It happens that private houses located within the city are located next to central heating networks, and some are even connected to them. Of course, nowadays the priority is individual heating, and centralized heating is gradually becoming a thing of the past. But if the house is already connected to the network or there are problems with the autonomous system, then you need to use what is available. To work together between a heat source and consumers, a dependent and independent heating system is used. What they are, as well as the pros and cons of both schemes will be outlined in this material.

Dependent (open) heat supply system

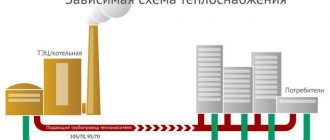

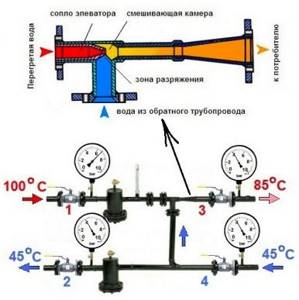

The main feature of the dependent system is that the coolant flowing through the main networks directly enters the house. It is called open because coolant is taken from the supply pipeline to provide the house with hot water. Most often, this scheme is used when connecting multi-apartment residential buildings, administrative and other public buildings to heating networks. The operation of the dependent heating system circuit is shown in the figure:

When the temperature of the coolant in the supply pipeline is up to 95 ºС, it can be sent directly to the heating devices. If the temperature is higher and reaches 105 ºС, then a mixing elevator unit is installed at the entrance to the house, whose task is to mix the water coming from the radiators into the hot coolant in order to lower its temperature.

For reference. A centralized dependent heating system has a calculated and real temperature schedule. The calculation graph characterizes the maximum water temperature and in an open system it can be 105/70 ºС or 95/70 ºС. The actual schedule depends on weather conditions and may change daily, it is maintained at the central heating point. When there is no severe frost outside, the coolant temperature is significantly lower than the calculated one.

The scheme was very popular during the Soviet era, when few people were concerned about energy consumption. The fact is that the dependent connection with elevator mixing units works quite reliably and requires practically no supervision, and installation work and material costs are quite cheap. Again, there is no need to lay additional pipes to supply hot water to houses when it can be successfully taken from the heating main.

But this is where the positive aspects of the dependent scheme end. And there are many more negative ones:

- dirt, scale and rust from the main pipelines safely enter all consumer batteries. Old cast-iron radiators and steel convectors didn’t care about these little things, but modern aluminum and other heating devices definitely don’t;

- Due to a decrease in water intake, repair work and other reasons, a pressure drop in the dependent heating system, or even water hammer, often occurs. This has implications for modern batteries and polymer pipelines;

- The quality of the coolant leaves much to be desired, but it goes directly to the water supply. And, although the water in the boiler room goes through all stages of purification and desalting, kilometers of old rusty mains make themselves felt;

- Regulating the temperature in rooms is not easy. Even full-bore thermostatic valves quickly fail due to poor quality coolant.

Comparison of reliability and durability

The practice of operating technically complex and multi-level systems shows that they are less maintainable and more often must be subject to preventive inspections with maintenance measures. It cannot be said that independent connection of the heating system reduces the overall level of reliability and safety (in some cases it even increases it), but the tactics for carrying out repair and restoration activities should be at a different and more responsible level.

At a minimum, an increase in labor and time resources will be required when inspecting the heat exchanger and adjacent piping. Possible uncontrolled accidents at this site can lead to damage to the pipeline. Therefore, experts recommend installing several sensors that monitor pressure, temperature and tightness. The latest manifold cabinets also provide for the use of self-diagnostic systems for continuous monitoring of the system condition. As for the closed heating infrastructure, such control and measuring equipment will also not be superfluous, but in this case its need is not so high.

Independent (closed) heating system

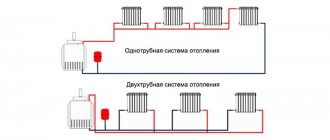

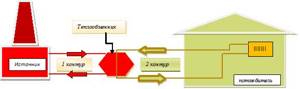

Currently, when installing new boiler houses, an independent connection scheme for the heating system has become more often used. It contains a main and an additional circulation circuit, hydraulically separated by a heat exchanger. That is, the coolant from the boiler room or thermal power plant goes to the central heating point, where it enters the heat exchanger, this is the main circuit. The additional circuit is the heating system of the house; the coolant in it circulates through the same heat exchanger, receiving heat from the network water from the boiler room. The operating diagram of the independent system is shown in the figure:

For reference. Previously, bulky shell-and-tube heat exchangers were installed in such systems, which took up a lot of space. This was the main difficulty, but with the advent of high-speed plate heat exchangers, this problem ceased to exist.

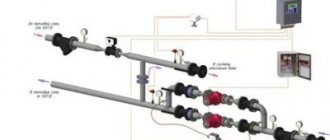

But what about the centralized supply of hot water, because now you can’t take it from the mains, the temperature there is too high (from 105 to 150 ºС)? It's simple: an independent connection diagram allows the installation of any number of plate heat exchangers connected to the main pipelines. One will provide heat to the heating system of the house, and the second can prepare water for household needs. How this is implemented is shown below:

To ensure that hot water always flows at the same temperature, the DHW circuit is made closed with automatic replenishment in the return pipeline. In apartment buildings, the DHW circulation return line can be seen in the bathroom; heated towel rails are connected to it.

It is obvious that operating an independent heating system has many advantages:

- the home heating circuit does not depend on the quality of the external coolant, the condition of the main networks and pressure drops. The entire load falls on the plate heat exchanger;

- it is possible to regulate the temperature in the rooms using thermostatic valves;

- the coolant in a small circuit can be filtered and cleaned of salts, the main thing is that the pipes are in good condition;

- The hot water supply system will contain drinking quality water entering the house through the water main.

However, due to dirty, low-quality coolant in the central network, periodic flushing of the independent heating system, or more precisely, the plate heat exchanger, will be required. Fortunately, this is not so difficult to do. Another disadvantage is the higher costs of purchasing equipment, namely: heat exchangers, circulation pumps and shut-off and control valves. But a closed system is more reliable and safer than an open one, it better meets modern requirements and is better adapted to new equipment.

Electricity addiction

Now let's return to energy dependence. When does a heating system need electricity to function, and when can it be done without?

Solid fuel boilers

The canonical solution is a conventional steel or cast iron boiler with a water jacket in the firebox and mechanical adjustment of the blower using a thermostat. This unit is completely energy independent.

The photo shows a classic solid fuel boiler.

However, this design has an important drawback: the boiler requires frequent loading of fuel. Three technical solutions allow you to make heating as independent from humans as possible:

- A hopper and a conveyor belt

supply new portions of sawdust or pellets as the fuel burns out. Electricity is required at a minimum for the transporter to operate. - divides combustion into two stages: pyrolysis of wood with a limited supply of oxygen and combustion of the resulting gas. In this case, the gas combustion chamber is located below the pyrolysis chamber. The movement of combustion products against the vector of natural draft requires the operation of an electric fan.

- An upper combustion boiler

can operate on one load of coal for up to five days. Only the top layer of fuel smolders; air is supplied to it from top to bottom, and the ash is carried away by a stream of hot combustion products. Air circulation is provided by... that's right, an electric fan.

Gas

Non-volatile gas heating boilers use manual ignition using a piezoelectric element and flame regulation by a mechanical thermostat. When the main burner is extinguished at a high coolant temperature, the pilot burner continues to operate.

Boilers with electronic ignition stop the gas supply completely when idle. As soon as the coolant cools below the critical temperature, the discharge ignites the main burner and heating resumes. In addition, electricity often drives a blower fan that supplies air to the burner.

Which scheme is better? If you have frequent power outages, a non-volatile gas heating boiler would be more appropriate. Precisely because he is able to do without electricity in principle. On the other hand, these devices are less economical: up to 20% of the total gas consumed is spent maintaining the pilot flame.

Another useful feature that gas-independent heating boilers lack is the ability to control the weather and control it using an external thermostat, which takes the temperature, for example, in a remote room. Of course, we are also not talking about programming the temperature for a day or a week.

Solara

Everything is simple here: solar boilers are COMPLETELY identical to gas boilers with electronic ignition. Only the burners differ. In fact, a lot of dual-fuel units are being produced.

It is clear that without a forced-air fan and electronic ignition, the devices simply will not be able to work.

Terminology

Let's clear up the confusion first.

Energy independence

- this is the ability of heating equipment to operate in the absence of electricity. The ability is undoubtedly pleasant, but we are not talking about it now. However, we will also touch on this topic.

What is the difference between independent and dependent heating systems? Connection diagram to the heating main.

Dependent circuit

Imagine an ordinary residential building. How is it built?

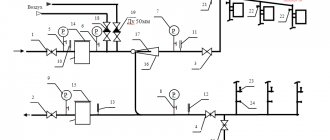

- Input valves cut off the elevator from the route.

- Behind them, on the supply and return lines, there are valves or valves embedded through which hot water can be supplied from the supply or return pipeline.

- After the hot water supply inserts, we see the elevator itself - a nozzle with a mixing chamber. A stream of hotter, high-pressure water from the direct pipeline heats up part of the return water and draws it into recirculation.

- Finally, house valves cut off the heating system. They are closed in summer and open in winter.

The key feature of a dependent heating scheme is that water enters the heating and water supply systems directly from the heating main.

Independent circuit

Now let's imagine another diagram:

- Water from the supply pipeline enters the return pipeline, giving energy to the heat exchanger along the way. Water, we repeat, is not used for heating and hot water needs.

- Drinking water from the water supply is supplied to the same heat exchanger, but to a different circuit. It heats up and enters the heating system. It can also be used for household needs.

Actually, we have comprehensively described the independent connection scheme for the heating system.

Comparison of solutions

The dependent heating connection scheme has, in essence, only one advantage, but a very important one - low cost of implementation. You can assemble an elevator unit for a small cottage with your own hands from consumer-grade shut-off valves

The only thing noticeable against the background of wiring batteries around the house will be the cost of manufacturing the nozzle - the only exclusive one made, the diameter of which determines the thermal power of the elevator.

What are the assets of an independent scheme?

Incomparably more flexible temperature control. It is enough just to reduce the flow of coolant through the heat exchanger - and the house will become colder.

- The practical consequence of flexible adjustment of heating to the needs of the home is efficiency.

Relative to the dependent system, it is estimated at 10-40 percent. - Finally, the main thing: in a dependent system we are forced to use water with a lot of pollution.

It carries sand, scale and a lot of mineral salts.

There is no talk of using water as drinking water; moreover, in some regions it is undesirable to even wash with hot tap water. An independent circuit makes it possible to use purified water or even non-freezing coolants as a coolant.

It is not a problem to heat drinking water for DHW needs.