Return to list of questions.

1. When can you turn on the heated floor?

The hydraulic part (mixing unit, manifold group, pipes) can be turned on immediately after installing the last connection and filling the underfloor heating system with water.

This will allow you to see the operation of the units “live” and check the circulation in each circuit for the absence of foreign objects in the pipe.

However, we would like to warn against introducing hot coolant into the circuit openly without a screed, as this will lead to thermal elongation of the circuit and displacement of the pipes themselves, which in some cases contributes to the detachment of the fastening pins from the polystyrene foam.

2. How to turn on the heated floor correctly?

Correct inclusion involves two important components:

bringing the temperature of the heated floor coolant to the calculated (design) operating mode. Commissioning of the system begins with the temperature of the coolant supplied to the input of the distribution manifold equal to 20 - 25 o C. Then every day the temperature is increased by 5 - 10 o C, bringing it to the design value.

3. If the system defrosts, what will happen to the underfloor heating pipes?

If the pipes are made of metal-plastic, they will become unusable.

If the pipes are made of cross-linked polyethylene, nothing will happen to them.

4. Is it necessary to drain the water from the heated floor in the summer?

There is no need to do this. Just like there is no need to drain the water from the entire heating system in the summer.

There is such a thing as “dead” water. That is, water that no longer enters or enters into minimal chemical reactions with the elements of the system.

Fresh water containing oxygen and other chemicals dissolved in it, when first filling the heating system, begins to interact intensively with all components. After some time, this process gradually ends. This kind of coolant is especially “valuable” for heating.

5. How to drain all the water from the underfloor heating circuits?

The reasons for the need to drain water from a heated floor system may be different. One of them is deep conservation of the heating system without switching it on during the next heating season. Another is related to the impossibility of quickly repairing a failed unit or element of the heating system (there are no spare parts for the boiler).

To drain water from underfloor heating pipes, you need to use an air compressor. Where should I connect the compressor hose? On the collector (especially if the entire collector block, as a ready-made single element, was produced by the manufacturer and was not assembled on its knees), in addition to shut-off and control valves, there are also valves for draining water from the collector, one on each. So we will use them.

Why do you need to remove air?

The formation of voids reduces the efficiency of the heating system. Pumping equipment, like other components, operates less efficiently. To ensure comfortable indoor temperature conditions for users, more resources have to be spent.

As such voids increase, the pressure gradually decreases. After reaching the maximum minimum level, the corresponding signal is sent to the boiler control unit. In addition to electronic devices, mechanical means for similar purposes are used. This is an emergency situation, so the automation turns off the supply of gas or other fuel.

To turn it on again, you have to manually increase the pressure. But there are a lot of gaseous inclusions in fresh water, so negative processes are accelerated. The equipment will turn off more often.

It should be remembered that oxidation, which destroys metals, occurs in the presence of water and oxygen. Adding a new coolant activates the corresponding negative processes. In this operating mode, the durability of heating equipment is reduced.

It is necessary to exclude the appearance of air “plugs” in the heat exchange units of boilers. These parts are exposed to very high temperatures.

The reasons listed above are enough to understand the need for preventive measures. Carrying them out will prevent complex breakdowns and costs associated with restoration work.

Types of heating systems in private homes

Residents of apartment buildings do not have to start the heating system themselves. Before starting repairs, specialists will warn all neighbors about the work and drain the liquid from the entire riser. The filling will also be carried out by services that maintain communications.

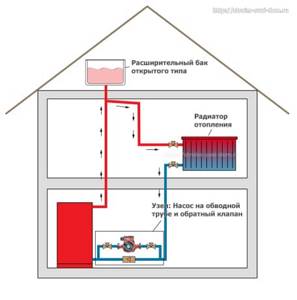

In a private house, heating can be installed in accordance with one of 2 standard schemes:

- Open.

- Closed.

An open network, also called gravity, is built without installing circulation pumps that circulate the coolant inside the network. The fluid circulation is carried out due to natural processes: hot water rises upward, where in the expansion tank installed at the top point the carrier comes into contact with air. The cooled water drops to the lower part of the circuit, to the boiler, and is supplied for heating.

Open systems are installed extremely rarely. You can find “classics” only in houses where old boilers, metal pipes and cast iron radiators are used for heating. The volume of coolant in these types of heating networks is large, and accordingly, energy consumption is not economical.

Closed circuits are heating with the connection of pumping equipment, which ensures constant circulation of hot water within the system. Energy consumption (gas or electricity) is minimal, because the volume of liquid is only a few tens of liters. Due to the constant movement of water, the boiler is turned on only to heat the coolant to the set temperature.

Technical subtleties and nuances

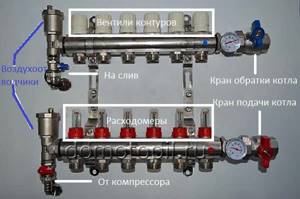

In preparation for draining, it is necessary to study the structure of the collector in order to find and mark on the supply and return the location of the valves, marked as follows:

- servers are red;

- reverse flow - blue.

If you confuse the supply with the return, the drain system will not work - the check valve will block the pipeline.

If there is no receiving container, then you can connect the drain hose to the return valve and stretch it to the nearest sewerage intake - a toilet, sink or drain.

Collector unit for a warm water floor system

Having finished draining water from one circuit, empty all the others in the same way. When draining a section of the system, the valves of the remaining circuits must be closed, and at the end of each stage, the taps of the emptied pipelines must also be closed.

To completely empty the circuits, the purge procedure can be repeated after an hour - when the moisture from the walls of the heat pipes has drained and accumulated in some area.

Video: subtleties of filling a closed system

By observing caution and starting rules, you can independently cope with adding water to the old system. At the first start, the inspection and filling must be done by the technicians who installed the heating. If you do not have the skills, do not try to fix the leak or replace the coolant in the circuit yourself. Entrust the work to a specialist - the master will select the optimal media, a cleaning agent that will not damage the internal surfaces, and will correctly fill the system.

Indeed, before you start replacing heating appliances in your apartment, you need to turn off the central heating riser and drain the water from the heating system. There are no other options, because even in summer there is residual water in the batteries.

You can entrust the process of draining the coolant only to representatives of the management company servicing your home, or hire another specialized organization, while coordinating the shutdown with the management company.

In this case, you will have to pay for the service provided in both cases. The cost of turning off the riser for each area and even for each house may vary - the final price is determined by the management company of the house. The fact is that prices and tariffs for services and work performed by housing services at the request of residents are not regulated by the state in any way. Therefore, each office has its own tariffs.

The cost of the work is indicated in the price list for paid services, which you can view by contacting the management company of your home. In addition to the service of disconnecting the riser itself, a fee is also charged for draining the coolant (water) in the radiators, as well as for filling the heating system after all the work has been carried out. These two components (runoff and physical water) are set by state tariffs (in practice, their cost is averaged), which, just like for the drainage/filling service, you need to pay to your management company.

In addition, if the riser is turned off during the heating season, then the payment will be added hourly. In winter, the riser can be turned off for a maximum of three hours (to avoid freezing), but usually only an hour is enough for repair work. If the temperature outside the window drops to minus 30 degrees, then turning off the risers is prohibited!

With the onset of the first cold weather, most owners of private houses and summer cottages need to drain water from the pipes of their plumbing and heating systems. Many people think about how to drain water from pipes with their own hands, they think that it is very difficult, and the help of experts is needed. In fact, it is possible to do this on your own.

In order to properly drain water from water pipes, their design must include the following details:

Draining water in stages

Warm floors are a closed system, so you should take care of the drain taps during installation work. The number of valves must be equal to the number of water circuits.

- This is basically a long hose that is laid on the floor. Laying option, i.e. the configuration of the circuits may be different, but the liquid circuit operates on the same principle - the coolant transfers heat to the surrounding space by heating the floor surface.

Before draining, the heating system must be turned off, then wait the time required for all its elements to cool completely.

Taking into account that the water circuit is connected to the main pipeline, and the connection point is located above the floor level, the water is drained forcibly using an air compressor.

The power of a household vacuum cleaner to drain liquid from a water heating system is not enough.

Emptying is carried out through a return line equipped with a drain valve, and the compressor is connected to the manifold on the inlet pipe; because of this, the check valve can create certain interference when purging the pipe.

After connecting to the collector, the compressor starts to displace the coolant from the circuit and the air supply pressure is slowly increased - until the point after which liquid begins to flow out at the outlet. Do not forget that the volume of water in each of the heated floor circuits is not that large, so an ordinary small container of 8-10 liters is enough to receive it.

The compressor must be turned on until air begins to flow continuously from the pipe immediately behind the water.

When you do not have the opportunity to use a compressor, you can use another method to empty the system of liquid and thereby avoid defrosting the heating system. A suitable size hose 1 meter long with a funnel at the end is put on the inlet of the heat pipe. The end with the funnel needs to be raised higher and antifreeze slowly poured into it (it’s better to take a brightly colored one). Gradually, water will begin to flow from the return pipe, and then liquid. The procedure will take time, but you will not regret the effort.

Replacing coolant in a standard closed home heating network

Starting a heating system in a private house with water filling is carried out using complex technology. To work, you will have to buy or borrow special equipment and follow the instructions. If you are not sure of the integrity of the circuit, or there is visible damage to the elements, be sure to call a specialist.

Preparatory stage: what is needed for work

Before filling the heating system in a private house, determine the method of filling the liquid into the circuit. There are 4 options to resolve the issue:

Heating circuit refill unit

The tools you will need are wrenches of the appropriate diameter for dismantling the tank, a pump if you plan to fill the distillate, and sealing tape for connections. If you are deciding how to start heating in a private house after a period of inactivity, or you need to replace the old media, you will have to purchase a special cleaning agent.

Checking tightness: how to do pressure testing

The old network must be checked for leaks and leaks. Also, a mandatory check is carried out when heating is started for the first time. The pressure testing stage should not be neglected, especially if the house has areas with underfloor heating that will be located under screed and decorative covering. Fixing a leak after the repair is completed is expensive and difficult.

Before checking the old heating, drain all the water. To drain the media, open the tap. You need to act slowly and carefully. Before draining, be sure to check the water temperature - the media must cool to 30 o. The drain valve is located at the lowest point of the circuit.

Important! Use a measuring container when draining the coolant to find out the exact volume of liquid. There will be no question about the amount of water that needs to be poured into the heating network.

After drying, open the air valve - the Mayevsky tap. The air will fill the circuit and equalize the pressure inside the system.

They begin crimping. Use a pump: connect the hose to the inlet pipe. The valve at the top point is left open so that air can escape freely.

The liquid is pumped until a pressure exceeds the operating value by 1.5 times. That is, if the operating pressure is 1.5 bar, when checking it is necessary to increase the indicator to 2.0 - 2.25 bar (but not more than the maximum value allowed for the boiler).

Close the top valve after water begins to flow from it. Assess tightness. Check the dryness of all difficult areas:

The liquid is left under high pressure for several hours: if no leakage appears during this time, then the heating is in order.

There are two ways to create excessive pressure: liquid (water injection) and dry (air injection). The difficulty of checking it yourself is that when pouring water, an unpleasant situation may arise if there is a break in the circuit (crack or leaky connection). It is better to entrust the crimping to a specialist.

Are you planning to use water as a coolant? Simply drain the excess amount until the pressure drops to an operating value of 1.5 bar.

Flushing your home heating system

Cleaning must be done:

Before washing, dilute the cleaning agent with water in the proportion specified in the instructions. Pour in the product using a pump and fill the circuit with water.

Washing is a mandatory procedure

Leave for several hours. During this time, the solution dissolves the sediment accumulated in the radiators and removes deposits from the internal walls.

After flushing, drain all the liquid and begin filling the system. Flushing is also mandatory before filling a closed heating system with antifreeze.

Filling with coolant: step by step

Before you start pouring liquid, measure out the required amount of coolant. If synthetic solutions are used, prepare the mixture by diluting the concentrate with distillate to the required volume. Before connecting the pump to pump coolant into the heating system:

A pump is connected to the pipe through which the liquid will be poured. Typically, pumps are equipped with flexible hoses with threaded connections. The water intake hose is lowered into the container with the carrier.

Begin filling the system. It is important to select the optimal pump power, avoiding filling too quickly. At the same time as drawing water, keep an eye on the open tap. Filling is stopped after the carrier begins to flow out of the open Mayevsky tap.

Checking and preparing for launch

The last step before starting the heating is removing excess air and checking. It is necessary to bleed any air remaining in the circuit from all air valves. To do this, open the taps at the extreme points one by one and release the air. The taps are turned off after water starts flowing.

When all the air has been bled off, check the pressure indicator. Normally, the readings of all pressure gauges installed in the circuit should match and be at 1.5 - 1.8 bar. When using antifreeze, the indicator is sometimes increased to a maximum of 2 bar.

After checking the pressure, turn on the boiler. At a carrier temperature not exceeding 40 o, the system operates for up to 1 hour. Then the heating is turned off. After cooling, perform another test at a higher temperature. Heat the carrier to 60 - 70 o. In this mode, the heating is left for 2 - 3 hours.

Why do you need to drain the water and when is the best time to do it?

Water from the boiler must be drained in the following cases:

- If the water heater is located in an unheated area, the tank must be emptied before winter arrives. With the onset of frost, the liquid will begin to turn into ice and increase in volume, which can lead to serious damage to the device and loss of its functionality.

- If the warranty period for the boiler has expired, and the structure needs to be repaired or the magnesium anode replaced, the water must also be drained. All such procedures are carried out only with a dry and clean tank. It is worth noting that during the warranty period you cannot carry out repairs yourself, otherwise the warranty will become invalid.

- At least once every 5 years, the water heater must be descaled. If the water supplied to the tank is not of good quality, it is advisable to carry out a similar procedure more often. The sediment that remains in the tank interferes with the rapid heating of water, which means that the boiler consumes more electricity to operate.

Now I would like to consider cases when there is no need to drain water from the boiler:

- When turning off the water heater during the warm season, it is not recommended to drain all the liquid from the tank. If the device is not threatened by frost, it is better to leave some water in the container - this will protect the interior of the tank from corrosion. In addition, if, out of forgetfulness, you plug in an empty boiler, a fire hazard may arise.

- If the device has been left unplugged for some time and the water in it has stagnated, it is also not worthwhile to completely empty the container. Stale water simply needs to be refreshed by filling the tank full several times. It is advisable to repeat this procedure every 3 months, running 100 liters of cold water through the heater.

- If the unit is still covered by the warranty, it is highly not recommended to drain the water, much less repair any parts yourself. In such a case, the warranty will become void. If problems arise with the boiler, it is better to simply call qualified specialists. They will drain the water themselves, fix the breakdowns and do it for free.

You can use a suitable container to drain water from the boiler.

Installing a new accumulator membrane

If water is detected in the air compartment, urgent measures are taken to replace the membrane. It serves as a fuse between the two main components of the device, the storage and air chamber. To get to the membrane, unscrew the flange with the water supply fitting. The membrane is removed. The tank is dried and a new part is installed.

During installation, sealants are used.

They coat the area of contact between the flange and the membrane. This allows you to organize the correct operation of the water supply system, protecting the tank from loss of air pressure through an unprotected joint. After all the work has been completed, the hydraulic accumulator is connected to the water supply and drainage pipes. If the membrane is replaced not before the winter period, the device begins operation.

When winter weather sets in, around the end of October, it is imperative to drain all the water from the water supply system of the dacha. If the water is not drained, the system will fail, the taps will burst, and the storage water heater will simply burst.

In all of our plumbing installations, we provide two valves for draining water from indoor pipes, a drain valve on the water heater, and drain valves in the well or borehole.

It will take us a little time to drain the water:

1. It is necessary to de-energize the electrical system by turning off the water pump circuit breaker or unplug the pump from the socket in the well or near the well.

3. Open taps 1,2,3,4 (see diagram below) - if they were closed for any reason and all taps (mixers) on all floors of the cottage or house, wait until all the water from the water supply drains into home.

4. Open the drain screw in the well to drain water from the main line. If you have a drain valve installed, the water will drain automatically when the pressure drops to 0.2 atm.

5. Unscrew the bottom part of the filter (such a transparent flask) after placing a basin or other container of at least 5 liters - it contains water!!! Discard the used internal filter. Install a new one next year. Do not screw the removed flask onto the filter for the winter!

6. To be safe, you need to drain the water from the sink siphon.

7. Don’t forget to drain the water from the toilet tank and the toilet itself.

1. It is very desirable that when draining the water, the water in the tank is cool and not hot. Therefore, the water heater must be disconnected from the electrical network one day before.

2. During installation, we always install a drain tap (6) and a safety valve (5). If the drain valve (6) does not have a flexible connection (optional), install it. With a flexible hose, it is more convenient to drain water into a container located on the floor. The volume of water drained is equal to the volume of your water heater!

3. Wait until the water is completely drained from the water heater drain tap. Now some water remains in the safety valve (5). To drain water from the valve, turn the lever on the valve up. Note: On some valve models, the tab is held in place by a small screw. The screw must be unscrewed, the water drained and put back in place.

If your country house is designed to freeze during the cold season, then you need to drain all the water from the water supply and all water-containing units every time before leaving the house. The concept of freezing the house in winter has its pros and cons.

to the cons

Constant heating of a seasonal home involves energy and therefore financial costs, the risk of power failures and freezing of un-drained water in the water supply, and the risk of fire of electric heating devices.

The disadvantages of the concept of freezing a house

include increased wear and tear on the house’s structural elements and interior decoration with more frequent crossings of zero, and the need for labor to drain the water every time before leaving.

The advantages of the freezing concept

include cost savings and reduced risk of accidents and fires.

In general, the optimal mode of operation of the house depends on your lifestyle: if you come to the dacha every weekend in winter, then it is more advisable to keep the house heated: +5C using electric floors, for example, as one of the most economical and safe means of heating. Before arriving at the dacha or in severe frosts, you can turn on additional convectors via SMS in advance (if you install the appropriate controller), which will raise the temperature in the house. If you don’t come to your dacha in winter or come a couple of times in half a year, then there is no point in keeping the house heated. To prevent the pipes from freezing, the water from the water supply must be drained.

Draining water before winter

In order to minimize the labor intensity of draining water from the water supply before winter, you need to think through several important details before designing the water supply and sewer system.

What you need to provide for convenient regular drainage of water:

1.

A tee and a drain valve in front of the check valve in the pipe supplying water to the house (in a well or in a well caisson.

2.

In case of emergency freezing or winter operation, pipes must be made of a material that does not break during expansion - for example, low-density polyethylene, polypropylene, etc.

3.

In each branch of the pipe distribution in the house, install a tap at the bottom point to drain the water.

4.

If it is impossible to reach the lowest point of the water supply system (the pipes are sewn into the floor and there is no basement), provide tees for connecting an adapter to a car compressor for purging each branch of the pipeline.

5.

When connecting the water heater, provide a tee and a tap for draining water with a hose attachment to the check valve on the pipe entering the water heater. And the same tee with a tap on the outlet pipe from the water heater for quick air supply when draining water.

6.

When the volume of the water heater is over 50 liters, provide a sewer branch that does not go into the septic tank in order to prevent the death of the septic tank microflora when discharging a large amount of boiling water. Or drain hot water through a hose into the street, but not into the septic tank.

7.

Selection of mixers. If possible, use traditional ceramic or rubber-sealed faucets rather than single-lever faucets, which are sensitive to residual water freezing.

8.

Expansion membrane tank. The amount of residual water in the rubber bulb after draining the water should not cause damage due to freezing. The author tested this on his tank - the tank survived 5 winters, but on the 6th the rubber bulb had to be replaced.

9.

Location of the washing machine. Don't forget to drain the water from washing machines, dishwashers, etc. devices. Unfortunately, simply draining the water is not enough in this case—you will need to manipulate it by turning the washing machine over or blowing it with a compressor. Therefore, when choosing a place for it, ensure easy access to it.

Below is an illustration of how to drain water from a simple temporary water supply system that is not specifically prepared for draining water before winter.

| First step: drain the water from the supply pipe. For this purpose, we have a tee and a tap in front of the check valve in the well (1). Use a long stick (3) to open the tap (2). We hear the gurgling sound and observe air bubbles rising from the tap: the water is drained. | Second step: draining the water heater. It is good to pre-cool the water. If there are no special drain taps, unscrew the safety valve on the supply pipe (on the right) and connect the hose to drain the water. Then we loosen the nut on the outlet pipe - air leaks in and water from the water heater begins to drain into the hose. |

| If there are no special taps for draining water from the water supply system, disconnect the pipe joint at the lowest point and drain the water from the pipeline. | If there is a special tap for draining water, use it. |

| Disconnect the drain and supply hose of the washing machine. We drain the water from them. | Turn the washing machine upside down. This will get rid of any remaining water in the lower points of the drain system. We leave the washing machine in this position for the winter when leaving for a long time. (I'm not kidding!) |

| Draining water from the washing machine. The remaining water is hidden in a corrugated pipe leading from the tank to the pump: we squeeze the tube like a pear and blow out the remaining water - it will come out through the drain hose. | We disconnect the supply pipes of the flexible shower cabin. We drain the remaining water from them. |

| We remove and blow out the rain shower head - there is always water left in it. We put the watering can in place. | Draining water from the shower stall. We begin blowing out the shower taps. Remove the shower head and place the three-way valve (1) in the hand shower position. And alternately open the hot and cold water tap (1), blowing the pipes through the shower hose (for blowing, you can use a compressor, a frog pump, or the power of your lungs). Then we alternately change the position of tap 2 to drain the remaining water in it. |

| The most enjoyable part of the job is draining the water from the toilet: for this you can use any household pump (bicycle pump, sprayer, enema, Janet syringe). Let's scoop everything out clean. If your sewer system tends to emit pleasant odors (my septic tank does not smell), then pour antifreeze into the toilet. In the spring it will also need to be pumped out, and not drained into a septic tank. In addition to the toilet, water will need to be removed from sink siphons and drains in the floor. | Draining water from the filter: Remove the fine filter housing (it is unscrewed clockwise) and the coarse filter housing. Pour out the water and throw away the used cartridge. |

| Draining water from the pumping station: Open the main plug on the pump housing of the pumping station and drain the water into a previously prepared container. | We unscrew the plug on the side of the pump housing and thoroughly blow out the pump, getting rid of any remaining water. If you use a submersible pump in a well or well, then do not worry, the water there will not freeze in normal winter conditions. |

The reasons why it is necessary to drain water from a heated floor may be different. Starting from the planned replacement of the coolant with a new one, when the water is already quite dirty and contains a large amount of rust and other impurities (although we have already considered heated floors without draining the system, so anyone planning to drain the heated floor for this very reason, feel free to follow the link), or when the heating system antifreeze has expired. Finishing due to some emergency situations, when it is deep winter outside with low sub-zero temperatures, and a long period of downtime of the heating system is expected when it is turned off, due to the lack of materials or equipment to repair the system or a long shutdown of heat, gas, and electricity supplies. At this moment, the owner of the house has an idea about how to drain the water from the heated floor so that it does not freeze. At the same time, this must be done quite quickly, especially if the circulation pump or other equipment has failed, in which there is no circulation of coolant through the system. In this situation, cold bridges are formed in the places where the floor adjoins the external walls and the water in the pipes in these places can quickly freeze, which will make it impossible to start the heated floor before the onset of heat. If the heated floor is made of a metal-plastic pipe, defrosting will lead to a rupture of the pipe, and of course to large financial costs for repairs.

The difficulty of draining water from a heated floor is that it does not have a lower point for draining the system, as in a conventional radiator heating system. Therefore, water from the heated floor will not flow by gravity and because of this, you have to resort to other solutions.

Why drain the water?

There are many reasons why you may need to drain your underfloor heating system. For example, this procedure should be carried out if the owners are away from home for a long time, or when there is a need to replace water as a coolant with antifreeze. Everything must be done correctly so as not to violate the integrity of the system. Below we will consider the rules for draining liquid.

Often this need arises when preserving the heating system for the winter. This procedure is often carried out in summer cottages and in houses outside the city that have been empty for a long time. To simplify and speed up the draining process, a special technique is used.

Remember that water in houses with seasonal use must be drained. Otherwise, frost will cause the system to freeze. That is why the use of antifreeze as a coolant is more preferable - in addition to resistance to low temperatures, this solution also protects pumps from excessive wear.

Another, also important point when using heated floors is preventive maintenance in the heating system. The water from the boiler contains many impurities, which, when heated, precipitate or form deposits on the walls of the pipeline.

Due to a decrease in the internal clearance of heat pipes, the circulation of the coolant in the system is disrupted, and the heat output becomes lower. Therefore, experts recommend draining the coolant from the system at least once a year when using water.

A liquid circuit that is filled does not have this problem. In this case, the coolant can be replaced only once every 3-5 years (the main condition is that the boiler operates without overheating; for heated floors, the maximum threshold for permissible liquid temperature is 45-55 °C).

Another reason why it may be necessary to drain the water is the loss of the liquid’s own physical properties. The antifreeze parameters change after overheating - the solution begins to form foam. When foam fills individual sections of heat pipes, it disrupts the circulation of the coolant in the system and heat transfer becomes lower.

Inconsistency in the installation technology of heated floors and the use of materials that are not intended for contact with chemicals contribute to the formation of corrosion in the heating system. As a result, the circulation of the coolant is disrupted and leaks in the water circuit appear.

Of course, you will have to drain the water from the heated floor circuit when replacing it with antifreeze.

These are the main reasons when systems need to be drained

And no matter what the base, water drainage must be carried out in accordance with all the rules, following safety precautions and the technological sequence of all points

Composition and order of preventive work

To maintain the functionality of water heating, there is a whole range of measures. Certain types of work are carried out at different intervals.

Performed annually:

- Preventive inspection of gas boilers.

- Checking the functionality of the automation.

- Boiler room alarm test.

- Chimney inspection/cleaning.

- Heating pipeline inspection.

Once every 3-5 years the following may also be carried out:

- High pressure system testing.

- Chemical flushing of the system.

- Replacing the coolant.

- Calibration of automation devices.

It is clear that the frequency of some work is a purely individual concept. For example, when using well and borehole water for heating, it is recommended to carry out annual flushing without chemicals, and if you have a plunger pump, test the system annually with high pressure. More specific recommendations are provided by equipment manufacturers and the organization that installed the system.

Consequences of air jams

Possible consequences depend on the installation object, as well as the design features of the heating system.

- Warm floors from a centralized heat supply source: partial or complete cessation of heating, possible freezing of pipelines in corner rooms;

- Houses with heated floors and heating appliances from a centralized heat supply source: partial or complete cessation of floor heating;

- Warm floors from an individual heating source: partial or complete cessation of heating, possible emergency stop of the boiler and freezing of the heating system;

- Houses with heated floors and heating appliances from an individual heating source: partial or complete cessation of floor heating, frequent boiler shutdowns.

Considering the specific design of the “warm floor” heating system, namely: the presence, depending on the area, of one or several water circuits per room and separate wiring for each room, complete cessation of circulation is almost impossible.

Only if air jams occur on all horizontal branches in all rooms at once will the movement of the coolant and the functioning of the system stop.

How to protect the system from freezing?

In addition to being able to drain the water, the system must be protected - at least partially - from frost. Not only a simple drain of water can save an individual water supply system from freezing - modern materials and technologies are at your service. To protect water shut-off valves from freezing of residual water, use faucets with ceramic parts and taps with rubber seals. The most resistant to water freezing are pipes, as we said above, not made of steel, but of low-density polyethylene (HDPE). Flexible plastic can withstand some increase in the volume of internal ice without collapsing, but it is still safer not to test the water supply for strength and remove all water from the water supply system before the onset of cold weather.

Lay water supply pipes from the well to the residential building along the bottom of a trench dug to a frost-free depth. This guarantees complete protection of the external water supply system from any frost. The pipes must be sloping towards the water source so that the return flow occurs unhindered. Protect pipes that go to the surface - for example, a short section of pipe from a trench into a house - with a heating cable.

Draining water from the water supply system for the winter will not be difficult if this function is initially included in the design of the external and internal water supply. A technically competent solution to this problem is only possible if the design and installation of pipes for individual water supply are entrusted to professionals.

How to drain water from a heated floor - methods and features of the work

Installing underfloor heating means long-term and stable operation of the heating system. This system is equally convenient in a city apartment, in a country house, and in a country house. Such a floor can be installed in almost any residential space, but its operational efficiency is affected by the compliance of the technical characteristics of the products with the design features of the room. Correctly carried out calculations and correct installation of heating circuits, high-quality pressure testing of a heated floor heating system allows property owners to forget about servicing heating equipment for a long time.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery throughout the Russian Federation and CIS countries.

But nothing lasts forever, and any product may require repair work. Warm floors are a complex complex of very different equipment; a malfunction in one of the elements can cause a breakdown of the entire heating system.

Sometimes, for example, if there are problems with the throughput or tightness of such a floor, or when preserving a house, it is necessary to drain the water from the heating circuit.

In the article we will look in more detail when this procedure is required and how, in principle, to drain water from a heated floor.

Draining water from heated floors

Materials, equipment and procedure for draining water

To perform the necessary work, you will need a compressor, and of good performance, with a receiver for storing compressed air.

As you already understood, a car one is not suitable for these purposes.

If you are planning to drain used antifreeze, then you yourself understand that it is not worth draining it anywhere.

Clamps of the appropriate size for a reliable hose connection will also be needed.

Connect the hose from the compressor to the underfloor heating supply manifold.

The supply manifold may or may not have a special fitting in its design for filling the system under the hose. Therefore, the automatic air vent is unscrewed on the supply comb and a hose is connected through a suitable adapter and tightened with a clamp.

Arrangement of elements on the manifold for draining

- In the same way, connect the hose to the return manifold and lead it to the drainage point.

- Close the supply and return valves coming from the boiler in the manifold area.

- Using flow meters or valves (depending on your collector), close all underfloor heating circuits, except one, which, on the contrary, needs to be opened to the maximum.

- Turn on the compressor, open the valves or tap (depending on the type of comb) that are designed to fill and drain the system (those with hoses on them). At this moment, the coolant will begin to flow out of the drain hose under pressure. Wait until the water runs out and air comes out. At this point, pay attention to the pressure gauge on the compressor. If the pressure in the receiver at this moment is not high (1-3 atm), then close one of the taps on which the hose is attached (preferably, it would be a tap on the supply manifold, or if the pump is equipped with its own shut-off device, it is better to use it) . Wait for the pressure to rise to 5 atm. (no more) and blow out the floor loop under this pressure.

- Close the blown circuit and open the next one. Repeat the same procedure with him.

- In this way, drain the water from all underfloor heating circuits.

- For better efficiency, repeat the procedure after half an hour, since the remaining droplets of water in the pipe can connect with each other and eventually block the cross-section of the pipe in a certain place.

By following this method, you will solve the problem of how to drain water from a heated floor. The only problem is getting a compressor that can handle this task.

Self-pressure testing of underfloor heating systems

First launch of a warm water floor

Rules for installing a heated water floor based on a concrete screed

How to flush a heated floor heating system and how to completely flush the heating system in a private house with your own hands

Installation of water heated floors without concrete screed

Warm water floor system technology

The role of the hydraulic accumulator in the water supply system

The hydraulic accumulator reduces the frequency of switching on an important component of the water supply system - the hydraulic pump. The electric motor is subject to minimal wear, thereby increasing its service life.

Another important property is the volume of the hydraulic tank.

It has a reserve of liquid in case of a pump or power outage or in case of breakdowns of the water supply system. This function is convenient for its use in suburban areas where there are problems with power supply. The hydraulic accumulator protects the water supply system from water hammer that occurs when the pump is turned on and maintains the required level of pressure in the pipes.

Hydraulic tank - a vacuum reservoir required for liquid

Hydraulic tank is a vacuum reservoir for liquid. When it is taken from the system, the pressure in the device drops. At this moment the pump automatically turns on. It works until the required pressure in the system is reached. During operation, some parts of the accumulator require replacement and scheduled repairs. Therefore, the surface of the hydraulic tank is regularly inspected for problems. If malfunctions are identified, measures are taken to eliminate them.

Formation of air masses in a heated floor system

A pump is needed to bleed the system.

How to bleed air accumulated in the system will depend on the incident that led to such a result.

Some circumstances require immediate intervention, while others are not capable of causing significant damage to the system.

If the heated floor was installed with noticeable differences, it is worth acquiring an additional pump for pumping the coolant.

Running the circulation pump will also help expel excess air. The more air has accumulated, the louder the circulation pump will work.

It is worth paying attention that the system must be pumped at maximum speeds. This will significantly save time and allow you to completely remove air from the system.

If it was recently pumped, but the air has already collected again, the problem may be in the pump itself.

Air vent

With the comb installed, each circuit is closed in turn, and the air vent must be open on each of them. It is necessary to bleed air gradually, so after cleaning the first circuit, the next one opens. The descent is carried out in stages and at the moment of bleeding only one circuit should be open.

If this procedure does not give the expected result, the next air release should be carried out no earlier than in a few days.

To properly clean the system, a person must understand the structure of the comb and understand the principle of its operation. If you do not have the necessary knowledge, you should seek help from specialists. watch the release of air in this video:

Replacing the coolant: reasons and frequency

Replacing water in a closed and open heating circuit is carried out:

After installation, the system is filled and started

Regular topping up of liquid is required during operation if it has not been drained after the heating season.

Why drain your home system?

A question for which there is no clear answer is whether it is necessary to drain the circuit annually after the end of the heating season? The decision depends on the type, age and material of manufacture of the main elements - pipes and radiators, as well as on the total volume of liquid.

Each type has its own frequency of media replacement

Most often, systems with old cast iron radiators are drained for the summer. The reason is the appearance of a leak after the boilers are turned off. The old cast iron ribs are connected to each other by threaded connections with old gaskets. When there is hot water inside the batteries, the seals expand, providing a stable seal at the seams.

After the water cools, the material from which the gaskets are made naturally contracts and begins to flow at the junction of the ribs. But prolonged idle time of old radiators without water is fraught with accelerated corrosion; the rust inside the radiator and old pipes crumbles in a dry environment, and can damage the entire riser.

In closed new circuits, filling the heating system is not a costly process. But it is not recommended to completely drain the liquid every year - this is not necessary.

Frequency of replacing and topping up fluid in the heating system

How often do you need to change the fluid in your heating system? A few general rules:

If a leak occurs, it is necessary to drain the water and carry out repairs.

The frequency of filling with new liquid depends on the characteristics of the water, the service life of the synthetic coolant, and the general condition of the system. If the extreme points are very airy, it is recommended to identify the cause - find the location of the leak and check the tightness of the heating network. Typically, water changes are carried out every few seasons.

Emergency situation

By emergency we mean a case where the battery leaks. Again, if there is a tap that turns off the battery, turn it off and drain it; if not, you cannot do without calling a plumber.

The battery does not heat up

Cold water in the radiator, although the heating has been turned on a long time ago? Means, . In theory, your radiators should be equipped with a Mayevsky tap. If your battery is installed correctly (the angle in which the valve is installed should be slightly higher), then when you open the valve to bleed off excess air, only air will come out; as soon as the water starts flowing (don’t forget to immediately replace the jar), it means that the air has escaped and there is no more plug. If the radiator is installed completely horizontally, you may have to drain more water.

The rifar radiator has special drain taps

The Mayevsky crane is not installed? Perhaps it is better in this case to turn to specialists. Why?

Equipment tends to break down over time. Imagine that you managed to cope with coking and drain the water. But closing them is no longer possible.

Can you imagine what consequences this will lead to?

- Firstly, you will flood your neighbors, and you will still have to call a locksmith to turn off the heating in the entire house.

- Secondly, you will leave the entire house (or at least the entrance) without heating for quite a long time - until the consequences of your “amateur activity” are eliminated.

- In addition, if heating in your home is provided by an individual boiler, then the contract you concluded with the service organization states that it is prohibited to drain the water yourself. This is due to the loss of the required pressure level, which is signaled by special emergency sensors.

Starting an open heating system

It is easier to fill an open heating system. No special tools needed. It is enough to determine the upper point of water in the expansion tank. You will need an assistant to monitor the air valves.

Work rules

The liquid is drained through the drain pipe located at the lowest point. If necessary, the circuit is flushed. Filling the system is performed in the following sequence:

Tank for open type heating

Continue to fill the system with short breaks so that the air rises evenly to the surface. Filling is carried out until liquid begins to flow out of the air valves. The valves close.

Add water to the expansion tank up to the mark. Do not fill the expander completely. When heated, the volume of liquid increases, and water will begin to pour out over the edges of the tank. The maximum coolant level is 2/3 of the internal volume of the tank.

System check and maintenance

After completing the work, bleed the air from the radiators. Each air valve is checked in turn. Add the required amount of water to the tank.

When operating an open system, it is necessary to remember that the warm medium is constantly in contact with air and, accordingly, evaporates. Therefore, it is worth periodically looking into the expansion tank. If the level drops, you just need to add enough water.

Before checking, be sure to turn off the boiler and wait until the water cools to room temperature. Do not add media to hot water. Use liquid with a temperature of up to 40 o.

How to start a warm water floor correctly

The first launch of a warm water floor is carried out by heating the coolant to +20-25 degrees. You need to let the system settle for a couple of days, after which every day increase this indicator by 10 degrees if water is used and by 5 if the coolant is antifreeze.

The entire process of gradual heating of the structure directly depends on the size of the room. If it is small, then you can do it in just a couple of days, but since the launch of a warm water floor is arranged after all the checks, pouring concrete and laying the floor covering, it is better not to rush with a sharp rise in temperature. This may cause cracks to appear in the screed.

Choosing a coolant: what to pour into the home system

Before pouring new liquid into a closed heating system, you must select a coolant. There are only 3 options:

- Water.

- Synthetic carrier.

Antifreeze for home systems

Important! Water can be used in any home heating systems if part of the circuit is not in contact with cold outside air. If the boiler room is outside the house, the pipes are laid in the ground without thermal insulation, you need to use non-freezing liquids - when the boiler is turned off, frozen water will lead to cracking of the pipes.

Is it possible to fill the system with tap water?

Don't try to save money by adding tap water to your new system. Tap water is “enriched” not only with chlorine, which, when heated, negatively affects the surfaces it comes into contact with. Under the influence of temperatures, which can reach 60 - 80 o, plaque begins to form on the inner walls of pipes, connectors, and radiators. The deposits are reminiscent of scale inside an electric kettle with the same consequences: solid deposits eventually block the internal gaps. As a result, some radiators may remain cold even at high media temperatures.

Deposits in the pipe when using tap water

In addition to problems with water scale, which forms a layer of plaque on the walls of pipes, the use of ordinary tap water can provoke problems that arise due to chemical reactions that occur in the medium when heated. Aggressive impurities have a detrimental effect on the condition of the coating inside radiators, corrode seals, and accelerate corrosion processes.

Conclusion - with a small volume of liquid there is no point in saving. It is better to fill a closed heating system with distilled water.

Distilled water with surfactants and heating additives

Advantages:

- Low cost.

- Reduced viscosity, good fluidity.

- No impurities.

- No chlorine.

- Increased boiling point.

Distillate as a coolant has a beneficial effect on the operation of the entire system: purified water warms up faster, the load on pumping equipment is reduced, there is no risk of clogging inside the pipes or the appearance of deposits on the internal walls.

Synthetic coolants: application features

Ready-made solutions and concentrates based on:

- Propylene glycol.

- Ethylene glycol.

- Glycerin.

Concentrate for home use

Despite the imperfect performance qualities of ethylene glycol, it is better not to pour solutions based on it into the home heating network - the substance is dangerous to health.

When purchasing, you should focus not on the price, but on the degree of concentration of the active substance. Different brands of coolant are diluted in a certain proportion. Before preparing the solution, be sure to read the instructions for diluting the composition.

Synthetic media degrade over time, so before throwing away the concentrate canister, find information about the expiration date and make a mark near the boiler or inlet pipe with a marker so you don’t forget to replace the coolant on time.

How to drain water from a heating system

When is it necessary to drain water from the heating system? Most often, the need for it arises when it is necessary to clean or replace a heating radiator, for example. If we are talking about a city apartment that is connected to a central heating system, then such an operation can be carried out independently on the internal section of the network. In the event that it is necessary to drain the heating system of a private house equipped with a boiler, it will have to be temporarily emptied.

The essence of the

The first step is to shut off the branch of the heating riser that goes to the apartment. It is enough just to close the distribution valve located here. For a private house with an autonomous heating system, this process is slightly different:

- firstly, you need to stop the supply of fuel or electrical energy;

- secondly, you should carefully read the user instructions for this case.

Only after this can the boiler be turned off. Then you should close the valve through which water is drawn into the system.

Only after this can the boiler be turned off. Then you should close the valve through which water is drawn into the system.

To speed up the process a little, you will need to know those places in the system where taps with air-type valves may be located. They all need to be opened. In this case, nothing will interfere with the flow of water to the hose.

During this operation, small leaks of water from the system onto the floor are possible. Therefore, at the very beginning, it is better to place a large bowl or basin under the place where the hose is connected to the tap (drain). As all the water leaves the system, it is necessary to disconnect the hose and drain the remaining water from it into a substitute container.

Only after completing all the described procedures can you move on to the main thing - to the work for which the water was drained from the heating system of a residential apartment or private housing construction.

If the owner of an apartment or house does not quite understand how to drain the water from the heating without harmful consequences, then it is better to contact a qualified contractor. For example, to a plumber from a company that services a specific home.

termosyst.ru

Draining and replacing water, inspecting pipelines and fittings

To avoid corrosion of steel pipelines, they are kept constantly filled with water. This rule does not apply to systems with plastic pipes, however, if the boiler has a black iron heat exchanger, water can only be drained with the valves on the forward and return pipes closed.

Water is drained to replace it or flush the system, repair pipelines and connections. Inspection of pipelines begins from the boiler and proceeds in a circle, starting with direct supply pipes. Leaks are often local and periodic in nature, most of them are not detected during the heating season. However, leaks can be detected by characteristic traces: white or rusty coating, stains from small puddles of water, discoloration of the sealant. Even with slight traces of leakage, the connection or connection should be repacked, or the radiator sections should be sealed.

Replacing the water in the heating system is carried out at the final stage of prevention; it is recommended to do this before the start of each new heating season no later than 30-40 days before its start. Water is drained from the system and the deposits that have formed are washed out of the pipes by applying pressure to the upper point of the circuit through a direct supply pipe. The washing liquid is drained until it becomes clear, then the system is filled with water through the lower supply pipe under low pressure.

We expel the air

It is a well-known fact that air in heating systems accumulates at the highest points of the system. For underfloor heating systems, this is a collector comb, where air discharge devices are installed (Mayevsky valves, automatic air vents or conventional ball valves).

Mayevsky tap installed on the underfloor heating manifold.

To remove air from the underfloor heating system, you must perform the following steps in a certain sequence:

- Shut off all horizontal branches on the collector.

- Remove air from the circulation pump housing.

- Open the Mayevsky valve or ball valve on the comb (in the absence of automatic devices).

- Open the first water circuit, start the pump, setting the minimum capacity on the regulator.

- After waiting for water to appear from the air outlet of the pumped branch, turn off the tap and turn off the pump.

- Repeat the operation several times at intervals of 5 - 6 minutes until the air is completely removed.

- Similarly, perform all operations with the remaining contours.

- Then, switching the pump to maximum performance, pump the entire system as a whole, periodically bleeding air.

- Considering the likelihood of new plugs forming during subsequent warming up of the system, it is necessary to bleed the air again.

Important! Putting the system into operation is possible only after all these measures have been taken and it has been fully checked for leaks. To work with Mayevsky taps, you must have a special key or slotted screwdriver

It would be useful to prepare a special container for drained water.

When using automatic gas vents or separators as air removal equipment, no additional means are required. It must be remembered that as the complexity and quantity of equipment used increases, the cost increases and the reliability of the system as a whole decreases.

Types of fan coil units, their differences and features

The lower the degree of automation of the process, the higher the performance of heated floors. Adjustable manifold valves with a mechanical drive, Mayevsky taps are easy to service or replace with your own hands.

Repair of more complex equipment with servo drives and automation units requires the participation of specialists. In addition, automatic air vents, while effectively removing air pockets, do not always allow immediate detection of system leaks.

We drain water from the central and autonomous water supply

In modern summer cottages, many people install a pipeline system. The pipeline can be connected:

If you need to drain water from the central pipeline during the winter, you must perform the following steps:

To drain water from pipes at your dacha for the winter from an autonomous pipeline system, you must do the following:

If water is not drained from the pipeline in a timely manner, the system may freeze. What to do in this case?

How to solve the problem depends on the type of pipeline installation. He can be:

If an open type pipeline is used, solving the problem of pipe freezing is quite simple. To do this you just need to heat it up. A blowtorch can easily handle this.

If the pipeline is buried in the ground, and even hidden by a layer of insulation, solving the problem of pipe freezing is much more difficult. To do this, you need to connect a hose to the hot water supply system. It should be placed inside the pipeline and moved along the pipe to the place where the ice has formed. After this, the hot water tap opens. The water will melt the resulting glaciation.

To avoid problems with freezing of the pipeline, it is necessary to drain the water in the pipes in a timely manner.

To ensure high-quality operation of the heating system using a gas boiler, it is necessary to understand the principles of its operation and follow the rules for installing and operating the boiler.

The information below will help you do everything correctly, following the manufacturers' recommendations and rules for using such equipment.

Starting the heating system

Installation and commissioning of the boiler must be carried out by specialists. This process consists of several stages: installation, filling the system and setting up its operation. How to fill a heating system with water:

You need to know that air enters the system with water in any case, this is normal. Small amounts of air are removed from the heating system using a deaerator installed on the pump. This leads to a gradual decrease in pressure. If during operation of the boiler the pressure gauge shows a pressure below 0.5 bar, you will need to add water to the system again.

How to add water to the heating system

If the water pressure has dropped to a critical level (0.5 bar or below), it must be increased by adding water. On boilers with an LCD screen, this situation can be indicated by a code that stands for “low pressure”. We carry out recharge observing the following rules:

The make-up valve must be closed in any case. Otherwise, the pressure in the system may rise to critically high levels. Typically this value is 3 bars. In this case, the automation will work and excess water will be discharged using a safety valve.

How to drain water from a heating system

In some cases, for example, when leaks are detected or other situations requiring repairs, it is necessary to drain the coolant from the system. This is easy to do by following these instructions:

In double-circuit boilers, it will also be necessary to drain the water from the hot water supply circuit. To do this, after the boiler is completely turned off, open the cold water supply valve and one of the hot taps to ensure complete drainage from the DHW system.

Even minor repairs to one of the radiators or heating pipes inevitably involve complete drainage of the coolant from the heating system. After completing the work, you will have to fill the circuit with water. The question arises - how to start the heating correctly? What temperature should the water be, and at what speed should the liquid be poured? How to prepare and flush your home heating network? It’s better if the work is done by craftsmen; many factors will have to be taken into account.