water supply system. Proterm wall-mounted gas boilers are equipped with special devices that perform protective functions:

- they prevent the heating system from freezing;

- if necessary, turn off the gas supply themselves;

- prevent jamming of the pump unit;

Error and fault codes

Proterm boilers are very reliable equipment, which is confirmed by more than ten years of experience in using units in Russia and the CIS countries. Almost the majority of failures are caused by disturbances from the outside, in external utility networks: water, electricity and gas.

Errors on Bear boilers can be easily removed

Failures occur in the control unit due to violations in the grounding system of the boiler equipment. The boiler software package has a good diagnostic system, which will not only identify malfunctions in the operation of components and mechanisms and report them to the user so that corrective measures can be taken

Basic fault codes for Proterm boilers:

- F00 - the line of the primary sensor NTC2 is open, the temperature of the supply pipeline.

- F01 - NTC5 primary sensor line is open, return pipe temperature.

- F10 - short circuit in the line of the primary sensor NTC2.

- F11 - short circuit in the line of the primary sensor NTC5.

- F20 - high coolant temperature in the supply circuit above 90 C.

- F22 - low pressure in the heating circuit.

- F23 - high temperature difference between forward and return.

- F24 - low circulation in the heating circuit.

- F25 - flue gas leak in the room.

- F27 - separation of the torch from the burner.

- F28 - low gas fuel pressure.

- F33 - low air supply to the firebox.

- F49 - low voltage in the mains and at the Ebus terminal, less than 15 V.

Description and prices of Protherm wall-mounted boilers

The Protherm Cheetah 23 MTV wall-mounted gas boiler does not have a chimney, which is very good for an apartment, its installation will not take you much time, its price is reasonable, and it is also able to maintain a comfortable temperature regime. Water is heated at temperatures from 38 to 60 degrees for hot water supply and up to 80 degrees for the heating system, respectively.

In addition, such a unit reacts very strongly to hard water.

As we have already mentioned, the price of this model fluctuates around 27 thousand rubles, which exceeds the cost of economical models very slightly. But economical, cheap boilers are not as high-quality, not as durable, and if they break down, they cannot be repaired.

Characteristics of the gas boiler Protherm Panther 25 KTV

This wall-mounted model is perfect for an apartment with a large area, for a private home or office. It has seven modifications, with a power from 12 to 39 kW. The series includes wall-mounted boilers with an open and closed combustion chamber, single-circuit and double-circuit. A powerful pump helps increase the rate of heat transfer within the system.

The price of such a unit is about 33 thousand rubles.

The key characteristics of boilers in this series are:

- compactness;

- presence of a built-in circular pump;

- the volume of the expansion tank is 5 liters;

- the presence of a modulation burner;

- there is the possibility of switching to liquefied gas;

- protection against overheating, hypothermia and short circuits;

- the presence of automatic recirculation, which will allow you to work with heating of any type.

Modification "Lynx"

The Protherm gas boiler, which belongs to this model range, has a dual-circuit heating device. It can be used to heat living spaces. It is also used to create a hot water supply system.

This type of equipment is distinguished by reliability, high efficiency and ease of operation. During operation, it makes virtually no noise. Its distinctive features include:

- presence of a liquid crystal display;

- possibility of smooth power control;

- frost resistance;

- built-in microprocessor;

- bypass valve for adjustment;

- filters for heating fluid;

- overheat protection system.

Price range

Convection models of Lynx boilers have been discontinued, so it is almost impossible to see them on sale.

Modern types of boilers have a condensing type of design, which significantly increases their cost.

The price range is between 60-65 thousand rubles. depending on capacity and delivery region. Price fluctuations may occur due to logistical requirements.

NOTE! When planning to purchase a boiler, you should add to its cost the costs of delivery, the purchase of additional devices and the conclusion of a warranty agreement. All this will require considerable expenses, for which you need to be prepared in advance.

Inspection is required

Over time, owners of gas boilers may experience some problems. To prevent this from happening, regular inspections must be carried out. After analyzing consumer reviews, it became clear that this procedure should be carried out at least once a year, preferably before the heating season. You should also invite specialists from a service company to set up heating equipment.

When inspecting heating equipment, special attention should be paid to:

- The tightness of all connections located in the smoke duct.

- Burner condition.

- Emergency thermostat functions.

- Boiler heat exchanger.

- The condition of the burner nozzles. If necessary, they should be cleaned.

Model range of gas boilers from Proterm

The line of similar products includes: floor-standing units Beaver DLO, Wolf KSO, Bear TLO, Bear PLO, Bear KLOM, Grizzly KLO, Bison NL.

Some of them are made of cast iron, others of steel.

Many are designed to run on natural and liquefied gas. But among them there are also solid fuel ones. Interesting devices that allow the use of both gas and liquid fuel as a heat source.

Gas boiler Protherm Bison

For example, the Bizon NL boiler has a power of 30 to 80 kW and is capable of not only heating a large house, but also heating water for household needs. It is economical and safe.

Protherm wall-mounted boilers include models such as Cheetah, Panther, Tiger and others.

For example, a boiler called Panther is ideal for heating and producing hot water in a small house, country house and even in a garage. It does not require a separate chimney pipe, since it has a built-in coaxial outlet to remove combustion products.

Equipped with a liquid crystal display, this device allows you to see all the operating parameters of the boiler at any time.

This boiler is produced in two versions - with one circuit and with two. This brand of gas equipment is most in demand because it has a nice design, convenient operation and is absolutely safe. Security is ensured by a built-in microprocessor that controls the operation of the entire device.

The lineup

It should be noted that Protherm gas wall-mounted and floor-standing boilers are available in different modifications.

Therefore, it is worth considering widely used models in more detail. Among the wall ones is the Jaguar model. The boiler is used for heating country houses and cottages, the area of which does not exceed 220 sq.m. It also provides the organization of hot water supply. Heat exchangers are separate. The equipment mainly runs on main gas. Although the unit can be converted to run on liquefied fuel. For this you will need to buy a set of jets.

The technical characteristics of the Proterm Jaguar wall-mounted gas boiler are as follows: closed combustion chamber, efficiency is 90.2%, maximum net power is 25.3 kW, minimum net power is 10.5 kW, power consumption is 98 W, liquefied gas consumption ranges from 2.73 cubic meters/hour to 1.02 kg/hour.

The Panther model is also widely used. Hydraulic blocks of boilers are made of composite materials. This allows the strength of the structure to be increased significantly. The unit is equipped with a tank and pump. There is a “Comfort” option, which allows you to heat the water in just 5 seconds. Equipment power ranges from 12 to 35 kW. Many owners prefer to install a Protherm Panther 30 ktv gas wall-mounted boiler in their home to create an effective heating system.

The Lynx model is also chosen by many users. The series is characterized by two separate heat exchangers. It is possible to separately regulate the temperature level in each of them. There is an expansion tank with a volume of 7 liters. The Proterm double-circuit gas wall-mounted boiler is also equipped with a circulation pump. There are two versions of devices: with a power of 24 kW and 28 kW.

Among the floor-standing modifications are the “Bear” series of gas boilers. This is a single circuit type. Power is 18-44.5 kW. It can operate on main gas or liquid fuel. No electrical connection required. Most often used for heating industrial buildings. You can learn more about this model from our article “Gas boiler Proterm Bear - model range and advantages”

The Grizzly model is also widely used. The series is easy to operate. Designed for heating structures with an area of up to 15,000 sq.m. Productivity is 150 kW. Operates on main gas. It is considered the most environmentally friendly equipment among boilers with similar power. But this series is dependent on the power source. There are also floor-standing models “Wolf” and “Beaver”.

To summarize, we can say that Proterm gas boilers are widely in demand among domestic consumers. All products are distinguished by high performance characteristics, reliability, durability, and at the same time, affordable prices. Which model to choose depends on the parameters of the heated room and the preferences of the owner of the house.

Basic faults

All possible malfunctions are immediately detected by the sensor system and displayed on the display in the form of an alphanumeric code.

Unit errors occur for various reasons, including:

- Break or short circuit of one or another sensor.

- No flame.

- Lack of water.

- Stopping smoke output.

- Circulation pump failure.

- Fan stop, etc.

Most errors cause immediate blocking of the boiler for safety reasons. Situations are possible when there is no one in the house, and there is no one to respond promptly to the appearance of signals.

NOTE!

Therefore, the security system produces an emergency lock, which is reset by the owner when restarted. A complete list of error codes is available in the user manual.

It is a rather lengthy list, and there is no point in listing it in its entirety.

Kinds

Protherm gas boilers are available in different design and model options and can be divided into several groups that have certain characteristics.

For example, according to the type of installation, boilers are:

- Wall-mounted (mounted).

- Floor-standing.

By number of circuits:

- Single-circuit (only heat the coolant for the heating system).

- Double-circuit (provide the room with hot water in parallel with the preparation of the coolant).

In addition, they differ in the heating method:

- Convection. Heat transfer occurs only in a heat exchanger heated in the flame of a gas burner.

- Condensation. Preheating is carried out in the condensation chamber, where water vapor is deposited from the exhaust smoke and exhaust gases.

By type of combustion chamber:

- Atmospheric or open. Combustion and smoke removal occur using natural draft.

- Turbocharged or closed. For the process to proceed correctly, a fan is used to supply air flow to the burner and ensure smoke exhaust.

NOTE!

Such an abundance of options creates an extremely rich assortment, allowing you to choose the appropriate sample for any conditions and needs.

Protherm wall-mounted boilers

Let's start with the most popular model - the Tiger.

Model "Tiger"

The power of the heating equipment of this model varies between 3.5 and 23 kilowatts. All devices are economical and reliable, developed in accordance with the latest trends in technology and design. They also comply with all standards and requirements for heating systems.

“Tigers” are equipped with a 25-liter boiler, which has a unique “Spin” system and a temperature sensor for hot water supply. Thanks to all this, boiler owners receive not only high speed and efficiency, but also constant hot water. The technical characteristics in this case are as follows:

- the device is reliably protected from frost;

- the pressure in the system is read using a special electronic device;

- it is quite possible to place the device in the bathroom;

- heating and hot water parameters are configured separately;

- power is adjusted smoothly;

- the boiler is protected from possible overheating;

- built-in microprocessor;

- a special display displays the main operating parameters;

- There is a pump protection function that prevents jamming.

The approximate cost of “Tigers” varies between 60.5 and 90.5 thousand rubles, depending on the specific variety.

Model "Scat"

The gas unit called “Scat” is characterized by a modern design, stepwise power adjustment, low noise output and ease of operation. All devices are quiet and require virtually no maintenance, and are used mainly in apartments/houses of small areas. Comply with all safety standards, environmentally friendly (do not harm the environment). For this reason, they can even be used in protected areas!

Finally, such Protherm gas boilers are easy to maintain and can warm up the room almost instantly. The average cost of “Scats” ranges from 26.3 to 152 thousand rubles.

Model "Panther"

This particular model is distinguished by the fact that it has a special “Comfort” function, which provides extremely fast heating of the water. There is a built-in microprocessor, an “i-BAS” communication bus, it is possible to adjust the boiler power, control of all parameters is convenient and simple, since it is adjusted on the monitor. There are two heat exchangers, as well as electric ignition.

All “Panthers” can be classified as middle class gas heat generators. They are capable of heating and heating water not only in private homes, but also in offices, apartments and other premises. "Panther" is produced in three models:

- devices with a sealed combustion chamber (28-KTV);

- 24-KTV;

- devices with an open combustion chamber designed for two circuits (24-KOV).

In terms of hot water supply, the performance of this model ranges from 12-15 liters, and the area of the heated room can reach 270 square meters. The possibility of functioning in low pressure conditions is provided.

It is worth mentioning special protective functions, including:

- preventing system freezing;

- gas supply shutdown;

- anti-cyclicality of the heat generator;

- preventing pump jamming.

The approximate cost is from 35.2 thousand rubles.

Model "Cheetah"

All boilers of the “Gepard” model are not too different from similar middle-class appliances. They have fairly low functionality, although they are relatively inexpensive. To adjust the power of the device, a special modulation burner is provided. If we talk about efficiency, then during the heating season it can reach 92 percent. As in the previous version, there is an “i-BAS” communication bus.

The functions of "Cheetah" include:

- ability to select operating mode (summer or winter);

- adjusting performance using the monitor;

- heat exchanger made of stainless steel;

- working fluid pressure sensor;

- diagnostic system;

- burner, which is made of chrome-nickel steel.

The approximate cost is from 32.2 thousand rubles.

Proterm devices with bithermic exchangers

This class is represented by only two models; let’s take a look at each of them.

Model "Lynx"

Protherm gas boilers of this model are dual-circuit combined equipment intended for both heating residential premises and supplying hot water. Known for their uninterrupted and reliable operation, excellent quality/price ratio, excellent efficiency, ease of operation and low noise output.

Here are the main properties of the structural elements that the Lynx is equipped with:

- smooth power adjustment;

- display of basic operating parameters on a special display;

- protection of the device from severe frosts;

- built-in microprocessor;

- valve for additional supply of working fluid to the system;

- regulated using a bypass valve;

- separate filters for heating fluid and hot water supply;

- effective protection against overheating.

The approximate cost starts from 30.5 thousand rubles.

Model "Leopard"

The average power of Leopards ranges from 8-24 kilowatts. All devices in this line are characterized by high efficiency and cost-effectiveness. Produced in two variations:

- with an open combustion chamber;

- with closed.

The productivity in terms of hot water supply is 12.5 liters per minute, and the area of the heated room can reach 220 square meters. You can adjust power, as well as other operating parameters, directly from the panel

Excellent performance even in low pressure conditions, which is especially important in today's times when fluctuations in gas supply occur quite often

Each of the Leopards, if necessary, can be converted from natural gas to bottled gas. To do this, you do not need to perform complex manipulations; you just need to change the gas valve and nozzle.

Protective functions include:

- antifreeze;

- anti-cyclicality of the heat generator;

- anti-inertia of thermal energy.

This also includes cessation of gas supply in such cases as:

- exceeding the temperature of the device set value;

- burner goes out;

- craving disorder;

- interruption of electricity supply.

Note! Each of the described functions only works if Protherm gas boilers are connected to the mains

The cost of “Leopards” starts from 13 thousand rubles.

Types of Proterm boilers

The Proterm line of boilers includes models running on gas, electricity and solid fuel

Protherm heating equipment is a device that runs on various types of fuel: gas, electricity, coal. They are designed for heating apartments, private houses, office and commercial premises. The company's factories produce boilers for floor and wall mounting, as well as high-power units. All products undergo strict quality control. Before being put into production, models are tested in the laboratory.

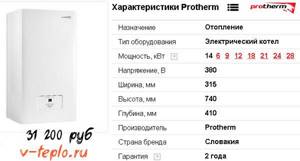

Electrical

The Skat series is an alternative to gas equipment; it includes 8 models with a power from 6 to 28 kW. The electric boiler is designed for connection to a 220 or 380 V network. The equipment heats the coolant to 85°C, the installation efficiency is 99%. Among the advantages of electric boilers:

- No connection to a chimney is required, the equipment does not emit combustion products.

- The compact boiler fits into any interior.

- High performance.

- Possibility of programming control of heating medium heating temperature.

- When installing electrical equipment, fewer requirements are imposed than when installing gas boilers.

Electric wall-mounted boiler Proterm Skat - economical, does not emit combustion products

The unit is manufactured with wall mounting. Its functions include:

- Diagnosis of breakdowns using error codes.

- Pump and valve blockage protection.

- Protection against freezing, pressure drop.

Gas

The equipment heats water for heating and domestic needs of house residents. Several series are offered, differing in the method of installation and heating. The product line includes:

- Single-circuit installations - heat water in the heating system. They are designed for houses up to 350 sq.m.

- Double-circuit models - in parallel with heating the premises, the boiler provides the owners with hot water.

Floor-standing gas boilers differ in the design of the combustion chamber - open and closed

According to the type of combustion chambers, the equipment is presented in two types:

- Open - with a chimney and natural draft.

- Closed - a fan is used to force smoke out.

The equipment runs on main and liquefied gas. A distinctive feature of the units is the expanded functionality of the settings. Some models can be connected to the “smart home” system; it is possible to install low-temperature operation for heated floors.

Solid fuel

The units operate on coal and wood and are designed to heat rooms up to 500 sq. m

The Bober series are cast iron boilers for heating residential and industrial premises. A special feature of the equipment is the large area of the heat exchanger covering the entire firebox. Pros of the series:

- energy independence;

- durability;

- ease of operation;

- safety.

The unit runs on coal and wood. Its disadvantage is the need to add fuel every 2-4 hours. Non-volatile floor-mounted boilers. Their power ranges from 19 to 48 kW. They are designed for heating rooms ranging from 190 to 480 square meters. m.

The best wall-mounted gas boilers

This section presents single-circuit room heating systems placed on the wall. They are compact and easy to maintain, although they have some limitations in functionality.

Viessmann Vitopend 100-W A1HB003

4.9

★★★★★ editorial assessment

89% of buyers recommend this product

The A1HB line includes three boilers with a capacity of 24, 30 and 34 kW. This is enough to heat a home with an area of up to 250 m2. All cases are equally compact: 725x400x340 mm - such units have a place in any room.

Viessmann boilers are assembled on a single modular platform, which simplifies their installation and maintenance. In addition, there is no need to leave additional space near the body, so any Vitopend can be combined with kitchen furniture if there is a free corner for it.

Advantages:

- Low gas consumption - no more than 3.5 m3/h in the older model;

- The valve body is equipped with quick-release connectors;

- Automatic power adjustment depending on the outside temperature;

- Efficiency up to 93%;

- New coaxial chimney system with frost protection;

- Intelligent control with self-diagnosis function;

- Possibility of switching to liquefied gas.

Flaws:

There is no remote control panel.

Viessmann provides the opportunity to choose a boiler for an apartment of any size. The appearance and dimensions for the entire line are absolutely the same - the models differ only in performance and, accordingly, gas consumption.

Baxi Eco Four 1.24 F

4.8

★★★★★ editorial assessment

88% of buyers recommend this product

See review

Despite the prestige of the brand, the Eco Four model is relatively inexpensive. The boiler has a flat body measuring 730x400x299 mm, which allows it to be hung flush with kitchen cabinets. When used in northern latitudes, such a unit can heat an apartment up to 150 m².

Fourth generation boilers were developed taking into account our operating conditions. That is why the presented model operates even when the inlet gas pressure is reduced to 5 mBar. In addition, it has two separate thermostats: for heating radiators and for the “warm floor” system.

Advantages:

- Built-in water flow meter;

- Pump with air vent and post-circulation mode;

- It is possible to connect to solar collectors;

- Dual-mode thermal control;

- Pressure switch for protection against low coolant pressure;

- You can connect a remote thermostat and remote control.

Flaws:

Low-informative built-in display.

As for Baxi, Eco Four's price is very attractive. In addition, this is an excellent solution for placement in a small kitchen or studio apartment.

Vaillant AtmoTEC Plus VU 240/5-5

4.7

★★★★★ editorial assessment

87% of buyers recommend this product

This boiler has all possible means of protection: gas control, pressure switch with safety valve, pump air vent. Here, overheating of the medium and combustion chamber, freezing of liquid in the system and in the chimney are completely excluded. The built-in auto-diagnostics helps monitor the correct operation of all systems.

AtmoTEC is adapted for operation in Russia: it takes into account the low quality of main gas and can operate on LNG. The programmer control is fully automated, and the panel itself is covered with a neat decorative cover.

Advantages:

- Volumetric expansion tank 10 l;

- Low gas consumption – 2.8 m³/h (or 1.9 m³/h when connected to a cylinder);

- Almost eternal chrome-nickel burner;

- Possibility of combination with other heaters;

- The minimum side clearance during installation is 1 cm.

Flaws:

Classic (atmospheric) chimney.

The boiler dimensions of 800x440x338 mm and a maximum power of 36 kW are more suitable for a private home than for a city apartment. Although in a spacious kitchen there will be no problems with its placement.