About company

The Ariston brand is the brainchild of Vittorio Merloni. His father, Aristide, founded a small business back in the 30s of the last century. Today this enterprise has become the largest industrial giant, uniting several large companies. The Merloni Elettrodomestici concern was renamed Indesit Company in 2005, which includes several brands, including Ariston. The company ranks 3rd in the world in terms of sales of household appliances.

CLAS EVO

Ariston CLAS EVO wall-mounted boiler, similar to the GENUS EVO model. It differs only in that in this line there are units with both combustion methods: closed chambers (24CF, which is wall-mounted) and open (24FF and 30FF). The efficiency of a closed unit is 91-92%, and for open models it is 93%.

The 24CF has a flow rate of 10.2 liters/min, while the 24FF and 30FF have 9.9 liters/min and 11.6 liters/min. The price of the dual-circuit model CLAS EVO is 40,000-50,000 thousand rubles.

Advantages and disadvantages

Italian boilers are able to operate uninterruptedly even at a pressure of 5 mBar and at a temperature of minus 52 °C. They are equipped with two mechanical filters that purify the water. The developers took into account almost all the dangers for gas equipment in high-risk environments.

Each model is equipped with a self-diagnosis system that simplifies their operation and maintenance. Security systems prevent emergency situations by stopping the operation of the device in a timely manner. Self-diagnosis is periodically repeated - if the parameters return to normal, the device will start without human help. Ariston advantages:

- Absolute safety – despite explosive fuel.

- High efficiency. After the combustion of gas, almost no combustion products remain - all the heating is used for heating.

Minuses:

- Floor-standing equipment should be placed in a separate room.

- To eliminate pressure surges, it is necessary to install an additional adjustment unit.

Difference between boilers

The double-circuit wall-mounted boiler is the most popular among consumers. This popularity is due to some of the qualities that these boilers possess. The main ones are ease of installation, small size with the ability to be built into a wall cabinet.

Less popular Ariston floor-standing gas boilers do not have any special weight restrictions and are made from thick metal parts, due to which the power of such models is noticeably greater, which cannot be said about the wall-mounted version. Double-circuit floor-standing boilers work only to heat water, which acts as a coolant to heat the liquid in the storage tank. Single-circuit floor-mounted ones, unlike their counterparts, have more power and, accordingly, efficiency. Below you will find detailed descriptions of some of the models that are in particular demand.

What do Ariston products have in common?

Traditional gas heaters are produced in nine lines - each of them contains a different number of modifications - from 2 to 7. The lines represent single-circuit and double-circuit versions. Some have a wide range of capacities, others consist of 2-3 options. All traditional Ariston models are distinguished by the following features:

• Automatic control. All modifications have the “auto” function - the intelligent unit itself selects the optimal modes, taking into account changing conditions.

• Can work with a conventional or coaxial chimney.

• Russified control panel. Its logic is intuitive – you don’t even need instructions to understand it.

• Burner material – stainless steel. Its power is modulated taking into account the specified mode. This solution saves gas.

• Self-diagnosis.

• Hydraulic devices are made of high-strength composite materials.

• Expansion capacity – 8 l.

• Automatic removal of air from the heating system.

• Protective systems – against blocking, scale, freezing.

• The double-circuit device has a copper heat exchanger - the primary one, and a stainless steel one - the secondary one, for heating domestic water.

• In 2-circuit versions, a “summer” mode is provided - operation only on DHW.

• Condensate container.

• Temperature sensors – 2-4 pieces, depending on the series.

• High-quality sound insulation. Almost silent operation.

• Includes instruction manual. All documentation is presented in Russian.

• Warranty – 2 years. For condensing versions – 3 years.

• Average dimensions 70x42x60 cm - this is slightly larger than those of competitors.

The models of each line have distinctive design and technical solutions. Models may also differ in functionality, dimensions, and design.

Official website: where to view all models and operating instructions

In Russia, the official website of the manufacturer is located at: ariston.com/ru-ru/

By going to the section “Boilers” → “All boiler models” you can see all available models and their descriptions. Each model is accompanied by electronic copies of full instructions for use, installation, configuration, technical data sheets and certificates. The manuals for each model describe the characteristics, installation diagram, algorithm for switching on and adjusting the operation, maintenance features, and contain clear schematic images.

What are they?

By installation method:

- Wall-mounted - it is compact, has a copper heat exchanger (less often - steel). Complete with strapping elements. Mounted on a flat wall. Mounted models are more sensitive to unstable gas and water supply parameters.

- Floor-standing devices are more powerful, heavier and larger in size. They need a fairly large area. They are mounted on the floor - on a stand. Manufacturing material – cast iron. Power – up to 64,000 W. This heating output is enough to heat an area of up to 500 square meters.

By number of circuits:

- Single-circuit - they work only to heat the room.

- Double-circuit - they heat the house and heat water for domestic use.

By type of combustion chamber and thrust:

- Open firebox (natural draft) - air for combustion comes from the room. Such a device is atmospheric.

- Closed chamber (forced draft) - the operating principle is based on forced ventilation. This is a turbocharged version.

Ariston double-circuit gas boiler: instructions

Types and features of the design of Ariston double-circuit boilers

If we talk about installation, Ariston double-circuit gas boilers are available in floor-mounted and wall-mounted types.

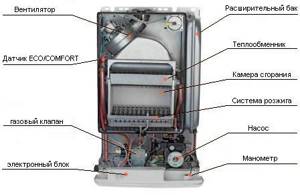

Floor-standing boilers are placed on a flat, stable base. They have a steel or cast iron heat exchanger, so they are quite heavy and bulky. Very durable and can last quite a long time. A more compact and lighter wall-mounted gas boiler Ariston, with a copper or stainless steel heat exchanger. The quality of operation of such boilers directly depends on the pressure of energy carriers (gas and water) in the pipelines. The Ariston double-circuit gas boiler functions as a house heater and as a water heater. One circuit supplies heat to the radiators in the form of hot water, and the second circuit heats domestic water. When a hot water tap opens, the valve automatically closes and the boiler begins to work to heat the newly incoming cold water.

Ariston gas boilers come with an open or closed combustion chamber. The open type of chamber implies an influx of air from the home where the boiler is located; combustion products are removed through ventilation. A boiler with a closed combustion chamber requires a forced draft device, that is, air is taken in from outside the room, and combustion products are also released. There are built-in fans for this. Expansion tank 8 liters. The power of Ariston gas boilers can be either 24 kW or 28 kW, which is enough to heat an area of 500 sq.m.

There is protection for blocking the pump, against scale and freezing. The equipment has a self-diagnosis system; all possible errors and failures are displayed on the liquid crystal display. There are several modes that the Ariston double-circuit gas boiler is equipped with, the price of which does not depend on what mode is present in the boiler.

The following modes exist:

“Chimney Sweep” - the mode is responsible for the operating power of the gas burner. “Auto” mode – is responsible for a comfortable microclimate in the room. Any gas, double-circuit boiler listens to commands from external temperature sensors and, based on the data received, normalizes the burner gas pressure by opening and closing the supply valve. “Comfort” mode – regulates the operation of the second circuit, which is responsible for heating water for domestic use. The Comfort function maintains the desired temperature to quickly provide water for the bathroom or kitchen

When choosing a boiler, it is very important to take into account all parameters in order to save energy resources.

Just like Ariston wall-mounted gas boilers, Ariston floor-standing boilers also have different types of control: climamanager, t-control.

Popular double-circuit gas boilers Ariston

These gas boilers are capable of operating at low gas pressure (up to 5 mbar), neither water flow nor low pressure in the main line has any effect on the functionality of the boiler. Changes in voltage in the electrical network are also not a hindrance. The heating power can be reduced, but the water heating power does not change. There are options: start delay, continuous electronic modulation of the flame in the burner, protection against frost, against the accumulation of scale on heating devices, prevention of blocking of the pumping system and three-way valves.

The Ariston Egis Plus 24 FF gas boiler is equipped with independent diagnostics.

Three-way valve with motor drive. The boiler has two NTC sensors, two filters for mechanical cleaning, and an 8-liter expansion tank. If desired, you can connect a room thermostat and a T-Control digital thermostat-programmer. You can read how to choose a gas boiler for your apartment here.

GENUS EVO is a wall-mounted boiler of the Comfort subseries. Very economical. Can save up to 35 percent of energy resources. Has two heat exchangers. One works like a stove - for heating the home, the other for hot water supply. Externally beautiful and easy to operate. Three temperature sensors, electric water pressure sensor. The circuits are equipped with filters. Taking into account all the advantages, the Ariston double-circuit gas boiler price is not high. But excellent efficiency.

Quiet and lightweight. Combustion chambers are found both open and closed. Maximum power 35 kW. Thanks to sensors, it “feels” the weather and adjusts the boiler itself, focusing on the climatic conditions outside the window. You can set the temperature support level for a specific day of the week. For example, if you leave home every weekend, the boiler will not heat up at full capacity on those days. To buy a double-circuit wall-mounted gas boiler Ariston, you don’t have to go far. This line of boilers is known in almost every city.

CLAS B 24 CF – gas convection wall-mounted boiler. It has an open combustion chamber, electric ignition. Heat exchangers are made of copper. One of the advantages is the presence of a built-in circulation pump, a 40-liter boiler, and a built-in 8-liter expansion tank. Equally capable of operating on natural and liquefied gas. Equipped with a “Comfort” function. There is a power indicator, thermometer, pressure gauge, auto ignition, flame modulation.

BS II - economy-class wall-mounted double-circuit boilers with a power of up to 24 kW, operation and management are simplified as much as possible, designed for heating apartments and providing hot water to residents of apartment buildings. It is distinguished by uninterrupted boiler service when the pressure in the lines decreases. For this purpose, the option “continuous electronic modulation of the burner fire” is provided, a whole set of options ensuring the safe use of the boiler.

It must be said that any Ariston 24 wall-mounted gas boiler, reviews confirm this, is equipped with the following safety functions: semi-automatic replenishment, pumping air out of the system, blocking the operation of the circulation pump, protection against freezing and scale accumulation. Compared to other brands, the Ariston BS 24 FF gas boiler is inexpensive, heats up quickly and is very energy efficient; there will be an excellent bonus in the form of reduced payments for housing and communal services.

Economical, with a closed combustion chamber, protection against scale accumulation, non-freezing. Each Ariston double-circuit gas boiler has self-diagnosis; during use, you need to monitor the readings on the liquid crystal screen; it displays all failures and errors in the operation of the boiler.

The Ariston double-circuit gas heating boiler has two types of condensation model:

- Genus Premium is a boiler with a closed combustion chamber, a built-in circulation pump and a 120 liter boiler. You can connect remote control. Runs on natural gas and liquefied gas. We do not freeze, and has a “warm floors” mode.

- Genus Premium SOLAR - the same, only a 180 liter boiler. The control system is connected to solarsatelite and controls the solar system. The prices for these Ariston gas boilers are also not high.

Boiler malfunctions

Most problems that arise can be prevented during the installation of the boiler. Here is a list of the main malfunctions, their causes and measures to prevent device failure:

- Failure of the control board. As a rule, it occurs due to poor quality of electricity - power surges, frequent power outages. To prevent breakdowns for this reason, it is necessary to install a voltage stabilizer. For a private home, a good solution would be to install a backup diesel generator and an automatic transfer system. It is necessary to protect the device with a circuit breaker, power it via a separate cable line and reliably ground it.

- Deterioration in the nameplate characteristics of the device, expressed in underheating of water or reduced performance when heating. It is associated with the presence of contaminants in the water and excessive water hardness. In both cases, deposits appear on the heat exchanger tubes, making it difficult to heat and pass water through the system. To solve the problem of contamination, it is necessary to install a filter, and when using water with a high calcium content, it is recommended to heat the water to 45-50 °C.

- Frequent stops due to insufficient water pressure. The malfunction is detected by the device and causes a protective stop. BEFORE purchasing the unit, it is necessary to find out the parameters of the supply water network and make changes to it if the pressure is below 1.5 bar. If the pressure is higher than 6 bar, then install a pressure relief valve. If the parameters of the main network are normal, then turn off the boiler and check the system for leaks.

- Frequent stops on the smoke removal system. BEFORE installing the unit, calculate and install flue ducts and a chimney that will provide the required draft.

- Frequent stops due to lack of air. Before installing the device, equip the room with a supply ventilation system.

- Non-compliance of operating modes with the stated ones, non-compliance of the coolant with the specified parameters. The main reason is incorrect commissioning and incorrect device settings. Carefully reading the instructions often solves the problem. If necessary, you should involve a qualified specialist who will carry out commissioning and provide instructions on how to use the device.

Here are the basic recommendations when installing a gas boiler, which will avoid most problems:

- When choosing a model, contact a company that will select the necessary equipment based on your requirements;

- Entrust the installation and commissioning of the device to a qualified specialist;

- Please read the operating instructions carefully;

- Do not neglect periodic preventive inspections and maintenance of equipment;

- In case of any frequently recurring malfunction, turn off the boiler and call a qualified specialist;

- Entrust repairs and supply of spare parts only to a certified organization.

Malfunctions of heating boilers

Mostly, major malfunctions begin to appear during the heating season, when two boiler circuits are operating - heating and water heating. It may happen that it does not start at all, or does not heat well enough. With the launch, the issue will have to be resolved separately, but if the water does not heat up enough, then the reason may be a clogged heat exchanger. As you know, the water quality in our systems is far from ideal, and besides, few users install it in front of the boiler. This is where the heat exchanger becomes clogged, resulting in poor boiler performance.

Here are the most common malfunctions of gas boilers when they do not heat the water well:

- periodically switches off spontaneously,

- smokes a lot,

- does not develop enough power,

- makes noise

- clogged,

- the pump is broken.

If it happens that the gas boiler does not heat the water, then often the reason is the formation of limescale on the walls of the heat exchanger, which, as it accumulates, becomes very durable and not only reduces the water temperature, but also reduces the throughput of the boiler. The thermal conductivity of scale is tens of times less than that of metal, so it is not surprising that the boiler does not heat the water. If you do not take any preventive measures, then very soon you will have to completely disassemble the boiler and remove deposits mechanically.

This problem can only be helped by timely action, and it should be done regularly, especially if cleaning and softening filters are not installed in front of the boiler.

Special chemicals are used for flushing, but they should be used with great care, since they are equally destructive to lime deposits and to the material from which the heat exchanger is made. It is best to invite a specialist for this purpose. To ensure safe and efficient operation of your gas boiler, preventative maintenance is recommended.

It is advisable to do this regularly before the start of the heating season; you should not wait for a situation when the boiler does not heat the water. This approach will ensure its long service life and economical operation. Major repairs are carried out as needed by a service center employee - it is strictly prohibited to do this yourself

To ensure safe and efficient operation of your gas boiler, preventative maintenance is recommended. It is advisable to do this regularly before the start of the heating season; you should not wait for a situation when the boiler does not heat the water. This approach will ensure its long service life and economical operation. Major repairs are carried out as needed by a service center employee - it is strictly prohibited to do this yourself.

Vailant boilers are particularly reliable and safe. Breakdowns of such complex equipment must be repaired by a specialist. But, minor faults can be removed yourself if you have a basic level of knowledge about the design of heating and heating boilers.

Most faults are indicated on the boiler display. Having deciphered the errors, you can figure out the reason for the boiler’s failure to heat water. Where to start searching if water heating in the Vailant boiler does not work and the indicator does not show an error or can it be interpreted in different ways?

Gas equipment manufactured by Ariston

Gas production equipment, depending on the model in question, is designed for installation in autonomous heating systems with an area of up to 500 m2. Note that these models are capable of not only heating the coolant, but also capable of providing the user with hot water supply.

The Ariston double-circuit wall-mounted gas boiler is distinguished by its compact external dimensions, as well as simplicity and ease of operation and maintenance. To install the equipment, you do not need to allocate a separate room, as, for example, for liquid and solid fuel heating devices.

Thanks to the wide power range, equipment produced by Ariston can easily be selected for installation in a specific system, based on the characteristics of the room that will be heated.

Gas equipment "Ariston"

- The language menu on absolutely all models offers Russian.

- The AUTO function is installed, which allows you to automatically adjust the power based on the internal and external air temperatures.

- Absolutely all Ariston units have heat and sound insulation.

- The manufacturer provides a two-year warranty on all its traditional-type products, and a three-year warranty on condensing products.

Equipment safety is ensured by the following built-in functions:

- semi-automatic refill;

- pumping air out of the system;

- blocking the operation of the circulation pump;

- protection against freezing and scale formation.

Ariston double-circuit turbocharged gas heating boilers are distinguished by their simplicity and ease of operation and maintenance.

Main advantages of the equipment

Ariston equipment is offered in two versions: wall-mounted and floor-mounted

- with an open combustion chamber (combustion products are removed naturally);

- with a closed combustion chamber (removal is carried out in a forced manner).

Equipment with a closed chamber is connected to a coaxial chimney. The difference is that these models have a built-in fan, thanks to which combustion products are removed in a timely manner.

The main advantage of devices of the second type is high safety, and also in the fact that air is taken from outside the room, while devices of the first type take the oxygen necessary for normal gas combustion from the room.

It is important to note that Ariston double-circuit wall-mounted gas boilers stop working to heat the coolant immediately after the hot water intake is turned on. This point is important to consider when choosing and purchasing a device.

Design features and equipment design

Design features and device

All proposed gas boiler options differ in the type of combustion chamber: closed or open. If the device is equipped with an open chamber, then it will need to be connected to the chimney, while air is taken from the room in which the unit is installed.

If the Ariston wall-mounted double-circuit gas heating boiler is equipped with a closed chamber, then the combustion products are removed forcibly using a built-in fan. Such equipment is connected to a coaxial chimney. Air is taken from outside the room, which is a big advantage, since the oxygen in the room is not burned during operation of the device.

Ariston gas wall-mounted double-circuit heating boilers have two heat exchangers in their design. One is intended for heating process water, the second for heating coolant. Their production can be carried out in several versions: bithermic, separate and with a built-in boiler.

gas boiler Ariston Egis 24 CF NG characteristics

- the device menu is displayed in Russian; if necessary, you can easily set the required temperature for heating the coolant and hot water;

- high resistance to sudden changes in voltage in the network;

- the equipment will continue to operate stably even with reduced water and gas pressure in the relevant systems;

- ease and convenience of installation, maintenance and operation;

- high efficiency in operation.

All operating parameters are displayed on the built-in display, which makes it easy to monitor work processes and, if necessary, make the required adjustments to them.

The Ariston double-circuit wall-mounted gas boiler can have in its design special sensors for determining internal and external air temperatures. All operating parameters are displayed on the built-in display, which makes it easy to monitor work processes and, if necessary, make the required adjustments to them.

Causes of malfunctions of gas-type boilers

Even if the operating instructions for the Ariston gas boiler are thoroughly studied, it is impossible to insure against the fact that the device breaks down. There are many reasons why equipment can fail, for example:

- maintenance of the device was not performed in a timely manner or with violations;

- insufficient air supply to the combustion chamber;

- unprofessional repairs or maintenance of control units or burner regulation;

- low-quality spare parts were used during maintenance;

- Incorrectly set temperature.

There are other more complex breakdowns of gas heating boilers that should only be repaired by a service employee. Therefore, regardless of the complexity and cause of the malfunction, the Ariston double-circuit gas boiler must be repaired and serviced by a technician who has not only special tools and experience, but also special permission to carry out repairs and maintenance of gas heating boilers.

Features of some models using the example of Ariston EGIS Plus 24

The EGIS Plus 24 gas boiler is equipped with a dual-circuit heating system, a closed combustion chamber and a wall-mounted housing. They can heat an area of up to 250 square meters. m. In addition to automatic protection against major disasters (overheating, freezing or jamming of the pump), there are two important features. This is the ability to easily tolerate all power surges and stable operation under conditions of low gas pressure.

But, despite such a well-thought-out design, this model also has weak points. So, the sp3 error appears in it much more often than others. In various situations, the flame does not burn, even under seemingly favorable conditions, to the point that the masters shrug their shoulders. And they adjust the valves, check the access and removal of air/exhaust gases, clean the scale, and still the error can happen again at the most unexpected moment.

According to owner reviews, the supposed causes of the sp3 error look different. Either the connection to the water supply via a hose seems to be interfering, or an error appears after switching to the heating system after using hot water. In general, EGIS Plus is considered a reliable model, but defects that appear, such as the described floating error, reduce its popularity.

Small boilers for heating using gas are now often used in houses and apartments, and many of the best such devices are produced under the Italian brand Ariston. We will look at some models of this brand and provide instructions for the Ariston gas boiler regarding these models.

This brand is known all over the world. Its roots, like many other great brands, come from the early 20th century, when enterprising Italians started a family business. Nowadays, Ariston household appliances do not need any recommendations.

Ariston gas boilers, if you do a brief review, reveal themselves to be very reliable and popular. The company mainly specializes in wall-mounted domestic boilers with two heated circuits - for heating and for hot water supply. They are presented in several series:

- Genus;

- Clas;

- Egis;

The first family has rich functionality. The second family is famous for its practicality. The third series is distinguished by the compactness of the boilers coupled with their excellent design. We'll talk about the models of the last two series below. Every type of Ariston gas boiler has good reviews from consumers everywhere.

User manual

The first thing you need to remember before you start installing a gas boiler is that the installation and connection of the device should only be carried out by certified specialists. Self-installation is not recognized by gas services as legal; in this situation, the inspection company has the right to shut off the gas supply to the house and impose a fine on the owner of the premises. And this is at best, and at worst, the boiler can fail or even explode and cause harm to life, health and property.

Before starting use, you should check the level of ventilation - the room where gas equipment is installed must be well ventilated. Throughout the entire period of operation of the boiler, it is necessary to constantly monitor the water pressure in the heating system. Normally it is 1.5-2 bar; if the pressure drops, the boiler turns off and the control display shows an error. In this case, you should make sure that there are no leaks and “feed” the installation.

Even if the installation and connection were carried out by professionals, and the boiler was used strictly according to the instructions, there is always a possibility of the device breaking down.

There are many reasons why a unit may fail, but the most common are the following.

- Damage to the control board. This problem is usually associated with frequent power surges or power outages. To avoid problems even at the installation stage, you should think about installing a voltage stabilizer, and for a cottage, a backup generator that is equipped with a circuit breaker and grounded can be an excellent option.

- Low efficiency or underheating of water. Such damage is often accompanied by excessive water hardness or the presence of contaminants in it, so experts recommend using water filters.

- Stops due to lack of oxygen. This defect occurs if the room is not equipped with a supply ventilation system.

- Inconsistency between the actual parameters of the coolant and the declared ones. This problem is a direct consequence of improper installation of equipment and illiterate settings of the boiler.

And in conclusion, a few recommendations:

- do not neglect regular preventive inspections of the boiler and its quality maintenance;

- if a particular malfunction recurs too often, you should contact the service company;

- repairs should only be trusted to a certified organization whose specialists have all the suitable spare parts and necessary tools, and in addition, have the required permits to work with gas equipment.

With proper installation and operation, a 2-circuit boiler from Ariston will last at least 20 years.

How to choose?

To choose gas equipment for heating a private house or apartment, you cannot act intuitively - you need to calculate heat loss. For the calculation, the condition is taken that for 10 sq.m. area (height up to 3 m) should account for 1000 W. But this is only an approximate calculation. It is not recommended to select an option without a reserve, so that the device does not have to function at the maximum of its resources. It is also necessary to take into account the degree of insulation of the house.

More accurate calculations are ordered from construction and design companies. The cost of such services depends on the region and ranges from 2,000-7,000 rubles. Calculation errors can provoke:

• uneven distribution of heat throughout the rooms;

• lack of hot water.

Operation and Maintenance

You should find out from the instructions what the pressure in the expansion tank should be - since during operation it may decrease. It is recommended to monitor your blood pressure once a year. Periodically you should:

• check the filters and clean them if necessary;

• clean heat exchangers - this is especially important for hard water;

• change the corresponding gaskets.

The above activities, as well as installation, configuration and first start-up, are the task of the service technicians. The owner only needs to conclude an appropriate service agreement and follow the manufacturer’s recommendations regarding the operation of the device. A specialist should be called twice a year - you cannot start the heating season without an inspection. At the end of the season, you also need to invite a service worker.

Choosing a gas appliance for heating

Ariston products can be found in catalogs. There are many models of gas appliances available there. The main mistakes when choosing the wrong unit are made from a lack of information. Therefore, before visiting the store, you should familiarize yourself with the basic tips for choosing a wall-mounted gas appliance.

When choosing a boiler, consider the following points:

- The size of the kitchen as the place where the heating device is most often installed. In the store, the choice begins by considering the overall dimensions of the device and selecting it individually for your kitchen.

- Next, move on to the technical data and study the type of water heater in the device. If there are a large number of people in the family, then it is not recommended to purchase a boiler with an instantaneous water heater.

- In this case, it is more rational to purchase a boiler with a storage tank for hot water and select equipment for the amount of water that you will need for everyday use.

- Evaluate the combustion chamber of gas equipment. It can be closed or open. It is recommended to choose a boiler with a closed chamber because it is safer to use. The presence of a chimney is not necessary, which is important in multi-storey buildings. All you have to do is buy a coaxial pipe and put it outside.

Ariston series

The manufacturer offers three series, each of which has several modifications.

Egis

For those who like to save. Double-circuit models are compact and have increased efficiency. There are filters and an anti-scale function, intelligent control and frost protection. Allowed to operate at temperatures down to -50° C. Popular versions:

• Egis Plus 24 CF - open firebox.

• Egis Plus 24 FF – closed chamber.

The line is represented by one power - 24 kW. Specifications:

• Dimensions – 40x77x31.5 cm.

• Weight – 30 kg.

• Combustion efficiency. 24 CF has the second one. 24 FF is third.

• Efficiency for 24 CF is 92%, for 24 FF – 94%.

• Hot water capacity – 9.7 l/min.

You will have to pay 20,000-30,000 rubles.

Clas

Larger and more powerful than Egis. They also have everything for uninterrupted operation - frost protection, filters, auto-tuning, fuel consumption control. This series has an 8 liter expansion tank to heat water. Modifications:

• Clas Evo. AUTO and INFO PLUS functions. The power of the device with a closed chamber is 24 and 28 kW, with an open chamber – only 24 kW. Productivity – 9.9 and 10.2 l/min, respectively. Power consumption – 88.5 kW.

• Clas B – you can connect a boiler.

• Clas Premium – condensing boiler.

• Clas Premium Evo – with PLUS, INFO and AUTO functions.

• CLAS EVO SYSTEM - there is automation that responds to the weather and copper heat exchangers. Versions with closed (FF) and open (CF) firebox. Power range – 16-32 kW. The former have an efficiency of 93%, the latter – up to 90%.

• CLAS SYSTEM – single-circuit versions. Mounted option. 16,000-32,000 W.

• CLAS and BS II – heating and hot water supply. Economy class.

Approximate price – 25,000-32,000 rubles.

Genus

Representatives of this series are the most functional wall-mounted versions with two circuits. There is a fan, an LCD screen, a remote control, and a weekly programmer. Modifications:

- Genus Evo. Open/closed firebox (turbo). Heating capacity 24-30 kW.

- Genus Premium. Condensing boiler. Increased efficiency – 105%. 24-35 kW. Remote control. Self-diagnosis.

Hotpoint-Ariston Cares X 15 FF

Wall-mounted 2-circuit option. Approximate cost: 27,000 rubles. Expansion tank 8 l. Turbocharged. Protection against overheating, flame failure and lack of draft. Weight – 30 kg. Dimensions (HxWxD) 77x40x31.5 cm.

UNO 24 MFFI R

Wall-mounted unit "UNO" with instantaneous water heater. Compact - 40x70x25 cm. Closed firebox. 24,300 W – heating output. Electric ignition. Protective systems - gas control, anti-freeze, heating limitation. There is a water filter. Weight – 29 kg.

Hotpoint-Ariston BS II 15 FF

Attachment with two circuits. Heating capacity – 15,000 W. turbocharged type. Heats an area up to 180 square meters. m. Weight – 30 kg. Efficiency - 91%. Power consumption – 106 W. Estimated price – 23,000 – 32,000 rubles.

Technical data of Ariston gas appliances

- Ariston boilers are used for heating and water heating, that is, they are double-circuit. Each modification has its own characteristics, but the common type of fuel is gas.

- The gas combustion chamber can be either open or closed. If there is a chimney, units with an open chamber are used. And in apartments of multi-storey buildings, where there are not always chimneys, equipment with a closed combustion chamber is used.

- Power. Using this indicator, the gas consumption required to heat the room is calculated.

- Compactness. Wall-mounted units are used in small, narrow rooms. Floor-standing units used in production or warehouse areas are heavier and require more space for installation.

- Availability of a control unit. This element is indispensable when the water is turned off or when there is a sharp decrease in gas. In case of any malfunction, the unit will immediately turn off the device, which will prevent breakdown. It can also help you save fuel consumption.

Ariston boilers are used for heating and water heating, that is, they are double-circuit

Launch and operation

Commissioning and commissioning work is carried out by company representatives - service employees. Failure to comply with this requirement will result in a denial of warranty. The user only needs to read the instructions to understand how to use the device. It is important to follow operating rules and perform seasonal maintenance in a timely manner. When a malfunction occurs, an error code appears on the display indicating the cause of the problem or the problem that has arisen. Complete with gas equipment - instructions, passport and connection diagram.

The lineup

The line of models of double-circuit boilers, in contrast to single-circuit boilers, is more in demand, since the models are designed for heating rooms and supplying hot water.

BCS 24 FF (closed combustion chamber) and Uno 24 FF (open combustion chamber)

Most buyers choose Ariston of these brands. In addition to the operating instructions, the device comes with all the elements of the heating system, which you can operate every day and without special skills.

Efficiency reaches 95%, power - 24 - 26 kW, hot water productivity - up to 14 liters per minute.

Genus

It is considered the most functional model. There is a display on the case that shows all the parameters of the device both inside and outside. Ariston of this brand is compact, equipped with a modulated burner, which helps to use fuel economically, and also has a programmer with a built-in timer.

You can set a program for the device immediately for the whole day, lower or increase the temperature of the coolant, set the parameters of the unit at your discretion. The tank volume is 8 liters, the air vent is automatic, a self-diagnosis system is built-in, all information is reflected on the display.

Egis Plus

Adapted for operation in Russian climate conditions . The models are not afraid of voltage drops in gas pressure in pipes. The unit has 2 heat exchangers: copper and stainless steel, as well as a condensate collector for uninterrupted operation at street temperatures below - 52 degrees. The panel has LED indexing.

All information can be read on the display.

How to secure?

When installing, you need to consider the following points:

- Anchor bolts are used for fastening. Install on any wall - solid or load-bearing. Wall material – brick, aerated concrete blocks, reinforced concrete slabs.

- Pipe connections are carried out according to the instructions. The data sheet describes in detail the purpose of all pins. Shut-off valves are installed directly in front of the apparatus. Cleaning filters and a pressure relief valve are installed at the water supply point.

- Most Ariston models are equipped with a coaxial chimney - exhaust gases are removed through a hole in the wall.

- Additionally, the equipment is equipped with a circulation pump.

- Control unit – regulation of the temperature of hot water and coolant.

- Ariston models are non-volatile, so the instructions require the mandatory installation of a UPS.

If the boiler pressure is low

If the question arises why the pressure in the heating boiler drops, the problem may be with the safety valve.

Once the valve has been actuated, either automatically by increasing pressure or manually, it may not close completely. Since the valve would have to be replaced if it continues to leak, there is no harm in operating it manually again now. Turning the red cap will release the inner valve from the seat, allowing system water to enter. If you turn it further, it will slam shut and fall back into place. You can repeat this by increasing the boiler pressure as needed. If the pressure still does not hold, the valve needs to be replaced.

If it is still not clear why the water pressure in the boiler drops, most likely the leak is under the floor. If the floors are solid or can't be lifted, this is a big problem, but there are leak detection companies that specialize in finding them.

Insufficient circulation, error 104. How I looked for the cause

According to the manual, I determined that 104 is “Insufficient circulation.” I reason: What could interfere with normal circulation? After all, the required flow of coolant can be hindered, for example, by a clogged filter in the heating system or slag that has accumulated in the primary heat exchanger. Or maybe the reason is the circulation pump? Has the pump really fallen off? To check it, unscrew the bleed screw on it, this will allow you to see whether the shaft rotates or not.

There is a slot on the shaft for a wide, flat screwdriver, I tried to turn the shaft with a screwdriver... it didn’t jam, it rotates. I try to start the boiler and see if the shaft rotates. The cauldron reproduces its terrible sounds and again goes into defense. The shaft does not rotate. At the moment of startup I tried to turn it with a screwdriver.... I thought, what if a “dead center” suddenly appeared..... no, the shaft did not rotate.

I decided to check the supply voltage of the pump. When the presence of 220 volts was detected on the chip, the output was unambiguous.... Pump to be replaced. Ehh I think, again unforeseen expenses.

However, the conclusion was hasty; when I looked for the wires going from the board to the circulation pump motor, I noticed that there were more than two of them. For what? I started looking into it and this is what I found out:

Ariston washing machine models

To understand which automatic washing machine is right for you, you need to decide on the requirements that it must meet. Let's look at different types of Hotpoint Ariston models and their parameters.

Hotpoint-Ariston WMSG 601

This free-standing front-facing washing machine is a typical representative of modern washing technology. The model is designed for 6 kg, equipped with electronic intelligent control and a convenient display. Relatively small dimensions - 60x42x85 cm - make it a frequent choice for residents of small apartments.

Washing efficiency – A, energy efficiency class – A+. The maximum rotation speed of the drum during spinning is 1000 rpm; 16 programs. And most importantly, the inverter motor: brushless, it does not have brushes that require frequent replacement.

Hotpoint-Ariston WMSG 7106 B

This machine is slightly larger in size: 60x44x85 cm. But the capacity of its drum has been increased to 7 kg. Spin – up to 1000 rotations per minute, 16 programs.

Washing class and energy efficiency efficiency is A, spin class is C. A display is also provided, since the control is electronic.

Hotpoint-Ariston RST 703 DW

Another narrow washing machine, designed for 7 kg of laundry with dimensions of 60x44x85 cm. With class A washing quality, the highest energy efficiency class is A+++. The manufacturer has provided 14 convenient programs and a high-speed spin, up to 1000 rpm.

Hotpoint-Ariston CDE 129

Are you interested in built-in models? Hotpoint Ariston has a wide range of such machines. This built-in machine can accommodate 5 kg of dry laundry with dimensions of 60x54x82 cm.

An additional bonus is the clothes drying function. You can dry up to 4 kg of laundry at a time. The model provides electronic control. Washing class is maximum, energy consumption class is B (due to the drying heating element). During spinning, the drum accelerates to a maximum of 1200 rpm.

The video provides an overview of a similar model:

Hotpoint-Ariston AVTXL 129

Convenient vertical washing machine with a load of 6 kg. Dimensions only 40x60x85 cm. Controlled electronically. Washing efficiency classes - A, spinning - B. Spinning laundry at speeds of up to 1200 drum revolutions in 60 seconds.

Of course, the market is represented by hundreds of other Hotpoint Ariston SMA models with different capacities, loading types, engines (collector or direct drive), and the purchase should be made based on your needs and budget.

Device selection

When choosing a device, you must be guided by the following criteria:

The area of the heated room in m2. It is necessary to select a boiler based on 1 kW of thermal power per 10 m2 of room. At the same time, it is necessary to understand that this is an ideal option and, taking into account the heat loss of the living space, the average annual air temperature at the installation site and the radiators used, it is necessary to introduce a correction factor. For a preliminary assessment, we recommend using any online calculator that takes into account the above factors and also makes adjustments for the location of the walls (windward or not), ceiling height, and type of windows.

Need for hot water. For high consumption, it is wise to choose the CLAS B model with a built-in boiler, which is more economical.

Boiler installation location. For water heating units with an open combustion chamber, it is necessary to equip the room with forced ventilation, since the combustion air comes directly from the room

Since devices with an open combustion chamber are designed to remove combustion products through a chimney with natural draft, it is necessary to provide for the installation location of the chimney and chimneys. IMPORTANT! It is not allowed to pass chimneys through structures made of flammable material.

Gas boiler design

The most common Ariston boiler error codes and troubleshooting methods

To quickly understand what happened to the heating device and why the double-circuit gas boiler does not heat hot water, it is worth familiarizing yourself with the list of Ariston boiler errors, grouped by component. In some cases, correcting errors and troubleshooting an Ariston gas boiler can be done independently, including by replacing parts.

Error 101 gas boiler Ariston 24, interpretation

The list of error codes starts with 101. If such a code is displayed on the equalizer (display) of the Ariston-24 device, this indicates overheating of the coolant. The failure occurs due to:

- increased pressure in the area of the gas valve;

- insufficient speed of water movement (this problem arises due to blockages in the filter, scale, pump breakdown);

- temperature sensor failure.

Read more: Why does a gas boiler go out? Main reasons

Error 103, 104, 105, 107. What should I do?

Error 104, 103, 105 or 107 appears when the H2O flow is incorrect, there is an obstacle in the flow of the coolant, or as a result of deterioration in pressure. Disrupted water movement is caused by air accumulation inside the device.

There is a simple solution: for a 24 kW double-circuit boiler - hold down “Mode” for ten seconds; for Ariston Uno - hold “Reset” for about six seconds.

After these steps, the pumping apparatus will operate for five minutes, pumping out air without ignition. After the procedure, it is worth assessing the pressure level. The normal value is 1.2 Bar avigeneric.com.

Error 108, how to fix it

Error 108 is caused by weak pressure in the heat exchanger, tank, pipes, mountings on the gas boiler, or the reasons indicated in the previous paragraph. Error code 108 means that it is worth inspecting the tank and other spare parts for leaks, and make sure that the membrane part in the expansion tank is in good condition.

109

Error 109 in Ariston indicates increased pressure (more than 3 Bar). To eliminate such a nuisance, you need to bleed the air (using a Mayevsky valve). The second cause of the 109th breakdown may be a broken heat exchanger that mixes water of different temperatures.

302

Such a failure indicates a breakdown in communication between the display and the control board. Error 302 is caused by disconnection/oxidation of contacts. Do-it-yourself repair of an Ariston gas boiler is accomplished by stripping and connecting the contacts.

Error 304

Code 304 is a broken electronic board. You should find a place that sells spare parts for Ariston gas boilers and purchase a replacement part.

Error 501, what it means and how to fix it

Error 501 means that the device does not start due to lack of ignition flame. The heating unit can be turned on by correcting the following causes of failure:

- lack of gas (you need to make sure it is present, open the gas valve);

- control board failure;

- violation of the electrode connection with the ignition control module;

- breakdown of the ionization electrode (it is necessary to clean the contacts, check the correct placement of the comb: a distance of eight millimeters must be maintained between the parts);

- reduction in the power of the smooth ignition system;

- leakage of electric current (remove the breakdown in the electrical network: the voltage should be 10 V).

The boiler does not ignite, the display shows error 607

If an Ariston double-circuit gas boiler shows the numbers 607, the contacts of the fan relay have stuck together and it simply worked before ignition.

Error Sp1

Sp1 or 5p1 reflects failed ignition. At the same time, 5p2 indicates a repeated unsuccessful attempt to light the wick. Causes:

- poor air flow;

- oxidized ionization electrodes;

- low gas pressure (it is difficult to immediately say why the pressure drops, so detailed diagnostics will be required).

Sp3, 5p3

If the wall-mounted gas boiler Ariston 24 gives one of the indicated designations (error sp3 or 5p3), there may be a problem with the flame. Eliminating the error of flame separation from an Ariston gas boiler is associated with cleaning the chimney. It is too clogged with dust and soot or is not arranged correctly, so the fire is immediately blown out or the so-called flame separation occurs.

Error 025

When the boiler shows error 025 constantly (it can also look like this: “e25”), this indicates that the maximum permissible temperature of the boiler has been exceeded (see the paragraph about the 101st error).

What to do if 6p2 lights up on the display

A light on the display showing error 6p2 or 6p1 tells the user that the room with the unit is not properly ventilated: either it is not ventilated enough or combustion products are not removed.

How does a gas water heater work?

Such devices are intended to provide hot water to domestic and industrial facilities. The essence of their work is quite simple: cold water from the pipeline enters the heat exchanger of the column, where it is heated by burners (they are located under the heat exchanger). As you know, fire needs oxygen, so to prevent the burners from going out, the column is connected to the ventilation system of the house/apartment. The exhaust gas is eliminated through a special chimney, which is combined exclusively with a gas water heater.

Read about what you should pay attention to when choosing a water heater here

All of the described types of speakers function slightly differently.

So, if the device is turned on manually, that is, the gas has to be ignited with matches, the burner will ignite when you turn the fuel supply valve. Although it is worth noting that such designs have long been outdated. Modern designs are equipped with either electronic ignition or a piezoelectric element.

New models are activated with one click of a button located on the front panel of the device. Piezo ignition creates a spark that ignites the igniter. In the future, everything happens automatically - the tap opens, the water heater lights up, and hot water begins to flow.

If the geyser is ignited electronically, then it is perhaps the most reliable and durable device. The system is turned on by a pair of batteries that supply the charge necessary to produce a spark. No buttons, no matches, the only thing you need to do to turn it on is open the tap. In most cases, batteries last a very long time, since the energy required to charge is minimal.

How to calculate gas consumption for heating a house - read here