The author of the article is Admaer CEO Pavel Chervyakov

It is quite difficult to clean a newly installed heating system, since after completion of welding work a lot of welding scale remains in it. Objects that have been in operation for several years also require increased attention: slag accumulates in the heating system, which must be washed out annually, otherwise the heat transfer of the entire system will decrease. It is worth noting that representatives of heat supply organizations are very jealous of flushing the system.

The task of the heating network inspector is to go to the site and make sure that the heating system is flushed and ready for use. After this, the inspector signs the act. In my opinion, flushing is not necessary every year. I think it is enough to do it at least once every two years and pressure testing with high pressure once a year. When flushing a heating system, a lot of resources are wasted - water and electricity. Homeowners have to pay for this.

Washing methods

Before flushing the heating system in a private home with your own hands, you will need to study the methods and choose the best one in a particular situation. There are five washing options:

- chemical;

- dispersed;

- hydrodynamic;

- pneumopulse;

- hydropneumatic.

When choosing, it is important to consider the advantages, disadvantages and limitations of each of the listed methods.

Chemical washing

The technology is quite simple and effective. It is also distinguished by accessibility and low financial costs. But it is worth considering that if aluminum heating elements are installed in the house, the use of chemical reagents is prohibited. If the system continues to function after such a test, its service life will be greatly reduced.

Another important point: draining reagents from batteries. State standards and regulations prohibit the disposal of such waste into sewers. To comply with the requirements, you must purchase a special composition to neutralize chemical components.

The procedure for flushing the heating system in a private house with your own hands is as follows:

- selection of composition depending on the heating characteristics;

- preparing the solution in strict accordance with the instructions;

- filling the heating system with a chemical using a pump;

- cleaning for 2-3 hours (the period of exposure may vary depending on the type and complexity of the contamination);

- removing solution from pipes, flushing the heating system under pressure;

- filling the system with coolant.

Dispersed washing

The method is very similar to the first. But for the work they use more modern compounds. In this case, the flushing mixture acts only on contaminants without coming into contact with the pipe material.

Batteries made of any materials are washed in this way. The work can be carried out regardless of the time of year, but it is advisable to do it before the start of the heating season. In winter, you will need special equipment that will close the heating system.

Hydrodynamic flushing

The first two technologies cannot always effectively cope with contamination of cast iron batteries. In addition, they cannot be called completely safe for humans and the environment. Hydrodynamic cleaning does not cause any harm to the environment and allows you to completely eliminate the problems of the cast iron system.

One of the disadvantages of the method is its cost. Here you cannot do without professional equipment that will provide high pressure water jets. This is how pipes are most often cleaned by professionals. A substance is first introduced into the system to soften deposits.

The principle is to remove plaque with a stream of water. First, the coolant is discharged from the pipes, and then supplied back under high pressure. Exfoliated contaminants are removed when drained again.

Pneumopulse washing

For such cleaning, you will need a special device that creates a pulse wave in the pipes, removing deposits on the internal walls. At the same time, the pressure in the system increases. This option is suitable for any pipes and does not damage the battery material. Work can be carried out at any time, even during the heating season.

Hydropneumatic flushing

Another method using special equipment. The installation pumps compressed air into the pipes, which mixes with water and loosens all the waste on the walls. There are two technologies for using high pressure air:

- Flushing with the drain pipe open. Air is pumped until clean water begins to drain from the system.

- Air is forced into the system with the drain pipe closed for 10 minutes. After this, the waste liquid is drained.

Mechanical cleaning

You can do heating flushing yourself without the use of special equipment and reagents. To do this, drain the coolant from the radiator, remove the battery and wash it in the bathroom using a shower hose. The water pressure should be as high as possible. For large deposits, metal cleaning devices are used.

Before assembling the system, the pipes are washed using the same method and the threaded connections are cleaned of rust.

Flushing a separate radiator

This method is used strictly before the start of the heating season. You will need a flushing tap, a fitting with a suitable thread, and a rubber hose. The work is performed in this order:

- connect the tap;

- attach a fitting and a hose to it;

- the free end of the hose is lowered into the toilet;

- open the tap, holding the hose, rinse for half an hour.

Is it possible to wash a separate battery?

Now you know how to flush the heating system. However, sometimes it becomes necessary to clean a separate battery. There is a solution for this situation too.

Heating battery cleaning scheme

Important! Flushing a separate heating radiator must be done strictly before the start of the heating season.

Buy a flushing faucet from a plumbing store. Additionally, you need to purchase a rubber hose and a fitting with a thread that matches the diameter of the purchased flushing valve. Install the fitting onto the hose.

Direct washing is carried out in the following sequence.

First step. We connect the flushing tap to the heating radiator.

Second step. We connect a fitting with a hose to the flushing tap.

Third step. We direct the second end of the rubber hose into the toilet.

Fourth step. Open the flush tap and leave for 20-30 minutes. While waiting, hold the hose so that it does not jump out of the toilet.

Important! Although it is recommended to flush individual batteries strictly before the start of the heating season, in some situations the need for flushing arises when heating is in full swing. If this is your case, insert the hose deeper, directly into the riser. Otherwise, the hot coolant may destroy the toilet.

Video - Flushing a heating radiator

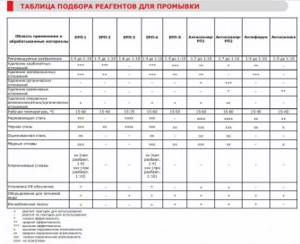

Table for selecting reagents for flushing the heating system

Prices for popular models of heating radiators

Heating radiators

Features of filling out the first paragraphs of the act

The commission includes representatives:

1.company that built communications.

2. service that carried out technical supervision of the customer.

3.operating organizations.

The act should indicate the name of the organization that includes the specialist participating in the inspection, and the position of this commission member in this organization, indicating his last name and initials. Next, detailed information about the object that is subject to inspection is written down. It is necessary to write down its name without abbreviations (information can be taken from the design documents), picket numbers that are indicated at the ends of the object, the length of the pipes, their diameter, and what material they are made of, how the joints of the elements are sealed. The header of the act consists of this data.

Components of the heating system pressure test report

At the top left is information about the organization that carried out the inspection. Ideally, there should be a signature for approval by the chief power engineer of the heating supply organization.

The top right should contain subscriber information. That is, about who is the client and consumer of heating services. This could be a partnership of residents of a particular house, any organization that occupies the building, the owner of a private house, etc.

It is important to provide names and other information accurately and in detail. In this case the address is required

The main part of the act states:

- City.

- The date of signing the act (and the pressure test itself).

- Heat supply organization: its form of ownership, name, full name of the representative.

- Which of the subscriber's representatives accepted the heating system after the test: full name, position.

- To what indicators the pressure in the system was raised is indicated in kgf/cm2.

- To what indicators did it drop after 10 minutes following the shutdown (the units of measurement here are also kgf/cm2, it is also permissible to measure it in mPa if accurate data on this matter is available).

- Whether the system passed or failed the test (the person completing the form needs to highlight the correct option).

The final part consists of the signatures and seals (if any) of the representatives:

- Subscriber.

- Heat supply organization.

- Service organization.

In general, the act of pressure testing the heating system is a convenient primary document, for filling out which the heat supply organization is responsible.

The procedure for carrying out work when performing pressure testing of the heating system:

— agreement on the availability of access at the time of work to ALL premises of the building and the presence of the minimum possible number of people; — checking that the system is filled with coolant (water) and that there is no air in the system (de-airing); — installation of plugs on safety valves; — shutting off shut-off valves on the lines of expansion tanks;

— shutting off the shut-off valves on the inlet pipelines (disconnection from the city) or from the boiler (for autonomous heating systems); — connection to the system of a booster pump and control pressure gauge; — raising the pressure in the heating system to the required (1.5 operating pressure of the system, usually from 6 to 10 Bar); — turning off the pump (press) and maintaining a technological pause (15 min); — inspection of the system for leaks, leaks, ruptures, monitoring of pressure drop (no more than 0.2 atm in the absence of leaks); — pressure release to working level; — registration of a pressure test certificate for the heating system;

When carrying out crimping there are several points that you should pay special attention to:— the scale mark on the control pressure gauge should be no more than 0.01 MPa (0.1 Bar); — the increase in pressure and its release should be carried out smoothly without the formation of “water hammer”; — when carrying out pressure testing of a heat supply system, including various types of heating equipment, it is necessary to ensure that the test pressure for one equipment does not exceed the maximum permissible for another. Otherwise, damage is inevitable; — all general rooms with equipment must be equipped with artificial lighting; — all floor spaces and passages must be cleared of foreign objects; — it is advisable to carry out disinsection and deratization measures in all general premises; — rooms with equipment must be dry. |

To contents

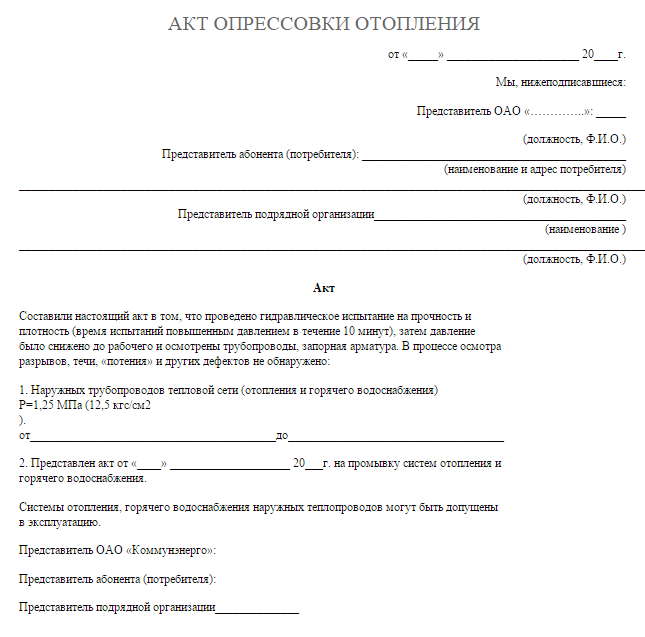

Heating system pressure test certificate

This document displays the following information:

- What type of crimping method was used?

- The project in accordance with which the circuit was installed;

- The date of the inspection, the address where it was carried out, as well as the names of the citizens who sign the act. This is mainly the owner of the house, representatives of the repair and maintenance organization and heating networks;

- How the identified faults were eliminated;

- Test results;

- Are there any signs of leakage or reliability of threaded and welded connections? In addition, it is indicated whether there are drops on the surface of the fittings and pipes.

In what cases is it compiled?

The act is required when:

- Commissioning of new equipment. The certificate will confirm that each element is in its place, the installation was carried out responsibly, and the system is working.

- The heating season is approaching. After a summer break in work, the pipes could fail. After checking their capacity, a report is drawn up.

- Already carried out repair work.

- The occurrence of contained emergency situations on the pipeline. In this way, specialists identify the amount of work required and the weak points of the existing heating network.

For the uninterrupted operation of the heating system, preventative control checks and reliable information about the quality functioning of the system upon startup are necessary.

Procedure for crimping

- Before starting tests, it is recommended to check the condition and functionality of the shut-off valves; visually assess the quality of existing connections; isolate the heat supply from the water supply system using plugs.

- Then you need to turn off the boiler and expansion tank and pre-flush the pipelines, radiators, etc. from dust, small debris (in the new circuit), from various deposits (in operating systems).

- During hydraulic testing, the system is filled with water (air pressure testing does not require this operation), a compressor is connected to it, usually to a drain valve. After this, the pressure is increased to the required value and its indicators are monitored using a pressure gauge. The absence of any changes indicates the tightness and possibility of operating the system. A decrease in pressure above the permissible value indicates the presence of any defects. In a heating circuit filled with water, it is not difficult to determine the location of leaks. To be able to detect damage during air testing, it is recommended to treat all joints and connections with a soap solution before starting work.

- After troubleshooting, the procedure is repeated. This step is carried out until the system becomes airtight.

- 5. Upon completion of all procedures, a pressure testing report is drawn up.

Figure 2 – Sample certificate of pressure testing of the heating system

What and how to flush heating systems

Washing and pressure testing of heating is carried out using specialized equipment. It also requires extensive work experience and qualifications. Therefore, we recommend that you contact our specialists, who, depending on many factors, will offer the best option for flushing and testing the heating.

The procedure for flushing and pressure testing the heating system in apartment buildings deserves special attention. After all, we have to deal with a branched system on a fairly large scale. It is important to choose both the optimal method and the equipment required in terms of power.

We invite you to familiarize yourself with our prices -

Today, we offer mainly the following types of heating system flushing:

- hydropneumatic;

- chemical;

- pneumohydropulse.

The hydropneumatic option involves pumping compressed air under sufficiently high pressure. The resulting air mixture pushes and literally crushes scale deposits at high speed, effectively removing them out.

Hydraulic flushing of the heating system is carried out in two ways:

- according to the so-called flow scheme. According to this method, it is necessary to first fill the pipes and radiators with water while the tap of the air intake device is open. Then the tap is turned off as soon as the system is completely filled. The compressor pumps up pressure to the required limit - the drain pipes are opened. As a result, the air-water mixture quickly passes through the pipes and drains. Flushing the heating system using this method is carried out until clean water comes out;

- the following method also involves filling the system with water, but without opening the air collector valve. Using duplicate pipes, the system is filled with a compressed air mixture for approximately a quarter of an hour (the exact time is determined by the operator). After this manipulation, dirty water is poured through the drain pipe.

Then the heating system is pressure tested to check for leaks, etc.

Chemical cleaning has proven to be an equally effective means of getting rid of deposits in pipes. In this case, the operator selects the appropriate chemical composition in the required concentration and pumps it into the system.

In each specific case, the selection of its own composition is required - so as not to destroy the pipe material, but to successfully dissolve scale and other contaminants. It is necessary to introduce solvents and inhibitors to protect the material from corrosion. After the deposits have dissolved, neutralizers are pumped into the system to reduce the toxicity of the solution. The heating system is also tested.

The advantage of the technique is that it is possible to carry out flushing using this method throughout the year, even during the heating season, without turning off the residents. As a rule, if a really good chemical wash is carried out, re-treatment will not be necessary for many years. So it is not surprising that this option is resorted to as an alternative to a major overhaul.

However, it will require the involvement of a truly experienced technician who can accurately determine the concentration of reagents and their retention time in the system. Otherwise, along with the scale, the pipes themselves can easily dissolve.

We recommend that you contact our specialists, since they have the necessary experience and have high-quality and effective chemicals at their disposal.

Pneumohydropulse flushing gives the maximum positive effect at an affordable cost.

This type of cleaning is carried out with specialized pneumatic equipment. The advantage is that there is no need to dismantle the system. The device generates a pulsed kinetic wave with cavitation bubbles inside the pipes. They create a powerful shock wave, which destroys the most stubborn deposits. However, inept manipulations can lead to pipe destruction. This is a serious argument in favor of turning to our qualified specialists.

Stages of crimping

The work is carried out at the following frequency:

- when starting a new system;

- annually after the heating season;

- after flushing or repairing the heating main with replacement of pipes.

For apartment buildings, preparation is as follows:

- Inspection of shut-off valves in elevators, central pipes, risers. On cast iron valves, the seals are changed, the paronite gaskets between the connection flanges are renewed, and unusable bolted connections are replaced.

- Using visual observation, pipes and fittings are examined for the presence of cracks, chips, corrosion, and defects. Make repairs if necessary.

- Check the thermal insulation of risers and main pipes in basements.

Pressure testing after pressure cleaning is necessary to identify possible leaks

Crimping procedures and testing are carried out taking into account the parameters of heaters and heating equipment indoors. Regulations allow the use of operating pressures of up to 6 bar for cast iron heating radiators. When they are in the walls, the maximum is 10 bar.

Hydraulic tests are carried out as follows: the system is checked as a whole, then a pressure higher than the working one is applied to the thermal unit.

According to Rules 115 clause 9.2.13., tests are carried out at a pressure not lower than:

- 1 MPa - elevators, heaters for heating and hot water systems;

- 0.6 MPa - cast iron and steel heating radiators;

- 1 MPa - convector, panel heaters;

- working pressure plus 0.5-1 MPa for hot water supply;

- pressure recorded in the manufacturer's instructions for air heaters.

The test pressure in steam systems is selected by the manufacturer from maximum to operating minimum:

- minimum - not lower than 0.2 MPa, but not less than 1.25 working;

- the maximum is established by strength calculations according to standards;

Crimping occurs at temperatures from + 5 degrees. If negative - in emergency cases.

If there is no visible leak, but the pressure drops, the pressure gauge shows problems in hidden places

Crimping stages:

- Filling the system with cold water. During work, the temperature of the liquid is no more than 45 degrees. The pressure increases gradually. Control is carried out using a pressure gauge.

- Once the set pressure is reached, the system remains at rest for about 30 minutes.

- During downtime, an inspection is carried out for leaks in pipes and batteries. Make sure there are no leaks. A method of control is to place toilet paper in dangerous places or wrap pipes with it. When there are leaks, spots of water and silt are visible.

- Control occurs according to the readings of the pressure gauge. The leak occurs in a place inaccessible to observation. A drop in pressure will warn of this.

Upon completion of pressure testing, a certificate of fitness for use is issued.

Pressure testing of heating radiators

heating radiator crimping

It was mentioned above that pressure testing of the heating system in a private house must be carried out with a pressure that does not exceed the maximum operating level of individual parts of the circuit. So, for example, for heating radiators this value depends on the material used to make the batteries. The maximum number of atmospheres that a particular radiator can withstand is indicated in its technical documentation. To perform crimp testing of heating batteries you need:

- cut off the radiator from the circuit;

- unscrew the Mayevsky tap and screw in a plug with a hole for the pump;

- pump up the required number of atmospheres and hold it for at least 5 minutes.

Pressure testing of heating radiators can be performed if there are suspicions that the battery may be a source of leakage or after repair work. In principle, you can check any individual section in a similar way by closing the necessary valves.

Types and principles of operation of pumps for pressure testing the heating system

Kinds

The classification of crimping devices is represented by the following main types:

- manual pump;

- electric pump.

The hand pump is a completely mechanical device. The big advantage of such a device is its low cost, as well as ease of operation and not pickiness. Typically, mechanical devices contain all the necessary components at once - hoses, a pressure gauge and a tank. Among the negative aspects, it is worth noting the low level of productivity. If you use this device yourself, you will have to make great efforts to perform high-quality work to check the system.

Based on the description of the manual pump, the following positive aspects can be identified:

- low cost;

- ease of use;

- high mobility;

- does not require power supplies.

Although electrically driven devices are more expensive and more cumbersome, the effort required to use them is kept to a minimum. Such a hydraulic pump can provide almost any level of pressure in the system. In many cases, these electrical devices are used by professionals when crimping work needs to be carried out frequently and on large objects. Electrical instruments allow you to check heating equipment, sanitary standards of technical devices, cooling and pneumatic devices.

The disadvantages of such equipment include the high cost, although there are many more advantages:

- full automation;

- Possibility of use on large objects;

- saving time and effort;

- high level of productivity.

How to choose?

When choosing a pump for pressure testing, you should consider two main factors:

- the capacity of the heating system in which the pump will be used;

- How often will pressure testing be carried out?

If the system check will take place in a small residential area and the frequency of checks will be rare, then it is not at all necessary to spend money on an electric pump. In this case, a hand pump will do just fine. But if the test involves pressure testing the system in a large room, then the power of a manual device may not be enough, so it is advisable to purchase an electric compression pump. Quite a lot of positive reviews are received by models not with a plastic case, but with an iron one, most often made of steel. And also in many devices there is a special valve that does not allow high pressure in the system during work. This aspect must also be taken into account when choosing a pump.

Connection

Before carrying out work to check the system, as well as connecting the pumping station to it, it is recommended to carefully read the connection diagram and take into account the design of the heating system itself. First, the system must be filled with water at a temperature above 5 degrees

Then a crimping device is connected to it using a hose. Typically a threaded connection is used. Under no circumstances should defects be repaired in a system with the crimping machine running. And also for safety reasons, it is not recommended to set the pressure too high, which can negatively affect the heating system and lead to its breakdown.

Models

Modern manufacturers offer a wide variety of models of pressure testing pumps.

Among the most famous, there are several options.

- NIR-25. This model of pressure testing compression pump is intended for pressure testing and hydrotesting of heating systems. This device is manually driven and is recommended for use with small objects. The pump is compact and light weight. This device is perfect for personal use when conducting tests in a private home.

- Compact-50. This model is made in Italy. Its advantages are contained in the name itself - it has small dimensions and light weight. This pump is equipped with a tank with a capacity of up to 12 liters, hoses and a pressure gauge.

- UGI-1. Another one of the most commonly used models of pressure testing pumps. Such a device allows for high-quality testing of the heating system and is suitable for performing various tasks. UGI-1 is equipped with a 20-liter tank.

Why should washing and pressure testing be carried out?

Timely flushing of the heating system in a private home or apartment building will allow you to both maintain it in working order and ultimately save significantly on repairs.

Moreover, the efficiency of heating systems can be influenced by a variety of factors:

- Serviceable heat generator;

- Availability of high-quality water in pipes;

- Maintaining optimal pressure in the system;

- Timely maintenance, including flushing and pressure testing of the heating system.

Timely flushing of the heating system in an apartment building or in a private country house will be the key to long-term successful operation of all elements of the system. Indeed, during operation, especially in hard water conditions, the inside of the walls of pipes and other elements of the system will become covered with scale.

Over time, the scale will develop into massive deposits that:

- Prevent the free flow of water inside the system;

- They deteriorate the thermal conductivity characteristics of pipes and reduce the efficiency of the system;

- The pipes themselves are also destroyed;

- They increase pressure, sometimes leading to a potentially dangerous situation.

This could ultimately lead to a serious accident. To prevent this from happening, regular flushing of the heating system followed by pressure testing is required. After all the work has been completed, accumulated scale deposits will be removed.

Our experts recommend the following frequency:

- flushing the heating system in an apartment building - annually;

- flushing the heating system in a private home - as the need arises.

If the heating system takes too long to warm up, the pipes are heated, but the radiator does not heat up, strange sounds appear during boiler operation, energy consumption has increased - it’s time to take care of flushing the heating system.

Heating system problems

Scale that appears on the walls of pipes causes mechanical wear of the metal. Due to deposits, the heat transfer of pipes decreases and their diameter decreases. In this case, the friction of the coolant against the walls increases significantly, which causes a drop in the flow rate of hot water. Therefore the temperature decreases due to thermal resistance.

All these consequences of scale formation cause increased fuel consumption. This will increase costs and the efficiency of systems will continually decrease. In this regard, pressure testing of heating systems is an extremely important undertaking.

Why is flushing necessary?

Most often, the question of flushing the heating system of a residential building is asked by property owners in the private sector. In this case, there are no management companies or other services that will take care of the necessary care in a timely manner.

Batteries are specially made of metal because it has good thermal conductivity. The system perfectly transfers heat to the room and works efficiently. But as liquid passes inside, various deposits can form. This is largely due to the quality of the water and the speed of its movement. Contaminants significantly reduce the thermal conductivity of the metal, so the batteries become slightly warm.

At the same time, the cost of every degree of temperature in the house literally increases. To guarantee a comfortable microclimate in the house and avoid overspending on heating, you need to flush the heating system on time. It is recommended to do this at least once every 7-10 years.

The main problems during operation are:

- Mineral deposits. The problem is relevant for non-galvanized steel pipes.

- Siltation. Most often, owners of cast iron batteries encounter silting. It is also important to be careful with large numbers of sections.

How to correctly draw up a pressure test report for a heating system

To draw up an act according to all the rules, it is important to indicate in it the following:

- Test method used.

- The project according to which the installation and installation of the test object was carried out.

- Date and address of testing events.

- List of persons whose signature must be on the document. In most cases, the property owners and representatives of service organizations are indicated.

- Methods for eliminating identified defects.

- Test results.

- Presence of signs of depressurization of the system or violation of threaded connections and welds. It should also be noted that there is condensation on the surface of pipes and fittings.

What is the importance of circulation pumps for heating systems?

There is an opinion that there is no particular need to use a circulation pump for heating systems. Proponents of this judgment argue their position by saying that a pump is a device that unnecessarily consumes a lot of electricity and makes the heating system dependent on it. That is, in the event of a power outage, problems will arise with the supply of heat to the house.

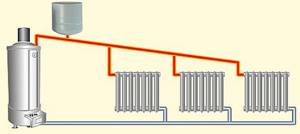

This judgment may seem correct. So, if the installation of a heating system is carried out in a small house where the pipeline is not very branched, then it is possible to organize natural circulation of the coolant from the boiler to the radiators.

Upon detailed study of this approach, it becomes obvious that its advantage is only independence from electricity (provided that the heating boiler is energy independent). In all other characteristics, a system with natural circulation is inferior, and it is much more difficult to install.

In order to ensure natural movement of the coolant, the pipes in the heating system must be of different diameters (50 mm or more). They are more difficult to install, moreover, they are more expensive

During installation, it is important to follow the rule - the pipes along the entire length of the circuit must have a slope towards the boiler. Often this cannot be achieved without spoiling the appearance of the rooms.

If a heating system with natural circulation has been carefully thought out and well-functioning, then the pressure drop due to the temperature difference in the pipes (in both directions of water movement) will still be no more than 0.6 Bar. This value will most likely be sufficient for a house that is not large in size. However, if the heating system has branches, is characterized by a large extent, and there are also large differences in height and pressure, then 0.6 Bar is unlikely to be enough. Moreover, the situation can be complicated by hydraulic resistance, due to which the circuit may “lock up”.

Connecting a circulation pump to the heating system will help solve many problems.

Circulation pumps for heating systems consume quite little electricity, which makes it possible, even when it is turned off, to heat the house from a medium-power UPS for several hours, which is especially important when using a boiler with “intelligence”

However, if the problem of power outages for your home is constant, then connecting a circulation pump to the heating system will make no sense. In this case, it is necessary to consider in a timely manner how to create an effective system with natural circulation.

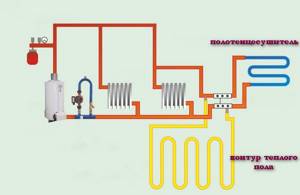

In heating systems operating using circulation pumps, it is possible to regulate both their operation as a whole and by room or group of radiators. If the heating system is well thought out, then there will be no problems with multi-way valves, electromechanical regulators and other thermostatic devices during operation.

If you need to “split” the heating system into several sections that differ in heating temperature, this will not affect its overall operation in any way (which cannot be said about heating systems with natural circulation). You can safely choose the most suitable heating options for your rooms - using radiators, any convectors, or underfloor heating circuits.

It is impossible to install water floors in houses without connecting a circulation pump for heating systems. A well-thought-out system operating with a pump is characterized by high operating efficiency, which is worth the money spent on its purchase and payment for the electricity consumed by this equipment. This system turns out to be more economical: the pipes can be of small diameters, they can simply be hidden in the floor or wall.

The pipe contours of a heating system with a circulation pump can have any number of branches, and the number of heated floors can also be any

It is important to choose the right pump that will create the required pressure. And yet, a heating system powered by a circulation pump is easier to start, maintain and carry out its prevention

So, installing a circulation pump in a heating system has many advantages, which definitely outweigh the disadvantages, so in almost all cases you should think about purchasing one.

If your home already has a heating system with natural circulation, you can still purchase a circulation pump, the efficiency of which will be obvious.

Read material on the topic: Hot water supply for a private home

Flushing heating systems

The accumulation of silt and scale in pipes and radiators reduces the quality of heating - just 1 mm of scale reduces the heat transfer of the device by 15%. To normalize the temperature in the house, you will have to increase the heat output of the boiler, which means additional fuel and labor costs. Lime is essentially a heat insulator. Its thermal conductivity is 40 times lower than the metal composition. Therefore, even a thin layer leads to a decrease in heat transfer by the coolant. Scale is aggressive. It interacts with the metal and leads to increased corrosion. The aggressiveness of scale creates fistulas and corrodes welds over several years.

In an apartment building

The hydropneumatic method of flushing the heating system is constantly used by utility workers. If you follow the technology, this is an effective way.

The principle of operation is simple - first the water is discharged, then it is supplied back to the heating system by pumps. Under the influence of the coolant flow, scale flakes peel off and come out along with the water when drained.

Step by step sequence:

- Before work, all taps are turned off.

- The end caps of the heating batteries are unscrewed using a special key.

- The return valve closes.

- The air pump is connected to the valve located after the valve.

- The return is reset.

- A pressure of over 6 atm is injected into the pneumatics.

- The valve to which the pneumatic equipment is connected opens.

- The risers are blocked one by one. Up to 10 pieces at a time - this will make the washing procedure effective.

The next step is to switch the system to reset in the opposite direction:

- The discharge closes, the valve connected to the device is closed, and the pneumatics are turned off.

- The open valve is retracted, after which a similar one on the return line is opened.

- The water is discharged - the pneumatic pump is connected through the valve in the opposite direction, the valve opens, and the pneumatics turns on. The liquid will flow in the reverse direction.

The productivity of cleaning is determined visually - if clear liquid begins to come out, washing can be completed. The dirt is poured into the prepared dishes. If possible, a hose is connected and the dirty coolant is discharged into the sewer.

In a private house

Rinsing in a private home is difficult to do with your own hands, but it can be done by reading the instructions. Produced in two ways:

- Flow method. Cleaning from slag and deposits using this method involves completely filling all devices with coolant while leaving the air vent valve open. After filling, the valve closes. Simultaneously with the supply of compressed air, the drain hole opens. The water-air mixture continues to flow until clean water appears. The amount of flushing liquid is 3-5 times greater than the working value. Therefore, prepare drainage containers or drains in advance.

- Flushing with filling. The system fills with the valves closed. Air is supplied under pressure for a period of 5-10 minutes. into the inlet pipe, while the outlet is closed. After the end of the compressed air supply, the flushing is drained along with dirt and scale.

The volume of supplied liquid and air is calculated individually. An incorrect calculation will lead to numerous pipe breaks rather than flushing.

In private homes, collectors, shut-off valves, boilers, boilers, joints with appliances, electric circulation pumps, and heated floors are checked.

There is no need to buy washing equipment - it is rented. If it is necessary to draw up official papers and a test report, a special team is called. The estimated cost of services is 1000–2600 rubles/hour.

What pressure should be in the heating system of an apartment building

Developers must know information about the test pressure value when testing a heating system. The regulatory documents say that the test is carried out with a pressure that exceeds the operating indicators by 1.25-1.5 times. This is stated in the relevant Sanitary Norms and Rules, as well as in the “Rules for the technical operation of thermal power plants.”

To determine the operating pressure of the system, it is necessary to focus on the number of floors of the house. In the autonomous heating of a private house with a height of no more than 3 floors, the pressure does not exceed 2 atmospheres. In this case, the adjustment is carried out automatically, excess pressure is released by a special valve. In houses up to 5 floors, the operating pressure can be about 6 atmospheres. In buildings with a height of more than 8 floors, the systems have an operating pressure of up to 10 atmospheres.

However, to carry out pressure testing of a heating system in an apartment building, it is important to know the maximum test pressure threshold. This data is provided by the organization that developed the project.

When determining what the maximum pressurization pressure for a heating system can be, the characteristics of all elements that make up the heating system are taken into account. In particular, we are talking about pipes, heat generators, heating devices and various fittings

In order not to cause harm to the heating during pressure testing, restrictions on the maximum test pressure are introduced. For example, for cast iron radiators you can use a pressure of no more than 6 atmospheres, and for panel radiators - no more than 10 atmospheres.

Newly installed heating system

The most common mistake that contractors make when preparing a heating system for delivery and commissioning is flushing the system with open heating devices. They need to be cut off.

If this is not done during flushing, scale and other dirt will clog into heating devices that are equipped with thermoregulatory valves. The passage opening of the valves is several times smaller than that of the pipeline. For this reason, trapped scale and dirt come out of heating devices with difficulty and in measured doses. It will take more resources (water and time) to flush the system.

Another mistake is flushing the entire heating system of the facility. For example, if it is necessary to flush a section of a multi-storey building or the heating system of a facility (kindergarten, school, business center), I recommend flushing the system in parts: risers, technical underground decks, technical floor decks. Otherwise, the process will become more complicated, the dirt will move in a large circle, and this will again lead to additional waste of time and water.

To flush the system you will need:

- An air compressor with a receiver of at least 40 liters (it is necessary to attach a regular plumbing check valve to the compressed air hose to avoid accidental water entering the compressor receiver).

- Hydraulic press for crimping the system.

- Walkie-talkies for staff.

- Flexible connections or sections of hoses - for looping heating risers, since heating devices will be blocked.

- Clamps.

- Flax and pasta.

- A tee is a device consisting of two incoming pipes with taps: one for compressed air, another for water, and a third pipe for connection to the pipeline being flushed.

- Hose for draining dirty water.

- New 16 atmosphere pressure gauge for pressure testing of the system.

- Set of wrenches.

- Welding machine.

- Minimum two people (depending on the number of simultaneously washed risers or heating beds).

Next, let's begin the preparation and washing itself:

- We turn off the heating devices.

- We cover the sun loungers in the basement and on the technical floor to cut off the risers. If the system has automatic balancing valves (usually installed in the basement), they must be excluded from flushing the system, since the existing impulse tube may become clogged with dirt. In addition, high pressure during pressure testing can damage the valve diaphragm.

- We loop risers or sunbeds.

- We connect the compressor and water to the riser or deck using a tee. We raise the pressure of the water-air mixture to 10 atmospheres.

- We check for leaks. If we find them, we eliminate them.

- We begin to wash the system with a water-air mixture until the water becomes clear and all kinds of suspensions (scale) are absent.

- After flushing the entire heating system, open the shut-off valves on heating appliances, risers, sunbeds and fill the system with water. We use a pressure tester to pump up the pressure in the system to 10 atmospheres and wait about an hour. If the pressure does not drop, then the system is flushed and sealed. If there are leaks on the shut-off valves, we fix them.

- You can present the heating system to representatives of heat supply and operating organizations.