Here you will learn:

- Old methods of compaction

- Sealant for sealing joints

- Sealant for sealing leaks

- Sealants for interior repairs

Characteristic signs of a properly functioning heating system are that the house is always warm, stable coolant pressure in the circuit, and no leaks. Reliability is laid down at the installation stage, which depends on the skills and qualifications of the installer. But sometimes leaks do happen, causing users a lot of problems. Let's see how to get rid of leaks and achieve a tight system even at the stage of its construction.

In this review we will cover the following topics:

- What is the best way to seal pipe joints?

- How to get rid of a visible leak.

- How to get rid of a hidden leak.

We will provide detailed instructions for each question.

Basic properties and functions of sealant for heating systems

The sealant is a self-compacting solution that can be used to eliminate liquid leaks in pipes and at joints. Various types can be used both outside and inside water systems. After application, upon contact with air, the sealant quickly hardens, which allows you to resume operation of the system almost immediately. In what cases is it rational to use sealant inside the water supply:

- there is no way to eliminate the leak using a clamp or soldering;

- the location of the leak is not visible;

- pipes are in an inaccessible place;

- if there is a heated floor.

In all such situations, using a sealant allows you to eliminate the problem without compromising the integrity of the walls and floors.

Sealant for heating systems is used both during pipeline installation and during repair or dismantling, for example, when batteries are disassembled into separate sections. Taking into account the conditions in which the sealing composition will work, the following requirements are put forward to it:

- heat resistance;

- resistance to deformation;

- moisture resistance;

- resistance to temperature changes.

Based on where the sealant will be used, choose its type.

Leak in the heating system

List of Best Pipe Sealants for 2021

“Repair 100%” white, all-season

The sealant contains silicone rubber, which increases adhesion to various materials, and acetic acid, thanks to which it can withstand temperature changes.

Average price – 150 rubles.

Characteristics:

| Volume/weight | 260 ml. / 350 gr. |

| Application temperature | +5°С – +40°С |

| Type | sanitary silicone sealant |

| Operating temperature | –40°С — +100°С |

| Application area | for interior use, sanitary, for pipes |

| Package | cartridge |

| Peculiarities | heat resistant, anti-fungal, elastic, waterproof |

| Processing material | ceramics, glass, aluminum |

Budget brand. Presented with a small assortment of the most popular household sealants on the market at the lowest possible price. It stands out among competitors not only in price, but also in its bright packaging design. Visible in any hardware store. Product quality is acceptable for economy class goods.

“Repair 100%” white, all-season

Advantages:

- affordable price;

- absence of foreign odors;

- copes well with small cracks;

- dries quickly.

Flaws:

- not identified for this price segment.

Kim Tec Silicon, clear, all-season

A one-component sealant based on silicone. In a humid environment it hardens and becomes rubber-like. Suitable for working in a vertical position, sets quickly.

Average price – 250 rubles.

Characteristics:

| Volume/weight | 310 ml. / 350 gr. |

| Application temperature | +5°С – +40°С |

| Skin formation time | up to 10 minutes |

| Storage rules | store vertically, with the valve facing up, in a cool, dry place at an ambient temperature of at least +5°C |

| Type | silicone sealant |

| Application area | for interior use, sanitary, for pipes |

| Package | cartridge |

| Peculiarities | UV resistant, heat resistant, anti-fungal |

| Processing material | wood, stone, concrete, ceramics, ceramic tiles, PVC and other plastics, glass, metals |

German brand of building materials. It is characterized by high European quality, responsible attitude towards customers and constant product development.

Kim Tec Silicon, clear, all-season

Advantages:

- can be used as glue;

- high quality;

- wide range of applications.

Flaws:

- has a pungent odor;

- doesn't wash well.

Ultima 80, white

"Ultima 80" - designed for use in rooms with high humidity.

Average price – 200 rubles.

Characteristics:

| Volume/weight | 80 ml. / 120 gr. |

| Application temperature | +5°С – +40°С |

| Operating temperature | –40°С — +120°С |

| Drying time | 10 – 25 minutes |

| Application area | for interior use, sanitary, for pipes |

| Package | tube |

| Peculiarities | UV resistant, heat resistant, anti-fungal, elastic, moisture resistant |

| The basis | Silicone |

| Processing material | wood, porcelain, plastic, glass, ceramics |

A brand from Europe, designed for both repair specialists and ordinary users. Contains a large line of high quality products at reasonable prices. Production is located in several countries and has a progressive control system for final products.

Ultima 80, white

Advantages:

- European quality at an affordable price;

- Excellent for gluing glass structures.

Flaws:

- Strong smell;

- inferior to competitors in smaller volume.

Penosil All Purpose Silicon Sealant, colorless, multi-purpose

Can be used with almost any type of building materials, with the exception of vinyl and bitumen. It does not deteriorate under sunlight, is resistant to detergents and temperature changes.

Average price – 425 rubles.

Characteristics:

| Type | sealant |

| Application area | for exterior work, for interior work, for roofing, for pipes, for windows |

| Processing material | metal, wood, glass, plastic, ceramics |

| Volume | 310 ml |

| Type of packaging | cartridge |

| Peculiarities | UV-resistant, frost-resistant |

| Color | white, colorless |

| Type of silicone sealant | neutral |

| Operating temperature | -40°C — +150°C |

Well-known international brand of construction chemicals. It has a wide range of products used in all areas of construction and repair. Many years of experience, compliance with international safety requirements and the desire for innovation allow the company to produce one of the best products in the world.

Penosil All Purpose Silicon Sealant, colorless, multi-purpose

Advantages:

- versatility;

- convenient universal packaging;

- contains a fungicide that is resistant to mold;

- excellent adhesion to most materials.

Flaws:

- pungent odor of acetic acid.

Tytan Euro-Line, white, sanitary

Sanitary silicone sealant, thanks to its special composition, prevents the formation of mold and mildew. Easy to use. Retains its properties for a long time.

Average price – 200 rubles.

Characteristics:

| Volume/Weight | 290 ml. / 350 gr. |

| Application temperature | +5°С – +40°С |

| Seasonality | all-season |

| Compound | silicone polymer with acid curing system |

| Skin formation time | from 15 to 25 minutes |

| Heat resistance | -40°C — +100°C |

| Application area | for interior use, sanitary, for pipes |

| Package | cartridge |

| Peculiarities | heat resistant, anti-fungal, waterproof |

| The basis | silicone |

| Processing material | ceramics, glass, metals, brick, aluminum, PVC |

Famous Polish brand Selena. The product line includes a wide range of products in various areas of construction and repair. The company's extensive experience in production and close cooperation with professional consumers allows us to achieve the best properties of the product.

Tytan Euro-Line, white, sanitary

Advantages:

- reliable and high-quality product;

- Ease of use;

- Suitable for rooms with high humidity.

Flaws:

- strong unpleasant odor;

- high price.

REMONTIX, universal

The product is made on a silicone acid base. Resistant to sunlight and humidity. Ideal for sealing joints and seams of ceramic, wood and plastic materials.

Average price – 220 rubles.

Characteristics:

| Application area | for exterior use, for interior use, for pipes, for windows |

| Processing material | metal, wood, glass, plastic, ceramics |

| Volume | 310 ml. |

| Type of packaging | cartridge |

| Peculiarities | UV-resistant, heat-resistant, frost-resistant |

| Drying time | 15 minutes |

| Method of release from the cylinder | gun |

| Operating temperature | -40°C — +100°C |

The REMONTIX brand is relatively young. The entire product line is the fruit of the developments of modern technologists and engineers. In addition to various sealants, the range also includes polyurethane foam, adhesive tapes and seals.

REMONTIX, universal

Advantages:

- lays down in an even layer;

- good for bathrooms;

- price-quality ratio.

Flaws:

- unpleasant odor;

- no cap.

STAYER Master, neutral

Sealant for wide application, resistant to environmental influences. Has no smell. Has good adhesion to various building materials. Can be used with metals and concrete.

Average price – 250 rubles.

Characteristics:

| Application area | for exterior use, for interior use, for pipes, for windows |

| Processing material | metal, wood, glass, plastic, ceramics |

| Volume | 260 ml. |

| Type of packaging | cartridge |

| Peculiarities | UV resistant |

| operating temperature | -40°C — +100°C |

| minimum application temperature | +5°С |

Brand of the German company KRAFTOOL. The main specialization of the company is construction tools and equipment for the home. Thanks to many years of experience in construction, the company easily began working in the construction chemicals segment. A well-known name, wide range and quality allow us to compete in the Russian and international markets.

STAYER Master, neutral

Advantages:

- hardens well and quickly;

- does not shrink;

- has no pungent odor;

- prevents the spread of mold.

Flaws:

- not identified.

Types of sealants for heating systems

Different manufacturers offer a large selection of sealants that differ in their chemical composition and purpose. They are conventionally divided into the following groups:

- silicone;

- polyurethane;

- liquid polymer.

Each of them has its own purpose and properties.

Silicone sealants

Silicone is the most popular. With its help you can seal any joints and eliminate leaks. Withstands temperature changes ranging from 30 to 60 degrees. The composition has all the necessary qualities to perform high-quality work:

- strength;

- penetrates into the most inaccessible places;

- elastic.

When purchasing, pay attention to the composition of the silicone sealant. The acid contained in some types can cause metal corrosion.

Universal silicone sealant

Polyurethane

They belong to the group of oligomers. In addition to polyurethane compounds, there are also polysulfide compounds. Both types are widely used in construction. To seal heating systems, carefully study the composition, since not all materials are suitable for these purposes.

A distinctive feature of polyurethane sealants is durability, resistance to aggressive environments and mechanical stress. In addition, material consumption is very economical.

Polyurethane sealants come in one- and two-component types. The former are cheaper, but take longer to harden. They have good elasticity, adhesion to metal, resistance to high temperatures and corrosion. However, despite many positive qualities, polyurethane sealants are not as in demand for household purposes as silicone ones due to their high price.

One-component polyurethane sealant

Liquid sealant for heating system

Liquid-type sealants are used where there is no easy access to the leak or it is simply not visible. The principle of operation of the polymer liquid material is based on the fact that it is poured into the system along with the coolant. In the section of the pipeline where there is a leak, the composition, interacting with air, begins to polymerize. Thus, thickening, it seals the cracks.

The following types of liquid sealants are distinguished:

- for systems installed in water;

- for heating systems running on antifreeze;

- for troubleshooting metal surfaces;

- for plastic pipes.

This variety allows you to choose a sealant to suit your individual needs, so carefully read the instructions before purchasing.

Liquid sealant for heating system

About the pros and cons of glycol antifreeze

The main advantage of artificial coolants based on glycols is the preservation of the liquid phase at subzero temperatures. We list other positive aspects of using antifreeze in closed water heating systems:

- coolants do not contain calcium and magnesium salts, which form scale inside the heat exchangers;

- due to the penetrating ability of glycols, the effect of lubrication of moving parts occurs, ball valves and thermostatic valves do not sour, the fittings last longer;

- the boiling point of antifreeze 103-106 °C delays the moment of vaporization and airing in case of overheating of a solid fuel boiler;

- When the temperature drops below the freezing threshold, glycol solutions turn into a gel mass.

Let us explain the last 2 points. Ordinary water, often poured into the heating system of country houses, begins to boil at 96-98 ° C, actively releasing steam. If the circulation pump is on the TT boiler supply, the steam phase penetrates the chamber with the impeller, water pumping stops, and the boiler completely overheats. A higher boiling point of antifreeze will delay the moment of the accident.

Unlike water, glycol hardened in the cold does not expand and does not destroy pipe walls. In the event of freezing, the only unit that will suffer is the forced circulation pump. The crystallizing gel will jam the impeller and the motor will burn out.

Unfortunately, there are plenty of disadvantages to non-freezing substances:

Ethylene glycol is poisonous and requires careful handling and disposal of the solution. Glycerin and polypropylene glycol are harmless. The heat capacity of the “anti-freeze” is 15% less

To deliver the required amount of heat to the batteries, the liquid flow will have to be increased. The viscosity of antifreeze creates additional hydraulic resistance. You will need a more powerful and expensive circulation pump. Good turnover is a double-edged sword. Glycols penetrate through the slightest leaks, from which plain water cannot flow.

Coolants and additives decompose during operation, losing their frost-resistant properties and forming flakes of sediment. The maximum service life of 1 refill is 5 years, then the heating is flushed and replaced. When using antifreeze, many gas boiler manufacturers void the warranty of the purchased product.

Glycol liquids are poorly compatible with electric boilers. Instructions for the use of various antifreezes categorically do not recommend filling systems operating in conjunction with electrolysis heaters with antifreeze. That is, for electrode boilers of the “Galan” type, a special coolant developed by the specified company is needed.

Under rare circumstances, antifreeze can release flammable gas that breaks through the automatic air vent. Example: the heat source is an electric boiler, the heaters are Chinese-made aluminum radiators. Heating glycol causes a complex chemical reaction and gas formation. The fact is demonstrated in the video:

How to choose a sealant to eliminate leaks in the heating system

Heating systems differ from other communications due to changes in operating temperature and possible deformations. To eliminate leaks in CO, certain compounds are needed that can withstand such operating conditions. The most popular types of silicone paste sealants are:

- drying - after complete drying, the material shrinks, therefore, if the drying technology is not followed, cracks and smudges may appear;

- non-drying - used to eliminate small leaks and seal threaded connections. Their disadvantage is that with excess pressure, the sealant can be squeezed out of the joints.

Silicone and thiokol sealants are suitable for sealing threaded joints because they do not deform or clog threads after curing.

Acrylic compounds are suitable for household radiators. They are resistant to temperature changes, mechanical stress and aggressive environments. Once in a crack or joint where there is no air, the sealant quickly thickens, forming a plastic mass. This makes the installation process easier, but dismantling in the future will be difficult.

In addition to the sealants described above, there are special compounds that work at ultra-high temperatures. For example, in fireplaces, chimneys or stoves.

The manufacturer must indicate for what specific case a particular type of sealing material is used.

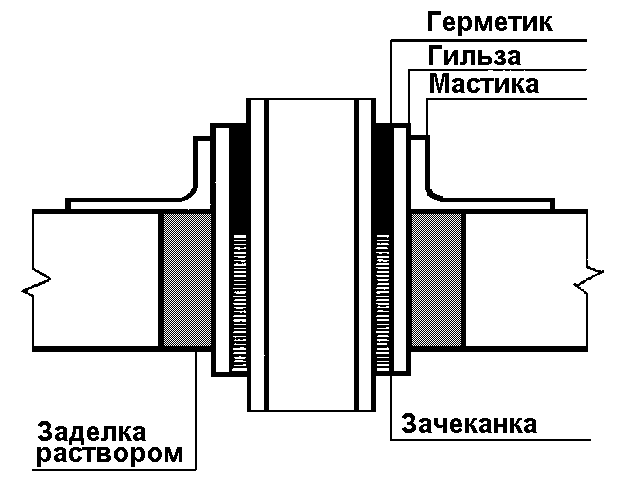

When is sealing of sewer pipes required?

Often the sewer riser or outlet parts of a cast iron pipe receive serious damage. An inspection shows that a piece of the cemented patch is falling off, and the pipe itself may fail. In this case, the master decides to use sealant for cast iron sewer pipes or PVC plastic pipes. During the work, the recommendations specified in SNiPs and technical regulations, pipe wear, hydraulic effects and the possibility of leaks are taken into account.

Sealant for sewer pipes must be selected taking into account the fact that this external sewer has a significant diameter and a large length.

Sealing PVC sewer pipes is necessary to prevent sewage from entering the apartment and eliminating unpleasant odors in residential areas.

Solving the problem of sealing joints must be taken quite seriously.

Having identified the cause of the malfunction that is interfering with the operation of the cast iron pipe, the owner can carry out the entire cycle of necessary work to eliminate it.

The causes of pipe leaks are varied:

- defect in the material used to install the sewer;

- improper laying of cast iron sections;

- the presence of cracks and holes in the riser.

Technology and methods of using sealant for heating systems

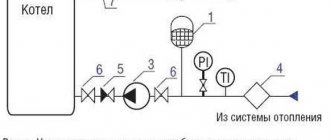

Using sealant for interior or exterior work requires prior preparation. The composition corresponding to the type of system is selected. The consumption of liquid sealant for the home heating system is calculated based on the volume of water. For every 60-80 liters, 1 liter of sealant is required.

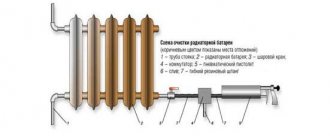

It is also necessary to prepare the system itself. All air is removed from it, filters are dismantled, and all taps are opened. A pump is installed on the first radiator, with the help of which the remaining air is eliminated and the pipe is heated to 50-60 degrees.

External treatment

Measures to seal joints and threaded connections are carried out in a certain order.

- There is a damaged area.

- All liquid is drained from the system.

- The damaged area is cleaned of dust, old sealant (if present at the joint), and degreased.

- The sealant is applied according to the instructions.

Only after the insulating composition has completely hardened is the coolant again poured into the system.

Repairing leaks mechanically

If you want to reliably repair the system and forget about the problem for a long time, you will have to spend money. Moreover, the list of means used is significantly expanded (the price of the product is indicated in brackets):

- clamp clamp for car cooling pipes (0.4 cu);

- pipe bandage with 4 bolts (0.7...10 cu depending on the material and workmanship);

- self-vulcanizing tape (2.5 cu);

- saddle clamp used for insertion, plus a plug (2...10 cu);

- reusable Kibosh clamp from the ROTHENBERGER brand for emergency leak repair (20 euros).

In addition to these devices, “original” fittings – couplings – are used to restore the tightness of plastic lines. The branch of the system is emptied, the pipe is cut at the point of leakage, then the ends are joined using a coupling.

Metal bandage (left) and plastic saddle clamp (right)

Another simple connector for steel is a reinforced hose of suitable diameter. The latter is installed instead of the cut out rotten section of the water supply system. Fastening method: tight or wire clamps.

Now we will explain one by one the technology of using mechanical sealing means:

As you can see, only vulcanizing tape is suitable for all types of damage. The remaining clamps and bandages are mounted on straight sections of pipes; it will not be possible to seal the battery, joint or bend. But there are various chemicals for this purpose.