To control the boiler and the entire heating system, special elements are provided that reduce energy costs for heating, and also help create an optimal temperature regime and at the same time prevent overheating of the room. These elements include a thermostat for a heating boiler. The temperature regulator allows you to save up to 20% of fuel resources, and by what means, we will tell you in this review.

A high-quality thermostat significantly reduces the cost of fuel raw materials

Thermostat for a heating boiler: temperature regulator or more?

There are several types of boilers. These are gas, solid fuel, and electric models. The material used to manufacture such equipment is cast iron or steel. Temperature control and adjustment is carried out using a special thermoelement. This equipment is a metal structure. As a result of thermal expansion, the position of the lever that moves the damper changes. To allow the combustion to grow, the damper is opened slightly. Newer designs include controllers that can regulate air flow.

Thermostatic draft regulator for solid fuel boiler

The most commonly used gas models are single-circuit and double-circuit. Some models have separate room thermostats for a gas boiler for a circuit with hot water supply and a heating circuit.

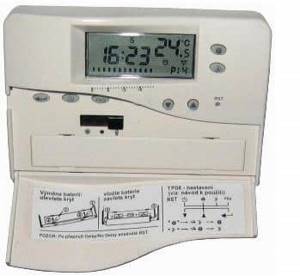

Electrical devices are distinguished by high efficiency and simple connections. In such designs there is protection against overheating and temperature control. Using a mechanical timer, various methods of temperature control are made. More often, the unit simply turns on/off when the temperature drops/exceeds. But it is also possible to set a specific switching time.

Helpful information! Mechanical devices have a round dial. To set the on time you need to turn the dial. Such devices are easy to adjust.

Types of control devices

Thermostats for heating boilers with the option of temperature control are divided into several types:

- mechanical models with one function;

- programmable models with a large range of auxiliary settings.

Also, similar designs are wireless and wired. Thermostats are installed in the selected location, a temperature sensor is connected and connected to the control device.

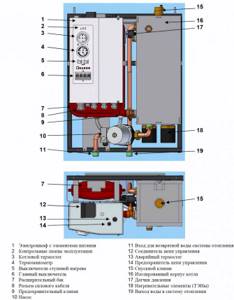

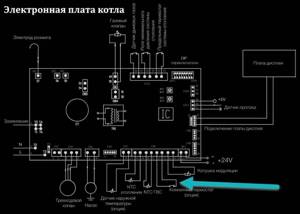

Design diagram of the control device

Note! Thermostats must be provided with constant air access to prevent overheating. It is also not recommended to install electrical appliances nearby.

Selecting a room programmable device

The option of an electronic temperature sensor for a heating boiler helps you select the appropriate temperature mode and change it at your discretion. The room thermostat sets the set values every day. Some setpoint values can be programmed, for example when day turns to night.

Such controllers have additional options. For example, a function that allows you to stop heating for a while and then resume it. You can also change the programmable temperatures for the duration of the configured periods. Another useful option is the ability to change the heating intensity.

Room type regulator

Thermostat as a central element

The central thermostat for the heating boiler (temperature regulator) is located at a certain distance from the heating unit and allows you to turn off and turn on equipment throughout the house.

Installation diagram of thermostats in the heating system

Related article:

Thermostat for heating radiator. What task does this device perform and what is its advantage? What is the operating principle and correct installation? Prices also matter. More details in a special publication.

Models from previous years are connected directly to the heating unit by wires, while more modern designs are distinguished by remote control. The latest devices are mounted in dual-circuit units Beretta, Ferroli and AOGV. Room control mechanisms for boilers of the Protherm and Gsm brands are popular. They differ in their dilatometric mechanism.

Protherm equipment models

Room devices stop heating when necessary. They monitor the air temperature and turn on the heating when the temperature drops. The best place for a microcontroller is considered to be the bedroom and living room.

Installing a controller will allow you to obtain accurate data on the microclimate of the room

Helpful information! The recommended temperature for the thermostat is 20 degrees, and in the children's room - 21-22 degrees. At night, the temperature can vary from 19 to 21 degrees.

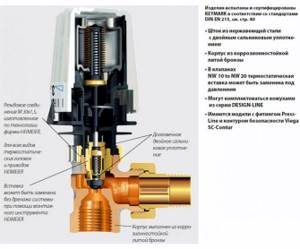

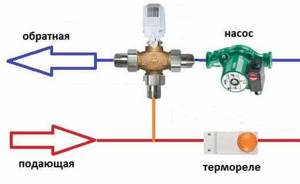

Thermostatic valves for regulation

Such a device allows you to create a certain coolant temperature by mixing the forward and return flows. The device helps control temperature values by changing the flow of hot water through the battery. In this case, the mechanism controls the supply of hot water through the battery, but not through the boiler. It is installed in any room where you need to maintain a certain temperature.

Thermostatic valve design using the example of a specific model

Selecting a temperature sensor for a heating boiler

When choosing a room temperature sensor for a gas boiler, it is worth considering that they are divided into two types. These are wireless models that transmit information using a transmitter mechanism and a device for receiving radio waves. And also wired ones, which transmit data to the controller through wires.

The manufacturer's temperature sensor has certain functions

According to the method of location, temperature sensors are:

- waybills that are mounted on the highway;

- submersible, which come into contact with liquid;

- indoor devices are placed indoors;

- external ones are mounted outside.

How to connect a thermostat to a boiler

To choose a high-quality model of a mechanical thermostat for a heating boiler, you also need to know the prices. The cost of individual models can be seen in the table.

| Image | Models | Cost, rub. |

| Viessmann 7817531 | 3670 | |

| TR 12 for boilers Bosh Gaz 6000 W for gas boilers | 2100 | |

| Galan Comfort | 3500 | |

| Galan MRI 15 | 4500 | |

| Terneo rk 30 for electric boilers | 2870 | |

| BeeRT regulator for electric boilers | 3300 | |

| Thermostat for solid fuel boiler Auraton S 14 | 5990 |

Connection diagram of the thermostat to the boiler

The following recommendations will help in installing such devices:

- it is desirable that the control device and the heating unit are made in the same factory, which will facilitate the installation process;

- Before purchasing, calculate the area of the heated room and the optimal temperature, which will allow you to avoid equipment downtime;

- Before installation, consider the thermal insulation of the room. this will prevent significant heat loss.

Connecting a mechanical regulator to a heating unit

Experts advise installing regulators in living rooms. If they are placed in utility rooms, this will lead to problems in the system. It is also better to choose a colder room. There should be no heat sources or electrical devices near such equipment.

The boiler is turned on using a relay. Modern gas boilers have a special place for connecting the thermostat. You can connect the device using the terminal located on the boiler. The connection method is indicated in the boiler passport.

After installation, the equipment needs to be configured. On the front panel there are buttons that are used to configure the device. Switches allow you to control air cooling and heating, as well as temperature fluctuations and sensor delay times.

Using the buttons, the optimal temperature is maintained during the daytime. And at night this indicator will decrease in order to ensure savings in fuel resources and prevent their overconsumption.

Thermostat in a system with an AOGV boiler

The thermostat is an important part of an autonomous heating system. It ensures high-quality operation of the system and also avoids unnecessary waste of fuel. This device, despite its simplicity, ensures long-term operation of the boiler and the entire system.

Installation and connection of the device

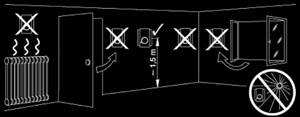

Installation of a household regulator consists of two stages - mounting in a convenient place and connecting to a gas (solid fuel) boiler. In order for the thermostat to record the temperature without deviations, position the control element according to the recommendations:

- minimum height from the floor – 1.5 m, maximum – 1.7 m;

- within 1 m from the device there should not be heating radiators, heaters or other household appliances that distort the thermal image (including air conditioners);

The temperature regulator should be placed away from various sources of heat or cold. - exclude exposure to drafts and running ventilation;

- It is not advisable to install the sensor away from heated rooms.

Advice. For a private home with heated floors, it is worth buying a thermostat model equipped with an additional temperature sensor. The latter is placed above the floor surface and measures the temperature in the lower zone of the room.

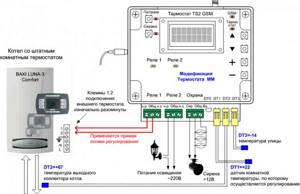

After mounting the device on the wall, according to the manufacturer’s instructions, lay the wire to the heat source in a hidden or open way (if there is a wired connection). How to connect the regulator to the boiler:

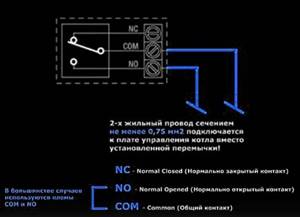

- Connect one end of the control cable to the contacts marked COM (common) and NO (normally open) of the thermostat. On the wireless version, these terminals are located in the relay block.

- In the operating instructions for the heat generator, find the connection diagram for the remote thermostat, markings and location of the contacts.

- Remove or fold down the front panel of the gas heater, which provides access to the control board and connectors.

- Remove the jumper inserted between the terminals indicated in the passport. Do not throw away the part; you may need it later.

- Connect the wires coming from the regulator contacts to the free terminals. There is no need to observe polarity.

- When installing a wireless thermostat, connect a three-wire 220 V power cable with a grounding wire to the relay unit.

Advice. If the contacts of your device have numbers or strange letters instead of the indicated markings, find the 2 required terminals using a tester (the circuit between them must be open). There are three contacts in total, the pair COM and NC are initially closed, as shown in the diagram above.

Details of installing a wireless thermostat are shown in the video:

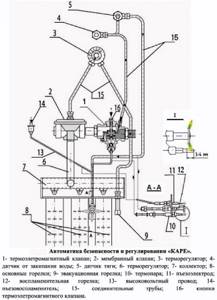

Non-volatile floor-standing boilers equipped with gas automatics 630 SIT, 710 MiniSIT, SABC, Orion and the like are incompatible with remote controllers. The reason is the completely mechanical design of the gas valve and the absence of electrical circuits where the breaker relay can be connected.

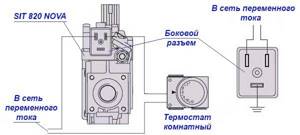

Connection diagram of the regulator to the SIT 820 NOVA valve

The exception is gas heat generators equipped with Kare automatics and the latest generation of Italian valves EuroSIT - 820 NOVA. These blocks provide solenoid valves and special contacts for connecting two types of external thermostats - mechanical and digital.

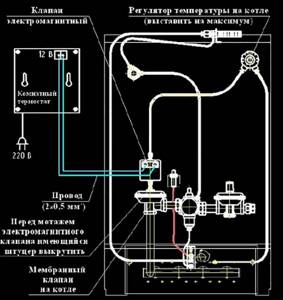

The “Kare” automation uses an electromagnetic valve, where the thermostat is connected

Types of boilers and the need for thermostats

Cast iron and steel boilers are often used . Steel ones have high heat transfer, fast heating and a relatively low price, but can be exposed to the external environment. Then, due to corrosion or clogging, the entire thermal system can deteriorate. To prevent this from happening, it is necessary to control the temperature in the boiler and regulate temperature conditions .

Cast iron ones have high strength, are practically resistant to corrosion and exposure to the external environment , are reliable and stable in operation, retain heat for a long time, and consist of easily replaceable sections. Long-burning solid fuel boilers made of cast iron can fail only in the event of sudden temperature changes. Therefore, when installing such a boiler, it is necessary to properly and professionally piping the boiler. You need to constantly monitor the temperature.

What is the difference between a thermostat and a thermostat?

The thermostat is already included in the heater system and is responsible for the operation of the coolant. This is a mechanical device that is sold together with the boiler. Its advantage is that you can constantly monitor the temperature in the coolant; this process does not depend on the availability of electricity in the house. The downside is that you will have to adjust the temperature manually.

The thermostat is a separately mounted mechanism that automatically monitors the temperature of the coolant, the room, controls it, regulates the correct required heat supply. It does all this automatically during the day , without user intervention .

Why does an electric boiler need a thermostat?

There are many types of products, some types of design are simple, while others allow you to configure more than 50 parameters for a comfortable stay in a house or apartment.

There are models that allow you to program equipment performance for one day or even a whole week; the main functions include:

- Temperature maintenance and control.

- Protection against freezing or overheating of the device.

- Saving resources.

- Remote control of the boiler.

A small device is capable of adjusting all functions of electrical equipment as accurately as possible, because comfort in each room is an important indicator for any owner.

Managing such devices is quite simple; modern models can connect to the phone using special programs, which allows manipulations to be carried out remotely.

Types of thermostats

- Room regulators are installed in any room and respond to the temperature in it . The main thing during installation is not to cover the devices with furniture, curtains, or any objects. Then the indicators may not coincide with reality, and the whole system will fail.

- The valve device regulator is tied to a specific fuel line and controls the temperature not of the boiler itself, but of a section in a certain place where the valve is installed, mounted in the pipe.

- An automatic cylinder thermostat is the simplest device for a two-chamber conventional boiler. This device is installed on the boiler, programmed only for the maximum temperature and causes the boiler to turn off when the temperature of the heating element exceeds the programmed one.

- Zone controllers are programmed for a specific zone of the room and prevent not only shutdowns or high temperatures, but also report all the indicators that the consumer needs to know.

All thermostats are divided into:

The main selection criterion is ease of installation. It must be taken into account that the boiler and thermostat are compatible .

Effective heating control is a vital part of running your boiler and home heating system efficiently. Proper use of controls will reduce the energy consumption of the unit, while creating a comfortable temperature in every room of the house, avoiding overheating of the premises. A thermostat (or programmer) controls the operation of the boiler depending on the room temperature.

Solid fuel

For solid fuel boilers, the use of an external thermostat is possible in two options:

- Connecting the thermostat to the automatic boiler control unit. Depending on the controller model, it is possible to use electronic or mechanical plate thermostats;

- Using a mechanical thermostat with a bellows filled with gas or liquid. The working part of the thermostat for solid fuel boilers is specially designed to control the air supply damper and/or adjust the draft.

There is no particular choice among thermostats for solid fuel boilers. You will have to look for a ready-made solution from the boiler equipment manufacturer or equip the boiler with an automation unit complete with a thermostat.

Main types of boilers and temperature control

There are several types of boilers: solid fuel, gas, electric and liquid fuel.

Boilers have become widespread throughout the world. There are domestic samples, and there are also imported boilers. Material of manufacture: steel or cast iron. Easy to use, economical, with the function of adjusting the coolant temperature. In cheaper models, this function is implemented using a special device - a thermoelement.

Structurally, a thermoelement is a metal product, the geometric dimensions of which decrease or increase under the influence of temperatures (depending on the degree of heating). And this, in turn, changes the position of a special lever that closes and opens the draft damper. The photo shows an example of such a regulator:

Photo: thermostat sample

The more the damper is open, the stronger the combustion process, and vice versa. Thus, the volume of air that enters the closed combustion chamber is completely controlled by the thermostat, and if necessary, its supply is stopped and the combustion process is extinguished. More modern models are equipped with controllers that, depending on the specified thermal conditions, control the air flow, turning on (or off) a special fan (see photo below):

Boiler with temperature controller

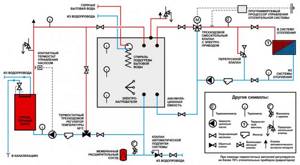

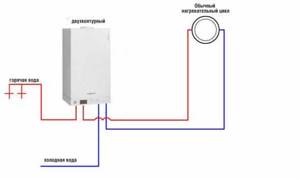

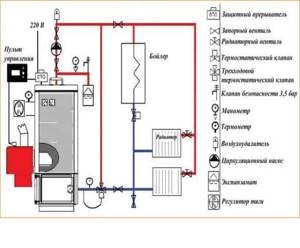

Gas boilers are the most common and cheapest units to operate. Boilers are single-circuit and double-circuit. Single-circuit boilers have one heat exchanger and are intended for heating only. The connection diagram is shown in the figure below:

Switching diagram for a single-circuit boiler

Double-circuit boilers have two heat exchangers and are designed for heating and producing hot water. The boiler switching diagram is presented below:

Switching diagram for a double-circuit boiler

Some boilers have separate controls for heating and hot water temperatures.

Electric boilers

A fairly common alternative to gas and solid fuel boilers. Lots of advantages, high efficiency, but long payback period. The connection is simple, like with gas boilers, but without a cold water supply. Temperature regulation and overheat protection are provided.

Mechanical boiler timer

Using a simple mechanical timer for an electric boiler, there are three options for starting the central heating system :

- The boiler is turned off;

- The boiler supplies warm water;

- The boiler turns on and off at the set time.

Mechanical timers usually have a large round dial with a 24-hour scale in the center. By turning the dial, you can set the desired time, and then leave it in that position. The boiler will turn on at the right time. The outer part consists of a set of tabs for a 15-minute period, which are inserted for easy adjustment of operation and mode settings. Emergency reconfiguration is possible, which is performed with the boiler connected to the network.

Mechanical timers are easy to set up, but the boiler always turns on and off at the same time every day, and this may not satisfy the owners if the family is large and bathing procedures are carried out several times a day at different times.

The most optimal solution

To choose the right thermostat for a boiler, you need to familiarize yourself with the advantages and disadvantages of both types of devices. Advantages of mechanical thermostats for heating boilers:

- affordable price and prevalence;

- thanks to the design, high reliability – a small number of elements;

- convenient control of the boiler using one thermostat knob, which is convenient for inexperienced or elderly users.

Disadvantages of mechanical thermostats:

- insufficient accuracy of the adjusted temperature;

- mandatory connection using wires that will have to be laid from the furnace room to the living room;

- low functionality.

Advantages of electronic thermostats:

- convenient operation;

- high autonomy due to long-term settings (for a day, for a week).

Disadvantages of electronic thermostats:

- high price compared to mechanical ones;

- complex interface;

- periodic replacement of batteries;

- possible disruption of radio communication when installed behind several walls

It is also worth considering the features of wireless thermostats.

To review the functionality, let’s select the thermostat for the Baxi Magic Plus boiler:

- temperature is adjustable in the range of 5-35°C;

- built-in frost protection function for the heating system, which starts the heating equipment when the room temperature drops to 3°C;

- backlit LCD display and push-button control;

- two operating modes: comfortable and economical;

- Possibility of hourly, daily and weekly settings.

Devices like “Baksi” are usually called chronothermostats. Given the complexity of the design, it is not easy to find spare parts for such models, and they are poorly repaired. After assessing the advantages and disadvantages of electronic and mechanical models, you can make your choice.

If your budget allows, then it is better to focus on manufacturers from Europe, Japan, Korea, and if you try, you can find a worthwhile device from China, but in general their quality is lower.

Types of thermostats

Based on the type of functions, they can be divided into several groups:

– with one function (temperature maintenance);

Thermostat with one function

– with a large number of functions (programmable).

Programmable temperature controller

Based on their design, thermostats are divided into types: wireless and with wires for communication with the boiler. Install the thermostats in a convenient place, connect the temperature sensor, connect it to the boiler control system and use it.

Room thermostats need a constant flow of air to function properly and properly, so they should not be covered with curtains or blocked by furniture. Devices adjacent to the electric thermostat may interfere with the correct operation of the device: lamps, televisions, heating devices located nearby.

Thermostat device

The design of thermostats of all types and manufacturers has a general scheme. The device contains three main blocks: temperature sensor, adjustment unit, control unit. The temperature-sensitive element of the device monitors the ambient temperature level.

If the temperature changes in one direction or another, they are recorded by the sensor and transmitted in the form of electrical signals to the control unit, which converts the signal according to a given program and transmits commands to execution devices: an electromagnetic relay, a mechanical valve, a device that processes the signal.

Programmable room thermostat

A programmable electronic room thermostat allows you to select the desired and comfortable temperature at any time; it is easy to reconfigure and change the operating mode. The timer allows you to set a different heating pattern on weekdays and weekends. Some timers allow you to set different settings for each day of the week, which can be useful for people who work part-time or shift work. Many Terneo and KChM models are equipped with such thermostats.

Programmable room thermostat

A programmable room thermostat allows you to set individual heating standards for each day in accordance with your lifestyle and maintain the temperature of the house all the time, regardless of the presence or departure of the owners. Video: Connecting a room thermostat to a gas boiler

If the heating system is controlled by a boiler with a radiator, as a rule, only one programmable room thermostat is needed to control the entire house. Some patterns need to be adjusted in the spring and fall as the clocks move forward and backward or certain changes in climatic conditions occur. We also recommend changing the temperature settings when changing from day to night.

This climate controller has several options that expand its capabilities:

- “Party”, which stops heating for several hours, then resumes;

- “Override” allows you to temporarily change the programmed temperatures during one of the configured periods;

- “Holiday” increases the heating intensity or reduces it for a certain number of days.

How to choose a thermostat

When visiting a specialized store, you should pay attention first of all to the following points:

- Connection.

- Mounting method.

- Functionality.

- Availability of Wi-Fi or GSM modules.

- Safety.

- Protection.

Most models can boast of good characteristics, the range of goods is also large, each owner can quite easily choose an item that will best satisfy his wishes.

Thermostatic control valves

The thermostatic valve is a simple solution to the problem of obtaining a coolant at a given temperature by mixing colder water with warmer water. The three-way valve is shown below:

Three-way valve

Scheme for connecting a three-way valve to the heating system:

Scheme for connecting a three-way valve to a heating system

Piping diagram for a solid fuel boiler using a thermostatic three-way valve:

Piping diagram for a solid fuel boiler using a thermostatic three-way valve

Piping diagram for a gas boiler using a thermostatic three-way valve:

Piping diagram for a gas boiler using a thermostatic three-way valve

The thermostatic radiator valve allows you to control the temperature in the room by varying the flow of hot water through the radiator. They regulate the flow of hot water through the radiator, but do not control the boiler. Such devices must be installed to adjust the temperature needed in each individual room.

This idea should be considered as an addition to the thermal control installation. Also, such devices require periodic readjustment and regular performance checks (every six months when changing operating modes).

For gas boiler

For a gas boiler, the solution is often similar to an electric heating boiler. It is enough to install the thermostat in the power supply circuit and set the target temperature. When the desired heating of the air in the room is achieved, the thermostat cuts off the power to the boiler and it automatically turns off . However, this is not true for all types of gas boilers.

The requirements for thermostats in this case are as follows:

- Permissible switching current. For gas boilers, a value of 1.5-2 A is often sufficient, since the consumption of a gas boiler is much less than that of an electric one;

- Temperature setting accuracy and adjustment range.

In gas boilers with electric power, a special standardized interface is more often used to connect an external thermostat.

For non-volatile heating boilers, mechanical thermostats are used, often with an external temperature-sensitive element connected to a control unit with a long copper tube. The automation unit is often equipped with a standard remote thermostat, so it cannot be supplemented or replaced.