Installation and operation of a geyser

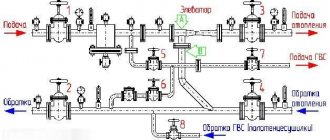

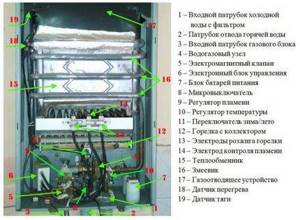

Gas water heater installation diagram.

Modern gas water heaters are quite compact and do not require much space. The service life of a geyser depends on meeting all the necessary requirements for installing the device.

The gas water heater runs on quite dangerous fuel, and therefore during installation it is necessary to ensure that there are no leaks. If this check is not carried out and all leaks are not repaired, the operation of this equipment will be dangerous and may subsequently lead to an explosion.

Due to the danger of self-installation of such equipment, installation of a geyser must be carried out by specialists who have approvals and a license to install gas equipment.

In order to do this, you will need the following tools and materials:

- geyser;

- magnetic and salt filters;

- gas and two water taps;

- corrugation for the chimney;

- Mayevsky crane;

- gas pipe;

- pipes for hot and cold water;

- drill;

- dowels

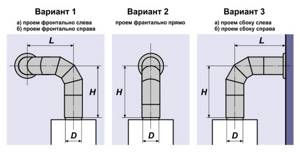

Options for installing a chimney for a gas water heater.

The geyser is installed on the wall, which must be made of fire-resistant materials in the part of the room where hot water will be supplied (bathroom or kitchen). The column should be located at least 2 cm from the wall (the more, the better). Sheet asbestos is laid between the wall and the speaker body, the thickness of which must be at least 3 mm.

It is imperative that the house has a chimney to remove combustion products. The chimney must have a slope of 2 cm per m in horizontal sections.

In order to prevent a pipeline break, the water heater is installed in an unheated room with the water drained from the entire system.

In order for your geyser to last a long time, you need to follow all operating rules. If you do not adhere to this, then even the most expensive water heater will quickly fail. To prevent this from happening, you need to heat the water no more than 60 degrees, because very high temperatures accelerate the deposition of salts on the surface of the heat exchanger. As a result, the heat exchanger will have to be replaced or cleaned.

Water that is too hard can damage the heat exchanger and water block. To prevent this from happening, you must use a special filter or soften the water using special means.

It is not recommended to disassemble it yourself and this should be done by specialists. It is dangerous to repair such devices yourself.

Reasons for diaphragm failure

Membranes are consumables with a service life of 5-8 years (on average). The elasticity of the material decreases over time. As a result of the action of alternating stresses, fatigue occurs over time in each material subject to bending—the formation and accumulation of damage. If the membranes operate in an intensive mode, when the gas water heater is used frequently and a lot, fatigue occurs earlier. Microcracks appear in the body of the diaphragm, then breakthroughs form.

The scale that forms inside the frog also contributes to rapid wear of the diaphragm. Another reason is the use of clandestinely produced diaphragms. Often such products are made from low-quality rubber.

Therefore, information on how to properly replace the membrane in a household geyser if it fails will come in handy. With such knowledge, you can repair the water unit on your own, without involving specialists.

This is what the water reducer looks like after removal. As a result of grooving the oil seal, scale formed on the rod and its nut, which is removed during the process of replacing the diaphragm

Documentation

In order to install a gas water heater in an apartment or private house, you will need the following documents:

- Technical passport of the purchased dispenser or indication of the model in case of subsequent purchase of the unit.

- A report on the technical condition of the hood or chimney, drawn up by the exhaust and chimney duct inspection service.

- Project for placing new water heating equipment and connecting it to the gas and water mains in accordance with the technical specifications.

- An application submitted by the owner for the reconstruction of a premises with a water pump must additionally provide proof of ownership and a technical passport for the apartment.

- An application for installation work sent to the gas supply organization (Gorgaz) with a project attached.

The company engaged in the maintenance of the purchased gas water heater or specialists from the gas supply organization are required to perform the following actions when installing the equipment:

- Make a connection into the gas pipeline with the installation of metering devices and a shut-off valve.

- Hang the column with the flammable surface of the wall lined with insulating materials (tin in combination with asbestos or basalt sheets), connect a flexible gas supply to the unit.

- Connect the column to the chimney or exhaust system using a pipeline.

- Connect flexible hoses from the unit to the cold water main and hot water supply pipes.

- Upon completion of the work, the Gorgaz specialist must set up and start the dispenser, seal the gas meter and draw up a report on putting the unit into operation.

The cost of installing a gas water heater at home by private specialists will cost about 3,000 rubles; gas supply companies, depending on the region, carry out the connection at their own prices.

Rice. 10 Recommended spacing and placement of insulation

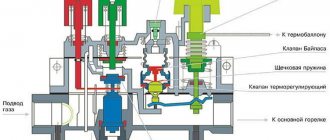

About the reducer and the location of the membrane

A device called a water reducer is part of almost any design of gas heat exchangers.

This part may have different configurations depending on the model of the water heating apparatus, but the principle of operation of such devices remains unchanged.

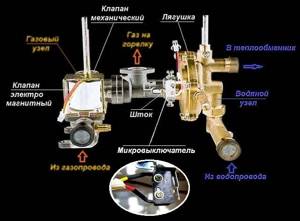

Gas water heater reducer, where the membrane is located: 1 – water inlet; 2 – rod head and stuffing box group; 3 – rod; 4 – ball valve; 5 – water outlet; 6 – nozzle; 7 – plugs for draining water from the internal areas of the device

A water reducer installed on a gas water heater serves to stablely maintain water pressure directly in the water heater heat exchanger system. Due to the uniformity of pressure, a uniform flow is ensured, which means the same uniform heating of the liquid.

A part of the gearbox that facilitates smooth pressure regulation is a rubber membrane. This gear component, made in the form of a gasket, usually based on technical rubber, has the shape of a circle. It is installed inside the gearbox housing.

Due to the long-term operation of water heating equipment, being constantly in motion, the membrane gradually wears out. Wear of technical rubber in some places leads to tears in the material. Accordingly, the function of regulating water pressure stops operating according to the specified algorithm.

A prototype of a classic membrane based on technical rubber. The shape of the plate is round, the surface has a characteristic feature - a convex central part. Similar accessories are used on most geysers

In such cases, it becomes inevitable to replace the rubber membrane of the reducer in the gas water heater, because the water heater does not work properly.

The quality of sanitary water heating decreases sharply, and in other cases the column simply cannot be put into operation. Comfort for the user is lost.

The right choice of geysers

If you decide to purchase a geyser device, then pay attention, first of all, to the power of the model you choose. It should be enough to provide all members of your family with hot water.

The power of almost all modern models fits into the range from 3 to 60 kilowatts.

Important! The more powerful the gas water heater, the larger volume of water it will be able to heat over a certain period of time. The average “cell of society”, consisting of four people, needs a device whose power averages 16-24 kilowatts

There is more than enough for the dishes to be washed and everyone to take a shower. Even if the device has a low power of 16 kilowatts, it will be able to provide 10 liters of hot water, which is enough to wash and wash dishes at the same time. Of course, if you can, then buy a column with a power of 24 kilowatts, as it can provide 24 liters of heated water

The average “cell of society”, consisting of four people, needs a device whose power averages 16-24 kilowatts. There is more than enough for the dishes to be washed and everyone to take a shower. Even if the device has a low power of 16 kilowatts, it will be able to provide 10 liters of hot water, which is enough to wash and wash dishes at the same time. Of course, if you can, then buy a column with a power of 24 kilowatts, as it can provide 24 liters of heated water.

In addition, it is advisable to take into account the water temperature that a particular model can provide. To designate it, the Latin letters DT are used. For example, if water already enters the heat exchanger at a temperature of 12 degrees, then it will heat up to 24 degrees. therefore, it can be used even without prior dilution.

Today there are models that can heat water even up to 50 degrees. Their power, as well as their cost, is an order of magnitude higher than conventional models. For this reason, if several plumbing elements are simultaneously connected to the system, then it is better to purchase a more powerful column so that it can provide them all with hot water at the same time.

Also, when buying a gas water heater, check whether it is equipped with safety sensors. They are of the following types:

- overheating;

- burner extinction;

- combustion;

- low blood pressure;

- temperature;

- sudden interruption of water supply.

And remember: geysers are only allowed to be installed in the kitchen! Installing a geyser in the bathroom is prohibited! Unless it (the bathroom) meets all existing requirements.

As a conclusion

So, we have looked at what a geyser is, what its features are, what malfunctions may arise during operation and how to repair them later. We only note that such devices are extremely economical, especially in light of ever-increasing utility tariffs. And lastly: do not forget that preventative maintenance of the column’s performance should be carried out annually.

What should you consider when choosing a water heater?

A household gas water heater is not a boiler for heating and it is difficult for the average user to choose it based on power. It is much clearer when it comes to the amount of water heated. This value is indicated in the technical data sheet of the product of any manufacturer and is expressed in liters per minute when heated to 25 °C.

For clarity, we present a table with data on water heaters of the Russian brand Neva, showing the dependence of performance on the thermal power of the unit:

Reference. Dispensers for DHW needs are inferior in efficiency to gas heating boilers by 3 to 5 percent. If the efficiency of an atmospheric heater is about 88%, then the efficiency of the same water heater is 84%. But it is impossible to feel this difference in practice.

When choosing a device for heating water, you first need to determine its performance. Next, we suggest following simple recommendations:

- If your budget is limited, and electricity is often cut off in your area of residence, then a simple non-volatile atmospheric model is just what you need. The ignition system is from a piezoelectric element or battery-powered; they last quite a long time (2-3 months with intensive use).

- In most apartments it is impossible to install atmospheric speakers due to the lack of chimney ducts, and the removal of combustion products into ventilation shafts is prohibited. No problem, buy a turbocharged water heater with a coaxial chimney that goes outside directly through the wall. Just determine the location of the pipe exit and coordinate it with your neighbors. Read more about connecting chimneys to gas water heaters in this article.

- In our conditions, when the water supply networks are worn out, it is better not to install devices with ignition from a hydrogenerator. The latter can quickly fail due to poor water quality and water hammer in pipelines. To protect the generator, you will need a water reducer, and this is an additional expense.

- Try to select modern modifications of devices where the igniter does not burn around the clock. It slowly but surely consumes gas, destroys the front wall of the heat exchanger and smokes onto the front panel.

Possible malfunctions of the water unit

- refusal to turn on the column;

- the flame does not light up the first time;

- there is a water leak from the gearbox;

- after closing the DHW tap the flame does not go out.

The membrane has broken - the average service life of the diaphragm is 5-7 years. Over time, due to constant mechanical stress and hard water, the rubber breaks through. A sign of membrane failure is that water drips from the gearbox.

The membrane has become coarsened - the quality of the water unit of the gas water heater depends on the elasticity of the diaphragm

To operate, it is important that the membrane responds sensitively to any changes in water pressure. If the gasket is roughened, the column will operate with a delay

After turning off the DHW tap, the gas burner continues to work for some time.

The rod is clogged - when the membrane breaks, water enters the metal surface of the rod, causing it to corrode. Rust prevents the needle from moving properly. Signs of malfunction: starting the column is difficult. The flame ignites only with strong water pressure. After closing the DHW tap, the burner does not go out.

The coarse filter is clogged - there is a mesh at the entrance to the gearbox, which quickly becomes clogged, especially if the connection conditions were violated and the piping diagram was carried out with errors. Symptom of malfunction: difference in pressure at the inlet and outlet of the water heater.

If the technological process described below causes difficulties, it is better to call a specialist from the gas service to your home for professional service of the instantaneous boiler.

Heat exchanger repair

There are several situations when heat exchanger repair is necessary:

- Additional noise appeared during operation of the unit.

- The liquid heats up, but not well.

- The outlet from the column does not provide sufficient liquid pressure. Then you will have to figure out how to remove the cap from the gas water heater.

One of the reasons is scale accumulated on the surface of copper tubes. Because of this, the heat transfer rate drops, and the same applies to the throughput of the product. If servicing has been abandoned for a long time, there is a high probability that dust and soot will appear between the plates. Because of this, water heating also deteriorates. Instantaneous water heaters also sometimes work with such problems.

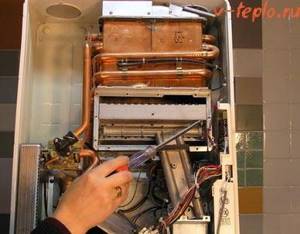

Removing the heat exchanger is not difficult.

- They start by disconnecting all parts from the main pipeline, then drain the residual liquid. To do this, unscrew the corresponding plug from the water section.

- Be sure to disconnect the tubes supplying and draining water. (shown in the figure by green arrows).

They proceed to unscrew the screws (blue arrows), remove the plate responsible for fixation (yellow pointer). The main thing is to purchase a repair kit for the water unit in advance.

Flushing the internal parts under water with high pressure is what is done when repairing any heat exchangers. This is necessary to remove any contamination. Afterwards, it is recommended to immerse the unit in water with at least a small amount of detergent added. This concludes the DIY gas water heater repair.

Clean the unit using a small, soft brush. After this stage, everything is washed again, including water. The tubes are cleaned by a strong flow of water in the opposite direction. You cannot do without a special solution if scale remains even after strong pressure. Otherwise, repairing the water block will not yield any results.

100 grams of acid are diluted in 1 liter of water heated to 40 degrees. The solution is poured into the heat exchanger pipe. The reaction will appear immediately, foam will begin to appear from the structure. Leave everything in this flooded state for a few minutes. Afterwards, all channels of the water unit of the Neva gas column are washed again with ordinary water.

Why does the burner burn weakly or turn off?

- The burner does not turn on - reasons:

- insufficient water pressure;

lack of spark;

- improper operation of the ignition wick;

- bad traction.

- Weak flame on the burner - reasons:

- problems with the water unit (frog), the membrane has failed or the rod needs maintenance;

insufficient water pressure in the pipeline;

- The burner of the gas water heater burns poorly and due to the nozzles being clogged with soot, owners of water heaters operating on liquefied gas especially often face this problem.

- The main burner does not work - the igniter is triggered or the wick is working. The reason lies:

- In a littered chimney duct, lack of air circulation leads to the accumulation of flue gases. Problems with draft affect the operation of the burner; there is no flame or burns unevenly.

- Problems with the water regulator - inside the block there is a rubber membrane and a rod connected to the valve. When water enters, pressure is applied to the metal rod, which turns on the gas supply. If the gasket ruptures or the rod is corroded, gas does not enter the burner and the flame does not ignite.

- In geysers with a modulating burner, the absence of a flame indicates a failure of the servo drive or valve. In battery-powered water heaters, failure is often due to the fact that it is necessary to replace dead power sources.

- The burner does not turn off - the flame continues to burn after the DHW tap has been closed. The decay period is several seconds or more. The reason is that the membrane installed in the water regulator has become hardened by hard water. The malfunction may be related to the stem. In this case, either rust has appeared on the rod, or the spring that brings it to its original position after turning off the water has weakened.

In all of these cases there is no flame. If the column turns on, it is only temporarily and after repeated opening of the DHW tap.

If the flame burns unevenly, has a red-white hue, protrudes beyond the heat exchanger, and there is a stable water pressure, it is necessary to clean the outer part of the radiator. In automatic gas water heaters, failure to modulate the burner flame indicates a malfunction of the programmer in the control unit.

Features of membrane replacement in new models

The water units of modern speakers work on the same principle. The main differences between new designs of instantaneous water heaters are the saturation of control units, monitoring units, touch screens, and wires.

Some fasteners have changed. For example, now screws are tightened and unscrewed with special screwdrivers with an asterisk. Innovations affected both the shape of the frogs and their connection to the gas block.

On devices Amina, Selena, Milla, Ross (popularly - Chinese), it is better to entrust the replacement of the frog gasket to specialists, since the gas part needs to be dismantled along with the water part

On branded speakers Bosch and Junkers, the water unit is located at the bottom right. To remove it, you need to disconnect the terminal of the draft sensor located in front of the control unit.

Having turned off the water supply to the column and opened the hot water tap, use a screwdriver to remove the bracket that holds the pipe running from the heat exchanger to the heat exchanger. Pulling the pipe slightly to the right from the water unit, wait until the water from the system pours out through the tap, after which the pipe is removed completely. After this, use a wrench to unscrew the nut securing the water block to the water supply.

Brackets are a new type of fastening of structural elements of the water block of Bosch and Jurkers speakers; they are pryed off and released using a screwdriver

Unscrew the VU fastening screws with a Phillips screwdriver. They are located at the bottom of the structure. There is no need to unscrew them completely. After this, the water block is at the owner’s disposal. It can be inspected, cleaned, and consumable parts replaced (the coarse filter mesh can be cleaned without removing the VU).

There are much more consumable parts in such a frog than in the gearbox of the Neva Group of Companies. Firstly, the water block itself is made of plastic, the mounting screws are screwed directly into the plastic (no brass inserts). The connection is not designed for many cycles of assembly and disassembly. If there is a leak along the VU rod, the cover will need to be replaced completely (maximum service life is 2-3 years).

Secondly, in addition to the functions described above, it additionally regulates the amount of water flowing through the column, so a stable liquid temperature is maintained at the outlet of the hot water tap.

In a Bosch water heater, the silicone membrane is a convex cap of complex design that cannot be cut from flat rubber. Just buy, and, moreover, your own one

Recommendations for maintenance and repair

All elements of the column structure are subject to destruction due to various factors. Any gas equipment requires regular maintenance. If defects are identified during maintenance work, they must be eliminated as quickly as possible. Of course, some repair work should be entrusted to a professional, but some can be done independently.

Dismantling and adjusting the gearbox

You must first turn off the fuel and water supplies. Only after this can you begin to carry out preventive or repair work. To remove the gearbox, you need to perform several steps:

- Water is drained from the heat exchanger;

- using an adjustable wrench, the gas and water pipelines are disconnected from the column;

- If no mistakes were made at the previous stages, the gearbox can be easily dismantled.

Depending on the model of the unit, changes may be made to its design. To avoid problems when dismantling the water reducer, you must first disconnect all pipes and parts that make the work difficult. The housing should be easy to remove; no physical effort is required.

Cleaning the water unit

This event must be held at least once every 12 calendar months.

When unscrewing the fastening bolts located on the unit cover, you must be careful not to damage the folds. When the cover is removed, it is necessary not only to clean the internal space of the gearbox, but also to perform the following procedures:

- All solid residues from the bottom of the part must be removed, and the coarse water filter must also be rinsed.

- It is advisable to lubricate the rod with grease or castor oil.

- If you suspect that the gasket has lost its former elasticity, it also needs to be lubricated.

With regular maintenance of the unit, its service life can be significantly extended. Most often, the rod seal and membrane fail. The first element must be replaced once every 3 years, and the second - after the appearance of ruptures or microcracks. In addition, during intensive work the spring for returning the rod to its original position may break.

Having carefully studied the design and principle of operation of the gas water heater, you can carry out all preventive measures yourself. If you don’t have confidence in your own abilities, then you should turn to professionals for help. When working with the unit, you must strictly follow the instructions.

How to clean the frog?

The unit should be cleaned every year. After removing the cover or disassembling the gearbox into two parts, the inside of the unit is cleaned and the elements are maintained. The process of cleaning the unit removes scale and solid particles that have settled at the bottom of the unit. You should also clean the mesh on the inlet pipe. It is recommended to lubricate the rod with castor oil or grease. The gasket also needs to be lubricated if it feels like it has lost its elasticity.

Caring for the elements of the water block will extend the service life of the gas water heater and reduce the likelihood of any malfunctions.

During each cleaning, the functionality of the components is checked and, if necessary, they are replaced:

- replacement of the stem seal is usually required approximately every 3 years to protect the gas valve from moisture;

- the membrane should be changed when microcracks appear or ruptures occur.

Worn parts need to be replaced with new branded products. The membrane can be purchased separately, however, if desired, you can also find a kit that includes all the components for replacement.

Distinctive features of the speakers

When choosing a device, you should pay attention to the operating principle of the Neva gas water heater. It has a good automatic protection system against accidental flame extinguishing

The heat exchanger in Neva should not overheat, and the system controls temperatures. The column is reliably protected from excessively high pressure. If the control system becomes faulty, the Neva’s security system will turn off the operation of the mechanism. A plus is the presence of auto-ignition when pressed. The system operates on batteries.

The main advantage is the outlet water temperature, which does not change. This installation is considered the main guarantee of safe use of the system. There is no danger of burns from hot water.

The operating principle of the Neva gas water heater makes it possible to install it even in the smallest apartments. It meets all regulatory requirements. And the durability of its use depends on the attention and diligence in the work of the apartment owner.

There are other brands. For example, the operating principle of the Astra gas water heater differs little from the Neva mechanism. This unit is widely available and can always be found in stock. The speaker is considered reliable, so many people are happy to buy this device. It is easy to set up; all you need to do is follow the step-by-step instructions. The advantage of this speaker is that you can always find spare parts for it on the market. The unit is distinguished by its affordable price. Almost anyone can afford it.

It is believed that the operating principle of the Electrolux geyser is quite simple. It has an electronic ignition system. In it you can find an indicator that shows where you can find out the water temperature. This speaker comes with a three-year warranty.

An important detail is that the heating element does not contain lead.

It is worth paying attention to the operating principle of the Oasis gas water heater. This model is in wide demand on the market and has good reviews

Many people are interested in what the principle of operation of the geyser draft sensor is. This element is necessary to promptly notify residents of a possible fire hazard. If the remains of the combustion process do not go up the chimney, but end up in the rooms, then you need to check the draft sensor of the gas boiler. It may be different. When installing it, it plays a significant role what type of camera is installed in the room. It can be open or closed.

If the material from which the sensor is made exceeds the specified expansion standards, then the sensor should operate, thereby saving it from overheating.

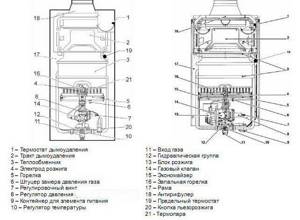

Internal structure of the Oasis speaker

Before you start troubleshooting the Oasis geyser and choosing a method to eliminate them, you must clearly understand what type of device it is, know the device, and the principle of its operation.

The layout of the Oasis gas water column components is typical for most models of Chinese-made flow columns

The diagram above shows the design of a typical gas water heater, which is also typical for Oasis columns. Let's look further at how the most common type of brand's flow-through chimney model with automatic ignition works.

When the tap is opened, water is supplied through the inlet pipe into the water-gas unit, which turns on the ignition and gas supply. As soon as it ignites, a signal is sent from the flame sensor to the electronic unit to stop sparking.

Next, the water passes through a coil rigidly fixed to a heat exchanger, which is heated by burning gas. The coil transfers heat to the flowing water coming out.

When the tap closes, the water-gas unit turns off the gas supply. The combustion stops and the column goes into standby mode for the water tap to open.

An important condition for the normal and safe operation of the column is the removal of combustion products through the ventilation chimney. If the hood is missing or insufficient, the draft sensor is triggered and the column is turned off.

An overheating sensor is responsible for timely shutdown of the column when the maximum temperature is reached. It is an important element of the column, providing protection against overheating

Maintaining the required temperature regime is an equally important condition for fire safety and long service life of the column. Overheating negatively affects the condition of all elements, primarily the heat exchanger, which leads to their premature failure

Causes of problems and DIY repairs

The use of geysers, however, like any other equipment, is accompanied by malfunctions, frequent or rare. At the same time, there are some malfunctions that can only be eliminated by specialists who have the necessary knowledge and permission to do so. But there are also some that can be easily eliminated with your own hands, so we will consider them.

Video - sensor malfunction

Video - repair of a Chinese gas water heater

- The most “popular” type of failure is that it simply does not turn on. If it has an electronic ignition, then you can easily solve a similar problem - just check the batteries and, if necessary, replace them with new ones. Often, such troubles overtake the owners a year after purchase, since the batteries last only that long.

- Also, when using a gas water heater, it may happen that the water in it does not warm up or warms up, but not well enough. Often the cause of such problems is the water node, or more precisely, its defect. As a result, the membrane stops responding to changes in pressure in the water supply system. And if this membrane stops stretching under the pressure of water, then, as a result, the gas valve will not open, or it will open, but not completely. To solve this problem, you must know at least in general terms the structure of the geyser, because the defect can be of several types. If salt deposits have accumulated.

- If the system is clogged.

- If cracks have formed, etc.

To fix this problem, you must first disconnect the column from the gas supply, then clean the water unit and check the membrane.

If the internal elements of the device are covered with soot or dirt, this can also lead to failure. To solve this problem, you must remove the outer casing of the device, then clean each of the elements using a vacuum cleaner. The next sign that the gas water heater has stopped working correctly may be that the burner goes out immediately after turning on. This happens because the ventilation duct is clogged. Modern models of geysers are equipped with special sensors for such cases, which will inform the owner if there is no draft. After this, the gas supply should be turned off immediately. Next, the chimney should be checked. To do this, the plug is dismantled and everything that has accumulated there is removed.

Important! You can check the draft of a chimney in the old “old-fashioned” way: bring a lit match to it. If the fire on the match deviates in the direction of the chimney, then everything is fine with it

If this does not happen, then it needs complete cleaning.

It is for this reason that the gas water heater should be inspected annually - this is the only way it will work correctly.

We also recommend that you familiarize yourself with the basic requirements

Typical unit problems

Most often, the unit fails due to poor quality water. Potassium and magnesium impurities settle and clog device parts. Pressure drops in pipes also have an effect. It has been proven that 80% of gas heater failures occur due to failure of the water-gas unit.

Study the main signs and causes of breakdowns.

The water pressure is normal, but the burner does not light

- Check the membrane. The rubber element quickly wears out, breaks, and leaks. It is better to install a silicone membrane instead of the old element.

- The rod is stuck and won't budge. Perhaps he got used to it. Lubricate this area and the oil seal with grease to restore operation.

The cold flow is quite strong, but the hot flow is weak

- The mesh filter is clogged with small debris and rust. Remove and clean the part.

- The nozzle at the entrance to the unit is clogged. Cleaning is also carried out.

When opening the mixer, the column does not start immediately

- The retarder ball channel is clogged. The elements are disassembled and cleaned. The ball is located in the unit cover.

- The retarder ball is not adjusted correctly. You need to tighten the adjusting screw.

After closing the taps, the device does not stop working

- The ball is jammed or its channel is clogged.

The equipment does not operate at full capacity and may go out during operation.

- The membrane was damaged. The faulty element needs to be replaced.

If you discover a malfunction and decide to do the repair yourself, read below on how to remove the gearbox.

The principle of operation of geysers

Diagram of the internal structure of a classic gas water heater.

The operating principle of a gas water heater is quite simple. The column works as follows: cold tap water is passed through the device’s heat exchanger. There it is heated by burners located under the heat exchanger.

Oxygen, which is necessary for this process, enters naturally through the ventilation system of the home, and exhaust smoke gases escape through a special chimney, which is intended only for the gas water heater. Hot water from the water heater enters the sink through a pipe.

Each type of geyser works differently.

For example, when turning on the device manually, ignition occurs by igniting the gas with a match, and the burner ignites when the gas supply knob is turned. However, columns with a manual operating method are already outdated.

Installation diagram of a homemade instantaneous water heater with multi-point water supply.

There are two types of ignition on modern gas water heaters: electronic and piezo ignition. With piezo ignition, the column is turned on by a mechanical force that is converted into a spark.

In this case, the equipment is turned on using a button located on the front panel. The piezoelectric element produces a spark that helps ignite the pilot light. Then everything happens automatically: when you open the tap, the column lights up and hot water begins to flow.

Geysers that are switched on using electronic ignition are considered the highest quality and most reliable. Such devices are turned on using two batteries, which provide a charge for the spark. This type of speaker does not require buttons or matches. To turn it on, simply open the tap. Batteries usually last a long time.

The most common breakdowns

Finally, I will give a few of the most common breakdowns of geysers.

Most often you can observe the following problems in the operation of heaters: Clogging of the coil with scale. If there is low pressure in the hot water tap, and cleaning the reducer does not solve the problem, it means that the coil is clogged. In this case, it needs to be washed with a remover such as Antiscale;

- Doesn't light up.

There are several reasons why the dispenser may not light up: low water pressure; - there is no draft in the chimney - perhaps a foreign object has entered the chimney;

- the batteries are dead (applies to speakers with automatic ignition);

- Doesn't heat water well

. There may be several reasons: gas equipment is clogged; - the need to adjust the burner - modern columns have a tap that allows you to adjust the gas supply to the burner.

These are all the most common malfunctions of geysers that you can fix yourself. The service instructions, which usually come with the passport, will help with this.

If you are not sure that you can fix the problem yourself, it is better to seek help from specialists. The repair price starts from 300 rubles excluding the cost of parts.

Performing serious operations, such as soldering a radiator, costs 1000-1200 rubles. Prices are valid for spring 2021.

Required water pressure

The minimum pressure required to turn on the selected column is indicated in the equipment documentation

Paying attention to this parameter is especially important when installing a heater in old houses built in the 60-70s, since the pressure in their pipes is often insufficient for the heater to operate. If the manufacturer states that the minimum requirement is a pressure of more than 0.15 bar, then in an old building there may be problems with the functioning of this column

Another point is the ability of the column to withstand the hydraulic shock that periodically appears during water supply. This is the name for a short-term increase in pressure in pipes, which can cause leaks and damage to connections. With a value in the range of 11-12 bar, the column is able to withstand such changes.

Removing the column lining

Repairing a geyser with your own hands, such as replacing batteries, is the only way to troubleshoot problems that does not require removing the outer casing of the unit. To repair geysers Vector, Oasis and any other malfunctions, you will need to open the device. To begin removing the casing from the water heater, you need to turn off all the water and gas supply valves, and then do the following (for example, we take the Neva 5611 water heater, which we will disassemble on the table).

At the very beginning, you need to remove the control knobs from the unit panel. They are not secured in any way, so just pull them towards you. If you can’t pull the handle out freely, you can use some flat object and carefully pry it from below so that it doesn’t break. The Oasis gas water heater (Turbo series) also has a third “winter-summer” handle located in the center.

Under one of the handles of the water heater there is 1 screw that needs to be unscrewed. The presence of a screw under the handle is observed only in the Neva 5611 model, while it is not present in the Neva 4510 and Neva 4610.

A display is attached to the casing of the device, to which 4 wires are connected. A pair consisting of red and black conductors is connected to the control module, and a black and blue one is connected to the temperature sensor. For convenient disconnection, the ends of the wires are provided with connecting blocks that can be easily opened

Disconnect all 4 wires by pressing the small release tab on the block (if this is not done, the block may break).

Next, you need to unscrew the screws from the housing that hold the cladding in place.

After this, place your fingers under the cladding (be careful, you can cut yourself) and slightly pull it towards you so that the guide pins located on the unit body come out of the slots.

The casing is then pushed up, after which it must be removed from the hooks. The picture below shows the holes for the hooks.

The following illustration shows the holes for the alignment pins and the locations for the mounting screws (blue arrow).

Installation of the cladding in its original place occurs in the reverse order.

Water heater operating algorithm

If you have little understanding of the structure and operating principle of a modern geyser, we recommend that you familiarize yourself with this section, otherwise you will not be able to repair the device. The design of an atmospheric heater with an open combustion chamber is shown in the diagram below.

Note. The photo shows an old type column with manual ignition of the burner from a piezoelectric element. Updated versions of the devices (including the Russian brand “Neva”) ignite automatically; the power source is batteries or a 220-volt home power supply.

A turbocharged column is designed in a similar way, only the combustion chamber is completely closed, and a fan supplies air to the burner. The algorithm for starting the unit and heating water for DHW needs looks like this:

- After opening the mixer tap, a flow occurs through the water unit and the column heat exchanger.

- A membrane installed inside the frog body pushes the rod forward due to water pressure. The latter compresses the spring of the mechanical valve in the gas block, opening the passage of fuel to the burner.

- At the same time, the rod releases the microswitch button, closing the solenoid valve circuit. It is triggered and releases gas into the supply tube, where there is an already open spring valve.

- At this moment, the pulse device delivers a high-voltage discharge to the electrodes installed near the burner. A spark ignites and the water begins to heat up.

- Three sensors are connected in series to the solenoid valve circuit - thrust, overheating and flame (ionization). When the latter detects the presence of fire, sparking stops.

Reference. In older water heaters, instead of two electrodes igniting the main burner, one contact and a constantly burning pilot light are used. The presence of a flame is monitored by a thermocouple.

Now let's look at the most important point necessary for a successful repair. Under what conditions does the column automatically turn off (the main burner goes out):

- when the flow and pressure of water disappear, the “frog” releases the pusher, the microswitch opens, and the power supply to the solenoid valve is interrupted;

- if the ionization electrode does not “see” the flame and does not give the corresponding signal, the magnetic valve closes the gas;

- the draft in the chimney disappears, the sensor breaks the circuit and the electromagnet turns off, cutting off the fuel supply;

- The overheat sensor installed on the heat exchanger affects the gas block in a similar way.

Having understood the principle of operation, you can proceed to diagnosing column malfunctions and making repairs yourself.

Dismantling the water unit

To carry out repairs, the unit must be removed from its seat. This is only possible together with the dismantling of the gas unit.

- Turn off the gas supply valve.

- Disconnect the cold water hose.

- Using a wrench, disconnect the assembly from the pipe.

- Disconnect the wiring from the gas valve and microswitch.

- Use a screwdriver to unscrew the flange bolts.

- Remove the water-gas block.

Read also: What a manual milling machine can do

Now you need to disassemble it and replace the broken parts:

- To disconnect the gas part from the water part, unscrew the two screws. One is on top, the other is on bottom. You can not unscrew it completely, but slightly loosen the fastening. It happens that the bolts stick. Spray these areas with WD-40.

- Separate the blocks.

- Now unscrew the frog screws on top.

- The body will split into two parts and the diaphragm will become accessible.

- Remove the rubber part (if it is faulty, prepare a new one).

- Pull out the disc with the stem. Behind them is a spring.

- Remove the spring and check the seal located behind it. It requires periodic cleaning and lubrication.

- Install new parts and reassemble the unit in reverse order. The oil seal can be lubricated before installation.

- When tightening the frog bolts, lubricate them with graphite lubricant.

To avoid running the column into a faulty state, check its components every six months and clean them of scale and dirt.

(No ratings yet)

One of the important units remains the water unit of the gas water heater or “frog”. The regulation and safety module is installed in semi-automatic and automatic flow-through gas boilers. A gearbox malfunction is reflected in failures to start the burner, refusal to turn on, and other disturbances.

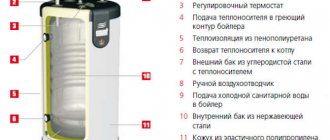

General structure of a household water heater

A geyser is a flow-through water heating device. This means that water passes through it and heats up as it goes. But, before moving on to an analysis of how a household gas water heater works, let us recall that its installation and replacement are associated with a centralized gas supply system.

Therefore, you must submit documents to the gas service of your region along with the appropriate application. You can read about the norms and necessary documents in our other articles, but now let’s move on to the device.

Different models of geysers differ from each other, but the general structure of a household geyser looks something like this:

- Gas-burner.

- Igniter/ignition system.

- Exhaust hood and connection to the chimney.

- Chimney pipe.

- The combustion chamber.

- Fan (on some models).

- Heat exchanger.

- Gas supply pipe.

- Water node.

- Connections for water supply.

- Pipe for hot water outlet.

- Front panel with controller.

The central element of the column is a gas burner, in which gas combustion is maintained, which helps to heat the water. The burner is installed in a housing; hot combustion products are collected in it, the purpose of which is to heat water.

The housing is made of metal and completely covers the front and sides of the speaker

It is important that the material of the housing conducts heat well, because the quality of heating depends on the transmission of heat.

Structural components of a geyser located inside the housing. Closed type gas equipment is shown here

On top of the device there is an exhaust hood and a chimney through which combustion products leave the column and the room. Their design depends on whether the column is open or closed, which will be shown below.

The pipes meander like a coil inside the body, water passes through them under natural pressure and is warmed by hot gases. This entire pipe system is called a heat exchanger. At the bottom there are two pipes: on the right - for receiving cold water from the pipeline, on the left side hot water flows out.

A filter is often installed between the water supply network and the gas water heater, which regulates the water hardness. Without a filter, the column may become covered with scale at high water temperatures. When entering the column, water passes through a water unit, which serves as a kind of “connection” between the water flow and the gas flow. We'll talk about this connection a little further.

Burning gas burner with electric ignition and flame sensor. Sensors play an important role in the functioning of equipment. We'll talk about their functions further.

Using another tube, which is also located below, the column is connected to the gas main.

There is also a front panel with a control unit. It is equipped with regulators to control gas and water consumption. Depending on the model, these can be either simple knobs that need to be turned, or liquid crystal displays, where you can see many characteristics of the column, or even the nature of its malfunction if the column does not work.

The column does not ignite initially

Before you climb inside the water heater, you should perform a number of basic steps:

- Replace the batteries and clean the contacts in the power compartment.

- Make sure there is natural chimney draft and normal pressure in the cold water supply system.

- In a turbocharged dispenser powered by mains power, check the fuse. Try switching an imported unit by turning the plug in the socket - some models are sensitive to phase location.

- Clean the dirt filter installed on the cold water supply pipe. Sometimes the mesh at the inlet is provided by the design of the water heater itself.

- After opening the DHW mixer, observe the ignition electrodes - a spark should jump from them. In a turbocharged apparatus with a closed chamber, the clicking of discharges can be clearly heard.

Heater repair begins with cleaning the electrodes and installing working batteries

Advice. If there is external access to the ignition electrodes through a window, immediately clean their working part with a long brush.

Did the above measures not produce results? Then remove the column casing and proceed to troubleshooting, following the step-by-step instructions:

- Open the hot water (ask an assistant) and watch the movement of the rod, which should move the pressure plate away from the microswitch button. If the pusher does not move, the reason is 100% inside the water block. You will have to disassemble it, clean it and change the membrane.

- The rod presses on the plate, but the button remains pressed. Probably, the stroke of the pusher has decreased due to scale inside the “frog”, which needs to be opened and cleaned.

- The pusher moves, the button turns off, but there is no sparking. Surely the microswitch is to blame, diagnosed as follows: disconnect its connector and short-circuit the 2 terminals with a screwdriver. If the switch is faulty, then after a direct short circuit a spark will appear on the electrodes.

- The discharge skips on one needle, the second is silent. Pull the high voltage cable out of the electrode housing, trim it slightly and insert it back.

- The “frog” functions, the microswitch is triggered, the electrodes spark, but ignition does not occur. This means that gas is not supplied - the solenoid valve is closed. The culprits of the circuit break are the traction and overheating sensors; to check they need to be closed one by one using a wire. Another option is a break or fracture of the supply wires, which is diagnosed by testing with a multimeter.

You need to short-circuit the connector connected to the pulse unit, and not the microswitch plug

An important nuance. When you discover a faulty microswitch, be sure to inspect the water block housing at the installation location. It happens that the element is flooded with water dripping from under the stem seal. It is necessary to dismantle the “frog”, pull out the leaky seal and install a new spare part.

In some models of electronically controlled gas flow columns, a special flow sensor controls the start. It operates on the principle of a limit switch - the water flows, the circuit is closed. Diagnostics is simple: open the DHW valve and test the element contacts with an ohmmeter or a light bulb - it should light up. The algorithm for a complete check of the water heater is demonstrated by the technician in the video:

Why does the speaker go out?

Let's think logically: if the gas burner device ignites, then the water block and the sparking system are working properly. The problem lies in the solenoid valve, or more precisely, in its shutdown and interruption of the fuel supply. Troubleshooting comes down to 3 sensors:

- traction;

- ionization;

- heat exchanger overheating.

The malfunction of the draft sensor was already mentioned above - the faulty element did not allow the column to start. The fact is that heaters of different brands can work differently; in some, the draft sensor does not allow the burner to light, in others it works later, after a gas flash. The result is that the column lights up and immediately goes out.

The test method is the same - we close the terminals of the draft sensor with a wire and turn on the water heater. If the burner does not go out, install a new part. It is strictly not recommended to constantly use a jumper wire instead of a non-working traction thermostat!

The flame control sensor creates a small EMF in the electrical circuit, which is directed to the ignition unit. Externally, the thermocouple is very similar to the ignition electrode

An ionization flame sensor (thermocouple) produces a direct current when the tip of the needle is heated by the burner flame. The signal is sent to the control module and the safety solenoid valve coil, keeping it open. Traction and excessive heating sensors are connected in series to the same circuit.

Key moment. As soon as the signal from the thermocouple disappears, the electromagnet turns off, the flow of gas stops - the column goes out.

How to check and repair the ionization sensor:

- An insulated cable from the pulse ignition module is connected to the needle located in the combustion zone. Remove the end of the wire from the socket and shorten it by 0.5-1 cm to ensure reliable contact.

- Adjust the gap of 6.5 mm (or other as required by the manufacturer) between the tip of the needle and the surface of the burner for optimal heating immediately after ignition.

- If the previous steps do not help, try shorting the terminals of the overheating sensor attached to the heat exchanger with copper wire.

- Does the column continue to die out a second after ignition? Remove the thermocouple, connect a voltmeter to its contacts and heat the needle with a gas stove burner. A working sensor will produce a voltage of 0.02 volts or more. If the reading is lower, go buy a new thermocouple.

In rare cases, the electromagnet itself or the ignition module coil fails. The first can be checked using an ohmmeter - connect the device to two of the three terminals alternately. Normal readings on the first pair are 400...600 Ohms, on the second - 7...8 Ohms, on the third - about 400 Ohms (the data are given for Neva speakers, they may differ on other devices). To diagnose the pulse unit, you will have to call a specialist.

Other malfunctions of flow-through heaters

In addition to the problems listed above, speaker owners have to deal with the following problems:

- weak sparking, sometimes single discharges slip through, the gas does not flare up;

- ignition is accompanied by a strong bang;

- after closing the DHW valve, the burner continues to operate until the electromagnet cuts off the fuel supply due to strong heating (at the command of the sensor);

- spontaneous ignition after connecting to a power source;

- insufficient heating;

- Water is leaking from the water heater.

Advice regarding weak discharges on electrodes. If the batteries and contacts are in order, try cleaning the ends of the electrodes and adjusting the gap between the needles and the plane of the burner (the value is indicated in the technical data sheet of the product). If there is no result, call a specialist - most likely the reason is in the pulse block.

Problems with sparking cause popping noises - gas has time to accumulate in the combustion chamber before a sufficiently powerful discharge is formed. If the spark remains weak, the fuel-air mixture ignites when it reaches a high concentration, which is accompanied by a micro-explosion. There have been cases where the pops damaged the heat exchanger, disrupted seals and normal contact in the electrical circuits of the sensors.

Continuing heating after turning off the water is a rather dangerous malfunction. If it coincides with a failure of the overheating sensor, a vapor phase will form in the heat exchanger that can rupture copper tubes and honeycombs. The reason is the jamming of the “frog” rod that opens the gas valve. How to repair:

- Remove the water module according to the instructions above.

- Disassemble the “frog” and remove the plastic plate.

- Unscrew the nut (or screw) in the left half of the membrane chamber and remove the pusher.

- Change the seals, thoroughly clean all parts from deposits, including the spring monostat (located on the right side of the “frog” behind the membrane).

Recommendation. Before assembly, check how freely the rod moves inside the new seals. For details on disassembling and repairing the speaker, watch the video:

Spontaneous start of heating without turning on the water is a consequence of sticking of the pusher. When the burner of the device does not turn off and the thermostat trips, the user temporarily turns off the power source. Since the rod remains pressed, after the power supply is restored, the column turns on itself, without opening the DHW tap. The “treatment” method is described above.

The reason for low heating is total contamination of the main elements of the unit - the heat exchanger and burner. The column needs to be completely disassembled and serviced; it is better to entrust such work to a specialist. In case of burnout and leakage, the heat exchange unit must be removed and properly soldered, which is not always possible to do at home.

Design and types of water block

The material used to make the water reducer varies and is therefore divided into several types:

- Brass. Alloy of copper and zinc.

- Plastic. The practical device is not subject to corrosion.

- Polyamide. Reliable device with fiberglass composition.

The column regulator or “frog”, as the block is also called, has protective functions. It serves to automatically turn on the device when water is supplied. It also protects against overheating when pressure in the line decreases.

How the gearbox works:

- Base and cover with bolts.

- Rubber membrane with a disc on the rod.

- Flow device.

- Temperature switch.

- Flow sensor.

- Venturi tube.

- Filtering device for hot water.

The water pressure regulator cover can be held together with steel screws or plugs. Since the parts do not come into contact with water, there is no risk of corrosion. By unscrewing the screws, you will remove the cover behind which the membrane is located. The device is quite simple.

When you turn on the water, pressure is created on the membrane. It pushes out the rod, which operates the gas valve. Fuel is supplied to the burner and heating begins. When the mixer closes, the pressure drops - the parts return to their previous position.

An important part of the gas-water unit is the Venturi nozzle. What is it for? For example, in technology the tube is at the bottom. The location in the “Oasis” and “Astra” columns may differ. The part serves to reduce the pressure of the working medium. This is how the gas supply is adjusted.

When you close the tap, the tube equalizes the indicators, causing the membrane fitting to return to its place. After this, the device turns off.

The water part is also susceptible to breakdowns, so we will list the main faults and ways to repair them yourself.