- We offer to buy wall-mounted gas double-circuit boilers with delivery in the Tavago online store.

- Price for wall-mounted gas double-circuit boilers from 32,632 rubles.

- Read instructions and reviews about Wall-mounted gas double-circuit boilers.

The boiler is the central element of any heating system, and if you want to purchase a high-quality gas double-circuit wall-mounted boiler, then you can consider that you have come to the right place. We will offer you the best gas boilers from the world's leading manufacturers. Only the best prices, only positive reviews and a huge selection are already waiting for you in our catalog!

Turbo boiler or atmospheric boiler

An atmospheric gas boiler is designed in such a way that the air required for gas combustion comes from the room in which the boiler is located, and combustion products are removed through a regular chimney.

It is necessary to provide and organize additional air flow into the room. This point needs to be remembered when choosing a gas heating boiler. In atmospheric gas boilers, an open combustion chamber is installed, which increases the fire hazard, but if safety rules are followed, the risk of open fire is reduced to almost zero. Such boilers are cheaper, because... simpler. An atmospheric gas boiler operates more quietly and is also independent of electricity. A turbo boiler is more complex. Before choosing such a gas heating boiler, you need to understand that it has a different system. A turbo boiler has a closed combustion chamber, into which air is supplied using special fans, and combustion products are removed using an exhaust hood. This means that such a boiler operates with a lot of noise and requires a constant supply of electricity, requires additional installation of air ducts and is generally more expensive. However, turbo boilers do not burn oxygen in the room and allow you to save up to 30% on fuel due to better fuel combustion.

Gas boiler heat exchanger

A heat exchanger is a device where energy from burned gas is transferred to water. Heat exchangers are made from several materials. Cast iron heat exchangers are cheap to manufacture, however, they do not like temperature changes. Copper heat exchangers are the most efficient and economical, but are more expensive. Steel heat exchangers are the most versatile, and most gas boilers are manufactured with steel heat exchangers. Volatile or non-volatile gas boiler

Before choosing a gas heating boiler, it is necessary to take into account such a parameter as energy dependence. After all, there are boiler models that are equipped with an electronic control system or supercharging. Therefore, if power outages are common in your area, it is not recommended to buy such a boiler, because it will not be able to work without a constant power supply.

Various additional options when choosing a gas heating boiler

Weather sensor. It will be useful in cases where people do not permanently live in the house, but, for example, in the country.

Temperature sensor. It makes at least some sense if the boiler is installed in the room that it heats. Otherwise it's useless.

Magnetic system to combat scale. Useful in areas with very hard water rich in calcium.

You should not completely focus on these options when choosing a gas heating boiler; we recommend that you first concentrate on its power and efficiency.

TOP 5 leading brands

Wolf

Wolf is a leading German manufacturer offering customers the best gas heating boilers. The products of this brand are equipped with control systems that allow you to select optimal operating modes. Gas boilers are tested and certified in accordance with European directives. Wolf CGB boilers are in stable demand. They operate on natural/liquefied gas and are used for efficient heating and supply of hot water to large country houses and multi-family buildings.

Wolf CGB condensing boilers are equipped with a closed combustion chamber. During operation of the units, air is supplied from the room or from the atmosphere

Baxi

"Baxi" - an Italian company produces units that combine excellent performance and functionality. For example, “Baxi MAIN Four” is the fourth generation of wall-mounted units with a display, electronic ignition, and bithermic heat exchanger. “Baxi Nuvola Duo-tec” are single-circuit wall-mounted boilers with a modulating burner and a stainless steel heat exchanger. They are equipped with an energy-saving circulation pump and an automatic air vent. The manufacturer has introduced an innovative control system, thanks to which the consumer can adjust the operation of the boiler to the type and quality of gas.

Baxi MAIN Four gas boilers are installed in confined spaces and have an elegant design

Vaillant

“Vaillant” - the model line from the German brand includes conventional, condensing, single-circuit units and gas heating boilers with a water heater. Equipment from a well-known company has a high efficiency and is equipped with built-in circulation pumps. Prominent representatives of the model line are the Vaillant turboTEC PLUS VU boilers. They are equipped with a closed expansion tank, automatic air vent, safety valve, primary copper heat exchanger and chromium-nickel steel burner.

The wall-mounted boiler “Vaillant turboTEC PLUS VU” is equipped with an LCD display with large buttons and backlight

Dakon

“Dakon” - with the help of gas heating boilers from a Czech manufacturer, you can economically solve problems with heating your home and providing hot water. For example, DAKON GL Eko cast iron gas heating boilers equipped with an atmospheric ejection burner, Honeywell electronics, and a draft breaker are in good demand. They are equipped with control units, to the outputs of which additional elements are connected: room thermostats, anti-freeze devices, external sensors.

Wall-mounted gas boilers “DAKON” are equipped with a bithermic heat exchanger and a system against limestone accumulation

Navien

“Navien” are Korean-made units with excellent technical performance. They are used for a long period, operate stably at low pressure, and have minimal dimensions. Double-circuit wall-mounted boilers “Navien Ace ATMO” with a natural system for removing combustion products are in great demand. Such units are equipped with an automatic system that turns on the pump when the temperature drops below 10 degrees. The developers took into account the possibility of operating the device under conditions of frequent voltage surges. Therefore, the boilers are equipped with a special chip that is triggered when the voltage in the network changes.

"Navien Ace ATMO" - popular heating equipment equipped with separate heat exchangers

Each buyer can independently select a unit that meets individual needs and financial capabilities. But the installation of gas heating boilers must be trusted by professionals, because the safety of operation of the device depends on the correctness of actions.

Features of the chimney device

The coaxial chimney system of a turbocharged gas boiler has two channels. The “pipe-in-pipe” device allows for several processes to be carried out simultaneously: drawing combustion air in from the street and exhausting exhaust gas outside. At the same time, thanks to the special design of the boiler, combustion air penetrates through the chimney directly into the combustion chamber.

To increase productivity, the coaxial chimney is equipped with an electric turbine. The rotation speed of the blades can be adjusted. This function is very important during pressure drops in the main pipeline, as it equalizes the ratio of components in the gas-air mixture. That is, it is possible to make the rotation of the turbine correspond to the gas pressure. Thanks to this design feature, the boiler burner operates throughout the heating season with maximum heat output.

Turbo boilers are equipped with automatic sensors that monitor the safe operation of the unit. In the event of an accident, they will immediately turn off the system and cut off the gas supply.

A gas double-circuit turbo boiler does not require the installation of a large chimney structure, so its installation is significantly simplified. There is no need to build a separate boiler room, because it does not take oxygen from the combustion room. Such a boiler can be installed in both residential and non-residential buildings and structures.

Flaws

Among the disadvantages of turbocharged gas boilers are:

- use of electricity. Boiler controls and turbines depend on electricity;

- With regular power surges in the network, the automation may fail;

- there is condensation. Since the temperature of the exhaust gases does not exceed 120°C, condensation occurs in coaxial chimneys, which can block the channel if it freezes.

To solve the latter problem, the chimney is usually insulated and a condensate collector is installed.

Advantages

Supercharged devices have a number of features that allow them to be used there. Where it is impossible or difficult to install other types of wall-mounted or floor-standing boilers.

Consumers appreciated turbo boilers for the following qualities:

The design features of the turbo boiler make it the most cost-effective. When compared with other types of heating equipment. The relatively small dimensions of the coaxial chimney and ease of installation allow the use of many modifications of turbocharged heaters in those rooms where it is unacceptable or impossible to install other equipment. Air intake to support the process is not taken from the room itself. In this case, there is no danger of the release of toxic gases due to a lack of oxygen and incomplete combustion of fuel. One of the main advantages is the compact size of the boiler. Pressurized gas boilers have an efficiency level of about 95%. This is ensured by automatic control of the entire work process. In this case, the most optimal operating parameters of the installation are set. Using a coaxial chimney is the most cost-effective compared to other models

In this case, the organization of a stationary chimney is not required; it is very important when installing heating in an already occupied apartment or house

The wall-mounted device can even be installed in the bathroom or kitchen due to its safety and size. At the same time, it will not create additional difficulties or inconveniences.

Reviews of household models with forced air exchange: advantages and disadvantages

According to reviews from owners of turbocharged gas boilers, the following pros and cons can be identified:

| Advantages | Flaws |

| safety - the tightness of the closed combustion chamber virtually eliminates the risk of smoke entering the room | high cost - prices for wall-mounted models are higher by 20-30%, for floor-mounted ones - by 20-50%, but you can eliminate the cost of building a full-fledged chimney |

| free placement - air intake from the street allows you to install the boiler in very small rooms (of course, meeting the requirements) | constant noise - the active operation of all turbo boilers is inevitably accompanied by a monotonous sound of fan rotation, its volume depends on the model, as well as the presence of a sound insulation layer in the boiler |

| simple installation of the chimney - to output the coaxial pipe, just make a hole (Ø 110) in the outer wall of the house | Volatility dependence - any problems with voltage (interruptions, non-compliance with the norm) cause the fan to stop |

| low fuel consumption - efficiency is achieved due to automation, which controls the turbine rotation speed |

Difficulties with energy supply can be easily avoided by connecting a voltage stabilizer and a backup power source to the turbocharged boiler - an electric generator (gasoline, diesel) and an uninterruptible power supply (UPS). However, it must be taken into account that this will lead to additional material investments.

Installation procedure for turbocharged boilers

Installing such a device usually does not cause serious difficulties. There is no need to allocate a separate room (boiler room) and build a stationary chimney for it.

Typically, installation of a gas boiler occurs in the following sequence:

Wall mounting. Wall-mounted gas units are now the most popular; for safety, it is necessary to ensure their secure fixation

To do this, it is important to select fasteners that are designed to hold the required weight and are suitable for the material from which the wall is made;

Connection to the heating main. Depending on the type of boiler (single-circuit or double-circuit) and the characteristics of the heating system, a different number of pipes can be connected;

Gas pipeline connection

This procedure, as already noted, must be performed by a specialist with the appropriate clearance;

Connection to the power grid. A prerequisite is the use of a voltage stabilizer and a grounding device;

Chimney installation. Wall-mounted boilers are usually equipped with the necessary piece of coaxial pipe. A hole must be cut in the wall through which the double-circuit chimney is vented to the street;

Setup and first launch. For proper operation of a turbocharged boiler, gas automation must be configured. It must be performed by a specialist certified by the manufacturer.

general description

AGV gas boilers have always been characterized by rather low efficiency, but this is not so important if gas is the cheapest fuel. Old models of autonomous water heaters were equipped with very unreliable automation, which could completely fail within a few years.

Of course, it could always be turned off, and this did not affect the performance of the boiler in any way - but positive emotions could not arise because of this.

When choosing an AGV for a private home, it is necessary to correctly select the number and sizes of main pipes. Their minimum diameter is two inches. If the diameter of the pipes is smaller, then, firstly, their throughput will not be enough, and secondly, air pockets and water turbulence will form in the line, interfering with the normal circulation of the liquid.

The use of wide pipes, in turn, leads to a significant increase in the amount of coolant in the circuit. A large volume of liquid means more energy spent on heating. This feature must be taken into account when designing a heating system powered by AGW.

What criteria are used to choose a boiler?

The first thing consumers consider when choosing a heating boiler is the number of circuits. The double-circuit wall-mounted turbocharged gas boiler is in great demand among the population.

Its cost is much higher than that of a conventional boiler. But with its help you can save money on purchasing more equipment for organizing a hot water supply system.

Single-circuit units also have advantages:

- lower price;

- simplified installation;

- light weight;

- easy to repair if necessary;

- reliable and durable.

Most often, single-circuit units are installed for heating non-residential premises.

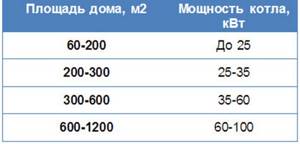

A gas boiler must be selected according to its power characteristics in order for it to justify itself in terms of reliability and efficiency. With a ceiling height of no higher than three meters, 1 kW of thermal energy corresponds to 10 square meters. meters of heated area.

There is also such a criterion for choosing a boiler as its size and shape. In some cases, it is preferable to install a floor-standing boiler with a turbine. It has larger dimensions than the wall-mounted model, however, it also has a longer service life. Its design uses high-strength materials in the manufacture of main components.

Each consumer has his own requirements for a turbocharged gas boiler. All options - two-circuit and single-circuit, wall-mounted and floor-mounted - find their buyer. Of course, if there is a need for hot water supply, then a double-circuit boiler will optimally solve the problem.

What to look for when choosing a device

When choosing methane boiler equipment, they are primarily determined by the thermal power that will be sufficient to heat a particular building. The standard ceiling height of up to 3 meters with average insulation of the external wall assumes the consumption of thermal energy per 10 square meters within 1 kW. You also need to consider:

- A single-circuit boiler is designed for heating only. To have hot water in the tap, you need a double-circuit one.

- Devices with copper heat exchangers have proven themselves well - they are durable and heat up quickly.

- For running models it will always be possible to find components and a service center for maintenance.

Modern devices allow you to control them through special applications on your smartphone.

Operation of a turbocharged boiler

In a conventional heating boiler, draft is created naturally. It is ensured by the presence of a temperature difference between unheated and warm air. Turbocharged boilers have a completely different draft principle. Such boilers have a built-in special fan and an automatic system for forced creation of air draft. The operation of the system is controlled by gas combustion.

The coaxial air flow is supplied through two pipes, rather rigidly inserted into each other. These pipes form the chimney. The outer pipe takes in air, and the inner pipe removes all carbon monoxide.

The entire boiler body is completely sealed; it can be installed not only in a special room, but also inside living rooms. It does not pose any danger to human health.

Both floor-mounted and wall-mounted modifications of gas boilers are popular. Their choice depends on individual conditions.

Natural and forced traction

In the second type, air enters and smoke is discharged through the same coaxial pipe, and the air mass is pumped through a built-in fan.

Types of automation for gas heating boilers

Closed models are more expensive, but their efficiency is higher: firstly, the street air along the way has time to heat up from the hot wall, behind which smoke moves out into the street, and secondly, part of the heat during heating does not go into the room, all the energy is spent on heating the coolant .

Another advantage of a closed firebox: installing a coaxial chimney is much simpler than installing a standard one and passing it through the roof.

But purchasing an open model may be worthwhile if a standard chimney already exists.

Criteria for choosing a double-circuit gas boiler model

Before choosing a specific model, it is necessary to correctly evaluate the advantages and disadvantages of the proposed equipment models. And also clearly formulate the main selection criteria.

To navigate among the huge variety of models, it is useful to read reviews about the work and performance characteristics of various modifications. Many consumers, in the process of installing boilers and their further use, have already encountered some technological problems, which they readily share in forums and blogs.

It must be taken into account that the power of almost all modifications of gas double-circuit boilers does not allow them to be used for heating very large areas.

They are usually installed in small apartments or private houses.

But due to their size, such boilers can be hidden behind pieces of furniture and placed in very convenient places for use without compromising the overall design of the room.

Floor and wall types of equipment

The floor structure is distinguished by its high weight - up to 100 kg. Its installation requires a lot of space, and installation is labor-intensive, complex and expensive. Most floor-standing atmospheric boilers do not heat water to be supplied to mixers. During operation, the floor-standing unit makes a lot of noise, and the chimney requires regular cleaning.

Positive sides:

- high power;

- durability;

- lack of electronics.

Wall heaters are smaller in size and weight (up to 50 kg). Such boilers are predominantly double-circuit. The model is easier to install and does not take up much space. The boiler can be placed anywhere in the room. Wall-mounted atmospheric boilers are single-circuit and double-circuit.

Both floor-mounted and wall-mounted boilers are produced to serve one or two circuits. However, if space allows, it is better to take two: a floor-mounted single-circuit one for heating and a column for preparing hot water

Disadvantage: a wall-mounted boiler depends on electronics. If something burns out, you will lose hot water and heating. Boilers are installed mainly in small apartments and houses.

How to choose a gas turbo boiler

Turbocharged boilers are no longer a rarity. Domestic consumers are offered several dozen models from various manufacturers, differing in functionality and internal design. The choice of a turbocharged gas boiler comes down to the following:

- Selection according to technical characteristics.

- To the manufacturer.

- Cost.

Experts recommend selecting heating equipment after analysis and thermal calculations of the room.

Selection by power and functionality

Choosing suitable boiler equipment begins with selection by power and functionality

Pay attention to the following characteristics:

- Productivity - accurate calculations are performed after an audit of heated premises for heat loss. There is a formula for calculating the average productivity value, 1 kW = 10 m². Calculations using the above formula are not suitable for boilers with a separate heat exchanger (double-circuit), as well as for rooms where the ceiling height is more than 2.7 m. Boiler equipment with a bithermal heat exchanger is calculated taking into account the required power reserve (+15%) and additional performance required for heating water (+15%).

- Number of heating circuits - if there is an urgent need for domestic hot water, choose a boiler with two heat exchangers. In other cases, a heat generator with one heating circuit is suitable. A modern 2-circuit gas turbo boiler for heating and hot water, operating in the “Winter/Summer” mode. After the end of the heating season, the primary circuit is turned off. The boiler continues to operate as a regular instantaneous water heater.

- Heat exchanger material - the primary circuit is made of cast iron and steel. Secondary heat exchanger, made of copper or aluminum. Each material has its own parameters of thermal conductivity and service life. The material of the circuits affects the cost of the boiler.

- Automation - the device of a double-circuit turbocharged gas boiler includes conventional or weather-dependent automation. Modern models are equipped with a remote control unit; at the customer’s request, they are additionally equipped with a remote warning module. The more functions the automation has, the more economically the boiler consumes gas.

Which brand of turbo boiler is better?

The rating of turbocharged gas boilers by company is headed by models from German manufacturers. The products of French and Italian factories are slightly inferior to them. Recently, Russian companies have begun to produce quite competitive boilers that are extremely popular due to their low cost.

The selection of turbo boilers in terms of reliability is led by Buderus, Bosch Gas, Protherm, Vaillant. In second place are Baxi, Neva Lux, Arderia. Somewhat worse in build quality and reliability are the products of Korean concerns: Navien, Daewoo, Kiturami, Hydrosta.

How much does a turbocharged boiler cost?

Pricing policy largely depends on the chosen manufacturer. A Buderus 12 kW double-circuit turbocharged gas boiler will cost 33-35 thousand rubles. The domestic analogue can be purchased starting from 20-25 thousand rubles.

Korean equipment, sold exclusively in the “premium” configuration. For a boiler equipped with weather-dependent automation, you will have to pay the price of a German boiler in the basic minimum configuration, 35-40 thousand rubles.

Specifications

type of instalation

Heating boilers, depending on the type of installation, can be wall-mounted or floor-mounted. In the floor-standing version, powerful (from 45 to several hundred kilowatts) units are made, the heavy weight of which (more than 150 kg) does not allow them to be mounted on the wall. Low-power devices that heat relatively small rooms weigh no more than 30 kg and can be mounted to the wall without any problems. Floor-standing gas units are more durable than wall-mounted ones, but they are not suitable for small spaces. The most popular among their residents are wall-mounted double-circuit turbocharged gas boilers.

Power

The main characteristic of any heating boilers is their power, measured in kilowatts. Some manufacturers also indicate the maximum heated area in the list of characteristics of a particular model. The calculation is usually performed based on the ratio of 1 kW per 10 m² of room.

Number of circuits

Boilers whose purpose is limited only to heating a house are called single-circuit boilers. But consumers often require that, along with heating, the unit also provides hot water for household needs, that is, it has a hot water supply (DHW) function. This type of unit is called dual-circuit.

In a separate article you can read about the pros and cons of a single-circuit and double-circuit gas boiler.

DHW system performance

Double-circuit modifications have one more, also important, technical characteristic - hot water productivity. It is measured by the amount of water in liters heated by 30 °C in one minute (Δt = 30 °C, l/min). Its value depends on the power of the boiler - the larger it is, the higher the productivity of the hot water system. For trouble-free supply of two typical hot water consumption points, in the kitchen and bathroom, a flow rate of at least 13 l/min is required.

Heat exchanger type

Turbocharged double-circuit gas boilers also differ in the type of heat exchanger. There are units with separate heat exchangers - one for each circuit, and with a double heat exchanger, which are also called bithermic. The latter option is cheaper, but during operation it will form scale, which will need to be removed periodically.

The material of the heat exchanger is important for the longevity of the boiler. Floor-standing boilers use thick-walled steel or cast iron, and they last for 25-30 years. For heat exchangers of wall-mounted models, stainless steel or copper is used. The service life of such boilers is 7-10 years.

Combustion chambers of gas boilers and their features

The combustion chambers of these types of boilers have significant differences in their design. This determines the method of removing carbon monoxide from them.

Turbocharged gas boilers

Here, “closed” combustion chambers are used to burn gas. Their peculiarity is that the chamber cavity does not communicate with the air of the room in which the boiler is installed. What does this give? The fact is that for normal combustion of gas, oxygen in the air is needed in the required quantity (for normal combustion of 1 m3 of gas, 10 m3 of air is needed) and it must be taken somewhere. So in this case, it is not taken forcibly from the room, but is sucked in directly from the street by a fan. This makes it possible not to arrange a fresh air supply for the boiler and not to place it in a specially designated and ventilated room. That is, in accordance with the technical requirements, such a gas boiler has more options for its installation location in a house or apartment.

Traditional chimney gas boilers

Boiler with open combustion chamber

These designs have an "open" (sometimes called "atmospheric") combustion chamber. It communicates with the air in the room where the gas boiler is located and the required amount of air for gas combustion will be absorbed naturally during operation of the boiler’s gas burner. That is, the oxygen in the air will gradually be consumed and its constant replenishment is necessary. For this purpose, supply and exhaust ventilation is needed. Its device must solve this problem, otherwise the normal operation of a gas boiler is both impossible and dangerous.

When there is a lack of oxygen, the following happens:

1) the gas stops burning completely, and we do not receive the amount of heat that we should receive during the normal process;

2) carbon monoxide (CO) is formed, which in certain concentrations is life-threatening (the presence of just 1% carbon monoxide in the air when inhaled can lead to fatal poisoning of the body).

Therefore, the operation of such gas boilers is considered more dangerous and, even with automatic protection, requires periodic monitoring of the process.

Rules for smoke removal in turbocharged gas units

Exhaust gases from turbocharged gas boilers must be removed only through a coaxial chimney. To install it correctly, the following requirements must be met:

- the pipe should be located horizontally with a slight slope towards the street; if the boiler is a condensing boiler, then the slope should be towards the unit so that the condensate can drain into the condensate receiver;

- the chimney should be installed in accordance with the instructions supplied with the device;

- the pipe is placed 1.5 m above the combustion chamber;

- protection is placed on the head of the pipe to prevent debris and insects from entering it;

- the maximum length of the horizontal section of the chimney is 3 m, but some manufacturers make a 5 m chimney;

- the distance from the pipe to window and door openings must be at least 0.5 m; to the window above the chimney – 1 m;

- in a wooden house, a gap of 5 cm should be left between the pipe and the wall; it is filled with basalt wool;

- You cannot arrange more than 2 rotary bends.

Some manufacturers equip their gas boilers with a coaxial chimney.

If this is not provided, then it is better to choose a pipe from the same manufacturer as the heating device. The suitable diameter of the coaxial chimney for a specific model of turbocharged unit is indicated in the instructions. The pipe design must have a closing hole to allow it to be cleaned from soot and a condensate collector leading into the sewer. Note! In exceptional cases, if the chimney cannot be brought out horizontally, the chimney is installed vertically in compliance with technical requirements.

What to consider when installing turbo boilers

When installing boilers, you need to take into account some points that may affect its performance. First of all, it is dependent on the supply of electricity.

This is the weak point of tube boilers. The fact is that they cannot work with inertial coolant circulation. If there is no electricity, the electric pumps will stop and the boiler will be idle.

Another disadvantage is the high cost of parts and repairs of a turbocharged boiler.

However, these points are not so significant compared to the convenience and efficiency of such equipment.

Units are selected in accordance with the size of the house, radiator models and taking into account the rules of the heating scheme. Experts will help you perform the necessary thermal calculations and suggest which boiler is better.

With a competent approach to choosing equipment for gas heating, you can ensure its economical and durable operation.

Installation Rules

Installation of a turbocharged boiler is carried out in strict accordance with the design documentation. The installation of gas equipment is regulated by SNiP, sanitary standards, environmental and fire safety.

The main standards for installation are the requirements for the boiler room. It is important to comply with the standards for chimney connection, safe operation and periodic maintenance. Before the start of the heating season, inspections and repairs are carried out annually.

You can install a turbocharged boiler yourself. However, it is worth understanding that if violations are made during installation, this may affect the efficiency of work.

There is currently no specific set of rules for installing turbocharged equipment. That’s why specialists use outdated SNiP standards.

To understand the conditions for installing a turbo boiler, consider the main criteria:

- Turbocharged boilers are allowed to be installed in apartment buildings only if the building is equipped with the necessary parameters, such as the presence of smoke exhaust ducts, sufficient space, etc.;

- Attachments are placed at a height of 0.8 to 1.8 m from the floor. A distance of 0.8 m must be left to the ceiling;

- Turbo boilers can only be used in non-residential premises. Sanitary standards prohibit the placement of such equipment in bedrooms, living rooms, etc.;

- It is important to have an entrance door to the room where the boiler is installed;

- The room must be equipped with two air ventilation ducts: supply and exhaust;

- The volume of the room must be consistent with the requirements of SNiP and depends on the power of the boiler. If the power does not exceed 30 kW, then an area of 7.5 sq.m. is considered sufficient;

- When using boilers with a closed combustion chamber with a power above 30 kW, it is necessary to allocate a separate room for them and cover its surfaces with fireproof materials with class EI 60;

- The boiler room must have a door with access to the street;

- Gas services regulate the total power of equipment not exceeding 150 kW.

In any case, the requirements for installing the boiler must be previously agreed upon with the Gas Supervision Authority of the relevant region, as they may differ depending on the area. Standards for installing a chimney are given in the technical documentation of the equipment and in SNiPs.

Let's summarize them:

- the horizontal section of the smoke exhaust duct should not exceed 3 m, and the vertical section – 1 m;

- the distance from the pipe head to the nearest building should be 3 m;

- the level of the chimney from the ground is chosen for reasons of least harm to pedestrians;

- a deflector is used to improve traction;

- the air intake duct is protected from condensation by installing a condensate collector;

- it is necessary to maintain a small angle between the chimney and the boiler;

- in a private house, supply and exhaust ventilation should be installed;

- The boiler room must be equipped with an uninterruptible power supply, since if there is a power outage, the automation will not be able to ensure the operation of the equipment. UPS must be selected based on sufficient capacity to maintain the boiler operation for 24 hours.

In the modern world, no one will be surprised by the fact that gas boilers have economical fuel consumption. Therefore, today traditional atmospheric models are being replaced by more reliable, environmentally friendly, high-performance and, most importantly, safe turbocharged boilers.

It would seem that the only difference is in the method of removing exhaust gases, but in fact it is this nuance that determines the efficiency of work, location, complexity and even the cost of installation.

Read in the article

Single-circuit or double-circuit gas boiler

A single-circuit gas boiler is intended exclusively for heating the premises. If the boiler is required to provide the house with hot water, then you need a double-circuit heating boiler. In this case, calculating the required boiler power becomes a little more complicated - to the power required to heat the premises, it is necessary to add the power for heating water. The characteristics of double-circuit gas boilers usually indicate how much water and to what temperature a given boiler can heat

Please note that it is not the outlet water temperature that is indicated, but how many degrees the water will heat up, i.e. if it says “40 degrees” and the initial water temperature is 10 degrees, then the output will be 50

(no votes yet)

The best known manufacturers and models: characteristics and prices

BAXI ECO-4s 24F

The Italian double-circuit turbo boiler with a power of 24.0 kW was designed taking into account the specifics of Russian conditions, so it is adapted to work with low gas pressure, power outages and other unstable indicators. It also has one of the best efficiency in its price segment - 92.9%, gas consumption - 2.54 m 3 / h. The primary heat exchanger is made of copper.

The owners note almost silent operation; after using it for more than 5 years, there were no serious service complaints.

Cost: 33,110 – 36,850 rubles.

Manufacturer: BAXI (BAKSI), Italy.

Vaillant turboTEC pro VUW 242/5-3

Double-circuit model from the reference German brand with a power of 24 kW. It is particularly reliable and durable due to excellent build quality, the use of high-tech alloys and the best materials. Efficiency 91%, maximum gas flow 2.80 m 3 /h. It also features a copper primary heat exchanger, a modulating burner, functional automation with many safety systems and a pleasant, stylish design.

Cost: 53,920 – 57,860 rubles.

Manufacturer: Vaillant (Vailant), Germany (assembled in Slovakia).

Viessmann Vitopend 100-W A1HB001

One of the best gas turbocharged boilers for heating a private home and another reference German model with a capacity of 24 kW. Like the previous Vaillant turboTEC, it is highly reliable and durable, while the boiler is absolutely not demanding on the quality of the coolant and the pressure in the gas line. Efficiency – 91%, maximum gas flow – no more than 2.77 m 3 / h.

A serious advantage is the presence of a programmer that allows you to set the boiler operation settings for the next day or week, for example, setting the temperature to 15°C during working hours when the owners are not at home, which will significantly reduce operating costs.

The only common problem is the boiler turning off due to icing of the chimney at frosts below -17-18°C. The solution is to monitor the condition of the chimney and promptly remove ice, insulate its outer part or install an anti-icing structure.

Cost: 36,010 – 43,550 rubles.

Manufacturer: Viessmann (Wisman), Germany.

Buderus Logamax U072-24

Wall-mounted turbocharged gas boiler with a power of 24.0 kW. In fact, this is another reference German model, but with Russian localization, which made it possible to significantly reduce its cost and distinguish it from analogues. Efficiency – 92%, maximum fuel consumption – 2.8 m 3 / h. The boiler is also equipped with a copper primary heat exchanger and a modulated burner.

The only drawback is the lower Russian build quality, which is not typical for other German and Italian models.

Cost: 27,950 – 34,820 rubles.

Manufacturer: Buderus (Buderus), Germany-Russia.

Navien GA 23KN

A floor-standing double-circuit turbo boiler with a power of 23.0 kW has a modest gas consumption of 2.24 m 3 / h. It is equipped with unique protection against voltage surges: with a difference of ± 30%, the SMPS chip on the microprocessor is activated, which allows you to continue working without the risk of damaging the electronics. At the same time, the boiler is equipped with a modulating burner, a programmer, and a room thermostat and remote control are already included in the factory configuration.

Notable disadvantages are the steel heat exchanger, mediocre build quality, and noisy operation relative to the above models.

Cost: 32,980 – 36,140 rubles.

Manufacturer: NAVIEN (NAVIEN), South Korea (often with Russian assembly).