If, in the case of choosing a pump, the question arose, which is better - a pump with a wet rotor or a dry one, then we will try to understand such units using the example of circulation pumps. It is known that such equipment is successfully used to create excellent and uninterrupted coolant circulation in the heating system of a private home.

In operating condition, a pump with any type of rotor forces a volume of liquid through the pipes, forcing it to constantly move forward. As a result of this effect on the coolant, we have the following advantages:

- Constant temperature indicator of radiators in all areas of the heating system;

- The absence of air locks in the system, which means eliminating the possibility of water hammer in it;

- Saving family money on fuel or electricity consumption for heating the coolant (now there is no need to fire the boiler intensively so that the desired water temperature quickly reaches the radiators in the back room of the house and warms it up). Wet or dry rotor pumps will make everything faster and more productive.

Important: pumps with rotors of all types have two openings in their design: suction and discharge. Thus, the unit does its job, moving it along a closed circuit.

How does such a unit work?

Circulation pumps have a structure similar to drainage pumps. The pump body with a dry or wet rotor is most often made of durable alloys such as brass, cast iron, stainless steel or bronze. Such metals interact well with high-temperature water or aggressive media (in the case of a drainage rotor).

The rotor itself is made of either durable stainless steel or ceramic. And the working unit (wheel with blades) is placed on the rotor shaft.

BC 1xBet has released an application, now you can officially click on the active link for free and without any registration.

The operating principle of such a device is to create centrifugal force inside the pump and looks like this:

When turned on, the rotor drives a wheel with an impeller, which rotates quite quickly, creating a decrease in pressure in the pump chamber. This promotes the flow of water into the tank. Next, the water that gets into the chamber increases the pressure and at the same time is pressed against the walls of the internal reservoir of the pump. As a result of this difference, water is pushed out into the outlet. The cycle is repeated again and again until the unit turns off.

Division of pumps with a rotor into types

All pumping equipment with a rotor can be divided into two types:

- Units with a “wet” rotor;

- Pumps with a “dry” rotor.

In the first case, we are talking about a mechanism whose rotor does not have direct contact with the pumped water. The isolation of the rotor in the pump mechanism is supported by special ceramic or metal seals in the form of rings. They protect the rotor from direct contact of components with the pumped medium. But here the principle of operation of a device with a wet rotor is that between the protective rings rubbing against each other there is a thin, barely noticeable layer of water. It helps maintain the pressure difference in the heating system and in the working chamber, and therefore ensures the tightness of the rotor compartment. At the same time, during operation, the sealing rings rub against each other more strongly, which ensures even greater tightness of the device.

The principle of operation of the circulation pump

In addition, the principle of operation of a pump with a “wet” rotor is that the device’s engine is lubricated and cooled by the water that the pump pumps.

Important: circulation units for heating or air conditioning systems with a “wet” rotor can be either single-phase or three-phase. That is, such pumps can be used both at home and in a large production or industrial enterprise.

Thanks to precisely these operating principles, a unit with a “wet” rotor has a number of advantages:

- Low noise level when pumping water through the system;

- Modest weight and small dimensions;

- Possibility of long-term operation without stopping;

- Economical energy consumption;

- Easy to install, configure, maintain and repair.

At the same time, monoblock devices with a “wet” rotor are more popular among modern consumers.

Important: but along with all the listed advantages, the efficiency of a pump with a “wet” type rotor is significantly lower and is about 55%. Thus, it is best to use such a mechanism in houses with a small area, where the closed circuit of the heating system is of short length.

If we talk about water supply pumps with a “wet” type rotor, then here too the devices will be slightly inferior to their counterparts with a “dry” rotor. But this applies only to surface aggregates.

Important: a prerequisite for high-quality operation of a pump with a “wet” rotor and compliance with the principles of pumping water is the correct installation of the unit on the circuit. Here the equipment shaft must be positioned strictly horizontally relative to the closed circuit of the heating system. Only in this case will a high-quality supply of fluid to the bearings for lubrication of working units be ensured through the sleeve.

Installation of the pump: stages and nuances during installation

The first thing to do is drain all the liquid from the heating system. Then, if necessary, the pipeline must be cleaned. In accordance with the connection diagram, work on installing equipment and fittings must be carried out. When the installation of the heating system is completed, fill the water. after which excess air is removed from the pump. This is done by opening the central screw

Please note that before each time the unit is turned on, it is necessary to carry out air removal work

When a circulation pump for heating is purchased, you need to decide on the place where it will be installed. Experts recommend installing this equipment on the return line in front of the boiler. The thing is that air can collect at the top of the boiler during operation if the pump is installed on the supply side. This may cause it to be drawn out of the boiler, causing a vacuum to form, causing that part of the boiler to boil.

If the pump is installed in front of the boiler, then water will be pushed into the heating installation. The consequence of this will be the creation of air space and the installation will be completely full. In addition, with this installation option, the pump will operate at lower temperatures, which will have a positive effect on its service life.

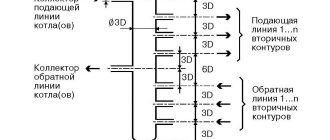

Having selected the installation site for pumping equipment, then create a bypass or outlet. The need for it is due to the fact that in the event of a breakdown or when the electricity is turned off, thanks to it, the operation of the entire heating system will not stop and there will be an opportunity for the coolant to pass through the main pipeline thanks to an open tap. When installing a bypass, it is necessary to remember that the diameter of the pipe should be smaller than the diameter of the main pipeline. When the bypass is ready, proceed to the main stage of work on installing the unit.

The heating pump shaft must be completely submerged in water. If it is only partially immersed in the coolant, this will lead to a reduction in equipment performance by 30%. In the worst case scenario, the work area becomes faulty.

In addition, the installation also includes the installation of a terminal box with a top location.

In addition, ball valves are installed on both sides of the pump. During the operation of the equipment, they will be required to perform maintenance on the pump and dismantle it if necessary.

The system must also include a filter. It will protect the unit from mechanical particles. Once inside its structure, they can adversely affect the operation of the pump.

A manual or automatic valve must be installed on top of the bypass pipe line. It is necessary to release air pockets at certain intervals.

Pumps with a dry rotor

Here, the principle of operation of the mechanism is that the rotor operates without contact with water. At the same time, the efficiency of such a device is high, reaching as much as 80%.

Despite all their productive power, units of this type have a number of disadvantages:

- High noise level during operation.

- The need for constant monitoring of the quality of the processed medium, since pumps with a “dry” rotor do not tolerate the presence of foreign debris in the water or air molecules. Such “neighbors” can break the tightness of the sealing rings in the mechanism.

At the same time, the entire range of pumps with a “dry” rotor is divided into three types:

- Block devices;

- Vertical units, in which the engine is in a vertical position and both pipes are located on the same axis;

- Cantilever (horizontal) ones, in which the engine is mounted horizontally and the pipes are located perpendicular to each other.

Types of circulation equipment, which is better?

Pumps for heating systems are divided into only two types - with a wet and dry rotor. Each has unique characteristics, individual advantages and is designed for use in specific conditions. All circulation pumping equipment is manufactured with the main goal of accelerating the movement of coolant in the system, regardless of what type of rotor it is equipped with.

“Wet type” equipment is designed for use in private homes where pipelines are not so long. The operating principle of this type of installation is simple. It begins to work, which promotes the rotation of the rotor located inside, thus accelerating the flow of coolant. The rotor mechanism rotates in a liquid medium, thanks to which it is lubricated and cooled.

“Dry type” circulation units are relevant for heating systems of considerable length. The rotor is not in contact with the coolant. The electric motor and rotor mechanism are separated by O-rings that can last no more than three years. The equipment is quite noisy, so you will need a separate room to house it. This refers rather to the disadvantages of pumping units.

Also, users must constantly monitor the quality of the coolant so that it does not contain suspended particles. The air space around the engine also requires increased attention. It should be clean, free of dust. If this is not taken care of, the O-rings will become unusable or be seriously damaged. Naturally, the result will be their inadequate tightness.

When considering a certain type of circulation units, special attention is paid to the following key aspects:

- equipment performance;

- conditions under which the equipment is planned to be operated;

- individual characteristics of the coolant, for example, how viscous or dense it is;

- coolant quality;

- advice from pump developers regarding the installation of equipment and the coolant used.

Rules for choosing a pump: “dry” or “wet” rotor

In order for the heating system to work as efficiently as possible, it is necessary to select the right pump in accordance with the parameters of the house and the characteristics of the heating system. Only in this case and provided that the mechanism is correctly installed in compliance with the principles of its operation, the heat in the house will be of high quality and long lasting.

Operating principle of a borehole screw pump

So, when choosing a pump, consider the following points:

- The total area of the house and the length of the closed circuit of the heating system;

- Number of radiators for the entire length of the heating system;

- Availability of “warm floor” systems, etc.;

- Quality and density of window metal-plastic bags;

- Insulation of walls, ceilings or roofs in a house.

Important: calculations of the required amount of heat should be carried out only by competent heating engineers, who will take into account all the important nuances and recommend a pump with pressure characteristics rated specifically for your room.

It is important to take into account that if you choose a pump for a heating system that already exists but requires modification, then it is better to buy an adjustable unit. This device perfectly adapts to the operating parameters of a given circuit.

Main characteristics of circulation pumps

The main characteristics by which the choice of circulation pump is made:

- pressure

, showing the ability of the device to raise water to a certain height; - performance and flow

, showing how much fluid the supercharger delivers per unit time.

These parameters are key in calculating the heating system. The pressure will allow you to understand whether the blower is capable of serving a pipeline network with a certain height difference. And the flow rate is calculated according to the requirements of the heating boiler for the planned volume of coolant.

All the data the user needs is contained in the markings on the front panel

. The numbers on the circulation pump mean:

- type of device (most often it is UP - circulation);

- speed control type (not specified - single-speed, S - step switching, E - smooth frequency control);

- diameter of the pipes (indicated in millimeters, means the internal dimension of the pipe);

- pressure in decimeters or meters (may differ among different manufacturers);

- installation dimensions.

The pump marking also contains information about the types of connections of the inlet and outlet pipes. The complete coding scheme and word order looks like this:

Responsible manufacturers always follow standard labeling rules. However, individual companies may not indicate some of the data, for example, installation dimensions. You need to find it out directly from the documentation for the device.

The choice of a circulation pump is always made after a careful calculation, which takes into account the type of heating equipment, the volume of coolant, elevation differences, and the minimum required blower performance.

Advice! You cannot buy products from unknown companies that copy products from reliable and popular brands. Such a pump is an ineffective investment. The use of low-quality materials, impellers, and turbines with limited service life leads to rapid failure of the supercharger. On specialized forums you can find many scary stories in photographs about the kind of technological nihilism that the housings of Chinese “no-name” products contain.

Therefore, you should choose a pump only from trusted brands. Reliable devices are also available in the mid-price category

And if you need the highest quality and have the opportunity to pay one and a half to two times more, you should pay attention to products from the brands GRUNDOFS, WILO

Principles for installing units with any rotor

In order for the circulation equipment to work efficiently, it is better to invite specialists to install it. But if you want to install the pump yourself, then follow these rules:

- The unit is installed on the return side of the boiler. That is, where the water, having passed through the entire closed loop of the system, returns back again. But this rule applies to premises whose area does not exceed 150-200 m2.

- It is important to follow the location of the arrow on the pump body when installing it. The arrow should point in the direction of the movement of warm water through the system.

- All flange and threaded joints must be treated with sealant to avoid possible leaks.

- If you are dealing with a reverse circulation heating system, then it would be useful to install a bypass - a piece of pipe that, in case of repair of the unit, can close the heating circuit after removing the pump.

Choice

Which is the best circulation pump for a heating system? When heating, the main attention is paid to such a parameter as the heat generated, which the device will provide to the room. In organizations where they evaluate device parameters, the data is evaluated using special programs, then after the calculation, real calculations are issued

Product design

One of the popular methods for choosing a pump is to estimate the area of the room that the pump can heat. According to European standards, houses with two or fewer apartments require a heating power of 100 watts per square meter. And for houses with many apartments 70 watts per meter. And depending on the quality of thermal insulation, the power parameters depend. If the thermal insulation is good, then 30 - 50 watts per square meter is needed.

For poor quality thermal insulation, high power ratings are taken.

The following data corresponds to our harsh climate:

- for a two-story house at an air temperature of minus 25 degrees - 173 watts per square meter, if minus 30, then 177 watts per square meter;

- for a building with more than two floors, 97 and 101 watts per square meter are suitable, respectively.

Popular models of pumps with a wet rotor

The most popular units for transporting water with “wet” type rotors are products manufactured by German, Danish and Canadian companies. The Wilo pump occupies a special place among the range of products.

The devices have a threaded connection and are equipped with a speed control system to control the performance and power of the pump. Wilo units are used in heating and air conditioning systems, as well as in cold water circulation systems in enterprises.

Grundfos pumps

Another leader in the modern Russian and global pumping equipment markets. Such pumps are characterized by high performance and reliability. Thanks to careful assembly by meticulous Danes, the units operate without failures or breakdowns for a long time.

Distinctive features of such mechanisms are:

- Absolute inertness to water and anti-corrosion properties of the metal;

- No need for frequent preventive maintenance and repairs (the wet rotor does its job);

- Reliable sealing of the housing.

Important: Grundfos pump casings are equipped with a special heat-protective casing, which prevents the risk of possible burns to the user.

Installation

Installing a circulation pump in a heating system will not take much time if you have the necessary tools and the necessary skills:

- keys in a set with sizes from 17 to 36;

- bypass, filter, check valve;

- "American" carvings.

To connect the pump to the heating system, follow the following guidelines:

Installation options

- Technical parameters of the pump, which are calculated as shown above;

- Connecting the mechanism to the return pipelines will ensure the operation of devices with chilled water. This will extend the service life of the products. also connect to the return pipeline;

- When the heating boiler is turned off, the inlet and outlet valves on the pump pipe are closed. Then the product should be installed in a horizontal position, tightened using “American” nuts. Vertical equipment will create excess noise during operation.

Important advice: when installing a gasket, it is better to choose one made of paranite, because rubber ones will become unusable when the temperature rises.

- Installing a circulation pump will be an addition if the circulation is natural. Here you should also purchase a filter and “American” nuts with a diameter suitable for the device. For closed wiring, a check valve will be needed, but for open ones it is not needed at all;

- When installing, do not forget to install taps, which will be useful when repairing the system. The bypass line, when installed, will allow circulation to continue when the device is removed and even in the absence of electricity.