On what principle does a gravity heating system work?

Gravity heating is also called a natural circulation system. It began to be used for heating houses from the middle of the last century. At first, the common population did not trust this method, but seeing its safety and practicality, they gradually began to replace brick stoves with water heating.

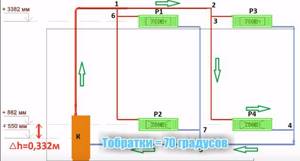

Then, with the advent of solid fuel boilers, the need for bulky stoves disappeared altogether. The gravity heating system works on a simple principle. The water in the boiler heats up and its specific gravity becomes less than cold. As a result of this, it rises along the vertical riser to the top point of the system. After this, the cooling water begins its downward movement, and the more it cools, the greater the speed of its movement. A flow is created in the pipe, directed to the lowest point. This point is the return pipe built into the boiler.

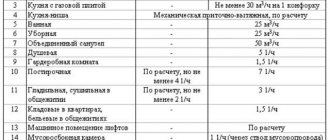

As it moves from top to bottom, the water passes through the heating radiators, leaving some of its heat in the room. The circulation pump is not involved in the movement of the coolant, making this system independent. Therefore, she is not afraid of power outages.

The calculation of a gravity heating system is made taking into account the heat loss of the house. The required power of the heating devices is calculated, and on this basis the boiler is selected. It should have a power reserve of one and a half times.

Connecting radiators

For sectional radiators, three connection methods are possible:

- One-sided lateral;

- Double-sided bottom;

- Diagonal.

Which one should you choose?

The answer depends on two factors:

- Number of battery sections;

- Its location relative to the bottling and/or riser.

With a short length of the heating device (up to 7-10 sections) and standing wiring, a side connection will be optimal. The difference in diameter between the radiator collectors and the vertical channels inside the section will ensure its uniform heating along its entire length.

If the number of sections is more than 10 and the heating device is connected to a riser or a dispenser located above it, our choice is a diagonal connection. It will warm up all sections, regardless of their number.

If the battery is long and is located above the bottlings , a two-way bottom connection will be more practical.

Here are its advantages:

- The radiator will begin to heat immediately after starting the circuit, even without bleeding air. The air plug will be forced out by excess pressure into the upper manifold and will not interfere with circulation through the lower one. In this case, the sections will be heated over their entire height due to their own thermal conductivity;

- In an open heating circuit, periodic renewal of the coolant will contribute to the gradual silting of the batteries and a decrease in their heat transfer. However, the continuous circulation of water through the lower collector will prevent sludge from collecting in it: the battery will not need to be flushed in principle. To flush the bottling, it is enough to bypass the circuit to discharge once every two to three years.

Description of the scheme

In order for such heating to work, the ratios of pipes, their diameters and angles of inclination must be correctly selected. In addition, some types of radiators are not used in this system.

Let's consider what elements the entire structure consists of:

- Solid fuel boiler. The water entry into it should be at the lowest point of the system. Theoretically, the boiler can also be electric or gas, but in practice they are not used for such systems.

- Vertical riser. Its bottom is connected to the boiler supply, and the top branches out. One part is connected to the supply pipeline, and the second is connected to the expansion tank.

- Expansion tank. Excess water, which is formed during expansion from heating, is poured into it.

- Supply pipeline. In order for a gravity water heating system to work effectively, the pipeline must have a lower slope. Its value is 1-3%. That is, per 1 meter of pipe the difference should be 1-3 centimeters. In addition, the pipeline should decrease in diameter as it moves away from the boiler. For this, pipes of different sections are used.

- Heating appliances. They are installed either with large diameter pipes or cast iron radiators M 140. Modern bimetallic and aluminum radiators are not recommended. They have a small flow area. And since the pressure in the gravity heating system is low, it is more difficult to push the coolant through such heating devices. The flow rate will decrease.

- Return pipeline. Just like the supply pipe, it has a slope that allows water to flow freely towards the boiler.

- Taps for draining and taking water. The drain valve is installed at the lowest point, directly next to the boiler. The tap for water intake is located where it is convenient. Most often this is a location close to the pipeline that connects to the system.

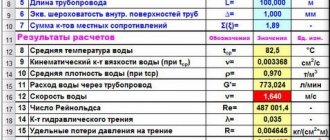

Overview of hydraulic calculation programs

Essentially, any hydraulic calculation of water heating systems is considered a difficult engineering task.

To solve this problem, a number of software packages have been developed that facilitate the implementation of such a procedure. You can try to perform a hydraulic calculation of the heating system in Excel using ready-made formulas. However, the following problems may occur:

- Large error. In many cases, as an example of a hydraulic calculation of a heating system, diagrams with one or two pipes are taken. Finding the same calculations for the collector is problematic;

- To correctly account for resistance in terms of pipeline hydraulics, reference data is needed that is not included in the form. They must be searched for and entered additionally.

Oventrop CO

The most simple and clear program for hydraulic calculation of heating networks. An intuitive interface and flexible settings can help you quickly understand the invisible aspects of data entry. Small problems may appear when setting up the complex for the first time. You will need to enter all the parameters of the system, starting from the pipe material itself and ending with the placement of the TENS.

It is distinguished by flexible settings, the ability to make the simplest hydraulic calculation of heat supply both for a new heating network and for modernizing an old one. It stands out from its substitutes with a good graphical interface.

Instal-Therm HCR

The software package is calculated for professional resistance in terms of hydraulics of the heating network. The free version has a lot of contraindications. Area of use: design of heat supply in large public and industrial buildings.

In practical conditions, for autonomous heat supply of private apartments and houses, hydraulic calculations are not always done. However, this can lead to deterioration in the performance of the heating system and rapid breakdown of its components - heating devices, pipes and boiler. To avoid this, you need to calculate the system parameters in time and compare them with the actual ones for subsequent optimization of the heat supply operation.

HERZ CO

It is characterized by flexibility of settings, the ability to make simplified hydraulic heating calculations both for a new heating system and for modernizing an old one. It differs from analogues in its convenient graphical interface.

Flaws

Proponents of closed systems cite a lot of disadvantages of gravitational heating. Many of them look far-fetched, but we will list them anyway:

- Ugly appearance. Large diameter supply pipes run under the ceiling, disrupting the aesthetics of the room.

- Difficult to install. Here we are talking about the fact that the supply and discharge pipes change their diameter in steps depending on the number of heating devices. In addition, the gravity heating system of a private house is made of steel pipes, and they are more difficult to install.

- Low efficiency. It is believed that closed heating is more economical, but there are well-designed natural circulation systems that work just as well.

- Limited heating area. The gravity system works well in areas up to 200 square meters. meters.

- Limited number of floors. Such heating is not installed in houses higher than two floors.

In addition to the above, gravitational heat supply has a maximum of 2 circuits, while in modern houses there are often several circuits.

Differences in the operation of a solid fuel boiler

The heart of any heating system is the boiler. Although the same models can be installed, operation with different types of heating will differ. For normal operation of the boiler, the temperature of the water jacket must be at least 55 °C. If the temperature is lower, then the inside of the boiler will be covered with tar and soot, as a result of which its efficiency will decrease. It will need to be constantly cleaned.

To prevent this from happening, a three-way valve is installed in a closed system at the boiler outlet, which circulates the coolant in a small circle, bypassing the heating devices, until the boiler heats up. If the temperature begins to exceed 55 °C, then the valve opens and water begins to flow into the large circle.

A three-way valve is not required for a gravity heating system. The fact is that here the circulation occurs not due to the pump, but due to the heating of the water, and until it heats up to a high temperature, movement does not begin. In this case, the boiler furnace remains constantly clean. A three-way valve is not required, which reduces the cost and simplicity of the system and adds to its advantages.

Device

All schemes of a two-pipe heating system for a two-story house have one thing in common: they have separate supply and return bottlings. The bottlings are connected to each other by jumpers with heating devices installed in their gap.

Top and bottom bottling

Depending on the location of the supply filling, there are schemes with lower and upper filling.

- In the first case, both the supply and return lines of the circuit are located in the basement and are connected by paired risers. Those, in turn, are connected to each other by jumpers located in the rooms of the upper floor or in the attic;

Taking lintels into a cold attic is not a good idea. When the circuit stops in cold weather, the water hangs in the risers, and the pipes in the attic become frozen within an hour after the heating is turned off.

- In the second case, the supply is routed through the attic, and the return through the basement. This scheme greatly simplifies resetting and starting the system: when resetting, it is enough to open the vent on the expansion tank located at the top point of supply filling, and all the water hanging in the pipes will drain down; When starting, the air is not released at each jumper between the risers, but only at the notorious vent in the expansion tank.

In my opinion, it is the top filling that is most convenient in terms of operation . In my memory, in houses with a top supply, there have never been serious accidents associated with heating defrosting, while in houses with a bottom supply, radiators and hoses in the entrances had to be heated every winter.

Gravitational and forced

A two-pipe heating system in a two-story private house can be implemented with forced circulation of the coolant (a circulation pump is used for this) or with natural circulation, due to the difference in the density of the hot and cold coolant.

Forced circulation schemes are advantageous because:

- Provide greater speed of coolant movement and, accordingly, more uniform and faster heating of radiators;

- Allows you to get by with smaller diameter bottlings.

Their main drawback is their energy dependence : the pump requires round-the-clock power. If the problem of short-term power outages can be solved by installing an uninterruptible power supply, then a power outage lasting several days will leave your home without heat.

Systems with natural circulation are completely energy independent.

How does such a heating system work?

- The boiler (usually solid fuel) is lowered as low as possible - into the basement or pit. Radiators are mounted above the boiler heat exchanger. The height difference between them will, in fact, ensure circulation;

- Immediately after the boiler, an accelerating pipe is installed - a vertical bottling section that rises to the ceiling of the second floor or into the attic. Through it, the water heated in the boiler rises to the upper point of the circuit, from where it moves through the bottlings by gravity, due to its own gravity. Hence, by the way, the name of such a system is “gravitational”.

- Immediately after the acceleration pipe, an open expansion tank is installed, which at the same time performs the function of a safety valve and a filler funnel for filling the circuit with water. If the coolant boils, steam will leave the bottle through the tank lid. Through it, you can always add water to replace the water that was discarded or evaporated;

- Both bottlings - supply and return - are installed with a slight constant slope in the direction of movement of the coolant;

- The internal diameter of the bottlings is made as large as possible (at least DN32, more often DN40 - DN50). The large diameter compensates for the minimum hydraulic pressure created by the temperature difference.

Hydraulic resistance decreases with increasing internal cross-section of the pipe. The thicker the pours and liners, the faster the water circulates in them.

How it works?

- The hot water heated by the boiler, due to its decreased density, is displaced to the upper point of the circuit by colder and denser masses of the coolant;

- From there it continues to move along the inclined bottling line, gradually giving off heat to the air in the rooms through the heating devices;

- The coolant that has released heat returns to the boiler and is drawn into a repeated circulation cycle.

The obvious disadvantages of a gravity heating system are large inertia, significant temperature differences between the first and last batteries in the direction of water movement, and high costs for installing bottling systems.

In those areas where power supply interruptions are periodic, installation of combined heating systems is practiced. Actually, they represent a classic gravitational circuit with a circulation pump embedded parallel to the bottling. A ball check valve is mounted between the pump taps.

This scheme works like this:

- When the pump is turned on, water flows through its inserts. Due to excess pressure at the pump outlet, the check valve is closed;

- When the pump is turned off, the valve opens and the water continues to circulate slowly with natural force.

Let me emphasize: in such circuits only ball valves are used. A spring-loaded check valve requires a significant pressure differential to open. Even if it opens (which is unlikely), it will lose a significant part of the hydraulic pressure.

Convection and in-floor

The classic heating scheme with wall or floor radiators is called convection: heat is distributed by heated air flows rising from the heating devices. Unfortunately, the mixing of air by these flows is not effective enough: the temperature under the ceiling is always several degrees higher than at floor level.

Since the inhabitants of the house, as a rule, do not have the habit of spending their leisure time on the ceiling, stronger heating of the upper part of the room volume has only one consequence - an increase in heat loss through the ceiling and roof.

Warm floors do not have this drawback . Pipes laid in a screed or under the finished floor covering heat the room as much as possible at the floor level, which allows you to achieve a comfortable temperature distribution at minimal cost.

Is it possible to combine a floor with a two-pipe system? If all the heating of the house is done using low-temperature in-floor heating, then only the section between the boiler and the collectors will be double-pipe. Further wiring will be collector (radial).

You see, heated floors have a limitation on the maximum circuit length (100-120 meters), so heating a house usually consists of several circuits connected in parallel.

If a heated floor is connected in parallel to high-temperature heating with radiators, it needs a temperature matching unit with a temperature sensor, a three-way or two-way valve and its own circulation pump.

The pump drives the coolant inside the low-temperature part of the circuit; the valve opens and lets a new portion of hot water into the underfloor heating pipes only when it cools down to a certain temperature.

Heating safety

As mentioned above, the pressure in a closed system is greater than in a gravitational one. Therefore, they take a different approach to security. In closed heating, the expansion of the coolant is compensated in an expansion tank with a membrane.

It is completely sealed and adjustable. After the maximum permissible pressure in the system is exceeded, the excess coolant, overcoming the resistance of the membrane, goes into the tank.

Gravity heating is called open due to a leaky expansion tank. You can install a membrane-type tank and make a closed gravity heating system, but its efficiency will be much lower because the hydraulic resistance will increase.

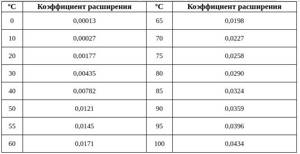

The volume of the expansion tank depends on the amount of water. To calculate, its volume is taken and multiplied by the expansion coefficient, which depends on temperature. Add 30% to the result obtained.

The coefficient is selected according to the maximum temperature that the water reaches.

Air locks and how to deal with them

For normal heating operation, the system must be completely filled with coolant. The presence of air is strictly prohibited. It can create a plug that prevents water from passing through. In this case, the temperature of the boiler water jacket will differ greatly from the temperature of the heating devices. To remove air, air valves and Mayevsky taps are installed. They are installed at the top of heating devices, as well as in the upper sections of the system.

However, if gravity heating has the correct slopes for the supply and return pipes, then no valves are required. The air in the inclined pipeline will freely rise to the top point of the system, and there, as you know, there is an open expansion tank. This also adds to the benefit of open heating by reducing unnecessary elements.

Radiator piping

There are no special tricks in connecting radiators. As expected, a Mayevsky tap is screwed into one of the upper outlets; hot water can be supplied through the second.

However, the lower side pipe supply will be more aesthetically pleasing. The modern word in this regard is considered to be single-point connection devices, due to which it is possible to run both the supply and return into the same lower outlet of the radiator.

Using the same principle, you can make a point-to-point connection, but only on one side. This harness looks less cumbersome, plus there are many standard solutions. Typically, threaded connections on radiators are no more than one inch, so they can also be packaged using FUM tape.

Is it possible to install a system made of polypropylene pipes?

People who do their own heating often wonder whether it is possible to make a gravity heating system from polypropylene. After all, plastic pipes are easier to install. There is no expensive welding or steel pipes, and polypropylene can withstand high temperatures. You can answer that such heating will work. At least for a while. Then efficiency will begin to decline. What is the reason? The point is the slopes of the supply and discharge pipes, which ensure gravity flow of water.

Polypropylene has greater linear expansion than steel pipe. After repeated heating cycles with hot water, plastic pipes will begin to sag, disrupting the required slope. As a result, the flow rate, if it does not stop, will decrease significantly, and you will have to think about installing a circulation pump.

Add-ons to improve system efficiency

The heating installation can perform better if improvements are made to the design. These measures optimize the system, increase efficiency and smooth out deficiencies that may affect the quality of operation. The following additions can be suggested:

- Installation of a reverse trap that blocks accidental movement of liquid in the wrong direction.

- Mounting the circulation pump. Installing this add-on reduces the inertia of the gravitational system. If the heating time is exceeded, this improvement increases the speed of water flow. As a result, the liquid is heated to the required level.

- Highway slope. Allows you to obtain the optimal pressure level during system operation.

Gravity heating in the basic configuration will work without additional measures, but installing auxiliary elements will significantly increase efficiency and reduce the likelihood of breakdowns. To make changes, they are discussed in advance with the heating engineer responsible for the project.

Difficulties in installing a gravity system in a two-story house

A gravity heating system for a two-story home can also work efficiently. But its installation is much more complicated than for a one-story one. This is due to the fact that attic-type roofs are not always made. If the second floor is an attic, then the question arises: where to put the expansion tank, because it should be at the very top?

The second problem that you will have to face is that the windows of the first and second floors are not always on the same axis, therefore, it is impossible to connect the upper batteries with the lower ones by laying pipes along the shortest route. This means that you will have to make additional turns and bends, which will increase the hydraulic resistance in the system.

The third problem is the curvature of the roof, which may make it difficult to maintain proper slopes.

Installation

To enlarge, click

When choosing a gravity heating system, the first thing you need to do is design it. Perhaps this is the only moment when it is impossible to do anything with your own hands.

This part of the work must be entrusted to heating engineers. In order for the system to have an aesthetic appearance, it is advisable to involve a designer in the design. When their work is completed, calculations are made, diagrams are drawn, you can proceed directly to installation.

First you need to select the heating pipes. The diameters and lengths are already known from the project, all that remains is to choose the material. It is better to give preference to polypropylene pipes . They have a lot of positive aspects. These include low weight, ease of connection, high anti-corrosion resistance, high noise insulation, and resistance to defrosting.

All of the above parameters are ideal for GSO.

The remaining heating devices are purchased based on capabilities and preferences, according to indicators, without going beyond the scope of the project. When installing the system, preference is given to two-pipe heating systems. This means that during installation it is necessary to make two pipelines - supply and return.

In this case, the supply line (with hot water) is located under the ceiling, and the return line on the floor or in the basement.

If you need to make a warm floor, you will have to make a collector insert. In this case, each circuit of the system can be powered through its own temperature controller, which will create additional convenience, but will also somewhat complicate the system as a whole. The supply manifold is located at the highest point, preferably in the attic. At the same time, you must not forget about its insulation, by the way, like the entire attic.

Now you can begin installing the system. You need to start with a water heating boiler. Maintaining verticality as accurately as possible, a pipe is led from it to the top, which connects to the compensation tank. Immediately it needs to be well insulated. A hot circuit pipe is inserted into the lower third of the tank. It is connected to the wiring.

At the very top of the tank it is necessary to install an overflow pipe connected to the sewer. It will drain excess water in the system.

Next, you need to lay the pipeline to the heating devices (radiators). After completing these works, you can start laying the return line - a line through which cold water will return to the boiler. When all connections are completed, water can be poured into the system. If there is no water leakage from the connection points, the system starts up.

Such a heating system can easily cope with heating a small two-story cottage with all household premises. Thus, of all types of systems, it is advisable to give preference to a two-pipe system.

Tips for installing gravity heating in a two-story house

Most of these problems can be solved during the design stage of the house. There is also a little secret on how to increase the heating efficiency of a two-story house. It is necessary to connect the outlet pipes of radiators installed on the second floor directly to the return line of the first floor, and not make a return line on the second floor.

Another trick is to make the supply and return pipelines from large diameter pipes. Not less than 50 mm.

Is a pump needed in a gravity heating system?

Sometimes an option arises when the heating was installed incorrectly, and the difference between the temperature of the boiler jacket and the return is very large. The hot coolant, not having sufficient pressure in the pipes, cools down before reaching the last heating devices. Redoing everything is labor-intensive work. How to solve the problem with minimal costs? Installing a circulation pump in a gravity heating system can help. For these purposes, a bypass is made into which a low-power pump is built.

Great power is not required, since with an open system, additional pressure is created in the riser leaving the boiler. A bypass is needed in order to leave the possibility of working without electricity. It is installed on the return line in front of the boiler.

Operating principle of closed CO

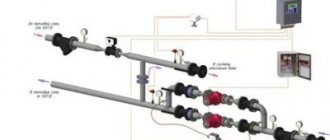

A closed (otherwise known as closed) heating system is a network of pipelines and heating devices in which the coolant is completely isolated from the atmosphere and moves forcibly - from a circulation pump. Any SSO necessarily includes the following elements:

- heating unit - gas, solid fuel or electric boiler;

- safety group consisting of a pressure gauge, safety and air valve;

- heating devices - radiators or underfloor heating circuits;

- connecting pipelines;

- a pump that pumps water or non-freezing liquid through pipes and batteries;

- coarse mesh filter (dirt collector);

- closed expansion tank equipped with a membrane (rubber “bulb”);

- shut-off valves, balancing valves.

Typical diagram of a closed heating network for a two-story house

The operating algorithm of a closed type system with forced circulation looks like this:

- After assembly and pressure testing, the pipeline network is filled with water until the pressure gauge shows a minimum pressure of 1 bar.

- The automatic air vent of the safety group releases air from the system during the filling process. He also removes gases that accumulate in pipes during operation.

- The next step is to turn on the pump, start the boiler and warm up the coolant.

- As a result of heating, the pressure inside the ZSO increases to 1.5-2 Bar.

- The increase in the volume of hot water is compensated by a membrane expansion tank.

- If the pressure rises above the critical point (usually 3 Bar), the safety valve will release excess liquid.

- Once every 1-2 years, the system must undergo an emptying and flushing procedure.

The principle of operation of an apartment building's SSS is absolutely identical - the movement of coolant through pipes and radiators is ensured by network pumps located in an industrial boiler room. There are also expansion tanks there; the temperature is regulated by a mixing or elevator unit.

How a closed heating system functions is explained in the video:

How else to improve efficiency

It would seem that the system with natural circulation has already been brought to perfection, and it is impossible to come up with anything that would increase efficiency, but this is not so. You can significantly increase the convenience of its use by increasing the time between firing the boiler. To do this, you need to install a boiler of greater power than required for heating, and remove excess heat to a heat accumulator.

This method works even without using a circulation pump. After all, hot coolant can also rise up the riser from the heat accumulator, while the firewood in the boiler has burned out.