Creating artificial heating of a room to compensate for heat losses and maintain the temperature at a comfortable level is important not only for a country house, but also in urban environments.

Topping up the heating system is one of the most important measures to maintain the functionality of the equipment in use.

Why do you need heating make-up?

The efficient operation of a modern heating system is based on maintaining a stable operating pressure of the coolant. Even in systems that have been tested for leaks, microscopic leaks that are invisible to the naked eye can be observed.

Among other things, a certain amount of coolant leaks from the heating system during the process of removing air bubbles using the Mayevsky tap, and can also seep through the seals of the installed circulation pumping equipment.

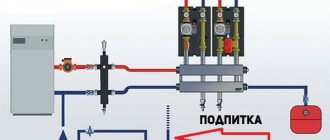

Thermal unit with make-up

A small part of the coolant is lost in the contour joints. General fluid losses can have a significant negative impact on the performance of the heating system.

Most often, tap water is used as a heat carrier, and recharging the operating heating system through the main water supply helps compensate for the loss of such liquid as effectively as possible.

Technical parameters of working fluids

The working fluid is not ordinary water taken from a water supply or the nearest body of water. On the contrary, this water must undergo special treatment, useful substances must be added to it, and impurities that negatively affect the pipeline and other elements of the system must be removed. In most cases, such liquid is poured into centralized heating networks. It is not so difficult to properly treat water, and it is inexpensive, and the make-up process itself can be carried out in boiler rooms.

Note! The main disadvantage of water as a coolant is that it freezes when it reaches 0C, and heating devices and pipelines are often destroyed after this. As for synthetic compounds, their freezing temperature is noticeably lower, and their chemical composition is already optimal for heating lines

But due to their high cost, such liquids are used mainly in individual closed-type heating systems

As for synthetic compounds, their freezing temperature is noticeably lower, and their chemical composition is already optimal for heating lines. But due to their high cost, such liquids are used mainly in individual closed-type heating systems.

Why is such recharge needed?

You may have come across the term “make-up valve” before. What is it and what is it required for? Let's try to find out. Let's start with the fact that in all closed heating systems (regardless of the type of working fluid circulation used), the coolant moves from the boiler, passes through all heating devices and, ultimately, returns back. And in order for circulation to constantly occur quite efficiently, constant support for operating pressure is necessary, which, in turn, is directly related to the volume of hot liquid.

Even if all requirements and standards were met during the installation of the system, as well as if it was absolutely sealed, the volume of the coolant will still decrease over time and this, alas, cannot be avoided. The reason for this is extremely simple: there will be leaks in the network in any case. Liquid can flow out through the connections of individual elements of the system, through the gland seals of the circulation device, and a small amount of liquid is lost each time the Mayevsky tap is opened. Of course, in a closed system, these losses are insignificant, but sooner or later it all adds up and can cause unexpected problems. The situation only gets worse if any system accident occurs.

The conclusion is obvious: the volume of heated coolant must be periodically replenished. For this purpose, the above-mentioned make-up valves were created.

Operating principle and types of node control

The most important task of the make-up unit is the ability to supplement the missing part of the coolant into the heating system, which will normalize the operating pressure.

Today, there are a couple of options for replenishing the volume of lost thermal fluid:

- Manual control is most convenient when servicing a small heating system, in which it is possible to independently control the pressure level in strict accordance with the pressure gauge. In this case, the supply of coolant occurs by gravity or using make-up pumping equipment.

- The automatic make-up mode automatically turns on when the pressure level inside the system drops below the established limits. In this case, the valve is activated to replenish the heating system and the flow hole is opened with a forced supply of coolant. After equalizing the pressure indicators, the valve closes, and the standard shutdown of the pumping equipment is performed.

Despite the convenience of the second option, it is very important to remember that the automatic recharge mode requires the mandatory inclusion of an additional element in the system that requires electrical supply. In case of frequent power outages, it is advisable to duplicate the automatic control of the manual recharge lever.

The simplest gravity installation in the manual version carries out the usual supply of tap water until the excess comes out of the overflow pipe on the expansion tank, and the advantage of automation is the almost complete absence of the need to control the process of replenishing the system.

Current advice on configuration and maintenance

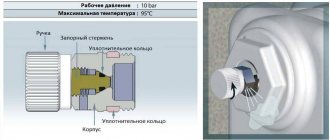

Whatever power supply you choose, remember, first of all, it should be safe and easy to use, made of high-quality materials. If the heating system is small, give preference to a device with the simplest possible design. The central support with moving parts and the internal compensation piston must be made of materials with a low adhesion coefficient: the risk of lime formation in the unit must be minimized. It is no secret that they are the main reason for the poor performance of the device.

Please note whether the product has a replaceable cartridge: this will greatly facilitate and speed up the process of inspecting the unit for you.

Periodic maintenance of the make-up device will help avoid malfunctions in the entire heating system.

To clean or replace the entire cartridge, proceed as follows:

- Insulate the installation.

- Unscrew the control knob located at the bottom.

- Unscrew the adjustment screw until it stops and remove the cover.

- Remove the cartridge with pliers.

- After the necessary manipulations, reassemble the device.

All that remains is to set up the equipment again and continue to enjoy the uninterrupted operation of the heating system in your home!

- https://teplodom1.ru/sistemotopl/2414-kak-sdelat-podpitku-otoplenija-vodoj-dolivka-sistemy.html

- https://cotlix.com/kak-sdelat-podpitku-sistemy-otopleniya

- https://oventilyacii.ru/otoplenie/podpitka-sistemy-otopleniya.html

- https://otivent.com/podpitka-sistemy-otoplenija

- https://aqua-rmnt.com/otoplenie/kotelnaya/podpitka-sistemy-otopleniya.html

Recharge

As a rule, heating is fed by connecting to a cold water supply system, but in some cases, feeding is done using a storage tank.

In an open heating system

A decrease in the volume of coolant in an open heating system is signaled by an expansion tank, which is mounted at the top point of the installed structure.

The gravity system is recharged when the level of coolant in the tank decreases and there is no sufficient pressure inside the control pipeline.

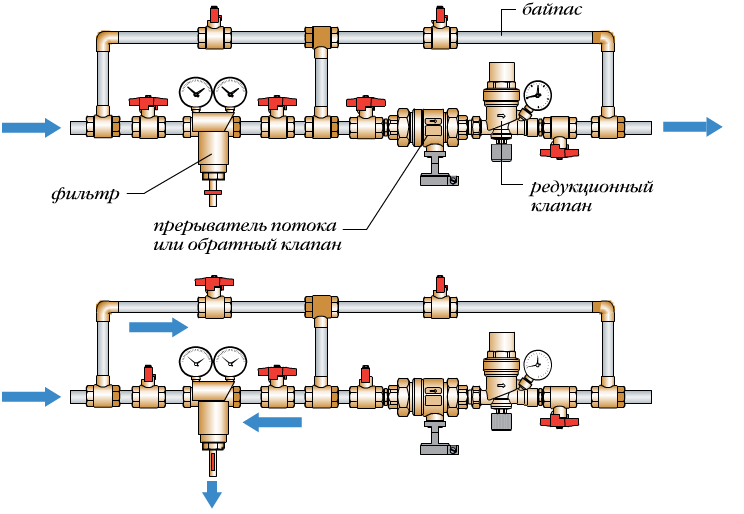

Diagram of the heating system recharge unit

In order to prevent increased coolant consumption, it is necessary to install shut-off valves that are activated at the moment of control opening of the tap.

In closed heating circuit conditions

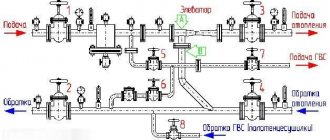

The best option for arranging a closed-type heating system is represented by the installation of an automatic feeding unit with various types of fittings. It is best to use a reducer that has a built-in filter, check valve, valve and pressure gauge that allows you to monitor pressure levels.

When using ordinary main tap water as a heat carrier, it is advisable to ensure the installation of a high-quality integrated filter device, which will extend the life of the entire heating system.

The feeding device is most often mounted on a bypass with all threaded connections packed and mounting taps soldered in, after which the fully assembled unit is installed.

Finally, about the safe addition of coolant

When filling water or partial replenishment, follow our recommendations:

- Replenish the heated system slowly by opening the valve a quarter of the lever stroke. In this way, it will be possible to avoid the formation of air locks and protect the boiler heat exchanger from temperature shock.

- Refill from scratch with the heat generator not working and the circulation pump turned off.

- Check the pressure in the expansion tank and go through all the radiators, opening the Mayevsky valves to release air.

- If your boiler is equipped with modern electronics, be sure to study the instructions regarding make-up. Often it is necessary to activate a special service mode in the unit.

- Excess pressure is easily released through the nearest air vent.

Injecting antifreeze with a hand pump does not have any pitfalls. Pressure testing units are equipped with their own pressure gauge, which allows you to monitor the current pressure at the insertion point.

How is the make-up line installed correctly?

In private households, as a rule, a gravity heating system is installed, so the design feature of the make-up unit is the mandatory presence of elements presented:

- a ball valve involved in supplying water from the water supply to the heating system circuit;

- a purification filter for the coolant, represented by water, to remove major contaminants;

- a check valve that prevents the movement of liquid from the heating circuit into the water supply system.

It is important to remember that hot water from the heating system should not flow into a cold pipeline.

The movement of the coolant in the opposite direction is most often the result of insufficient pressure in the central water supply system or failure of shut-off valves.

Make-up control

In a small-volume heating system, pressure level differences, as well as a decrease in the total amount of coolant, can usually be compensated by means of membrane tanks.

It is for this reason that adding liquid to the system is a relatively rare occurrence.

Simplification of the design involves manually turning on the pumping equipment, as well as opening and closing the make-up line. In this case, monitoring the pressure level must be systematic.

Controlled heating is more complex, but extremely efficient. It is in the automatic mode that a direct refusal to work on the “direct action” principle is assumed. There is no need to regulate the operation of the source of all generated thermal energy, or to add or subtract the resources used. This option is based on the use of a control module.

Thus, the automatic control mode is based on selecting the most comfortable temperature conditions and is more convenient, and also allows for significant savings in energy consumption.

The Italian brand of heating boilers “Beretta” has earned popularity in our country. Beretta gas boiler - types of equipment and overview of popular models.

How to calculate heat loss at home and why it is needed, you will find out here.

The piping diagram for a solid fuel boiler is presented at the link. We will also talk about the importance of proper strapping.

Example of an automatic make-up system

Despite the rich selection of systems that really deserve the attention of device consumers, in fact, there are not so many. Any manufacturer in the accompanying documentation for the device indicates the recommended connection diagram for the feed valve.

Most often, the design of such a device is self-sufficient and includes a basic filter water treatment and a check valve, as well as a valve for manual replenishment.

Heating system with automatic control of the make-up valve

Despite the fact that an automatic heating system make-up valve can simply be installed in the area from the plumbing system to the heating circuit, it is advisable to separate it on both sides with standard shut-off valves, represented by ball valves.

This feature of the automatic replenishment system is due to the need to periodically inspect and maintain the unit during operation.

A definite advantage of the control unit is its user-friendly interface, convenient for all consumers, as well as the ability to manually recharge the system in the event of an emergency.

Underfloor heating is becoming increasingly popular. Diagram for connecting a heated floor to a heating system - an overview of important points.

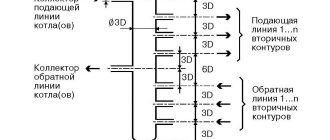

Why you need a distribution comb in a heating system, you will find out by reading this material.

When filling with coolant

There are only two known situations that require this technological operation:

- putting heating into operation (at the beginning of the heating season);

- restart after repair work.

Typically, coolant water is drained in late spring for two reasons:

- Water inevitably becomes contaminated with corrosion products (inside radiators, metal-plastic and polypropylene pipes are not susceptible to it). If you leave old water for the new season, you risk breaking the circulation pump with solid contaminants.

- Flooded systems in country houses that have not been started can “defrost” during a sudden cold snap - such cases are not uncommon. In this sense, antifreeze coolant is preferable. The high-quality composition has high anti-corrosion properties, increasing the drain interval to 5-6 years. There are known cases of uninterrupted heating operation with the same volume of antifreeze for 15-17 years. It is recommended to drain low-quality antifreeze after 2-3 years.

Pumping antifreeze into the heating system.