Here you will learn:

- Single pipe systems

- Single-pipe horizontal

- Single-pipe vertical

- Scheme "Leningradka"

- Two-pipe system with bottom wiring

- Two-pipe system with top wiring

- Beam system with collectors

- With forced and natural circulation

One of the stages of building a private house is the design and creation of a heating system. This is a difficult stage, since you need to not only design the heating, but also save on materials. An important factor is that the heating created must be efficient and economical. We create heating for a private house with our own hands - you can find wiring diagrams (the most basic) in our review.

There are many schemes for laying heating pipes in private households. Some of them are combined, which allows you to increase the efficiency of the system and achieve more uniform heating throughout the house. In our review we will consider only the most basic schemes:

- single-pipe horizontal circuit;

- single-pipe vertical design;

- "Leningradka" scheme;

- two-pipe system with bottom wiring;

- two-pipe system with top wiring;

- beam system with collectors;

- schemes with forced and natural circulation.

Let's look at the features of the presented schemes, and also discuss their advantages, disadvantages and installation features.

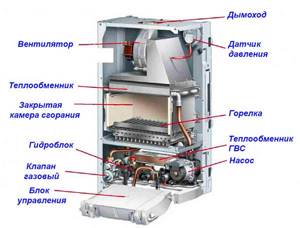

Gas heating at home

One of the most inexpensive options is gas heating, but only if gas is supplied to your land. With gas heating there is no dust, dirt or soot. A gas boiler should be selected depending on the heated area. Boilers come in low, medium and high power. Gas boilers are equipped with devices that ensure safe operation. But there is always a danger of explosion if used incorrectly, or gas poisoning.

For residents of Russia, gas is the best option for heating a private home due to the most affordable price. An important factor when installing a gas facility is a large number of permitting documentation.

Boiler installation instructions

Strict requirements are put forward only for the installation of gas-powered heaters. But we recommend following these rules when installing any heat generators:

- Equipment with a power of up to 60 kW can be placed in a kitchen with ceilings of 2.5 m (minimum). More powerful units are moved to a technical room - internal, attached or free-standing.

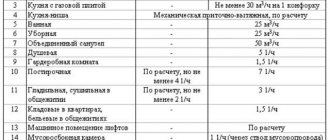

- The requirement for furnace ventilation is threefold air exchange, that is, the amount of supply and exhaust air is equal to three volumes of the room in 1 hour. The kitchen window is equipped with a window.

- When placing a floor-standing boiler, observe the minimum technological passages - 1.25 m in front, 60 cm on the side, 250 mm in the back from the nearest building structure, as shown in the photo.

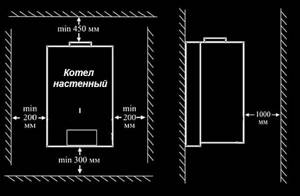

- The distances from the wall-mounted heat generator to the walls or cabinets are 20 cm on the side, 45 cm on the top, 300 mm on the bottom. Before hanging, a protective sheet of roofing steel is laid on the wooden wall.

- The height of the chimney is 5 m, calculated from the grate or gas burner, not from the ground. The head of the pipe should not fall into the wind support zone of the roof.

- The maximum number of turns of the chimney is 3, the distance from the chimney to combustible structures is 0.5 m.

Clarification. Double-walled sandwich-type chimneys can be placed at a distance of 38 cm from wooden walls and ceilings.

The heat generator piping depends on the fuel consumed. High efficiency boilers - gas, diesel - are connected to the system directly through shut-off valves. Floor-standing versions are additionally equipped with an external expansion tank and pump.

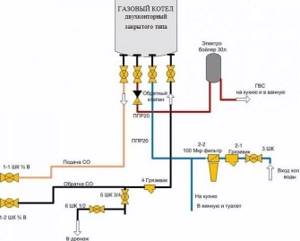

Typical wiring diagram for a double-circuit wall-mounted heat generator

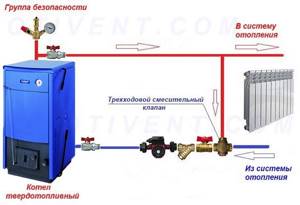

Solid fuel units must be protected from cold return flow and condensation; accordingly, a small boiler circuit with a three-way mixing valve is provided. Please note: the pump is always installed inside the circuit, on the supply or return line - it makes no difference. Detailed wiring diagrams are shown in the instructions for connecting TT boilers.

Important! In a closed system operating under pressure, there is always a safety group - a pressure gauge, an automatic air vent and a safety valve. The installation point is the supply pipe at the boiler outlet. To prevent dirt and sand from getting inside the heat exchanger, a filter - a mud filter - is placed on the return line in front of the heater.

Electric heating

The advantage of an electric boiler is ease of installation and a small number of permitting documents. This boiler practically does not require maintenance. Electric heating is suitable for areas where natural gas is not available.

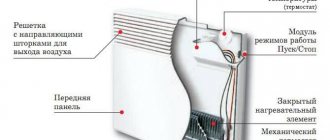

Electric heating is an environmentally friendly form of energy. It can be carried out using infrared heaters, using electric heated floors, using oil heaters, electric boilers of various designs. To convert electrical energy into heat, electric convectors are usually used for private houses. This is usually a metal case in which a heating element is mounted, which heats the air inside the case.

Warm heated air rising upward heats the room. Convectors are equipped with a temperature sensor. These devices are quite expensive, and the level of electricity consumption is quite high. When heating a large area, it is not advisable to use them. The water heating system using electric heating elements does not differ from systems that use boilers running on other types of fuel.

Electricity will be the best heating for a private home if the house is small, if you have nightly electricity tariffs, if there is no gas and there is no desire to heat it with coal.

Choosing an energy carrier

The main selection criterion is the cost of energy, depending on the country and region of residence. If in the Russian Federation the undoubted leader is natural gas, then in the rest of the states of the former USSR the picture is different - firewood, briquettes and coal take the first place. Don't forget about electricity supplied at half the nightly rate.

When choosing the right type of fuel, it is worth considering five factors (in addition to price):

- efficiency (efficiency) of heating equipment using this energy carrier;

- ease of use;

- how often the units will have to be serviced, prices for calling a technician;

- storage requirements.

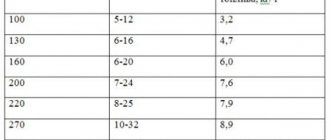

Below is a comparative table showing the prices of various energy sources and how much a kilowatt of heat produced in real conditions costs. Building area – 100 m², region – Moscow region.

Note. The calculation results and prices are given as of February 15, 2018. Over time, the data becomes irrelevant, but the difference in the cost of 1 kW remains.

Based on the numbers given in the table, it is much easier to find a suitable option (or several). Just make an adjustment for the cost of energy in your region. Based on other selection criteria, we will give 4 tips:

- It is most convenient to use gas and electric heating equipment. There is no need to store anything, constantly maintain and bother with cleaning water heating devices.

- Burning coal and wood is the most economical way to heat. Saving money will have to be paid for with labor - sawing, carrying, loading the firebox, cleaning the chimney. It is more comfortable to burn briquettes and pellets, but the price of the boiler installation and the fuel itself increases. Plus you will need storage for storage.

- Diesel fuel or liquefied gas is the best solution for providing autonomous and at the same time comfortable heating when other energy sources are not available. The downside is the decent cost of fuel and installation of the fuel tank.

- A proven option is the combination of 2-3 energy carriers. A common example: solid fuel + electricity at night tariff.

Which fuel is best to use in specific conditions is described in detail in a separate material. We also recommend watching the video and listening to useful expert advice:

Water heating pros and cons

Water heating devices play the role of a closed system or an open one. The closed cycle system does not require the consumption of additional water. This option reduces the amount of energy spent on “heating the street.” Water heating concepts do not trap dust inside or spread dust into the home. Don't forget that heating your home with water heaters is a long process.

Installation process

When the heating system design has been approved and materials and equipment have been purchased, you can proceed to installation. Like any construction procedures, work on installing heating for a house or city apartment is divided into several successive stages.

System type

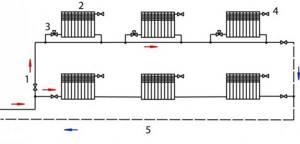

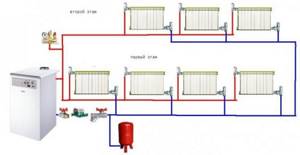

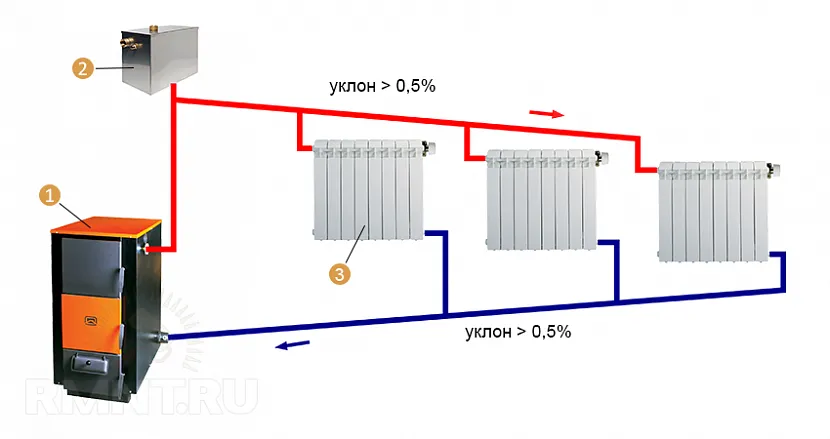

When starting the main work, it is necessary to take into account that the heating system can be one-pipe or two-pipe - it all depends on its connection diagram. In a single-pipe system, the coolant sequentially passes through all the batteries and returns back to the heating boiler.

Its disadvantage is that in each subsequent radiator the coolant temperature decreases. The advantages include lower pipe consumption and, accordingly, lower cost of project implementation.

A two-pipe system involves a separate supply pipe to each battery. The outlet circuit for all heating points is common; cooling water flows to it through a separate pipe.

Tools

In order to properly install pipes, you will need a set of tools:

- roulette;

- pliers;

- level;

- adjustable wrenches and wrenches;

- screwdrivers;

- Bulgarian;

- soldering iron for propylene pipes with nozzles;

- metal hacksaw or cutter (scissors);

- hammer drill

Marking

When all the tools are at hand, you can apply markings according to the diagram in the places where the pipes pass and the radiators are attached. Here you need to follow certain rules.

Installation points for brackets for attaching radiators are marked under the window openings. When marking, you need to take into account that the distance from the floor to the bottom point of the radiator must be at least 6 - 10 cm. The same distance is measured from the window sill to the top point of the heating element.

These places are leveled to avoid distortion. When laying pipes, it is necessary to observe their slope (5°) towards the circulation; according to this rule, markings are applied for attaching clips.

When the marking is ready, holes are drilled to fix the fasteners.

Installation of a heating boiler

There are a number of requirements for securing the main heating element:

- fasteners are mounted exclusively on load-bearing main walls;

- the proportionality of the hood and the chimney opening is strictly observed;

- free access to the boiler elements is left for its maintenance;

- fastening elements are selected strictly according to the type of walls.

At the fastening points, holes for dowels are drilled and metal corners are fixed. Then the top cover and front panel are removed from the structure, after which the boiler is hung on fasteners, and the mounting bracket must be well strengthened.

Boiler piping

As mentioned earlier, forced circulation of coolant works thanks to a pump. Such a unit is installed next to the boiler in a section of the return line, where the water temperature is not very high and its impact will not cause damage to the rubber gaskets of the pump.

If the heating boiler is not equipped with an expansion tank, its additional installation will be required (a closed type product is installed on any flat section of the pipeline). This heating element serves to accumulate coolant expanded from heating.

The connection of the tank to the boiler is carried out with an upper connection.

In addition to the tank, it is recommended to install a safety valve; it reacts to a sudden surge in pressure in the system and releases the coolant.

Radiator installation

First of all, brackets are installed in the holes made, which are fixed with cement mortar for reliability (this especially applies to cast iron radiators). Next, the battery is hung on the fastening element, while there should be a gap of at least 2 cm between it and the wall.

Now, using a building level, you need to check the position of the heating element along the horizontal and vertical lines. In this case, there should be no distortions, otherwise it will negatively affect the operation of the device.

In most cases, radiators are supplied with additional elements, which should be equipped with the radiator before connecting it to the pipes of the heating system.

To adjust the required temperature, you will need to install a thermostat. Don’t forget about the Mayevsky valve, which bleeds the air. Unused holes in the batteries are closed with plugs.

To correctly install parts on the battery, it is advisable to use a torque wrench. This tool will not allow you to break or undertighten the thread. It is recommended to seal all connections using flax fibers and a special paste.

Pipe laying

Propylene pipes do not have sufficient flexibility, therefore, in the places where they are attached to the boiler and radiators, fittings (angles, tees and crosses) will be required, providing for a transition from plastic to metal elements of the heating system. Pipe sections are connected by couplings. Most often, the installation of propylene pipes is carried out using the socket method.

At the beginning of the process, a pipe of the required size is cut at a right angle with special scissors. For reinforced materials, the top propylene and aluminum layer is removed to the level of entry into the fitting plus 2 mm.

Next, the structural elements are fixed to the nozzles of the heating device and maintained at a certain temperature, then joined together taking into account the alignment and cooled until completely solidified.

Fixation of pipes to the wall is ensured by clips installed in the marking areas. At the last stage of work, the pipes are screwed to the heating elements using soldered adapters.

When all installation work on the installation of heating elements is completed, you can start the boiler. It is better if professionals do this, because such a procedure requires increased safety measures.

Pros and cons of solid fuel heating boilers

Solid fuel boilers use solid fuel: fuel briquettes, pellets, firewood, coal. They have relatively low heat transfer. In order to properly heat a large house, you need to spend a large amount of fuel and your own efforts. In this situation, the fuel will burn quite quickly in two to four hours.

At this point in time, there are long-burning boilers. Fuel can be loaded into them twice a day, or even once every 30 hours. But these boilers also have their drawbacks, for example, low efficiency (70%).

There will also be a need for auxiliary devices - this is the arrangement of additional traction in some cases or a heat accumulator. Don’t forget about the positive components of solid fuel boilers. They work on all types of solid fuel and anything that can burn. It is not difficult to obtain such fuel at a reasonable price. Solid fuel heating is the best in areas where civilization has not reached and gas supply will not be available soon. And if on top of everything you have a big house.

Equipment, components and materials

The next step after developing the scheme is the selection of all heating elements:

- heat generator;

- radiators, underfloor heating collector;

- pipes;

- expansion tank, circulation pump, fittings and heater piping parts.

Clarification. Wall-mounted gas boilers and some floor-standing models are equipped with a pump and expansion tank located inside the unit. If you plan to purchase such a device, still make sure that the tank volume is sufficient for your system.

Let’s immediately make a reservation that we will consider a hot water boiler as a heating unit. You will not be able to install an air or geothermal heat pump without the help of specialists, and connecting the water circuit of the stove is carried out in the same way as connecting a solid fuel heat generator.

How to calculate the capacity of the expansion tank, choose the right pump and fittings:

- The useful volume of the tank must be at least 10% of the total amount of coolant circulating in the heating network. The water jacket of the boiler is also considered.

- If the building area does not exceed 150 m², then circulation will be provided by a pump with 25/40 or 32/40. The first number is the diameter of the threaded connection, the second is the developed pressure. The 25/40 unit is equipped with a 1” pipe thread and is capable of delivering a pressure of 0.4 Bar.

The most common model of pumping unit 25/40 from the Grundfos brand - For a large cottage and floor circuits, it is better to select a pump according to the algorithm.

- Shut-off ball valves are installed in front of the heat generator, expansion tank, pumping unit and on the make-up pipe. Additional equipment - a buffer tank, an indirect heating tank, a solar system - must also be cut off by taps.

- Each heating radiator is equipped with a thermostatic valve at the inlet and a balancing valve at the outlet. In the unregulated version, a ball valve is installed on the battery supply pipe.

The final list of components is compiled after selecting the main elements - a thermal power plant, batteries and a pump with a tank. Accordingly, we will next consider the issue...

What is the best way to heat?

There are as many opinions about how to heat a house as there are people. Some people prefer to heat with electricity, some with gas, and others with coal. Let's consider each option.

Coal is used in areas where there is no gas pipeline or as a backup type of heating. When burned, coal emits a large amount of smoke and soot. It has low humidity levels. This property ensures the release of high temperature. Due to the use of coal, the room becomes very dirty, and it is also necessary to have a place to store fuel. It is necessary to periodically maintain the combustion process by adding a new batch of coal into the boiler and cleaning the boiler itself.

Electricity is a costly service for heating large areas. It can be used in small rooms and compact spaces. In our regions there are often power outages, and therefore, despite the variety of electric heater installations (from infrared emitters to boilers and electric boilers), there is a risk of being left not just without light for an indefinite period, but also in a cold house.

Gas is the best and most popular heating option for a private home, for all types of areas and houses, since it completely warms up the space.

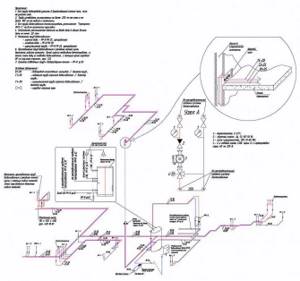

Development of a water collection scheme

You need a water supply diagram in an apartment first of all for yourself, so as not to get confused, not to miscalculate and then to know exactly where everything is - no special permission is required for this work. But when registering the meter, the water utility inspector may ask to look at the diagram, so you need to draw it correctly.

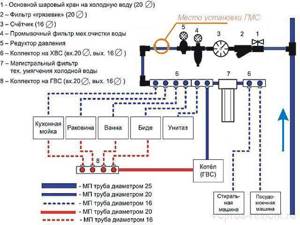

Complete water supply diagram for a private house

A complete scheme according to all the rules is a serious job for a knowledgeable specialist; for example, in the large picture there is a water supply diagram for a private house with a summer kitchen, which is necessary for the project to be approved. But to replace pipes in an apartment, you don’t need to bother so much; it’s enough that the diagram is clearly visible and understandable:

- Hot and cold water pipes, their type and lumen diameter.

- Metering devices.

- Emergency valves and drains.

- Shut-off valves.

- Parsing points indicating consumers.

- Backup branches and devices.

- Direction of water flow.

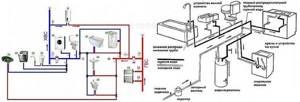

In order for all this to be clear not only to yourself, or to yourself a year later, certain rules must be followed when drawing. Let's look at examples, see Fig. On the left - more or less ok, but with some comments, on the right - incorrect:

Simplified water collection diagrams with ERRORS

- The diagram on the right is made in isometry - for beauty, or what? The intersections of the pipes confuse her, and she does not give an idea of the actual location of the analysis points: the washing machine and the boiler come out under the floor.

- There are also too many arrows indicating current where it is already clear where it flows, which also confuses the diagram.

- In the same place, shut-off valves with metering devices are depicted unclearly and not according to the rules.

- There, the type and diameter of the pipes are not indicated.

- In the same place - who, where and when saw that water was supplied to the boiler from above, and the toilet was flushed through the low tide?

- But in the diagram on the left, it is clear even to a non-specialist that the boiler (6) is a backup one. The comment will be: “Where is the check valve when it’s hot? Without it, when the supply stops, the boiler will drive itself into a hot riser if valve (10) is not closed.” But this is essentially the case and with full understanding.

Correct simplified diagram of plumbing in an apartment

An example of an arbitrary, not according to the rules for drawing up design documentation, but a completely clear and no-nonsense water collection scheme is shown in the following figure. This is also an example of parallel water withdrawal; where the combs are, it’s clear.

Radiators or water convectors, which is better?

Convectors are based on the principle of heating a room through air flow. It heats up as it passes through the body of the heating installation. In turn, radiators heat the room by radiating heat from the surface body.

Radiators have gained great popularity. Their operating principle can be compared to the operation of a Russian stove.

Convectors are heating panels; they heat a space using the movement of cold and warm air masses. The convector includes a pipe in which the coolant is located. The pipe is framed by ribs, plates that heat the surrounding space. The plates are often made of copper or steel. Convectors are divided into external and built-in. The first type of convectors is mounted on the wall, the second can be mounted along the floor or wall. Convectors also include warm baseboards. This device is an excellent solution for people who do not want to depend on public heating systems.

Convectors are used as additional and main heating; they are especially indispensable in places where standard radiators are not used. For example, built-in convectors in the floor are also located along sliding doors and glass walls. Convectors heat a room much faster and cool it down faster. The devices are durable in use.

If it is better for you when heating a private house when the room warms up faster and more evenly, then install convectors. The most common options are steel radiators (60% convection) or copper-aluminum (90% convection). If these points are not important, then install regular radiators.

How the system works

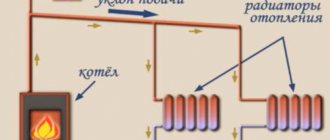

If you plan to conduct heat into the premises yourself, it is worth understanding the design and operating principle of water heating. Three components of any scheme:

- installation that generates thermal energy and transfers it to water;

- piping;

- heating devices located in heated rooms.

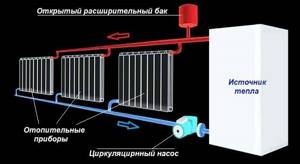

The principle of operation of the system is based on the transfer of heat from a source to heating devices through a liquid working fluid - ordinary water, capable of absorbing a large amount of energy (specific heat capacity - 4.18 kJ / kg • ° C ). In some cases, a non-freezing liquid is used - an aqueous solution of ethylene glycol or propylene glycol. How does this happen:

- By burning hydrocarbon fuel or consuming electricity, the installation heats water to a temperature of 40...90 degrees.

- The hot coolant moves through the pipes using a pump or naturally (due to convection) to water radiators.

- Heat exchange occurs between the heating devices and the air in the rooms - the water flowing through the radiator cools by 10-20 °C, and the atmosphere of the room warms up. Plus, the hot surface of the radiator emits infrared thermal radiation.

- The cooled coolant is returned through the line to the heat generator, where it is again heated to the required temperature.

- Excess water formed during thermal expansion enters a special container. When the temperature in the system drops, the liquid contracts again and leaves the expansion tank.

Heating operating cycle - water is heated by the boiler unit, sent through pipes to radiators, where it gives off heat to the surrounding air

Before heating, remember one rule: heating efficiency practically does not depend on the volume of water in the system. This indicator only affects the rate of heating/cooling of the house when starting or stopping the heat generator.

Let's list the really important characteristics:

- temperature difference at the inlet and outlet of the home heater, maximum permissible - 25 degrees;

- source power - must be selected by calculating heat losses through external walls + heating air for ventilation;

- coolant flow - the volume of water passing through heating devices within 1 hour;

- the hydraulic resistance of the pipeline network together with radiators should ideally not exceed 1 Bar (10 m of water column).

An explanation regarding the total volume of coolant in the pipes will be given by expert Vladimir Sukhorukov in his video:

Water heated floors

Water floors guarantee a comfortable stay in the room. A water heated floor is a rather complicated design, but it is cost-effective due to its convenience and coziness. Installation of such a structure costs a pretty penny, but is popular due to its low operating costs. Pipes are laid under the flooring, and heated water circulates through them. A pump is required for proper circulation. The heating option is very suitable for large country houses that do not have central heating connected. In this situation, purchasing and installing a water floor will be cheaper than purchasing and installing an electric heating system (due to electricity prices).

Video description

In our video we’ll talk about heating in a private country house.

Our guest is the author and presenter of the Teplo-Voda channel Vladimir Sukhorukov: The main criteria when choosing heating systems :

- Minimum costs with high heat transfer. Providing housing with the required amount of heat and low installation, operation and maintenance costs.

- Maximum automation . To ensure safety, heating systems must be operated with the least possible human intervention in their operation.

- High wear resistance of all elements . The necessary equipment must be selected taking into account its operational reliability.

In some cases, you can use the formula: “the simpler, the more reliable” Source promogaz.ru

Which radiator heating is better?

There are many radiator heating systems for private homes. They can be conditionally divided according to the following criteria:

With natural circulation

- Single pipe system

- Spider system

- Leningradka

- Moscow

With forced circulation

- Single-pipe

- Two-pipe (tee)

- Radial

Gravity systems are inferior in all respects to forced ones in heating a house. They should only be considered when there are serious problems with light. In other cases, choose a two-pipe or radiator radiator system. These systems are easy to balance and distribute heat more evenly across heating appliances.

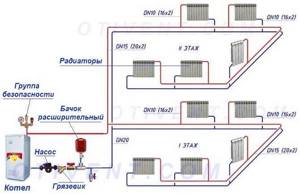

Two-pipe associated heating system diagram

The two-pipe scheme is the highest quality from a control point of view. In it, heating devices are connected to pipelines in parallel. This principle makes it convenient to regulate the temperature and allows you to turn off individual devices for prevention and repair.

Part of the coolant from the supply pipeline enters the radiator, the bulk moves to subsequent heating devices. This type of piping is applicable for autonomous and centralized heating systems. Installing thermostatic heads can completely automate the heating control process.