Washing methods

Today, it is customary to distinguish between four technological methods for cleaning a heating system.

Chemical washing. This cleaning method allows you to remove 100% of system contaminants, with a minimum of effort required. However, this cleaning method is only suitable for metal heating pipelines.

To perform chemical cleaning yourself, you need to have the following tools and materials on hand:

- washing solution, which may contain mineral or organic acids, as well as all kinds of solvents and alkalis;

- container for draining liquid;

- pump;

- hoses.

The procedure is as follows:

- water is drained from the heating system;

- acid solution is poured;

- a special pump is connected to the system, which pumps cleaning liquid throughout the entire heating circuit for several hours;

- the waste liquid is drained and clean water is pumped in.

An important point: it is strictly forbidden to pour the used acid solution into the sewer. If it is not possible to dispose of it yourself, then you can purchase special neutralization products.

Hydrodynamic flushing. This method of cleaning the heating system is carried out using special equipment, which includes thin hoses and special nozzles.

The principle of cleaning with this method is that water is supplied under pressure to a nozzle, which generates thin jets of water. With the help of these jets, all grease, rust and scale are removed from the working area.

It is worth noting that although this method of flushing pipes is quite effective, due to its high cost it is used too little.

Pneumohydropulse flushing of the heating system. In order to perform this type of cleaning yourself, you will need:

- compressor;

- outlet pipe;

- hose;

- clamp;

- ball valve;

- drain container.

The order of work consists of the following steps:

- water is drained from the system;

- the outlet pipe is connected to the “return”;

- the compressor is connected to the outlet, and we pump up a pressure of approximately 5 atmospheres. Strong pressure in the pipes causes all kinds of contaminants to break off from the walls.

- close the outlet pipe and disconnect the compressor and connect the hose;

- We open the valve, and as a result, all contaminants come out under pressure.

It is worth noting that for better cleaning, the pneumohydropulse procedure can be repeated several times.

And in conclusion, I would like to note that after studying our recommendations, you will be able to flush the heating system yourself with greater confidence.

Watch the video, which popularly explains the need to flush the heating system and the specifics of carrying out the relevant work:

Temperature standards in an apartment according to GOST

Temperature standards are regulated at the state level. There is a document that describes the parameters of indoor air temperature, this document is GOST 30494-2011.

Temperature fluctuations within these limits are considered normal. It is believed that such indicators are optimal for the human body.

In addition to GOST, you must also be guided by your mind; standards must take into account the purpose of the room.

During the winter season, when the temperature drops, more energy must be spent to keep warm.

In such a microclimate, a person experiences fatigue and stress, the level of immunity decreases and the psycho-emotional state worsens.

High temperatures in the apartment also lead to a deterioration in health; the air in the room becomes very dry.

For these reasons, it is recommended to comply with the established standards:

| Season | Purpose of the room | Recommended temperature |

| Cold season | Living rooms In the northern regions, living quarters Children's room Toilet Bath and combined toilet Kitchen | 20 – 22 degrees 21 – 23 23 – 24 19 – 21 24 – 26 19 – 21 |

| Warm season | Living spaces | 22 – 25 |

Types of air vents

Valves for removing air locks are automatic and manual. The second type of air vents includes Mayevsky taps. They are used not only to remove air, but also to start it up in order to drain the coolant from the system.

Mayevsky crane

This device is made of brass and has a simple but reliable design. The main parts of the Mayevsky crane are the body and the screw. All valve parts are located as closely as possible to each other, so that the coolant cannot escape outside. Open the tap using a special key, screwdriver or hand.

Before removing air from the heating system, it is necessary to prepare a container for the coolant and tools. Step-by-step instructions for removing air pockets using a Mayevsky crane:

- If the heating system operates using a circulation pump, it should be turned off while the air is being vented.

- Using a wrench, screwdriver or hand, turn the tap 1 turn counterclockwise. You will immediately hear the hiss of air escaping from the radiator.

- As soon as the coolant begins to flow out, it means that the air lock has been removed, the Mayevsky valve is closed back.

Automatic air vent

This device independently removes air from the heating system. Installs either vertically or horizontally. Consists of a brass body, float, release valve and articulated arm. To prevent coolant from leaking through it, the air vent is equipped with a protective cap.

The operating principle is as follows: if there is no air in the chamber, then the outlet valve is closed. As it moves in, the float lowers. Once the chamber is completely filled, the exhaust valve opens and the air is discharged outside. The float then closes the outlet valve again.

Air separator

This device consists of a metal body, an air vent, a drain valve and a tube with a mesh. Unlike conventional air vents, the separator itself removes air from the water. As the coolant passes through the mesh, it swirls, causing air bubbles to form. As a result, they rise to the top, and the gases are removed through the air vent. In addition to air, the separator separates sand, rust and other impurities. Remove sludge through a drain valve located outside at the bottom of the housing.

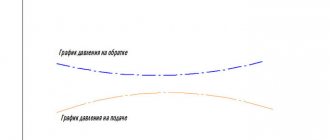

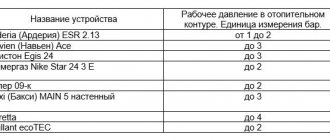

What is the difference between heating supply and return

Heating was invented to keep buildings warm and to ensure uniform heating of the room. At the same time, the design that provides heat should be convenient to operate and repair. A heating system is a set of parts and equipment used to heat a room. It consists:

- A source that creates heat.

- Pipe lines (supply and return).

- Heating elements.

Heat is distributed from the starting point of its creation to the heating block using a coolant. This could be: water, air, steam, antifreeze, etc. The most commonly used coolant fluids are water systems. They are practical, since all kinds of fuel are used to create heat, and they are also able to solve the problem of heating various buildings, because there are actually many heating schemes, varying in properties and cost. They also have high operational safety, productivity and optimal use of all equipment as a whole. But no matter how complex the heating systems may be, they are united by the same operating principle.

Briefly about return and flow in the heating system

The water heating system, using a supply from the boiler, supplies heated coolant to the radiators, which are located inside the building. This makes it possible to distribute heat throughout the house. Then the coolant, that is, water or antifreeze, having passed through all available radiators, loses its temperature and is supplied back for heating. The most simple heating structure consists of a heater, two lines, an expansion tank and a set of radiators. The conduit through which heated water from the heater moves to the batteries is called the supply. And the water conduit, which is located at the bottom of the radiators, where the water loses its original temperature and returns back, will be called return. Since water expands when heated, the system provides a special tank. It solves two problems: a supply of water to saturate the system; accepts excess water, which is obtained during expansion. Water, as a heat carrier, is directed from the boiler to the radiators and back. Its flow is ensured by a pump, or natural circulation.

Supply and return are present in one and two pipe heating systems. But in the first there is no clear distribution into the supply and return pipes, and the entire pipe line is conditionally divided in half. The column that leaves the boiler is called the supply, and the column that comes out from the last radiator is called the return. In a single-pipe line, heated water from the boiler flows sequentially from one battery to another, losing its temperature. Therefore, at the very end the batteries will be the coldest. This is the main and probably the only disadvantage of such a system.

But the single-pipe version will have more advantages: lower costs for purchasing materials are required compared to a 2-pipe; the diagram looks more attractive. It is easier to hide the pipe, and you can also lay pipes under doorways. The two-pipe system is more efficient - two fittings are installed in parallel into the system (supply and return).

This system is considered more optimal by experts. After all, its work revolves around supplying hot water through one pipe, and cooled water is discharged in the opposite direction through another pipe. In this case, the radiators are connected in parallel, which ensures uniform heating. Which of them establishes the approach must be individual, taking into account many different parameters.

There are only a few general tips to follow:

- The entire line must be completely filled with water; air is a hindrance; if the pipes are airy, the heating quality is poor.

- It is necessary to maintain a sufficiently high fluid circulation rate.

- The difference in supply and return temperatures should be about 30 degrees.

What is the difference between heating flow and return?

And so, let’s summarize the differences between supply and return in heating:

- Supply – coolant that flows through water pipes from a heat source. This could be an individual boiler or central heating of the house.

- Return water is water that, having passed through all the heating radiators, goes back to the heat source. Therefore, at the input of the system there is supply, and at the output there is return.

- It also differs in temperature. The feed is hotter than the return.

- Installation method. The water conduit that is attached to the top of the battery is the supply; the one that connects to the bottom is the return line.

Basic heating problems and methods for eliminating them

When operating a water heating system in a private home, various problems may arise. Problems that occur in heating elements and fittings can be fixed with your own hands. Some common problems are also solved by the owners themselves. Tasks associated with boiler repair require special knowledge and experience. It is better to entrust them to specialists.

Batteries do not work well and do not heat up

There may be several reasons for low heating of batteries in a private home. Main sources of the problem:

- Air got into the heating system and caused plugs.

- The radiators are clogged with dirt and no longer provide sufficient heat transfer.

- The pressure in the heating system has dropped and is not pushing through the entire circuit.

- The installation of heating equipment was carried out with violations.

- Someone turned off the taps at the battery.

The first step is to bleed the air. Modern radiators have special Mayevsky taps for this purpose.

Important! You should be careful when opening the tap. Move away unnecessary objects and place a container under the drain hole.

If bleeding the air does not help, then it is advisable to flush the system . The battery cap is unscrewed and a large container is inserted. It would be good if the system has a faucet for such cases. It is advisable to drain the water until the liquid becomes clear. In particularly difficult cases, you will have to remove the entire battery and wash it separately under pressure.

The pressure in the heating system of a private house is created by a circulation pump and an expansion tank. To increase the pressure, it is often enough to open the valve at the boiler and let additional coolant into the system. This problem often occurs in double-circuit heating devices.

In case of incorrect installation, it is not easy to deal with the problem. It's better to invite specialists.

Pressure drops

When pressure periodically drops, this indicates one of three phenomena:

- A leak has developed in the equipment components.

- Air is slowly escaping from the system.

- New aluminum batteries are being tested.

To detect the location of the leak, all parts of the heating system are carefully inspected . Where water leaks out, traces of corrosion or a white salt coating almost always appear. When a leak occurs in the pump and boiler elements, be sure to inspect them. To check the expansion tank, just press the nipple . Splashes from this part of the hydraulic compensator will mean that the membrane will have to be changed.

Often, a periodic drop in pressure in the system is associated with improper filling of the coolant. During the first start-up or after an unexpected shutdown of the equipment, air may enter the system. As air circulates through the pipes, it will gradually be removed and the pressure will drop. In this case, it is recommended to discharge water at the point furthest from the boiler when the make-up is turned on.

Aluminum batteries tend to extinguish pressure at the initial stage of their operation. This effect occurs due to oxidation processes inside the radiators.

Imbalance

Balancing in a home heating system is necessary to ensure even distribution of heat between radiators .

It is only possible to clearly balance the water supply to radiators using a special device.

At home, calibration is based on battery temperature . The supply is regulated by taps. At the farthest point, the valves open completely, and then go to the boiler in decreasing order of jet power. On the radiator closest to the AGV, the valve opens quite a bit. The leveling process is long and very tedious, in the absence of appropriate experience.

Actions for prevention

In operating condition, monitor the engine heating level. If it seems too high to you, then it is better to remove the pump and contact the point of sale with a request to replace the unit. The same can be done in case of pressure mismatch

Also, to protect pumping equipment from sudden failure, it is recommended to carry out preventive maintenance of the unit, which will include the following actions:

- Regular external inspection of the pump housing and careful listening during operation. This way you can check the functionality of the pump and the tightness of the housing.

- Make sure that all external pump fasteners are properly lubricated. This will make it easier to disassemble the pump if repairs are necessary.

- It is also worth following some rules when installing a pumping unit for the first time. This will help avoid repair work in the future:

- So, when you first connect the pump to the heating network, you should turn on the unit only if there is water in the system. Moreover, its actual volume must correspond to that indicated in the technical passport.

- It is also worth checking the coolant pressure in the closed circuit here. It must also correspond to what is stated in the technical specifications of the unit.

- In operating condition, monitor the engine heating level. If it seems too high to you, then it is better to remove the pump and contact the point of sale with a request to replace the unit. The same can be done in case of pressure mismatch.

- Also, make sure that there is a ground connection between the pump and the terminals when connecting the pump. Here in the terminal box, check that there is no moisture and that all wiring is securely fixed.

- A working pump should not produce even minimal leaks. The connection points between the inlet and outlet pipes of the heating system and the pump housing deserve special attention.

Unbalancing and installation

Another reason why water does not circulate in the heating system is improperly carried out imbalance during renovation or redevelopment of the apartment. This is affected by the uncontrolled installation of new radiators and heated floors.

The radiators on some floors continue to function normally, while on others they will remain cold because no coolant is supplied to them. Although the craftsmen can easily balance the distribution of water across all risers, in several apartments the system will not work.

If some residents removed the thermostats when replacing heating equipment, then heat will not flow into their neighbors’ homes. To fix this problem, you need to eliminate the thermostats in all apartments. You can increase the heat supply if you follow the example and also replace all radiators. Bimetallic or aluminum batteries fit harmoniously into modern heating systems. You must first obtain permission to replace devices, since you cannot do this yourself.

In a private house, batteries located closer to the boiler heat up more than others. To restore the balance, you need to turn off the control valves and limit the access of the coolant to nearby radiators. But sometimes the new battery does not heat up. If the entire system worked normally before its installation, then the problem lies in improper installation. When welding several polypropylene pipes, the master overheated the product, which caused its internal diameter to decrease. A specialist must redo all the work free of charge. All structural elements must be securely and efficiently fastened.

Overhaul of heating systems in a private home

Major repairs of home heating systems, as a rule, involve their partial or complete reconstruction.

With proper preparation, such repairs can be done by yourself without damaging the interior of the home. Currently, the market offers modern, functional and high-quality press fittings that allow you to repair home heating systems without soldering and welding, which is very convenient in cases where major repairs of heating systems do not involve repairing the house itself. This is the most cost-effective solution for doing home heating system repairs yourself.

Major repairs of home heating systems may include the following work:

- boiler replacement;

- replacement of radiators;

- replacement of pipelines;

- replacement of individual sections of home heating systems;

- replacement of the entire heating system;

- other repair work related to the replacement of certain parts and assemblies.

Heating diagram for a two-story house.

Major repairs of home heating systems can be spontaneous or planned. Of course, the second option is more preferable, because involves the opportunity to thoroughly prepare for its implementation with your own hands, to purchase the necessary equipment and materials. All other things being equal, this is the most profitable solution. However, practice shows that another option is much more common. Often, a major overhaul of home heating systems is caused by an urgent need, when it is no longer possible to avoid it. Sometimes this entails eliminating many serious problems, because even the most experienced technician may not immediately understand a system unfamiliar to him, not to mention doing the repair himself.

The likelihood of such cases can be minimized. Timely measures taken make it possible to independently choose the time for major repairs and slowly do it yourself. It cannot be completely avoided, because any equipment has a limited service life and sooner or later it will be necessary, for example, to replace the boiler or lay new pipelines.

How to protect the pump from malfunction

It is advisable to always maintain the required volume of coolant water in the pipes. Otherwise, the pump will wear out, both in case of excess water volume and in case of insufficient water volume.

To be on the safe side and avoid breakdowns of fairly expensive pumping equipment, it is recommended to adhere to some basic rules for operating equipment of this type:

- Do not allow the pump to turn on without coolant in the closed circuit. That is, if there is no water in the heating system pipes, then you should not “torture” the pump. This will cause your equipment to break down quickly.

- It is advisable to always maintain the required volume of coolant water in the pipes. Otherwise, the pump will wear out, both in case of excess water volume and in case of insufficient water volume. For example, if a pump can distill an amount of water from 5 to 105 liters, then the need to work with volumes from 3 to 103 liters will greatly wear out the working components of the unit, which will lead to its failure.

- In case of prolonged downtime of the pump (during the low heating season), it is necessary to run the unit in the operating position for at least 15 minutes once a month. This will avoid oxidation of all movable elements of the pump unit.

- Try not to exceed the coolant temperature above 65 degrees Celsius. A higher rate will negatively affect the working and movable parts of the structure.

- In this case, check the pump housing for leaks more often. If there is even the slightest leak somewhere, you should immediately identify the malfunction and carry out maintenance on the pump.

Installation procedure

To determine the material of new pipes and the features of the circuit, it is necessary to take into account the parameters of the already operating heating

It is important to know:

- operating temperature and pressure created by the boiler;

- permissible loads.

The system can be installed from one or two pipes. In this case, radiators are connected from the side or bottom for both types of system.

The work order is as follows:

For central heating, the risers are blocked, while for autonomous heating, all the coolant is drained from the system. Before starting work in the apartment, you must notify the housing office and neighbors

It is important to make sure that there is no water in the riser! All pipes are cut using a grinder and removed from the ceilings. Then the batteries are installed. For this, a building level is used - each radiator must hang on the wall as level as possible to ensure proper circulation

Holes for fasteners are made using a hammer drill.

Heating systems with natural circulation

The natural circulation heating system became widespread in the pre-war period due to its efficiency, simplicity and reliability. Most often, this type of heating system is used in dachas, as well as in country houses due to frequent power outages at such facilities. Such systems are conventionally divided into two types - with bottom and top water supply. To determine the choice of the type of heating system, it is necessary to consider their differences, characteristics and scope of application.

Schematic diagram of heating with natural coolant circulation

Heating systems with natural circulation

Two-pipe heating circuit

This water heating system is widely used in houses of any number of floors.

Its peculiarity is that water is supplied to the radiator through one pipe, and drained through another. The heat exchangers are connected to the heating system not in series, but in parallel. Main advantages:

- coolant with the same temperature is supplied to each radiator;

- it becomes possible to install a thermostat on radiators to set the desired temperature in each individual room;

- disconnection or malfunction of one of the batteries will not affect the operation of the others.

The system has a number of disadvantages. Its installation requires a large number of pipes and connecting elements, which leads to an increased degree of complexity of installation work and a higher cost of the entire water heating system.

There is no circulation in the heating system, what are the reasons?

If it is absent, you will regulate the temperature of the batteries not only in your room, but throughout the riser. It is unlikely that the neighbors will be happy with such actions.

Read more: temperature controllers in the heating system.

The simplest and cheapest option for a regulator is to install three valves: on the supply, on the return and on the jumper. If you cover the valves on the radiator, the jumper must be open.

There is a huge abundance of different thermostats that can be used in apartment and private buildings. Among the wide variety, each consumer can choose a regulator that will suit him in terms of physical parameters and, of course, cost.

The heating was never turned on - where can I complain next?

If your requests and demands are ignored by utility workers and the problem with the lack of heating is not resolved, you will have to take more stringent measures - complain to higher authorities. This:

- Rospotrebnadzor (you can send a complaint by mail or through the online service);

- prosecutor's office (options for sending a complaint are similar);

- local administration;

- court.

However, before contacting these authorities, try to inform your utility service employees about your intentions - perhaps the problem will be resolved very quickly. After all, if higher services find out about improper performance of duties, the case for the culprits can result in large losses and serious liability.

Consequences of cold return

Circuit for heating return

Sometimes, with an incorrectly designed design, the return flow in the heating system is cold. As practice shows, the fact that the room does not receive enough heat with a cold return is half the trouble. The fact is that at different supply and return temperatures, condensation may form on the walls of the boiler, which, when interacting with carbon dioxide released during fuel combustion, forms acid. It can also damage the boiler much ahead of time.

To avoid this, it is necessary to carefully consider the design of the heating system, special attention must be paid to such a nuance as the return temperature. Or include additional devices in the system, for example, a circulation pump or boiler, which will compensate for the loss of warm water

Radiator connection options

Now we can more than confidently say that when designing a heating system, the supply and return must be perfectly thought out and configured. If the design is incorrect, more than 50% of the heat can be lost.

There are three options for inserting a radiator into the heating system:

- Diagonal.

- Lateral.

- Bottom.

The diagonal system gives the highest efficiency coefficient, and is therefore more practical and efficient.

The diagram shows a diagonal inset

How to regulate the temperature in the heating system?

In order to regulate the temperature of the radiator and reduce the difference between the supply and return temperatures, you can use a heating system temperature controller.

When installing this device, do not forget about the jumper, which must be located in front of the heating device.

Installing a circulation pump, what you should pay attention to

To install the circulation pump yourself, use the following recommendations:

- To extend the service life of the entire system, install a filter to clean the liquid in front of the circulation pump. the filter must be installed on the suction pipe;

- do not choose a circulation pump for the heating system with greater power and performance than required. Otherwise, there is a risk of encountering additional unpleasant noise during its operation;

- Never turn on the pump before filling the heating line with water and removing air from it, this can lead to equipment failure;

- install the pump in an area as close as possible to the expansion tank;

- When installing the pump in a closed heating system, if possible, install the pump on the return line. This is due to the fact that this section of the highway has the lowest temperature.

Installing a circulation pump

Advice: before starting the heating system, it is necessary to rinse it with water to remove various foreign particles. Do not forget that even short-term idle operation of the circulation pump in the absence of liquid in the system can result in failure of the pump itself and other elements of the system.

Almost all circulation pumps on the market today are equipped with a connection to the automatic control of heating boilers. This function provides owners with the opportunity to regulate the air temperature in a heated facility by changing the speed of water movement in the heating system. In order to take into account the level of heat consumption in the premises, special meters are installed, thanks to which heat losses arising due to wear and tear of the lines are controlled. The heating circuit itself is not subject to any changes.

You can learn how to install the circulation pump yourself by watching the video:

What to do if there is no heating?

Many apartment residents wonder if there is no heating, what should they do to solve the problem? First you should find out whether there is heating in neighboring apartments. If the problem is in the whole house, you need to draw up a collective complaint and send it to the appropriate authority. There is a hotline to resolve the issue related to the lack of heating, which any resident of the house can contact.

If the owner of the apartment does not have free time to find out the cause and solve the problem associated with the fact that the heating battery does not warm up, you can call the emergency dispatch service. The dispatcher will record the details of the apartment tenant, the date of the request and send a plumber to identify the cause of the lack of heat. If the breakdown is simple, the worker will quickly fix the breakdown. If the problem is serious, the service will send an employee of the management company, who must draw up a report.

If the problem that there is no hot water and heating could not be resolved peacefully, then you can contact the following authorities:

- local government bodies. To do this, a representative of the house council must prepare a complaint from residents regarding the lack of heating and make an appointment with the official to whom all housing and communal services report. Of course, you can also contact us on your own behalf by sending an email. But the likelihood that the letter will be responded to quickly is very low;

- Rospotrebnadzor authorities. In response to the complaint, the government agency will conduct an unscheduled inspection of the house to determine temperature violations. Will draw up the appropriate document and send it to the organization that is responsible for the heating system of the house. In case of failure to comply with the order, the company will be forced to pay a fine;

- The prosecutor's office is the last authority where you should contact if there is no heating in the apartment, when complaints to lower authorities did not give the desired result. When contacting this body, you must draw up a written complaint against the head of the management company in order to initiate an administrative case.

Knowing who to call if there is no heating will help solve the problem of heating at home. The main thing is not to panic and act wisely. True, sometimes in order to determine who is to blame for the problem and to get the culprit to take action to correct the situation, it may require a lot of strength, perseverance and patience. But it's worth it. After all, you can’t leave your house without heating.

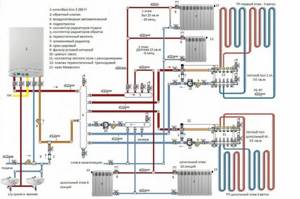

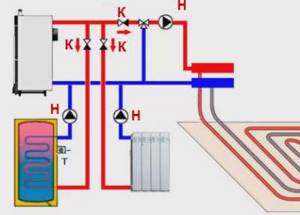

Coolant circulation in a combined branched heating system

Let's start analyzing the coolant circulation with a complex system - then you will understand simple circuits without problems.

Here is a diagram of such a heating system:

It has three circuits:

1) boiler - radiators - boiler;

2) boiler - collector - water heated floor - boiler;

3) boiler - indirect heating boiler - boiler.

Firstly, it is necessary to have circulation pumps (H) for each circuit. But this is not enough.

For the system to work as we want: the boiler is separate, the radiators are separate, we need check valves (K):

Without check valves, let’s say we turned on the boiler, but the radiators “out of the blue” began to heat up (and it’s summer, we just needed hot water in the water supply). Cause? The coolant went not only to the boiler circuit, which we now need, but also to the radiator circuits. And all because we saved on check valves, which would not allow coolant to pass where it was not needed, but would allow each circuit to operate independently of the others.

Even if we have a system without boilers and not a combined one (radiators + water heated floor), but “only” branched with several pumps, then we install check valves on each branch, the price of which is definitely less than reworking the system.

How to file a complaint

Depending on where you decide to complain when there is no heating in the house, the form of appeal depends. Usually it is free, but you need to indicate the main points:

- write your full name in the header. and the position of the person you are contacting;

- state the essence of the claim in an accessible and understandable manner in handwritten or typewritten form;

- put the exact number and signature;

- make two copies of any application so that the second one remains in your hands (you need to ask an authorized person to put a mark on it that the application was accepted for consideration and when);

- Attach existing documents and their copies.

However, there are standardized samples.

Return in the heating system

Return in the heating system - installation and installation methods

Return is the coolant (water or antifreeze) in the heating system, which, after passing through all radiators, loses temperature and is supplied again to the boiler for heating. The coolant occurs in a two-pipe and an improved single-pipe heating system.

Principle of operation

The principle of operation of a single-pipe system is that hot water is supplied from the boiler and flows sequentially from one radiator to another, gradually cooling. Thus, in the outer rooms, at the end of the chain, the batteries will produce less heat. If this system is slightly improved so that two pipes cut into the passing pipe from each radiator - one with supply, the other with return, and thermal valves are installed on each radiator, then it will be warmer in the outer rooms. The two-pipe system is more thought out - two pipes are connected in parallel (supply and return). The slightly cooled water leaves through the second pipe, which is located at a slight slope towards the boiler.

Heating

If the temperature between the supply water and the return water differs so much that it can cause “dew” on the walls of the boiler combustion chamber, then the boiler will not work for a long time. During the combustion of fuel materials, CO2 is released, which, when combined with dew drops, forms acid that corrodes the “water jacket” of the boiler furnace. In order to extend the service life of the boiler, they try to initially design the heating system so that “dew” does not fall out, i.e. they try to reduce the temperature difference between the two pipes. Most often, this is achieved by turning on a hot water boiler in the heating system or heating the return coolant. The boiler is installed next to the boiler. It is fixed on a short heating ring and placed so that the hot water, after passing through the main distribution manifold, immediately enters this boiler and then goes back into the boiler.

The return in the heating system can be heated by two pipes, between which a bypass is made, and a circulation pump is installed on it. You need to install a check valve behind such a pump, otherwise it may push through the recirculation circuit. For the circulation pump, you should select a power corresponding to one third of the power of the main pump (if there are several of them, then the sum). In general, the circulation pump allows you to avoid making slopes in the pipes to ensure the movement of the coolant, and also allows you to reduce the diameter of the pipes used.

Buy from Docker Chemical GmbH Rus.

What causes the battery to heat up unevenly?

Let us repeat once again that each case is individual; only a specialist can correctly determine the cause through a visual examination.

We will give the main reasons for this problem:

- the radiator is clogged;

With this “diagnosis” it is recommended to clean the battery from the inside.

- low quality coolant;

- presence of air in the circuit.

Shut-off valves

Its main purpose is to regulate the movement of the coolant and block it. If any component of this system fails, then a disruption of the normal flow of fluid will not take long to occur.

Which mechanisms are more susceptible to failure?

- Tap.

- Damper.

- Ball valve.

- Sealing washer.

The causes of breakdowns can be either wear or incorrect installation.

Lack of pressure in the circuit

To identify this problem, special instruments are required, therefore, it is hardly possible to cope without the help of a plumber.

The main reasons for this problem:

- “jambs” of utility workers (coolant leak on the line);

- unsuitable radiators;

- the circuit has a battery equipped with a bypass with a tap;

- adding several sections to an existing battery.

Installation problems

When the radiator was initially installed in violation of the rules and regulations, or it was connected incorrectly, then only the homeowner himself is to blame. And not a plumber who decided to save on technology.

To get rid of the problem, it is better to start by officially calling a plumber, and after eliminating the problem, you can turn to an experienced plumber on a commercial basis, but who knows his business well.

The coolant is moving at insufficient speed

There are two reasons for this problem: worn-out public heating networks, or narrowing of the lumen of pipes approaching the house.

To eliminate this defect, you need to make sure that the circulation pump installed in your house or cottage is working at full capacity. If it is working, you will have to look for the reason further.

Other reasons for this heating problem:

- polypropylene pipes are poorly soldered;

- strongly narrowed section of the installed control valve;

- Excessive deposition of chemical compounds on the inner walls of pipes.

Coarse filter

As mentioned above, one of the reasons that there is no coolant circulation may be the accumulation of debris in the pipeline. To completely avoid this, again, we don’t save on pennies, but install a coarse filter in front of each device:

Using a filter, catching dirt is easier than correcting the consequences of clogged pipelines or boiler heat exchangers.

Conclusion! We place coarse filters in front of each heating system device (pump, boiler, etc.) and in front of each plumbing fixture. We do NOT save pennies to “buy” problems. There are arrows stamped on the filter housing indicating the direction of movement of the coolant or water in the water supply...

The filter needs to be cleaned regularly. And this is very simple to do: close the valves before and after the filter - unscrew the plug (1) on the filter - remove and rinse the mesh under the tap - put it in place and tighten the plug. All. Not like changing pipes

These are the simple “body movements” you need to perform in order to never complain that there is no circulation in the heating system. Good luck.

no circulation in the heating system

The return in the heating system is the coolant that has passed through all the heating radiators, lost its primary temperature and is now cold and supplied to the boiler for the next heating. The coolant can move in both a two-pipe and an improved single-pipe heating system.

A single-pipe system implies a sequence of connections of heating radiators. That is, the supply pipe is connected to the first radiator, from which the next pipe goes to the second radiator, and so on.

If a one-pipe heating system is improved, its design will be something like this: along the perimeter of the entire room there is one pipe into which the supply and return pipes of each radiator can be inserted. In this case, it is possible to install a control valve on each battery, with which you can very successfully regulate the air temperature in a given room.

The big advantage of this option is the minimal number of pipes in it. And the minus is the temperature difference between the first radiator from the boiler and the last. This problem can be eliminated with the help of a circulation pump, which will move all the water through the heating system much faster, and thus the coolant will not have time to reduce the temperature.

The two-pipe option represents the wiring of two pipes. One pipe is the supply of hot coolant, the second pipe is the return pipe in the heating system, through which already cooled water from the radiators enters the boiler. This system allows you to connect all radiators almost in parallel, which allows for flexible configuration of each radiator individually without affecting the operation of the others.

Leaking heating pipe

Corrosion most often occurs at the junction of the pipeline with the radiator.

The cause of interruptions in the heating network is often a leak caused by corrosion or poor-quality pipe connections. If the location of the leak is visible, then the heating problem in the apartment can be solved faster. It is bad if the connection is hidden in the thickness of the wall or in the floor. Then you will have to cut off the entire leaking pipeline branch and install a new one.

How to seal a leak if necessary? To do this, it is recommended to keep in stock simple plumbing devices for clamping pipes of the appropriate diameter. As a last resort, you can make a homemade clamp: wrap a piece of soft rubber around the leak, and then tighten it tightly with wire.

We recommend: How to make a chimney for a potbelly stove: installing a proper chimney with your own hands

If a leak is found at the junction of the radiator sections, you will have to bandage this area with a strip of fabric, which has previously been soaked with moisture-resistant glue. It is permissible to use a special sealant, “cold welding” and other means.

The proposed methods of dealing with the problem of heating system leakage are only temporary, and subsequently a major repair will be required.

In advance, before the start of the heating season, inspect all pipelines and radiators in the apartment to see if there are any leaks. Owners of an autonomous heating system should test its performance in the fall.

Finally, we can advise: if you have any problems with heating in an apartment or in your private home, contact a specialist. Only they know how to correctly design a system, install a boiler, install pipes and connect radiators.

Do not skimp on the quality of the purchased equipment, so as not to spend money on repeated repairs if the faucet you bought on the cheap suddenly breaks and floods the room.

Learn to correctly identify the causes of heating problems and begin to eliminate them competently. In other words: think twice, fix once!

Air jams

The cause of cold batteries is usually air, which does not allow water to flow freely.

An air lock forms for several reasons.

:

Oxygen bubbles accumulate in one of the radiators or at the highest point of the heating system. Because of this, the bottom half of the radiators will be hot and the second half cold. Gurgling sounds also occur when the equipment operates. In multi-storey buildings in the highest apartments, boilers completely stop working.

In older apartment buildings, many of the pipes have long since expired. Therefore, they can cause accidents and reduce heat levels

. Microelements contained in the coolant are deposited inside the pipelines. They impede normal water circulation. The correct solution would be to replace the products, but this is not always possible.

Layers of scale form on the inner surface of the boiler, which reduces the pressure in the system. This problem is caused by the use of hard water, saturated with minerals and salts. Special reagents must be added to the equipment to soften the quality of the coolant.

When pipes are corroded or improperly connected, leaks occur. If it is in a visible area, it is easy to seal the hole with sealants. It is more difficult to deal with a problem hidden in the wall or floor. In this case, you will have to cut off the entire branch, fix the problem and install a new section. In addition to sealants, you can use special parts to clamp the pipeline, corresponding to its diameter. If it is not possible to purchase such devices, then it is enough to make a clamp. The leak area is covered with a piece of soft rubber and secured tightly with wire.

If a leak is detected at the radiator or at its junction with the pipe, wrap the hole with a strip of fabric, after soaking it in moisture-resistant construction glue. Sometimes cold welding is used. To avoid such problems, before the start of the heating season, inspect the entire system for damage. It is imperative to start the boiler and check the quality and reliability of its operation.

Bad polypropylene pipes

Often the consumer (customer) believes that polypropylene pipes are absolutely reliable and cannot cause heating problems or cold radiators.

We recommend: Mobile heated floors: types and their advantages, selection options, how to install

But polypropylene is much more insidious than old steel or metal-plastic pipelines. Each place of soldering (welding) is a potential increased resistance in the system or a cause of cessation of circulation (weakened movement of water through the batteries), due to deposits of material inside.

It is impossible to control the quality of connections from the outside; all that remains is to cut out pieces, resolder, and remake polypropylene pipes.

Poor performance of a polypropylene system is a real problem for the home installer. Good professionals don’t take on this material at all.

Troubleshooting in a two-pipe heating system continued

First of all, turn off the coolant supply to the radiator and leave the return line open. Open the drain, wait until the air comes out, close the drain and open the coolant supply. As a rule, this is enough.

If this method does not work, and we are talking about an apartment building, it is better to call a specialist. For private houses there is another option. First you need to turn off the heating supply, open the drain at the highest point of the system and use back pressure to squeeze out all the air.

Each heating system may have its own characteristics, and therefore there is a high probability of atypical problems arising. These include incorrectly selected pipe diameters, incorrect coolant distribution, poor throughput, lack of pressure, problems with the circulation pump or expansion tank. In any case, only a specialist can fully understand all the nuances, so in case of difficulties in solving the problem, it is better to seek help.

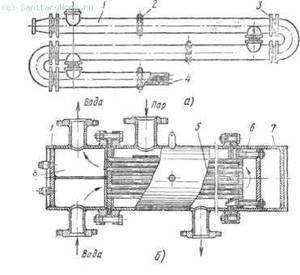

§ 87. Schemes of hot water supply systems

The schematic diagram of a hot water supply system includes an installation for heating cold water to a temperature not exceeding 75 ° C and a network of distribution pipelines. For this purpose, high-speed instantaneous water heaters are used. In such water heaters, water flows at a significant speed through the heating tubes, which in turn are heated by water from the heating network passing inside the body of the water heater and washing them.

When preparing hot water in a central heating station using a closed circuit, high-speed water heaters OCT 34-588-68 (coolant - water), OCT 34-531-68 and OCT 34-532-68 (coolant - steam) are used.

Rice. 174.

How to file a complaint?

Regardless of which structure the claim will be sent to, it is important to draw it up correctly and competently.

You can be guided by the following general design rules:

- In the upper right corner you must indicate the name of the structure to which the document is being submitted. Below is the tenant's full name and residential address. In order for the organization to contact the owner of the apartment, you should write contact information (telephone, email);

- The following describes the problem in detail. It should be indicated from what date there has been no heating, what measures were taken, which authorities were contacted and to whom exactly they were contacted. If there are acts, responses from any authorities or other important documents, copies of them must be attached to the complaint;

- in conclusion, it is necessary to state the requirement that the selected structure take measures to solve the existing problem. You can also add that if the heating issue is not resolved, then the complaint will be sent to court;

- at the very end there is the date of drawing up the document and the signature of the person who made the complaint.

Regardless of where the complaint is filed, it is desirable that it be a collective one from several residents of the house. Since public appeals are usually considered first. Appeals are considered within 30 days after receipt of the document. The complaint must be submitted in several copies. Residents of the house must have a second version of the document in their hands. In addition, you can contact a lawyer for help in filing a complaint.

Related news

The driver of a Semiluki regular bus hit a man and fled the scene

15.07.2021, 16:08

An entrepreneur faces a prison sentence for reporting bribes to the Borisoglebsk prefect and the head of the local police department.

14.07.2021, 12:05

The former rector of VSTU was refused to transfer his case to another region

14.07.2021, 10:10

A judge whose brother was prosecuted became the new chairman of the Lipetsk Regional Court

12.07.2021, 17:23

Former acting Rector of Voronezh State Agrarian University will remain under house arrest until September 9

08.07.2021, 10:53

Possible breakdowns and ways to eliminate them

troubleshoot the problem as necessary. By the way, it is recommended to protect the pump from surges in the network by installing a reliable stabilizer. This move will also protect the pump from the burning of a fuse, which fails as a result of constant pressure drops in the network

So, if something goes wrong with your circulation pump and it refuses to work, then we’ll try to repair the unit ourselves.

Important: but if you are not confident in your abilities or do not have the appropriate tool at hand, then it is better to contact a specialized center

If the pump makes a hum, but the impeller does not rotate

The reasons may be the following:

- Presence of a foreign object in the impeller area;

- The rotor shaft has oxidized due to long-term downtime of the unit;

- Loss of power supply to the mechanism terminals.

In the first case, you need to carefully remove the pump from the heating system and unscrew the housing in the area of the impeller. If a foreign object is found, remove it and rotate the shaft by hand. When assembling the pump in the reverse order, it is necessary to install a reliable filter on the pipe.

If there is oxidation, then clean it well, lubricate all movable elements of the working unit and reassemble the pump in the reverse order.

If there is a problem with the quality of the power supply, then you will have to check the voltage using a tester. First, completely replace the cable in all sections of the cable and if a break or fault is detected. Then, if the cable is OK, check the voltage at the terminals. If the tester shows infinity, a short circuit has occurred. If it shows less voltage, it means that the winding has broken. In both cases, the terminals are replaced.

If the unit shows no signs of life at all

This can happen if there is no voltage in the network. Using a tester, check the voltage and, if necessary, correct the problem.

By the way, it is recommended to protect the pump from surges in the network by installing a reliable stabilizer. This move will also protect the pump from the combustion of a fuse, which fails as a result of constant pressure drops in the network.

If the pump starts but then stops

The reasons may be:

- Presence of scale between the moving elements of the unit;

- Incorrect pump connection at the terminals.

In the first case, you will have to disassemble the pump and check it for scale. If detected, limescale deposits are removed and all joints between the rotor and stator are lubricated.

If there is no scale, then check the tightness of the fuse on the unit. You should remove it and thoroughly clean all the clamps. Here it is also worth checking that all wires in the terminal box are connected correctly in phases.

If the pump makes a loud noise when turned on

The reason for this is the presence of air in a closed circuit. It is necessary to release all air masses from the pipes, and install a special unit in the upper part of the pipeline to prevent the formation of air locks.

Another reason could be wear on the impeller bearing. In this case, you need to disassemble the unit housing, check the bearing and, if necessary, replace it.

If the pump is noisy and vibrates

Most likely, the issue is insufficient pressure in the system. It is necessary to add water to the pipes or increase the pressure in the area of the pump inlet.

If the pressure is still low

Here it is worth checking the direction of rotation of the working unit in the pump body. If the wheel does not spin correctly, then an error was probably made when connecting the device to the terminals in phases when using a three-phase network.

Another reason for a decrease in pressure may be too high a viscosity of the coolant. Here the impeller experiences a lot of resistance and does not cope with the assigned tasks. You will have to check the condition of the mesh filter and clean it if necessary. It would also be useful to check the cross-section of the inlet and outlet pipes and, if necessary, set the correct operating parameters of the pump.

List of additional organizations

If contacting the utility services has not yielded any results and the apartment still has problems with heat supply, then you should know where to complain in this case. The list of official bodies to solve the problem is as follows:

- A service serving a specific home.

- Management company servicing the building.

- Housing association house.

- City Housing Inspectorate.

It may happen that these structures will not show due attention to the problem that has arisen.

If no measures are taken, and complaints from residents of the house are ignored, then in this case you will have to think about another way to resolve the situation.

If there is no heating in the apartment, you can also contact the following institutions:

- Local administrative authorities.

- Rospotrebnadzor. You can contact this service by submitting an online application on the official website of the organization or by using mail.

- Prosecutor's office. You should also send your complaint here in writing via mail or online.

- Court.