The nuances of installing and connecting a fireplace stove with a water circuit

Installation of a fireplace with a water circuit involves its installation and connection to the heating system. To operate, you will need the following parts and components, depending on the device configuration:

- stand for installing a fireplace;

- expansion tank;

- copper or galvanized pipe for connecting the stove;

- circulation pump;

- automation for controlling the pump and turning off the main boiler;

- sensor for monitoring the interruption of water supply when the temperature rises by more than 95 degrees;

- a safety valve that is triggered when the pressure in the boiler is exceeded;

- mounting fittings and connecting elements;

- heat exchanger if the system is open.

Installed fireplace with a water jacket.

Further connection of the fireplace is carried out depending on the type of combustion system.

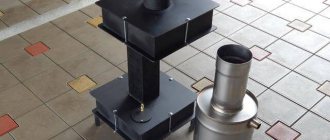

In open systems, the fireplace heats the coolant not directly, but through a plate heat exchanger. An open expansion tank is installed above the furnace, operating on the principle of communicating vessels.

In the case of the closed type, an individual tank for the fireplace is not used, but a common one for the entire system. After connecting the fireplace to the CO, the heated coolant moves directly through the circulation pump into the storage tank, and then enters the heating system.

Benefits of a closed system

- The presence of a system for protecting the coolant from possible overheating ensures the safety of the equipment as a whole. The protection includes a safety valve that is activated when the water temperature exceeds 90 °C. It sends cold liquid to a special coil located inside the heat exchanger. Water circulates and cools the coolant, heated to critical temperatures.

- A water-heated fireplace stove does not require smooth ignition.

- The number of heating devices that can be connected to the system is greater than in an open system.

- The ability to heat rooms with an area of more than 100 m2, while an open system is limited in area to this figure.

Manufacturers

On the Russian market, pellet fireplaces are represented mainly by European and Chinese models. The latter are several times cheaper than the former, although there is no need to talk about their low quality. Chinese units work no worse.

Until recently, there was one problem. Both European and Asian samples worked most efficiently on pellets with a diameter of 6 mm. In Russia, the production of 8 mm granules was established. Of course, 6mm ones were also produced, but they were more expensive and were not sold in all regions. Europeans reacted faster, so today you can buy devices that work great on 8 mm pellets.

Advantages and disadvantages of a granular fireplace

Let's summarize what are the advantages and disadvantages of a pellet fireplace. The advantages can be highlighted as follows:

- The heat generation mode in the fireplace is stable and precisely adjustable. This makes it possible not to worry about the optimal temperature in the premises.

- Automated and autonomous operation of the heating unit. To work, you just need to adjust the combustion parameters, sometimes add fuel, and get rid of ash.

- Pellet fireplaces are small in size, safe when used correctly and can be installed in various rooms.

- A pellet stove-fireplace, in addition to its main function of heating, allows its owners to enjoy the fire and creates a cozy atmosphere in the house.

- The efficiency of granular units reaches 95%, and this is significantly higher than that of the best models of solid fuel boilers.

You can also learn about the advantages of a pellet fireplace from the video.

The disadvantages of the units in question include the following:

- The design of pellet fireplaces is much more complex, which is why such fireplaces are much more expensive than their wood-burning counterparts.

- The fireplace is equipped with electric motors, various mechanisms, sensors and electronics. All elements are of high quality, but still require maintenance from time to time.

- Almost all individual, as well as some modifications of built-in structures, cannot function without electrical energy; the use of ordinary logs is not permitted.

Fireplace installation

In order for the stove to start heating the room, you need to connect it to the heating system. For this, special tools and materials are used:

- Stand for installing a fireplace.

- Expansion tank.

- Copper pipe to attach the structure.

- A controller to control the heating process.

- Thermal protection is a sensor that protects the stove from boiling. That is, when the water temperature reaches 90˚C, the water is transferred to the circuit.

- Anti-explosion valve. In other words, this protects the furnace from excessive pressure increases.

- Connecting elements: valves with couplings, sanitary technical connections that are used during installation.

- Heat exchanger, if the connection form is open.

Pros and cons of fireplaces with a water circuit

Among the advantages of fireplaces with a water circuit it is worth noting:

- System price. A ready-made stove model or custom-assembled brick fireplace will not cost that much.

- Cost of operation. The system is completely energy independent, the price of solid fuel is low, which means its use will not ruin the family budget.

- Multitasking. Such a system will decorate the interior; a separate boiler room is not required.

- A fireplace with a water circuit can be a replacement for a traditional heating system.

The disadvantages of such systems include:

- Not very high efficiency, especially when it comes to fireplaces with an open firebox. The power of such equipment may not be enough to heat the house in frosty winters.

- Lack of automation systems. It is impossible to quickly adjust the coolant temperature. You will have to add firewood or briquettes and clean the firebox manually.

Installation process

As noted earlier, if you have a regular fireplace or stove in the room, installing this pellet system will not be difficult. To do this, you will need to dismantle the old heating system, and install a new one in its place in the same portals; the chimney from the old fireplace or stove can also be used as a chimney opening for the new one.

If the fireplace or stove has not been used before, you can install the entire installation from scratch. The installation process in this case is also not an impossible task; moreover, all the necessary tools and materials, as a rule, are purchased along with the entire thermal system kit

You should also pay attention to the proposed instructions, as they contain installation steps, as well as the main parameters and technical characteristics of the boiler, including maximum power and operating conditions.

Profitable arithmetic

Before installing a pellet fireplace, it is necessary to consider issues of feasibility and profitability. First of all, do not forget that the fireplace is not a complete source of heat. However, this type of fireplace is not suitable as an additional source due to its high cost.

Fireplace power ratings range from 3 to 15 kW. Theoretically, a power of 1 kW is enough to heat 10-15 m2 of area. But the increased efficiency, which reaches 95%, increases coverage. However, there are some recommendations for choosing a fireplace or boiler. Up to 100 m2 can be safely heated with a fireplace. The fireplace will also cope with an area from 100 to 300 m2, but here boilers begin to enter the “arena”, and indicators over 300 m2 are not available for fireplaces.

Mobile home heating device

System design

It is practically impossible to distinguish by external signs whether a given fireplace has a water circuit, and only the pipes through which the coolant circulates indicate its presence. There are similarities in the internal structure. The fuel combustion process occurs in the firebox, therefore it is equipped with a grate and an ash pan.

If the power of the stove is selected with a certain reserve, and the heating system has automatic recharge, then the stove or fireplace with a water circuit can be used as a source of hot water. When you open the “hot” water tap, heated water flows from the system. At this time, the system is fed with cold water. The power of the fireplace should be sufficient so that during short-term use of hot water its temperature does not noticeably decrease.

Fireplaces with a water circuit are suitable for both open and closed heating systems. An open type system implies the presence of an expander at the top point. The pressure of the liquid is equal to atmospheric pressure. Circulation is carried out by convection. In a closed system, the expander is sealed and excess pressure is created in it. As a result, the liquid can be heated above its boiling point under normal conditions. Circulation is carried out by a pump.

Visual design of the heating system

The body of the stove itself is made of stainless steel, and the firebox can be made of brick or heat-resistant tiles. In modern models, the metal firebox door is replaced with glass. Moreover, special, heat-resistant glass is used. It provides an overview of the hearth, so you can observe the combustion. This means that a fireplace with a contour also performs a decorative function.

The brick design of the fireplace implies some randomness in the shape of the body. But the idea remains the same and is that the coil is located above the firebox itself and is heated by the flame or the walls of the firebox. Heat exchangers in the form of a boiler and a register are often found. They not only differ in performance, but also in cost. The easiest to manufacture, and therefore the cheapest, is a metal box containing water. Its advantage is that it is not subject to clogging of channels with scale, and it is easy to clean from carbon deposits.

Heat exchangers differ not only in appearance, but also in the installation method. There are top and rear locations of the coil. Design thoughts do not end with what is presented by the manufacturer. Optimization work is still underway, which includes issues of increasing the area in the core. Bringing the heat exchanger as close as possible to the fire can lead to a sharp reduction in its service life.

Detailed description of the heating system operation

The “house” shape of the heat exchanger is popular. It is inserted into the firebox and the fire heats most of the area. There is another type of heat exchange that can be highlighted in a separate line. The pipes through which cold water flows cut into the brick of the firebox. The bricks need to be prepared in a certain way, and then the pipe can be laid in them.

An innovative solution is a register that looks like a radiator. It is formed from vertical pipes that are connected to each other. One part of the register is immersed in the firebox, and the other can heat the room due to its large area.

Construction of a pellet fireplace

Air-heated fireplaces today are entirely automated structures that require minimal maintenance and operate independently of humans. The house is heated in the following ways:

- by heating the air;

- water circuit.

There are also universal options on the market that simultaneously provide air heating in rooms and water heating for the water circuit. Convection automatic fireplaces using pellets are popular.

The design of the fireplace in question implies the presence of important structural components: firebox, burner, transportation system, automation, smoke removal and air distribution. The functions of the heat generator are monitored by the controller. If necessary, the system can be additionally equipped with weather-compensating automation.

Insulated container for filling with pellets

The heating accuracy in a granular fireplace can be adjusted in increments of a couple of degrees. The combustion force changes by changing the supply of pellets to the burner device.

Pros and cons of traditional stove heating

Heating a house from a wood-burning brick stove is traditional for Russia, although recently it has been practically replaced by water systems. This transition is largely due to the disadvantages of heating from a stove.

However, here are a few positive aspects of using stoves:

- Heating of the room from the stove is carried out by transferring thermal energy through waves, which have a beneficial effect on the human body - this is what scientists believe.

- A traditional stove, decorated in ethnic style, gives the room a certain flavor, and sometimes allows you to observe an open flame.

- You can increase the efficiency of a brick stove with the help of smoke channels, through which heat will be transferred throughout the house.

- The stove does not require electricity to operate.

- Some designs of solid fuel stoves allow you to heat a room on the second floor of the house due to built-in smoke channels.

Despite all the listed advantages, authentic stove heating is now practically unheard of, although sitting near a warm stove and warming up from the cold can be very pleasant.

Arguments against the use of stove heating can be formulated as follows:

- Heating from such a unit occurs unevenly - it is very hot near the stove itself, and cool in the corners.

- A Russian stove with smoke channels and other elements takes up a lot of space.

- From such a heating device, only those rooms into which its walls open are heated.

- The air temperature in different rooms cannot be adjusted as desired.

- Low efficiency. As a rule, the maximum efficiency of a furnace is no more than 60%, and for gas boilers, for example, it can exceed 90%.

- A wood stove must be constantly maintained - clean out the ash, melt it, adjust the draft with dampers and periodically add fuel. Not everyone likes it.

Some of the listed disadvantages can be compensated for by equipping stove heating with a water circuit by integrating a heat exchanger into it.

How the burner works

An automatic pellet fireplace for heating functions autonomously due to the design features of the burner. A microprocessor controller is responsible for control.

For the purpose of stable and proper operation, the burner device in the fireplace is closely interconnected with several important components. Namely:

- Fireplace electronics. It performs the functions of monitoring the functionality of the fuel supply system, maintaining the flame in the burner niche, artificially pumping air into the furnace and removing combustion products. When switching to the mode of long-term combustion of pellets in the fireplace, the rate of supply of pellets into the combustion chamber automatically changes, the combustion intensity is made lower due to cutting off the air volume.

- Ignition system. This is a device for burning pellet granules, it is equipped with electric ignition. The fireplace starts working after pressing the “Start” button. After the start, the first batch of pellets is set on fire. If the fire dies out, the photocell is activated. Electric ignition is restarted. Ignition methods may vary, it all depends on the chosen modification. Piezo ignition, electric ignition, and plasma ignition are used.

- Auger for pellet feeding or conveyor. Pellets are fed into the burner using a screw transmission. The auger (with the help of which the fuel moves into the combustion chamber) rotates due to an electric motor. Electrical energy consumption is a maximum of 180 W/h. The downside of the device is the presence of noise, which is associated with the operation of the engine.

- Artificial air injection and smoke removal system. Fireplaces have forced draft. Air is supplied to the burner device by turbines, the blades of which create turbulence of the required intensity to maintain the best combustion of the torch. Combustion products are removed by a smoke exhaust fan. Air supply and removal devices for combustion products operate together with the burner. Various changes in the operation of the burner device affect the intensity of rotation of the turbines.

- Burner bowl. This is an important component in the design of a granular burner. The granules are loaded using a screw.

The design of the burner device is completely safe and efficient. The microprocessor, which controls the functions of the device, gives a signal to shut down in case of various malfunctions in the operation of the fireplace. Modern modifications can boast of lower consumption of pellet granules due to the established pyrolysis process.

Burners in a pellet fireplace are very demanding on the quality of the fuel used. The granules should be on average 7 mm in diameter and up to 30 mm in length. Each fireplace has its own instructions included with the unit. Malfunctions in most cases occur due to the use of low quality pellets.

Disadvantages of stove heating with a water circuit

- Loss of usable space. A heat exchanger built into the firebox significantly reduces its size, so this factor must be taken into account when laying the firebox. Well, if the heat exchanger is built into an existing structure, the only solution is to frequently add fuel.

- Increased fire hazard.

Since a stove or fireplace requires the presence of an open fire and a fuel supply nearby, it is not recommended to leave such a stove unattended for a long time. Having organized stove heating in the house, you must constantly monitor fire safety - Carbon monoxide. If used incorrectly, carbon monoxide, which is dangerous to human life, can enter residential premises.

Combustion chamber

The combustion chamber of a pellet fireplace can be made of different materials, and can be either steel or cast iron.

To improve convection heat output, special fins are present. The combustion chamber of some fireplaces is never deep, because other parts are mounted behind it. Namely the hopper, drive and engine.

The door is always closed. In built-in structures, the combustion chamber is characterized by a classic “wood-burning” size. All backup elements are mounted externally. Due to the great depth, the chamber can be heated with pellets and firewood, as in a standard wood-burning firebox.

Operating rules

In order for the stove to serve its intended life, its operation must be carried out in accordance with a number of rules:

- The chimney and the stove itself must be cleaned of various contaminants at least twice a year;

- Ash must be removed as it appears;

- In the summer, the water circuit can only be drained if the stove will not be used at all;

- Before the start of the heating season, the entire system must be checked for problems;

- The fuel used must meet the requirements specified in the passport for the device.

Conclusion

A fireplace stove with a water heating circuit is a good heating equipment that carries both a purely practical and decorative purpose. A competent choice and correct installation of such a device will ensure complete heating of the building, and the opportunity to observe a live fire will create a cozy atmosphere in the room.

Advantages and disadvantages of fireplace stoves

Not a single heating unit is without drawbacks, which should be described first. So:

- Operating mode – manual. You will have to constantly add firewood and optimize traction.

- The efficiency, unlike a gas or electric boiler, is low - 75-80%.

However, these disadvantages more than outweigh the advantages. This:

- Low cost of the unit.

- Possibility of combination with other media - diesel, antifreeze.

- Fuel for a wood fireplace is cheaper than electricity.

- Fast heating of the room.

- Any fireplace stove with water heating is independent of energy resources.

- A wonderful interior attribute.

And that is not all. The models combine not only heating functions, but also cooking functions - this is an excellent purchase for a summer house, where there is no other source of heat and resources for cooking. Disadvantages that are significant for purchasers can be easily eliminated if the system is modernized.

How to make it yourself

The stove in a private house must be connected to a chimney

To heat your house in the winter cold, you can build a heating system yourself. To make a stove with a heat exchanger for heating, you need to follow the following order:

- Making a stove from sheet material. The prepared elements are welded together at an angle of 90 degrees. The exception is the front wall. The bottom of the device should be located at least 20 cm from the floor.

- The space between the firebox and the ash pit is separated by a grate.

- Preparing the canopies and installing the door.

- Chimney installation. It is installed at the top of the structure.

- Preparing a container for liquid and fixing it.

After connecting the device to the system, it should be checked for defects. The stove must be designed and operated in compliance with safety regulations.

Stove with water circuit for home heating

Water in the circulation system can move naturally due to the creation of a pipeline slope and differences in the density of the liquid in the heated and cooled states. The method allows the furnace to operate autonomously. For forced supply of coolant, an electric pump is required. It improves the heat transfer process because water can move through the pipeline at a higher speed. Correct installation of the system with its natural supply allows you to create a circulation mode close to forced. For this, the slope of the main pipeline is 4°, and the distance between the pipes is 1.5 m. After leaving the register, a pipe called the acceleration manifold is placed.

The best option is a combined coolant supply system. If it is necessary to increase the heat exchange process and when heating the furnace, a forced mode is used, and in other cases - a natural one.

Recommendations for choosing a home wood stove

Today there are quite a few types of stoves. When choosing a stove you should consider:

- area of the home;

- preferred fuel type;

- the most suitable material.

Heated room area

The size of the building affects the choice of furnace power. To warm up 10 sq. m of house requires about 1-1.2 kW. This rule works for ceilings with a height of 2.5-2.7 meters; if they are higher, a little more power will be required.

For factory stove models, this indicator is indicated in the passport. For homemade structures it is calculated approximately.

Fuel used

Water heating can work due to combustion:

- firewood;

- coal;

- fuel briquettes;

- peat

All types of fuel differ in their characteristics. First of all, they produce different amounts of thermal energy when burning the same volume.

But this is not the only thing that matters when choosing. Cost is important, as is how easy it is to find fuel in the area where your home is located. It is better to choose a type that can be purchased from several suppliers. The space you need for storage also matters.

Material

- brick;

- stainless steel;

- cast iron.

Brick kilns are the most massive. They require more space, and a separate foundation is installed under the structure. It is best to initially install a brick oven with a heating tank. Sometimes it is added later, although this requires dismantling part of the masonry.

Such heating devices give off heat for a long time and evenly. If desired, they accommodate voluminous oven chambers, but they take a long time to warm up. You will have to look for a specialist to lay the structure.

Cast iron stoves also heat up quickly and give off heat longer than steel ones. But cast iron is more fragile and at the same time a heavy metal.

Photo 2. Wood-burning stove with a water circuit, made of cast iron. Heating pipes are made of copper.

Steel structures are very popular. They heat the coolant less and faster. Water-heated stoves do not have the traditional disadvantages of metal appliances. They give off heat not only during fuel combustion, but also for a long time after it.

Metal and cast iron stoves do not require a separate foundation. It is enough to protect the floor from exposure to heat and random sparks. For this purpose, fire-resistant materials are used, for example, metal sheets.

Reference. There are models with a combustion door made of heat-resistant glass. They allow you to admire the play of fire. The atmosphere in the room becomes more comfortable.

Factory oven models are available on height-adjustable legs. Thanks to this, they are easy to position even on a not entirely level floor.

The difference between granular fireplaces in shape

Based on their shape, the units under consideration are divided into the following types:

- separate;

- built-in

A pellet fireplace, which is installed separately, has its own body that does not require finishing. The casing is made of double, high-quality metal. To improve the thermal inertness and safety of the structure, the outer side is covered with ceramic tiles.

At the top of the fireplace there is a separate container where pellet granules are placed. Their volume must ensure stable operation for 8-24. The period will depend on the configured combustion mode.

A fireplace meant to be built into a wall, after installation is completely similar to a solid fuel firebox. There is no outer casing. The hearth is located in a special niche. The external surface is tiled.

A large pellet storage tank is designed for heating for 48 hours. It is mounted in another, adjacent room or inside the stove lining. The fuel storage niche also collects ash.

Screw pellet feeding mechanism

This classification is the main difference between pellet fireplaces. Fuel supply is carried out by a screw drive connected to the electrical network. Modifications are also produced with the possibility of rotating the auger manually. In addition to the fuel storage tank, a special container is installed where ash accumulates. Although the ash niche can only be cleaned by hand. Pellet granules are burned with almost no residue. They leave significantly less ash compared to logs. Because of this, the large volume of the ash niche does not require daily maintenance. You can look there once a week if the heating is used every day.

Stove with a water circuit for heating a house: advantages

As already mentioned, a conventional stove is not able to provide uniform heating of all rooms in the house. In modern stoves and fireplaces, this problem is partially solved by installing a convection chamber to which an air duct system is connected. As a result, the flow of warm air from the stove is not left to its own devices, but moves in the limited space of the pipes and is regulated by valves, dampers, grilles and other additional devices.

However, air ducts are bulky, eat up useful space, and as their length and number of turns increases, heat loss increases. They need monitoring and maintenance: periodic cleaning of dust, soot and soot. The air itself has a low specific heat capacity; in order to transfer heat to a room remote from the furnace, forced injection of heated air masses by a fan is required. Therefore, water, as a coolant, is in many respects preferable to air.

The principle of operation of a stove with water circuits

The coolant is heated in the heat exchanger and distributed through the radiators using a circulation pump

The principle of operation of a stove for a home with water heating is to heat the coolant during the combustion process. After this, it is distributed through a pipeline, from which heat is released into the surrounding space.

The heat exchanger is located inside the stove. The device can be used as the main source of heat or as an additional one. Moreover, the device provides not only heating, but also hot water supply. Such a stove uses and distributes heat more efficiently.

Analogues of heating stoves with a water circuit

Analogues of the furnace are:

- Solid fuel boilers with a water circuit - the use of a combined or solid fuel boiler makes it possible to heat a room with an area of up to 170 square meters. m. The boiler runs on wood or electricity. Made from strong steel. Equipped with a built-in electrical unit.

- Fireplaces with water circuit and stove/oven. Solid fuel thermofireplaces can be connected to solar collectors and other heating systems. A device that combines the qualities of a traditional fireplace and the functional properties of a solid fuel boiler. Designed for heating water using circulation pumps in all types of heating systems.

Do you need a water circuit - how do you know?

Personal experience. We make stoves with a water circuit in two cases: 1. if the layout of the house is unsuitable for stove heating (for heating with a wood stove). The second case is when the customer requires 100% complete autonomy from the power grid. But the house is still larger than the recommended heat circuit for one stove, and there is supposed to be one stove.

Let's consider the first option - unsuccessful planning. What I call an unsuccessful layout is the presence of remote bedrooms in the house, where convective heat will take a long time to reach. There are also long corridors, an oblong shape of the house with one floor. But these are only the first signs. A detailed analysis takes into account the material of the walls and the method of insulation, the location and size of the windows. Indicators of the construction region and a dozen or two more indicators that are important when heating with a stove are calculated.

When the customer demands complete autonomy from electrical networks, the reliability and durability of the furnace is often not taken into account. As a rule, such houses are not very well insulated (saved on construction). And there are also savings on the stove, because... For the register, it is advisable to make a boiler stove, and not just a fireplace stove. The possibility of placing two ovens or a two-story oven is not taken into account. Or two stoves - one on top of the other - again for reasons of economy.

In the design of stove heating, in addition to a number of basic parameters, it is advisable to take into account many factors and additional parameters. You need to know some everyday nuances that not every heating designer, and not even every STOVE heating designer, knows about.

Let’s say you have a house that has already been built, perhaps a long time ago. And you want to install/remodel a stove or fireplace stove. In this case, it is also better to approach the issue very carefully. My experience shows that the customer, faced with the nuances of stove heating, cannot immediately answer questions about heating the house. Those. This work is not only for the designer, but also for the customer. After all, each oven, each oven location, each layout option has its own characteristics.

Additional Pros and Cons of a Water Loop System

The design of the water circuit makes it possible to distribute heat more evenly throughout the home. Stove heating, supplemented with a water circuit system, is characterized by improved parameters and additional advantages:

- Performance

. A system with a water circuit is capable of efficiently warming up large areas of housing. Due to its high specific heat capacity, water absorbs and releases significant amounts of energy, with little loss during transportation.

- Size

. The water circuit has small dimensions, unlike, for example, the air ducts of an air-convection system, which often remain visible.

- Multitasking

. A stove for heating a house with water heating can easily cope with several tasks: maintaining a comfortable air temperature in the rooms, heating water for domestic needs and cooking.

- Coolant qualities

. Water is a safe and affordable filler for the home circuit.

Visualization of a structure with a large firebox and water circuitSource yandex.uz

The use of water has disadvantages due to its physical and chemical properties:

- High freezing point

. If people live in a country cottage all year round, nothing threatens the water circuit. If your home sits empty during the winter, water can freeze, expand, and damage the system. A common solution is to drain the water (but then the corrosion of metal parts increases). An alternative option, the use of antifreeze, is not suitable for all systems and radiators and requires additional cash injections.

- Water composition

. If the water circulating through the system has a high salt content, scale forms on the internal parts and corrosion begins. Undesirable processes can be slowed down by adding special additives to the system. Arranging a closed system will also help extend the life of the water circuit.

The Dutch oven has high heat output and takes up little space. Source opalennia.com

Basic properties

So, let's look at the main properties that a water-heated stove with a fireplace has:

- A classic stove can release 6500 kcal of heat in 60 minutes. This is quite enough to heat a small building. This type of heating is perfect for a small country house. While a fireplace stove with a water heating circuit is several times more efficient, it allows you to heat large areas. At the same time, the same amount of fuel will be required for heating. Thus, such heating leads to savings.

- The heating system, which includes a fireplace stove with a water heating boiler, is also effective. The combination of the two systems significantly increases productivity. The simultaneous use of these options allows you to get about 21,000 kcal of heat in 60 minutes, which is enough to heat an area of about 300 m2.

- Very often coal or wood is used for heating. The cost of such fuel is quite reasonable. Its delivery is also not difficult. In this case, you can combine the use of firewood with coal.

- A water-heated stove with a fireplace does not require continuous combustion. Adding fuel only needs to be done a few times a day. Regardless of the outside temperature, the house will be warm.

- If we compare the efficiency of a conventional stove with a combined heating system, then the level of this indicator is 35% higher. When using firewood these figures are excellent.

- To create a heating system with a water circuit, you will need to purchase materials whose cost is affordable and acceptable for many.

Review of popular models

There are many models of stoves and fireplaces on the market from different manufacturers, and it is easy for a buyer who is planning to buy them to get confused in the characteristics and descriptions of these devices. Below is an overview of the most popular models, according to reviews from Russian consumers.

AQUA stoves and fireplaces

The line of fireplace stoves with a water circuit from the META company is represented by the Angara, Pechora, Varta models, which differ in thermal power, shape and appearance, as well as installation method.

The AQUA hangar with a water circuit has the following characteristics:

- heating power emitted by the stove during combustion is 13-16 kW;

- heating power of the connected heating system - 5-7 kW;

- steel heat exchanger;

- wall-mounted version;

- the side walls are lined with ceramics;

- panoramic heat-resistant glass;

- outlet diameter of the smoke pipe is 150 mm.

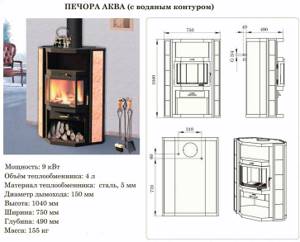

Pechora AQUA differs from Ankara in the shape of the body - it is made in the form of a compressed prism. The power of the furnace is 13 kW, the heating system is up to 5 kW.

Warta AQUA is equipped with a hob. A special feature of AQUA fireplace stoves with a water circuit from the META company is the ability to connect only to systems with forced circulation.

Fireplace stoves Bavaria

Eco-fireplace Bavaria in a wall-mounted version with a thermal power of 12 kW is equipped with a 6 kW heat exchanger, which can be connected to a system with any type of circulation. The connection diagram is shown in the figure.

Corner fireplace model Bavaria

Advantages of Bavaria stoves:

- firebox made of heat-resistant steel 6 mm, lined with fireclay;

- cast iron heat-resistant grates;

- heat-resistant panoramic door glass with a self-cleaning system;

- long burning mode available;

- the smoke pipe is located at the rear, which allows the use of Bavaria stoves with chimneys of any type;

- the side surfaces of all Bavaria models are lined with tiles in different colors;

- the stoves are equipped with a hob, which makes them universal;

- simple design and detailed instructions allow you to buy and install these models yourself.

Consumer reviews from Bavaria fireplaces speak of their convenience and efficiency both when used for constant combustion and for periodic heating of country houses.

Review of famous models and opinions about them

So, a fireplace stove with a water heating circuit receives different reviews. You need to focus on them, but you should remember that the human factor plays a big role - incorrect installation of the unit will lead to its poor operation and, consequently, the user will remain dissatisfied. Consider the following models:

- Stove-fireplace made in Italy by Edilkamin. It has a beautiful design and functionality - it can be used as a hob, and can work in tandem with a heated floor.

- The unit is from Sky. German quality dominates throughout the world. A large firebox is capable of heating large volumes of rooms; connection to radiators is possible. The design feature of the stove is that the side panels are made of tiles, which gives the fireplace the classic look of a Dutch stove.

- It is worth paying attention to domestic products - the Meta fireplace stove with a water circuit. The advantages include complete adaptation to the harsh climate of Russia. This happens thanks to the brick furnace, which is capable of equalizing temperature changes and storing heat for a long time, even after the last coals have died out.

Such a system will fully provide the house with heat at any time and even at sub-zero temperatures outside. In addition to everything, the oven is equipped with a spit, which allows you to cook food delights directly on the coals.

The list, of course, is incomplete - manufacturers are expanding their range every year. Opinions from users who have installed a fireplace stove and have been using it for at least one year will help you choose your own model:

We installed JOTUL 100. The first time it smoked with terrible force, we wanted to call a technician who installed it for us. It turned out that the factory coating was burning. It’s not clear why this is? Otherwise we are satisfied.

Elena, Perm

You should not purchase fireplace stoves that cost more than 15-20 thousand rubles. There are enough functions even in small units, and the fuel savings are significant.

Nikolay, Tomsk

We have been combining a fireplace stove with an infrared heater for a long time. Everything is fine. Only when children are in the living room does the IR have to be turned off - the theory about the dangers of such things is strong. We’re thinking of combining it with heated floors – the reviews from people are quite good.

Sergey, Tula

We made the water circuit for the stove ourselves - my husband is a craftsman. Now we have moved to the dacha as a permanent place of residence - we are happy with everything, especially in the cold.

Natalya Ignatievna, Artem

You should approach the issue of purchasing a heating unit responsibly and thoroughly - you cannot allow discomfort, especially before the upcoming cold weather. Therefore, when choosing a unit, preference should be given to the installation described above, because a stove-fireplace with a water circuit generally has only good reviews. Economical and comfortable heat is provided throughout the house.

Pavel Smirnov

Author of publications on 1Drevo.ru with topics: Roof windows | Material for a wooden house | Imitation timber | Double-circuit gas boiler| Geothermal heating | Log house | Log house | Decorating a wooden house | Solid or laminated timber | Log house made of laminated veneer lumber | Gazebo made of timber | Siding | Sealant and others.

Collections of publications on topics:

Water heating furnaces

Was this publication useful to you?

Bookmark it on social networks!

Total score: 6Votes: 1

How to make your own solar collector heating system at home

Geothermal heating at home: equipment and operating principle

We recommend! — Encyclopedia Wooden Houses — NEW

You can find out detailed and expanded information on the topic of the article from the book “Wooden Houses,” which reflects all stages of building a house, from laying the foundation to installing the roof. Book price = 77 rubles.

You may also be interested in other BOOKS on building houses from wood with your own hands.

We recommend other posts on this topic:

How to make a brick stove in a wooden house

Pellet boilers for heating a private house - advantages

What types of water systems are used to heat a home?

Gas boiler for space heating: floor or wall mounted

Alternative heating of a private house with hydrogen

Water heating from a wood stove

Types of fireplaces with a water jacket

Today, water fireplaces come in various designs. Depending on the type, devices are divided into brick, metal and combined.

Brick

Brick fireplaces are the most popular. They will fit perfectly into any interior and are easy to use and maintain. There are some nuances that need to be taken into account when installing such devices. During the masonry process, the heat exchanger is first installed, and then connected to the water circuit.

Compared to cast iron fireplaces, brick ones are not as expensive, and they look more aesthetically pleasing in modern homes. In addition, metal devices must be installed subject to certain rules, while masonry fireplaces can be installed anywhere.

Metal

Metal or cast iron fireplaces are difficult to make with your own hands, and the cost of ready-made structures is not affordable for everyone. They are capable of heating the room not only by spreading the coolant, but also by heating the surface of the housing. However, when installing such fireplaces in living rooms, you must follow certain safety rules. Therefore, if the fireplace should serve as a decoration, and not just a heating element, then it is better to give preference to brick or combined options. In addition, heavy cast iron installations require laying a foundation, and this is an extra cost. The advantages of such fireplaces are their durability.

Metal fireplace with water jacket

The best long-burning fireplace stoves with a water circuit

MBS Thermo Vesta plus

Intended for heat supply to premises equipped with water heating systems . The stove can be connected to the system in tandem with a solid fuel boiler or in independent mode.

The maximum possible water temperature inside the heat exchanger is 90°C.

The stove is made of high quality cast iron and steel. The outer enamel coating is particularly aesthetic and retains its attractive appearance for a long time.

There is a continuous cooking surface made of cast iron.

Rapid heating of the room is ensured by convection. The ash drawer can be pulled out directly during lighting, which simplifies maintenance.

Characteristics:

- power: 11 kW;

- Efficiency - 83%;

- hob - yes;

- location: wall;

- heating area - up to 110m2;

- chimney: 150mm, ;

- material: steel, cast iron, ceramic tiles, fireclay;

- glass type: straight;

- dimensions: 90*46*44cm;

- weight: 91.5 kg.

Advantages:

- design;

- build quality;

- high efficiency and long-term heat retention.

Flaws:

- The internal surface of the firebox may require replacement after just a couple of years of use.

MBS VULKAN

A wood-burning stove-fireplace can heat large rooms while having compact dimensions . Perfect for use in a country house outside the city.

It will help organize autonomous heating or supplement the existing one.

The firebox is voluminous, while fuel is consumed in economy mode.

With the MBS Vulcan Thermo stove, your home will not only have a unique atmosphere, but also be more comfortable. There are modes of intense heating or smoldering.

Characteristics:

- power: 24 kW;

- Efficiency - 83%;

- hob - yes;

- location: wall;

- heating area - up to 140m2;

- chimney: 120mm, ;

- material: steel, cast iron;

- glass type: straight;

- dimensions: 65*78*64.5cm;

- weight: 151kg.

Advantages:

- ease of kindling and maintenance;

- high reliability;

- room heating rate;

- fuel economy.

Flaws:

- none.

Romotop GRANADA

The stove has a modern appearance, high quality workmanship and uses an innovative method of burning wood..

The body is made of steel covered with decorative tiles. Steel stoves heat the air faster - already 15 minutes after lighting.

The combustion chamber contains fireclay that can withstand up to 1300 degrees . The combustion chamber is separated from the body to reduce the risk of fire and extend the life of the stove itself.

Characteristics:

- power: 13 kW;

- location: wall;

- heating area - up to 130m2;

- chimney: 150mm, ;

- material: steel, ceramics;

- glass type: straight;

- dimensions: 125*50*56cm;

- weight: 254kg.

Advantages:

- modern design;

- wide choice of body colors;

- heating efficiency.

Flaws:

- high price.

META Pechora Aqua

Pechora is one of the most efficient fireplace stoves that can effectively heat a large house . The installation is connected to heating radiators.

The stove warms up in a matter of minutes, and the fireplace itself is made of non-combustible materials, the main one being stainless steel. If you need to heat a small room, this model is suitable for that.

Then it does not need to be connected to the water heating circuit; the air heating power will be sufficient . You cannot connect the stove to heating radiators if there is no water in the radiators.

Characteristics:

- power: 9 kW;

- location: wall;

- heating area - up to 90m2;

- chimney: 150mm, ;

- material: steel, ceramics;

- glass type: straight;

- dimensions: 104*75*49cm;

- weight:155kg.

Advantages:

- does not take up much space;

- economical consumption of firewood;

- smoldering mode.

Flaws:

- cools down quickly.

EdilKamin Warm CS

The stove belongs to a new generation . Depending on the area of the room, you can choose the Warm Base or Warm Scaldavivande configuration.

This stove can not only heat the home, but also provide hot water supply.

The design is in a classic rustic style, but will also fit into a modern interior. The ends, facade and base are cast iron, the hearth is made of steel, the cladding is made of ceramics.

Characteristics:

- power: 14 kW;

- location: wall;

- heating area - up to 140m2;

- chimney: 150mm, ;

- material: cast iron, steel, ceramics;

- glass type: straight;

- dimensions: 108*56*51.5cm;

- weight: 253kg.

Advantages:

- efficiency;

- heating and hot water;

- reliable components;

- perfect assembly.

Flaws:

- high price.