How does a gas water heater work?

The term “gas water heater” is a legacy of the Soviet period. In those days, when hot water supply was just being established, during the construction of houses, simplified wall-mounted gas boilers were installed in apartments, not equipped with automation and security systems.

Morally, technically and technologically outdated units were inconvenient and dangerous. Modern equipment is radically different from its ancestor. The devices are convenient, beautiful and do not pose any threat to the health and property of the owners.

Geysers can be manual, with piezo ignition and electronic ignition, equipped with sensitive sensors that interrupt the fuel supply in case of extinguishing

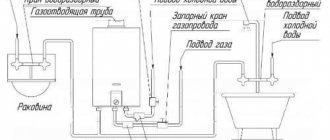

Instantaneous gas water heaters are a metal structure with a heating system. Pipes are connected to it for cold water inlet and hot water outlet, for coolant circulating through the heat exchanger, as well as for gas. The igniter is located at the bottom of the equipment. It functions like a lighter.

The gas valve opens automatically immediately after turning on the water or activating the heating process of the coolant. Gas enters the main burner, which is ignited by the igniter and produces heat. The water enters the heat exchanger, which is a spiral tube, where it is prepared for supply to the heating circuit or to the hot water supply.

Hot water is already flowing into the water tap. It heats up within 2-3 seconds after turning on the burner. Its temperature depends on individual settings. To remove combustion products, a chimney is required.

Columns with ignition wick

Why the gas water heater turns on with a bang did not worry the owners of old water heaters too much. Their design and operating process were not as convenient when compared with modern equipment. But repairing them was much easier and cheaper.

In this case, a pop when the gas water heater is turned on is possible if the ignition wick is in the wrong position. The device bangs because the flame has decreased and cannot reach the edge of the burner. This is due to insufficient gas supplied to the wick. The main reason why a water heater makes noise is considered to be a clogged nozzle.

You can cope with this problem yourself, the main thing is to be able to completely disassemble the device. The design diagram of instantaneous water heaters is similar, so the instructions will fit each device.

To cope with a breakdown and prevent an explosion of a gas water heater, you must act in the following sequence:

- Shut off the flow of water and gas to the equipment.

- Dismantle the protective casing.

- Open access to the ignition wick.

- Unscrew the fasteners from the guide tube and remove the nuts securing the sensors and supply tubes.

- Pull the tee out of the groove.

- Pay attention to the lower pipe. A small screw with a hole through it will be visible at the bottom. It is called a jet.

- Remove the element from the tube and clean it thoroughly. To do this, you can use a thin wire and a needle.

- After completing the procedure, all parts must be put back together.

After completing these steps, the popping noise in the water heater should stop. Having found out why the gas water heater is noisy, you just need to fix the problem. If the breakdowns are complex and the noise in the device increases, you need to visit a specialist. He will do everything to ensure that the column does not explode and functions normally.

Causes of geyser pops

For automatic geysers:

- • electrical ignition malfunction.

The automatic column has electric ignition from an electric discharge. It produces a spark that ignites the gas on the main burner. This spark must be between the glow plug and the main burner. If the electric candle is faulty, then an electric discharge can occur at the end of the burner or on the supply wire at the bottom of the candle, so the gas column slams, since the spark appears in the wrong place and, when it ignites the gas, it manages to accumulate inside the combustion chamber.

- • weak electric ignition discharge.

In a column with an automatic ignition type, batteries are installed. If they sit down, then the discharge on the spark plug becomes weak, and the gas supply to the burner remains the same. The result is a loud bang.

For geysers with piezo ignition:

- • the wick burns to the side.

When the pilot wick is clogged with dirt and dust, the flame may burn weakly or away from the burner. In this case, the fire does not reach the combustion chamber and gas pop occurs.

For any geysers:

- • the occurrence of popping noises may be a consequence of long-term operation of the device without carrying out its maintenance, which includes a detailed inspection, thorough cleaning, preventive maintenance, and adjustment of all parts of the equipment. If maintenance is carried out on time, annually, many problems can be avoided.

Weak traction

Combustion products must be discharged through the chimney. When they are heated and there are no obstacles, this happens quickly. If carbon dioxide and steam have time to cool, they can fall back into the column and contaminate the mixture of gas and air.

Checking traction

To check the draft intensity, you need to bring a burning match or lighter to the chimney opening (some models also have special test holes for this). The flame should actively deflect towards the water heater. If it remains in place, this indicates weak traction.

The main reason for poor draft is a clogged chimney. Over time, soot accumulates in the chimney, which narrows the diameter of the pipes. Debris can also get into the chimney from above. If the clog is small, you can remove it manually. If the chimney is clogged much higher up the riser, you need to call utility services to clean it.

Also, if an active hood with a fan is installed in the kitchen, then the exhaust gas can be drawn into it instead of going up. It is necessary to turn off the propeller while the water heater is operating.

Common breakdowns

Popping noises when turned on are typical for Soviet models. Due to flaws in the design, undesirable effects arose, causing concern to the owners. When using modern instantaneous water heaters, this problem is rarely encountered.

Attention! When you turn on the geyser, a strong bang occurs due to the fact that gas accumulates in the heat exchanger.

If this problem is not corrected, the consequences will be very serious. The gas will concentrate in the gas pipe and gradually move into the chimney, which is why the gas water heater will explode. Therefore, at the first sign of a problem, you should carry out diagnostics and find out why the device is breathing.

The process of gas accumulation is usually associated with:

- Clogging of the chimney, which makes normal draft impossible;

- Damage to the valve, which causes a fire after switching on;

- Deflection of the ignition wick light.

If popping noises when turned on are heard from a modern water heater model that ignites automatically, this may be due to:

- Low battery;

- A faulty microswitch;

- Defective spark plug.

Strange sounds require close attention. Therefore, it is advisable to contact specialists who will determine the causes of the problems and correct them.

Diagnostic method

If you decide to carry out repair work yourself, the owner must strictly follow the instructions. First of all, experts advise checking the intensity of the chimney draft. The main part of the geysers is equipped with a casing, which has holes provided just for this procedure. If the column manufacturer has not made such holes, the draft can be checked right next to the slot located at the smoke hood. In addition, the draft is perfectly felt at the chimney cleaning hatch.

Troubleshooting Methods

Problem. What to do

| Electric ignition is not working correctly. | It is prohibited to use a gas water heater. It is necessary to close the main gas supply valve, remove the batteries (to ensure that no one uses the faulty equipment) and call a specialist. |

| There is not enough electric ignition discharge. | Replace the batteries, turn on the column: if within 3-4 seconds the flame does not appear on the burner, turn off the gas supply tap to the column, remove the batteries, and call a technician. |

| Incorrect wick direction. | The column cannot be used. It is necessary to turn off the gas valve. In this case, it is necessary to clean the ignition group. This type of work should only be carried out by a competent specialist. |

Column microswitch failure

Often the problem with a loud bang during ignition is the insufficient discharge of batteries, which provokes the inability to instantly ignite the gas-air mixture.

The power supply is connected to the control unit via special microswitches, which are responsible for generating a signal to activate the ignition when the DHW tap is opened. If the signal arrives at the wrong time, this causes the problem. This malfunction occurs most often due to oxidized contacts. The microswitch cannot be repaired; it will need to be replaced.

If the microswitch breaks down, repairs cannot be carried out, since this system will have to be completely replaced

Flow sensor malfunction

Often the problem with popping is the flow sensor. It is located in the input circuit. A signal is sent to the control unit controller indicating the presence of liquid in the pipe. The data instantly activates the ignition system. Intensive use of this element creates an increased risk of breakdowns. For example, contact groups can be oxidized.

Such sensors are most often manufactured in a non-separable design, therefore, if a problem occurs, they cannot be repaired and must be replaced.

Working candle offset

The problem may be with the spark plug. After applying voltage, it provokes the formation of an electric spark. Modern candles are made in such a way that they can last for a long time. Element failures are rare, but they do happen.

The most common occurrence is that the ignition device is displaced relative to its nominal position. It can occur as a result of repeated heating and cooling. Such processes are associated with changes in the dimensions of individual structural elements. As a result of adjusting the position of the spark plug, the spark parameters become normal, and extraneous noise completely disappears.

Incorrect operation of the ignition retarder

A rare breakdown is considered to be incorrect operation of the ignition retarder. When disassembling the column, you need to remove the water regulator. On its cover there is a hole in the bypass channel, in this hole the ball is located. The adjusting screw determines the position of the ball.

If, when shaking the lid, you hear the sound of a moving ball, then you should not manipulate this part further. If there is no knocking, then you can move the ball using a thin copper or aluminum wire through the passage channel hole, which is located in the regulator cover.

Most often, the retarder is a ball of metal or plastic that blocks part of the bypass channel in the water regulator. In most column designs, this moderator is located in the boss of the water regulator cover.

As a last resort, you will have to resort to the procedure of parsing the element. It must be said right away that the external screw does not affect the position of the ball in any way. The inner screw must be removed very carefully. You should first remember its original position, and also clearly determine the number of revolutions by which this screw is screwed. This will allow you to maintain the required location of the element (ball) during subsequent assembly.

After repair work, be sure to check all connections to completely eliminate leaks of both water and gas. All connections must be treated with a sealant to ensure tightness. After which you can put the casing in place and use the column as usual.

Column with automatic ignition system

Gas equipment equipped with a special ignition system when turned on saves the owner a significant amount of gas. The ignition device is controlled by an electronic control module, which is directly connected to microswitches. They are installed on the liquid and fire regulators. As a rule, this system does not fail and is considered one of the most reliable, however, expensive repairs in the event of failure can be a significant disadvantage for the owner.

Why is it important to fix the problem immediately?

Even small pops are warning beacons indicating that the equipment is faulty. If the problem is not solved immediately, it will get worse in the future. The boiler may turn off, in addition to popping noises, an open flame comes out of the boiler, etc.

Despite the fact that modern equipment is equipped with good protection systems, the owner must still use it competently, maintain it in a timely manner, remove blockages, etc. Then the boiler or column will work for a long time, efficiently and without failures.

If you find that the boiler slams when turned on or makes noise during operation, and the reason cannot be determined, contact the experts. They will advise you on this issue, and if necessary, they themselves will diagnose and eliminate the cause of incorrect operation. Call.

The autonomous gas heating system from the Korean manufacturer Navien is quite popular among consumers; it is installed both in country houses and apartments.

Navien units have gained popularity due to their good technical characteristics, ease of operation and installation. Like all appliances for domestic use, the Navien gas heating system has its own faults.

Of course, the manufacturer provides a guarantee for its device and claims that the likelihood of breakdowns is almost zero, given the high quality of the equipment. But if this happens, then with a competent and timely approach they can be quickly eliminated.