There are several reasons why the Oasis geyser lights up and then goes out after a while:

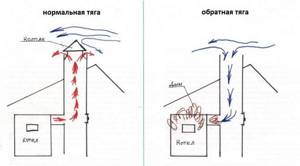

- The chimney is clogged. If the chimney is clogged and a large amount of soot has accumulated in it, carbon monoxide is difficult to remove outside. This triggers the flue gas sensor. It opens the thermocouple, the flame of the water heater goes out.

You can check whether the draft is strong enough by holding a burning match to the chimney opening. If the flame does not deflect at all, then the draft is not strong enough.

The ventilation should be cleaned and dirt and foreign objects should be removed. It may be that the chimney shaft is clogged much higher. If you live in an apartment building, you will have to call specialists to clean it. If you have your own home, you can try cleaning the ventilation shaft yourself.

- Also, poor draft may be due to the installation of a satellite dish above the chimney, which is prohibited by safety regulations. In this case, you should require your neighbors to reinstall the antenna in another location.

- The hood over the gas stove is too powerful. This leads to the fact that the gases do not naturally escape upward, but are drawn into the room by the hood. In this case, you should reduce the power of the hood or remove it completely.

- The radiator of the Oasis speaker is clogged. When using a water heater for a long time, its heat exchanger becomes clogged with soot. This also makes it difficult to exhaust and remove carbon monoxide.

Soot and carbon deposits on the gas water heaterIn this case, you need to disassemble the column, remove the heat exchanger and wash it with chemical detergents. This must be done carefully so as not to damage the thin copper pipes.

- Strong gust of wind. If there is a draft in the room where the Oasis water heater is installed, the flame may go out. In this case, the protective system will immediately work and shut off the gas.

Excessive drafts should be avoided. But at the same time, it is impossible to completely close all the windows in the room - for safety reasons, the water heater must operate with the window open. If no air enters the room at all, the flame will go out due to weak draft.

- Water pressure has dropped. The Oasis column will go out if the water flow decreases. The protection will work, which is necessary so that the water heater turns off when the tap is closed.

You should open the cold water tap and check the pressure. If it is weak, then you need to contact utility services. If the pressure is strong, then you need to clean or replace the inlet filters.

Adjusting the water pressure knob on the body can also help. By screwing this regulator on, the pressure inside the water heater will increase and the heater will start working. Such controls are installed on newer models of Oasis speakers.

- Gas pressure has dropped. In this case, the gas sensor will work. You should also call utility services about this.

- The membrane has deteriorated. Over time, the rubber membrane, which is responsible for opening the gas valve, stretches and may break. Then the Oasis column will either stop working or the flame will be very small. Replacing the membrane will help here. The water heater is opened, the water regulator is pulled out and the membrane is replaced. It is sold in stores both separately and as a set with gaskets. It is recommended to take one made of silicone - it will last much longer.

- Mixing hot and cold water. If, while the Oasis column is operating, you begin to dilute hot water with cold water from the water supply, the pressure in the column will drop. It is recommended to initially set the gas regulator to a comfortable level and use only water from the water dispenser.

- Gas sensor failure. If all the previous reasons do not apply, the gas sensor may simply be broken. To repair it, you will need to call specialists.

All repair work should be carried out with the water and gas turned off, even if you do not intend to touch the gas components.

If you are not confident in your abilities, it is better to call specialists.

Why does the gas water heater igniter go out:

• Air flows from the outside (flame separation); • Lack of draft in the chimney; • Traction control sensors are faulty; • The thermocouple is worn out or burnt out; • Poor contact between the sensor and the control unit; • Ionization sensor outside the flame range. The most common reason why the pilot light goes out is a faulty thermocouple. The thermocouple is an element of a safety device designed to shut off the gas flow in case of unstable operation of the gas column. When the pilot goes out, the thermocouple detects the lack of heat due to the lack of fire and turns off the gas. However, if the thermocouple is burnt and its tip has become loose from prolonged exposure to fire, then it becomes the reason why the igniter goes out.

| DIAGNOSTICS On this page we have described in detail all the faults, so the cost of this service for you is 0 RUBLES |

| CALL We will charge 500 rubles for the call if the repair is refused, but this service costs RUBLES |

| SERVICE The cost of the technical work performed without the cost of the required spare parts in our company varies from 900 RUBLES |

| GUARANTEE Before leaving, our employees will issue a guarantee from our company for the work done for a period of time. up to 6 MONTHS |

However, if the thermocouple is burnt and its tip has become loose from prolonged exposure to fire, then it becomes the reason why the igniter goes out. Another problem is that the gas injector holes on the igniter are small in diameter and can become clogged with debris and dust, thus preventing the gas at the igniter from burning properly and resulting in insufficient heating of the thermocouple.

Why does a geyser turn off spontaneously and how to deal with it.

Outgoing air currents from outside can blow out the pilot burner. Downdrafts typically occur if the appliance is not properly ventilated. When repairing a gas water heater, be careful not to confuse this phenomenon with a lack of traction.

Geysers have electromagnetic valves that belong to the gas control system. If the ventilation system is faulty and carbon monoxide enters the room, the solenoid valve will shut off the gas supply and the igniter will go out.

Black soot deposited around the igniter area and on the heat exchanger itself is another problem why the igniter goes out. This soot appears from incomplete combustion of gas. The accumulation of soot on the heat exchanger can cause major problems with air ventilation and cause the pilot to go out during operation.

Signs that the igniter is not working properly

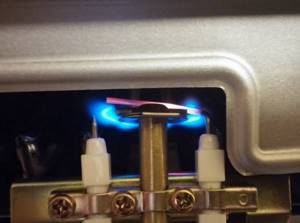

Pay attention to the color of the igniter flame. It shows how well and correctly the gas burns

A wick that effectively burns natural gas burns with a blue flame. The blue flame color should be at least 90% with small red flecks and a slightly yellow tip. An orange or predominantly yellow color indicates problems with the pilot burner, which can lead to an emergency stop of the column.

Why does the igniter smoke? If the ratio of air and fuel becomes less than standard values, the color of the flame turns yellow and the igniter begins to smoke and burn sluggishly. This leads to insufficient heating of the thermocouple and the igniter goes out.

Why does the column not go out after turning off the water?

Another common problem. The cause of the malfunction is the low quality of water entering the column and the resulting disturbances:

- The rod in the water unit (gearbox) gets stuck - the reason: the appearance of rust, as well as the weakening of the spring that returns the device to its original position after turning off the water. If the geyser does not go out after turning off the water, within just a few minutes the liquid will reach the boiling point and rupture the heat exchanger tubes.

- Damage to control valves - the water heater has a valve that opens the gas supply to the burner. The unit turns on and off simultaneously with the opening/closing of the water tap. After the valve fails, gas is supplied to the burner continuously. When the hot water tap is closed, the regulator does not operate. It is necessary to completely shut off the gas supply and call a technician.

If the gas water heater does not go out when the water is turned off, you should not try to repair it yourself. The breakdown requires a qualified technician to fix it.

Why does a geyser go out and how to deal with it yourself?

If the speaker does not work well, turns off quickly and turns on slowly, then you may be faced with one of the problems described above. In this case, you need to find out the reason, and if it is not very serious, try to eliminate it yourself. Let's talk in more detail about several of the most common problems that you can deal with without the help of a specialist.

The most common problems due to which the wick in a gas water heater does not burn:

- If there is no draft in the chimney, there may be two reasons: a clogged chimney and poor ventilation. In the first case, you will need to clean the chimney. You can do this yourself or use the services of a specialist. However, there is another equally common problem. The fact is that nowadays most apartments are equipped with sealed plastic windows, which limit the ventilation of the home. In this case, it is necessary to install a special supply valve that will ensure proper air circulation; if this is not done, the column will only work when the windows are opened. If you have a supply valve, but suffer from the column constantly turning off, then check the draft by holding a lit match to the inspection window. If the flame does not deflect, then repeat the experiment with the chimney. If there is draft in the chimney, then the heat exchanger in the columns is cleaned, if not, then the chimney itself is cleaned.

- When the burner itself goes out, most likely the reason is a strong gust of wind. To prevent this from happening, do not open windows in windy weather. To resume operation of the device, you need to turn it off and on again.

- The column may also go out due to overheating. Such a nuisance can occur from mixing hot water with cold water or due to the formation of scale in heat exchangers. To prevent this from happening, you need to regulate the temperature by changing the water pressure, or using the regulator on the column. You also need to constantly clean the heat exchanger from scale using special products.

These are the three most common reasons why both Chinese and branded speakers may not work. With some simple manipulations, you can deal with this problem yourself.

Reasons for column fading

Any of the nodes described above can cause the speaker to attenuate. The flame goes out if the security system detects a violation of normal operation. To start the device, you will need to determine and eliminate the cause of this violation.

Here are the most common possible problems:

- there is no draft in the chimney;

- the main burner has gone out;

- there is a dangerous increase in the water temperature in the heat exchanger;

- Some elements are worn out and require replacement.

If the column does not produce a flame, you first need to make sure that its operating conditions have not been violated and check the manufacturer’s warranty periods. The necessary information is contained in the technical data sheet of the product and the instructions for its use.

Reason #1 - lack of draft in the chimney

Checking traction is the easiest way to diagnose the condition of the device. You just need to bring a strip of thin paper or the flame of a lighter, match, etc. to the viewing hole of the column. But if there is even a slight suspicion of a gas leak, it is better to avoid using open fire.

Backdraft is a dangerous phenomenon; it can blow out the flame of the pilot burner, after which the flow of gas to the device will be stopped

If the paper or flame is pulled inward, everything is in order, there is a draft. The absence of changes in their position indicates the absence of thrust, and a deviation in the opposite direction indicates that reverse thrust is observed.

To verify the causes of the problem, you need to disconnect the column and check the draft in the same way only in the chimney. After this, it will become clear whether there are faults in the chimney duct or inside the column too.

When the chimney structure is in order, the “culprit” for the lack of draft is the heat exchanger, or rather, the soot particles that clog it and interfere with normal air exchange. You need to remove the protective casing from the column and clean the heat exchanger with a stiff brush.

Improper installation of a geyser chimney can lead to decreased or absent draft, rapid clogging with soot and soot, as well as other dangerous problems

If the chimney is dirty, all that remains is to simply clean it and reconnect it to the device. If there is no positive reaction, you need to make sure that the chimney structure is assembled correctly from suitable materials. Sometimes the reason for the lack of traction can be flaws in the installation of this section of the system.

Often problems of this type arise for external reasons, such as lack of normal ventilation of the room. Plastic windows and a tightly closed door practically seal the room in which the speaker is located. There is no influx of fresh air flows, so there is no movement in the chimney duct.

It doesn’t hurt to check the ventilation system in the entire house or apartment.

Checking draft is an important safety point when using a gas water heater. This procedure should be carried out regularly, without waiting for problems to appear.

You need to make sure that there is enough fresh air entering the room. If it is not possible to organize ventilation naturally, you can install a supply valve on the windows or in the wall.

Then you should make sure that air flows not only enter the house, but also move freely throughout all rooms. To do this, you need to install ventilation grilles on the doors or make a small gap at the bottom.

Reason #2 - regular burner extinguishing

The absence of a pilot burner flame is detected by a sensor, after which the gas supply is immediately shut off. This situation can occur if a small light was knocked down by a strong gust of wind. There is no need to create a draft in the room while working, especially if it is very windy outside.

Strong air currents can penetrate not only through windows and doors, but also through the chimney duct. The result may be the same - the burner goes out, the automation shuts off the gas flow.

To restore normal operation of the device, you need to turn off the column, check the condition of the pilot burner (a flame should appear here), and turn on the device again.

Reason #3 - significant overheating of water

This occurs when the pressure of the water flow passing through the heat exchanger decreases, but the heating intensity remains unchanged. In some cases, water may even boil, which is dangerous for the integrity of the device.

The pressure decreases when cold water is opened to dilute the flow to a comfortable temperature, and cold water displaces hot water. It is better to regulate the heating using the column settings.

Another reason for this phenomenon is limescale deposits accumulated inside the narrow heat exchanger pipe. To restore normal pressure, you need to regularly descale the device and ensure that the water is not too hot. For domestic needs, it is enough to warm the water to 45-50 degrees.

This mode helps reduce the formation of solid sediment. If the water in the system is too hard and you have to frequently clean the heat exchanger, it makes sense to think about installing a special filter that will remove salt from the flow. The heat exchanger is cleaned using special products or household chemicals: soda, vinegar, etc.

You will have to remove the protective casing from the column, and also turn off the gas and water. Then the heat exchanger is disconnected from the water supply and dismantled. A cleaning compound is poured into the coil pipe and left for a while. After this, the heat exchanger is washed, replaced and the column is reassembled.

Inside the water-gas unit there is an elastic membrane that wears out over time. In this case, it needs to be replaced, although sometimes simple washing helps.

The mesh filter installed at the tap water inlet into the heat exchanger periodically becomes clogged with contaminants. It also needs to be cleaned. To remove ordinary contaminants, it is enough to simply rinse the mesh in water, but sometimes you have to use chemicals. If damage is found on the filter, it is better to replace it immediately.

Reason #4 - insufficient water pressure

The lack of normal water pressure in the system and without overheating can lead to the valve blocking the gas flow and the burner going out.

In this situation, you should check the condition of the water supply system; perhaps you just need to install a circulation pump. When purchasing a speaker, you should also inquire about the minimum pressure values for a specific model.

To get a spark and light the pilot burner, on most modern models you need to press the electric or piezo ignition button. If the flame immediately goes out, you should check the condition of the igniter

Reason #5 - lack of timely maintenance

Following the manufacturer's recommendations, you should regularly clean the column. Late maintenance does not improve the situation. Let's look at the main problems that arise for this reason.

Dead batteries

If the column has electric ignition, it is carried out using batteries. Dead batteries need to be replaced, and the problem will be solved.

And when a piezoelectric element with a turbine is used to produce a spark, it will not start with low water pressure, this point will need to be taken into account.

If a spark does not form in the igniter, you need to immediately check and replace the batteries, and also clean the contacts if they are oxidized

Significantly clogged igniter

The absence of a pilot burner flame often occurs when the igniter becomes clogged. There is simply not enough gas coming in to light the burner. The igniter must be cleaned with metal wire for the column to start working.

It is better to clean it in advance, without waiting until the hole becomes clogged. Blockages accumulate gradually.

If the igniter in the gas column is clogged, the burner will not receive enough gas for a flame to appear, you will have to clean it

If the flame has noticeably decreased, it’s time to check the condition of the igniter. Another sign of such a problem is a popping sound that is heard when the burner is turned on. A weak flame is not able to immediately ignite the gas entering the device. It gradually accumulates and ignites with a pop that resembles a small explosion.

Contaminated or worn membrane

As mentioned earlier, there is a membrane in the water-gas unit. This is a polymer element that, with constant contact with water, gradually loses its elasticity. Sometimes cracks even appear on it, limescale deposits, etc. The membrane stops responding to the flow of water, and as a result, gas does not flow to the burner.

It is necessary to disassemble the water-gas unit, remove the worn element and replace it with a new membrane.

If upon inspection it turns out that the contamination is not too large and the element remains elastic, you can simply wash the membrane and install it in its original place.

In modern models with a large number of electronics, the control board may burn out, after which the column, of course, will not light up.

Coarse filter clogged

The reason for such a breakdown is the low quality of power supply, for which foreign devices are not designed. In addition, some electronically controlled models should not be turned off at night, but must be turned on at all times. To solve the problem of voltage drops in the network, you can use a stabilizer.

A clogged coarse filter can lead to a dangerous decrease in the pressure of water flowing to the gas water heater. This element must be cleaned regularly and replaced if necessary.

Causes

It is worth considering that breakdowns can be of a very different nature. For example:

- the flame does not ignite (clicks, there is a spark, but it does not work or there is no reaction to switching on at all);

- goes out immediately or after a short time (both with automatic and manual ignition);

- the fire goes out when you try to turn on the water, increase the pressure or weaken it;

- the flame ignites, the water comes out lukewarm, and then the column goes out;

- the speaker pops, crackles, mini-explosions appear when turned on;

- piezo ignition does not work;

- the piece works constantly, but when ignited the flame goes out;

- the dispenser does not light up and there is a smell of gas;

- When the tap is opened, the GSV rod does not move.

Column malfunctions can be divided into breakdowns caused by external factors and those of a purely internal nature. The former are not related to parts inside the unit itself and depend on additional parts or external influences (for example, adding temperature).

External factors

External breakdowns are as follows.

- The most common situation is the lack of draft in the chimney of the column. If it is not cleaned, it will become clogged with dust and dirt, and combustion products will not find an outlet and will extinguish the burner. Then, when the security system is activated, the gas supply will be cut off.

- A foreign object could accidentally end up in the chimney.

- The unit could simply have run out of battery or batteries. This type of malfunction only exists if there is an ignition, which operates automatically using batteries.

- If the device does not work after the first installation or due to repair work on the plumbing system, then there is a high probability that the hot water supply line was simply connected in the wrong place.

- Reduced water pressure. It is necessary to evaluate the water pressure (it will be weakened, the water will flow in a thin stream). The ignition will stop working with low pressure, so the reason is no longer in the column, but in the water pipes. Although, it is likely that the filter itself, installed in front of the column, is clogged with something.

- A faulty faucet that adds too much cold water, causing the water in the tap itself to heat up too much and extinguish it.

- Electronics. Modern speakers contain a large number of control modules and sensors that control the operation of the entire unit. Their failures can lead to the gas stopping igniting.

Internal breakdowns

Internal factors are like this.

- Incorrectly configured water heater. Due to the change of seasons, the water temperature also changes, so the column needs to be adjusted, which is often forgotten to do.

- The membrane on the water unit has failed. If the membrane is many years old, it could have lost its elasticity, cracked, deformed, or become covered with lime deposits.

- Filters or heat exchanger clogged with soot and scale.

- The pilot or main burner is clogged with dirt.

- Problems with the gas outlet sensor.

- Pops or small explosions when trying to turn on the equipment can occur due to insufficient draft in the ventilation or blockages of various parts of the water heater.

Reasons for attenuation

If the wick goes out, this indicates that the gas supply has stopped, since in the event of any breakdown that causes the fire to disappear, the dispenser safety system shuts off the fuel supply. Therefore, there is no need to worry about possible leakage.

Lights up and soon goes out

When igniting, the igniter button must be held for at least 10 seconds. Otherwise, the fire may go out. In addition, the column lights up and goes out after several minutes of combustion due to an excess of exhaust gases. The removal of gases is controlled by a sensor, which, if there is a dangerous accumulation of gases, signals a breakdown and stops the operation of the entire system. The reasons for this phenomenon may be the following.

- There is no natural ventilation or, on the contrary, it is very powerful. Even a strong wind can blow out the wick if the chimney opening is not protected. It is necessary to ensure natural ventilation in the room, otherwise the draft in the chimney will disappear.

- Soot, soot and debris accumulate in the chimney, preventing the free passage of air.

- The heat exchanger is clogged. This problem is accompanied by a change in flame color from blue to yellow.

The burner does not turn on

If the wiring between the ionization sensor and the control unit is damaged, or the sensor itself fails, then the following symptoms are present:

- the column goes out 3-5 seconds after switching on;

- the second time the operating time increases;

- the next switching on takes place in normal mode;

- After some time the breakdown returns.

If the burner turns off, this can also be caused by a sharp drop in water or gas pressure, which is not always caused by external factors, but may result from clogged filters or damage to the membrane.

Goes out when mixed

It is not recommended to turn on cold and hot water at the same time, since when the flows combine, the pressure in the column drops.

Goes off during operation

The following factors can cause shutdown during operation:

- insufficient pressure in gas and water supply systems;

- lack of contact between the magnetic valve and thermocouple;

- temperature jump over 100 °C;

- enabling automatic shutdown mode.

Most reasons do not require repair of the unit.

Fading after turning on the shower

If the problem appears after turning on the shower, then the cause will be low water pressure, which is caused by a blockage in the faucet, in the hose or directly in the shower head, as well as due to a clogged filter at the inlet to the faucet.

Why does the speaker go out during operation?

Another common malfunction is that the flame does not die out immediately, but after several minutes of operation. When figuring out the cause of the malfunction, you should pay attention to the following signs:

- duration of operation after switching on;

- whether the malfunction is eliminated when the water heater is restarted.

The main reasons that a geyser goes out during operation:

- The chimney is clogged - combustion products have time to escape from the combustion chamber. A characteristic manifestation: the igniter and burner go out. The speaker turns on with a bang. Troubleshooting: cleaning and restoring the smoke channel.

- The supply and exhaust ventilation and the gas heater in the kitchen are turned on at the same time - while the water heater is operating, the hood must be turned off or set to a lower power. Burner extinction occurs due to the accumulation of flue gases, which cannot escape into the channel due to insufficient draft. The speaker turns off automatically after a short period of operation.

- The overheating sensor in a gas water heater is triggered - the block consists of two metal plates that are triggered when heated. The reason for the shutdown is the oxidation of the contacts between the control module and the fuse. You can check the temperature sensor by moving it closer to the burner. If this is the reason, the column will begin to work temporarily without failures. Protection against overheating of the geyser is an important part of the internal structure. It is prohibited to turn off and start the water heater without a module.

- The radiator is clogged - the heat exchanger has fins. When using the speaker for a long time, debris accumulates between the plates. A characteristic sign of a clogged heat exchanger is a change in the color of the flame to yellow. The problem can be resolved by washing the coil with warm water. At the same time, clean the igniter using a wire or a brush with coarse bristles. Spontaneous shutdown during operation should stop.

- In models with piezo ignition, it is important that the wick is constantly burning. If there is insufficient draft (the reasons are given in points 1 and 2), the igniter goes out, which leads to the column turning off.

After eliminating the described disturbances related to air circulation in the room and the need for good draft, as well as replacing the overheating sensor, the water heater will continue to function normally. The speaker will stop turning off regardless of the duration of operation.

The water doesn't heat up well

Reason 1. Insufficient speaker power

Perhaps you often need to simultaneously supply water to the kitchen and bathroom, but the water heater does not have time to warm up such a volume.

- Select a unit with greater power.

- Turn on hot water in different rooms alternately.

Reason 2. The column is clogged

A blockage may occur in the burner or heat exchanger due to excess soot. This will be signaled by the red-white color of the flame at normal water pressure.

The solution is to clean the column, preferably with the help of a specialist.

Reason 3. The column water assembly membrane is damaged

If at first the water flows at an acceptable temperature, but gradually it becomes colder, the flame of the column is blue, and the light is weak, then the problem is in the integrity of the membrane. Cold water wedges into the hot flow, and the outlet temperature drops.

The solution is to replace the membrane.

Reason 4. Water inlet/outlet hoses are installed incorrectly

If you have just turned on a new water heater and there is still no hot water, errors were probably made during installation.

The solution is to switch the hoses.

Work principles

A thermocouple is two welded conductors. One is made of alumel and chromel. The thermocouple has one main function - supplying power to the solenoid valve.

Such a part rarely fails. At the exit from the housing there is a bottleneck equipped with a central conductor. The latter is equipped with high-quality insulation, but even it sometimes gets worn out, causing the speakers to go out.

Another problem is contact failure at the thermocouple welding points. In this case, it is impossible to restore the original characteristics. After all, the current generator passes through the same place. It is recommended to purchase a replacement for the old part.

A solenoid valve is also known as a copper wire coil. Inside this structure there are metal cylinders called a solenoid. There is a mechanical connection between this part and the shut-off valve for gas to enter the burner.

When the thermocouple heats up, a current is generated. It creates a magnetic field when passing through the coil. It is due to this that the solenoid is pulled inward. The solenoid also has a mechanical connection with the valve. Gas flows to the igniter when the valve is moved.

The thermocouple cools down if the gas does not ignite. Because of this, current production stops. The gas supply stops altogether as the solenoid itself returns to its original position.

This is how you can ensure safe operation of devices under various conditions. This is also due to the fact that problems can arise due to a simple blow of wind if the systems are not equipped with protective mechanisms.

A bimetallic plate is how a thermal fuse can be described. The plate begins to sag when the temperature where the part is installed reaches 90 degrees.

The solenoid power supply circuit is then broken. The thermal fuse is connected to the general circuit using special terminals.

It often breaks due to the fact that the design is complex and has a lot of features.

Reasons for extinction after ignition

If the gas water heater goes out or functions unstably, it is necessary to establish the cause of the problem. For these purposes, you need to find out what causes malfunctions in the functioning of the device. Often the device does not turn on due to:

- turning on an indicator that detects a gas leak;

- difficulties with the chimney;

- valve failure;

- wick clogging;

- main burner attenuation;

- too much ventilation;

- thermocouple opening;

- breakdown of the automatic system.

Important! If the column smokes, turns off, or does not light up at all, you can try to solve the problem yourself. However, it is best to call a specialist in such a situation.

Flame ionization sensor failure

When the device turns on and starts to go out, the ionization indicator is 70% at fault. This component is regularly in contact with fire. The ions produced during combustion are attracted to the sensor and produce a current. When there are enough ions, the device will work. When there are not enough of them, the column turns off.

- the wick goes out after a few seconds after ignition;

- during restart, the column operates longer;

- You should turn on the device several times and it will function normally;

- difficulties arise only after a long break.

Important! It is necessary to inspect the wiring running from the part to the board. For these purposes, contacts are checked

Next, the fixing screws are unscrewed and the heating electrode is placed in the hottest place of the fire.

This technique extends the service life of the indicator by years. When everything is normal with the contacts and connections, the element needs to be replaced.

Wear of the water unit membrane

The effective operation of the device will depend on the serviceability of each component and mechanism. The membrane in such a heater is one of the most important components, but wear occurs over time.

A flexible membrane will be located at the base of the assembly and respond to changes in system pressure. When the mixer opens, the rubber element will bend under pressure and push out the stem. It will turn on the gas valve, causing fuel to flow into the burner.

Important! With intensive use of the device, the membrane will wear out. The rubber will stretch, become clogged and damaged.

As a result, fuel will not flow into the burner: the device does not start or lights up, but immediately goes out.

- Pressure force of gas and water. When the tap opens, you need to calculate how many liters will be consumed per minute. Within normal limits it will be 2-3 liters. The gas supply can be determined visually by looking at the fire.

- Fire position. In devices with wick ignition, the flame burns from the edge and has a height of at least 30-50 mm. If not, then check the jets for clogging. Once the cleaning is complete, you need to look at the fire again. When the situation has not changed, the problem is in the diaphragm.

- Ignition speakers should click when the button is pressed. This means the diaphragm is working. When there are no sounds, the part is probably broken.

- In a number of models, a rod that controls the functioning of the control unit helps to identify a breakdown. The protective cover is removed and the water opens. When the rod is immobilized, the diaphragm needs to be replaced.

When a breakdown is found, you need to choose the right replacement part.

The wick is clogged with dust

In products with an igniter, such an element often becomes clogged. The fire will become weak and a yellowish tint will appear. However, a change in the color of the fire also indicates a lack of air in the gas-air mixture.

The result is that the column either does not ignite the burner at all, or will perform its functions when a large volume of fuel arrives. In the latter situation, a certain click is felt. To clean the element, you will need 2 screwdrivers and an adjustable wrench.

- The case is removed - the adjustment handles are pulled out, the bolts in the corners from the bottom are unscrewed, the cover is lifted and removed.

- The traction sensor tube and the one that draws in fuel are unscrewed.

- The screws are removed and the structure is disassembled.

- The nozzle is cleaned, the tee is blown out, and assembled.

Clogging occurs in the draft indicator, which is why the igniter begins to smoke. When dust and dirt are removed, the igniter lights up with a stable blue flame.

Important! When the column is cleaned, the device is somewhat noisy. The sound will be produced by air being sucked through the cracks in the wick guide housing

It is possible to get rid of the noise by tightening the wick screws a little.

Specific problems for individual models

Even speakers from well-known companies can break down over time for a variety of reasons. During operation, device owners noticed breakdowns that most often occur with specific models.

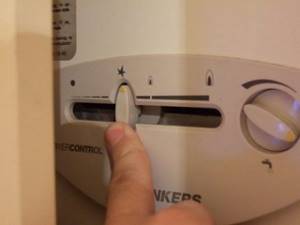

Junkers Bosch thermocouple problems

For example, the weak point of the Junkers WR 13-P device manufactured by Bosch is the thermocouple.

Two to three years after the start of operation, it stops responding normally to heat from the pilot burner. As a result, the igniter flame constantly fades, and over time it will simply stop lighting normally.

Sometimes carefully cleaning the thermocouple with fine sandpaper helps, but when this method no longer brings the desired effect, the element will have to be replaced.

In some models of geysers, the thermocouple breaks down over time, which is easy to replace with a new element

Displacement of the igniter tube, which in such models is not secured too tightly, can also lead to similar problems. The tube can be moved accidentally, even just by touching it with a match during ignition. There is a gap between the gas tube nozzle and the burner through which air flows.

When displaced, this gap decreases, and the air required for normal combustion becomes insufficient. The flame does not reach the thermocouple, it does not heat up, and gas does not flow to the main burner. If you restore the normal position of the tube, the column will work properly again.

Practical recommendations for cleaning and eliminating breakdowns of the JUNKERS column:

Oxidation of contacts on Vector speakers

For Vector speakers, a typical problem is oxidation of the contacts in the power supply. If this is the case, then replacing dead batteries with new elements will not give the desired result; a spark will not appear until the contacts are cleaned. Sometimes in such columns the microswitch rod on the water valve becomes sour.

If the column hisses or whistles a little during operation, the fastenings of the coil tubes may be loose, you need to check them and solder them

After cleaning, normal operation of the device is usually restored. If a characteristic whistle appears soon after turning on the column, you need to check the condition of the gas outlet tube connections; they may need to be resealed.

Problems with the rod in Neva models

In Neva brand dispensers, sometimes the rod jams in the gas valve. As a result, this element stops working normally.

To eliminate such a malfunction, you need to remove and disassemble the water-gas unit, and then move the rod with a regular screwdriver. If the part cannot be mechanically affected, the element should be completely replaced.

This video demonstrates troubleshooting for a NEVA speaker:

Reasons why the wick goes out

The problem of a dying wick is especially relevant when this happens constantly and it is impossible to light it manually. Let's look at all the cases. First of all, you need to decide when the burner goes out, whether there are any extraneous sounds, smells, etc.

When you turn on the gas water heater

In the first case, the problem is most likely with the ionization sensor. It is responsible for maintaining the flame in the burner. You can understand that the problem really lies in the sensor by the following signs:

- Burning occurs only for a few seconds, usually no more than 5 seconds.

- With each subsequent launch the performance improves. It even works for some time. But then the problem arises again.

To solve this case, you need to check the wiring to the sensor; if everything is fine with it, you should replace the part itself. It would be more correct and safer to contact specialists or those who understand the operation of gas equipment.

In progress

The second case of wick fading occurs when it is operated for a short time. The main reasons may be:

Bad traction. Soot accumulated in the chimney, debris got in, and birds began to build nests. Determining the presence of chimney draft is very simple. You just need to bring a match or lighter to the window through which it goes out and turn on the boiler. If there is a deviation of the flame, then the reason for the fading of the wick is something else. If the fire does not flutter, there is no draft. The flue gas pipe must be checked. The heat exchanger needs to be cleaned. It may happen that it is covered with scale or soot. These problems lead to overheating of the heat exchanger and also prevent it from operating in stationary mode. No natural ventilation

Therefore, it is so important that the room in which the boiler is installed has a window or an opening window. There may be strong ventilation nearby to prevent the wick from burning. In this case, it should be turned off when the boiler is operating or reduced to minimum. Another interesting case could be a piezo ignition column

that is, using the ignition button. For it to work, you need to hold it for at least 10 seconds. That is, the issue may not be that the burner is broken, but rather its correct use.

If you don’t find yours in the above reasons for the wick fading, then you should contact the company. With whom you have a contract.

Emergency shutdown of the gas water heater

Reason #1. The sensor is faulty.

The first sign that the sensor is worn out and needs to be replaced is a chaotic shutdown of the column. Bimetallic sensors are used to prevent overheating of the column and the penetration of carbon monoxide. It works by heating, or more precisely, when heated inside the sensor, two plates repel and disconnect the electrical circuit. When the sensor wears out, the plates can become separated at the slightest vibration, which leads to a break in the circuit and as a result the column turns off.

Reason #2. Poor water pressure or membrane wear.

The geyser may turn off due to poor or floating water pressure, a faulty mixer or shower head. If the column is sensitive to water pressure, it is advisable to contact the service department to inspect the membrane of the water part for cracks. We are such a service, so if you have problems when using a geyser and you cannot solve it yourself, call us and use our services - repair of geysers.

|

|

Conclusions and useful video on the topic

Finding the cause and ways to eliminate the problem of speaker attenuation can be found here:

Column attenuation is a symptom of an internal malfunction or violation of the operating conditions of the device. You need to correctly find out the cause of the problem, after which a significant part of the described breakdowns can be eliminated yourself. But to solve complex problems you will have to contact a service center.

Do you have any questions when searching for the cause of speaker attenuation? Ask them under this article - our experts and site visitors will try to help you.

Or maybe you want to tell other users about the problems that arose with your speaker during operation, and how they were successfully resolved? Share your experience and leave recommendations in the block below.

Actions with Neva

Geysers from this company have various modifications. Each has its own weaknesses.

There are often cases when users find it difficult to turn off the Neva gas water heater with index 4511

The most common causes of this problem in this model are:

- Problems with the water block.

- Flow indicator (micro switch) failures.

- Low battery voltage.

The arrangement of elements in Neva 4511 looks like this:

Here the operating principle of the water and gas units is identical. That is, when water opens, the membrane of the first component bends and puts pressure on the rod of the second. The EMC opens, gas flows to the main burner.

The batteries power the control mechanism, which is responsible for ignition and other processes in the device.

The microrelay is located under the water block in a free state. When the rod of the water mechanism moves, this relay closes, and current flows from the batteries to the control system.

To solve the problem there are the following methods:

- Repairing or cleaning the water block. It is better to trust the work to experts.

- Replacement of microrelay.

- Installing more powerful batteries.

Main causes of malfunction

It is not always necessary to call the experts. There are a number of malfunctions in the gas water heater that the user can repair independently.

Lack of draft in the hood

As a rule, this is caused by a dirty chimney. During operation, combustion products enter it and settle in the form of soot on the walls. Therefore, the ventilation duct requires systematic (once a year) maintenance. Checking the presence of draft is simple: you need to bring a lit match to the hood.

If it functions adequately, the flame should move towards the exhaust path.

Often, a lack of normal draft occurs when the plastic windows in the room are tightly closed

- they obstruct air flow. During operation, the protective relay overheats, the security system is activated and the device turns off.

Insufficient pressure

The automatic system blocks the gas supply in case of insufficient water pressure. You can estimate the pressure by simply opening the water taps. If it is small or absent altogether, it means that an emergency shutdown in the gas water heater is not due to a breakdown of the device.

In the case of normal pressure in the tap, it is worth looking for reasons in the water heating system. As a rule, a decrease in pressure is a consequence of filter contamination.

or

membrane disruption

.

Coarse filter

To correct the sources of failure due to which the wick of the geyser goes out, the owner will have to:

- clean or change the filtration system;

- install a new membrane partition for the water unit;

- clean the pipeline.

Ignition and instantaneous extinction

This situation most often occurs due to improper operation of the device by users. When such a water heater is in working condition, it is strictly forbidden to open cold water to dilute hot water. This action is a most dangerous violation of the rules of its use. It can cause serious damage to the device. The temperature of the liquid is regulated solely by supplying gas.

Faulty ignition system

Depending on the models, there are three types of ignition: electric ignition (in modern versions), an igniter, which has a small constant flame, and a hydraulic turbine - from pressure.

The electric ignition runs on built-in batteries. According to manufacturers, they last for about a year. But as practice shows, the service life of such batteries is shorter. For example, in the Bosch gas water heater models W 10 KB or WR 10-2 B, there is an LED on the front panel that indicates the status of the batteries. The Neva Lux range of gas water heaters is also equipped with this type of ignition. If necessary, old batteries are replaced with new ones

.

If the cause of the problem is the wick, then it is best to seek help from qualified specialists. They will check the functions of the thermocouple and gas control system, clean and adjust the igniter. Often the problem when the pilot light of a gas water heater goes out is solved by completely cleaning the water heater

.

In the case of a hydraulic turbine type of ignition, for example, as in the Bosch WRD 13-2 G or WRD 10-2 G, a malfunction may occur due to a lack of water pressure

on which it is based.

Microexplosions during ignition

These unpleasant processes are only a consequence of low thrust, unsuitable batteries, contamination of the device itself, or a very large volume of gas supplied to the column. To fix the problem yourself, the owner can only clean the exhaust duct

or replace batteries. If the problem is not solved, then only gas service employees can understand why the dispenser goes out.

Dirty ventilation duct

The main causes of geyser failure

The heat exchanger is clogged

Among the most common causes of malfunctions of water heating units is the formation of scale inside the radiator. Most often, the catalyst in such processes is a high level of water hardness. Scale, in turn, appears when the temperature of the liquid is heated to 80 degrees; if the temperature exceeds this limit, the processes are activated.

Correct operation of the gas burner will help you get rid of such consequences. Do not install the unit at high temperatures; for swimming, washing things in an automatic machine, heating the water to 60 degrees is sufficient.

Apartment owners especially often face the problem of scale formation in the heat exchanger, leaving the product to work using the igniter in constant mode. As a result, within an hour the temperature reaches 90 degrees, and scale formation can no longer be avoided. In this case, it is advisable to connect the installation as needed and not modify the automatic device in your own way. Or don’t be surprised why the device doesn’t work.

But what to do if a breakdown has already occurred, how to eliminate it and repair the unit? First, you should make sure of the reason, namely, if hot water flows from the tap in a thin stream, while there are no problems with cold water, and at the same time the column refuses to turn on, this means that the problem is scale.

Arm yourself with screwdrivers with different attachments, a set of open-end plumbing wrenches, a number of gaskets and a rubber elastic hose. You can’t do without anti-scale, which can be purchased at any hardware store. In extreme cases, the product is replaced with vinegar essence.

Remove the water heating product from its fittings and casing, turn off the water supply and open a tap close to the column. Unscrew the nut from the battery and wait until the water has completely drained into a previously prepared container.

Pour the product through the hose attached to the inlet of the heat exchanger. Do this carefully so that the anti-scale agent does not spill out. Leave the gas water heater for several hours, then turn on the water. The presence of a large amount of dirt in the liquid and strong pressure means that you have completed the task. If you feel that some of the scale still remains inside, do the same manipulations again.

Leak detected

If the geyser does not work due to a leak being detected, ideally you should replace the outdated one with a new one. However, the price of heat exchangers reaches one third of the total cost of the entire product, so it is more advisable to repair it yourself.

Soldering, which can withstand up to 100 degrees of water heating, will help with this. Open the hot water, remove the nut from the cold pipe, wait until the water drains. If some liquid remains inside, blow the product with a vacuum cleaner.

The leak is eliminated by soldering

You should start soldering by cleaning the area with a piece of cloth treated with a solvent. Walk along the surface of the fistula with fine-grained sandpaper. Rosin can act as a flux; if it is not available, crushed aspirin tablets will do.

As a result, the solder thickness should be 1–2 mm. You can assume that the fistula has been eliminated. Feel the heat exchanger pipe, if you notice a green spot, it means there is a micro-hole in this place, take care of it too.

Gas device does not ignite

The reasons why the device cannot be ignited are simple: there is no draft in the ventilation. Perhaps the chimney is clogged or an object has fallen inside. In this regard, modern water heating models have a control and protection system, according to which gas stops flowing.

To repair the device, you need to check the presence of traction. Light a match and place it close to the chimney, the flame sways - there is a draft.

It is not possible to light the speaker if the batteries are discharged. Weak water pressure is also a signal for the device to stop heating. Alternatively, you may need to clean the filter, presented in the form of a fine mesh. Move the nut aside, pull out the mesh and clean thoroughly.

Determine the condition of the membrane component - unscrew the two nuts and three screws securing the water unit. It should be separated and the membrane should be washed to remove dirt. The membrane, made of silicone, lasts longer than its analogues.

The geyser heats up incorrectly

This can happen if the unit is equipped with low power. This shortcoming can only be corrected by purchasing a new model.

Frequent breakdowns of the geyser are a reason to replace it

If the color tone of the flame has changed, the product is probably clogged. Adjust the gas supply to the burner using a tap that determines the volume of water moving through the column within one minute. Reducing the bandwidth manually helps fix the problem.

Very hot water coming out is not a defect, so no repairs are required. Limit the gas supply using the gas shut-off valve installed at the inlet of the water heater, located.

The principle of operation of the gas water heater

To better understand the reasons why a geyser may go out, you need to understand the operating principle of such a device. Only after studying the essence of the process of heating water with a similar device can you talk about its malfunctions.

There are many manufacturers producing geysers. These are the world-famous expensive Bosch and Zerten, and more budget analogues such as Oasis, Vector, Neva Lux 5514, Beretta, Avangard, Astra, Mora speakers. In any case, the basic operating principle of all the above models is the same. The only thing is that there are automatic and semi-automatic speakers, but the difference between them is insignificant.

Main elements of a gas water heater:

- A gas burner is one of the most important elements of a gas water heater.

- A heat exchanger is located above the gas burner. It is a tube bent into a spiral, flowing through which water is heated.

- The ignition device can be electronic, and ignite from a button, or have a pilot light or wick that never stops burning. Old gas water heaters had to be ignited with matches, but modern models have piezo ignition activated by pressing a button.

- The water-gas unit includes two components: a membrane and a gas valve. When the water is turned on, the membrane bends and opens the gas valve, thereby ensuring gas flow into the burner.

- The safety automation includes sensors and a solenoid valve. If there is any malfunction, the electromagnetic sensor closes the valve and the column turns off. The kit also includes a thermocouple, which is activated when the pilot burner is turned off.

Thus, there is no reservoir for storing water in geysers. Passing through the heat exchanger, the liquid heats up in a matter of seconds, thereby ensuring a constant supply of warm water to several water intake points at once.

Knowing the structure of the gas water heater, you can understand why it goes out. We will describe to you the main problems and tell you what to do in this case.

Related Posts

- How to properly install a hood for a geyser

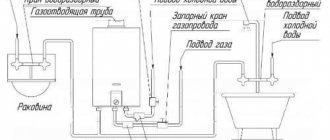

- Rules for connecting a gas water heater in an apartment and private house

- Water column for a country house

- Why gas burns with a red flame on the stove: factors affecting the color of the flame

- Ceiling acoustics: “and a voice came from heaven...”

- Gas in an apartment: safety rules, signs and consequences of a leak, harm to the body

- Why does the air conditioner gurgle when not working when there is wind?

- Household gas analyzer. household gas analyzers for apartments with gas stoves. wireless gas leak sensor with valve

- Features of analyzing water from a well: when is it necessary and what is the cost?

- Dielectric coupling for gas. safety precautions

- Selection and use of carbon monoxide and smoke detectors

- Why does a gas boiler go out: what could be the reasons and what to do if it turns off

- US biological laboratories around Russia are being added. what to do?

- What is a boiler for heating water: types, applications and some nuances of operation

- What to do if the suspended ceiling is flooded

- Why does a water heater shock and what to do?

- How to clean a well and water

- Why the water station does not gain pressure: the main reasons

- Gas consumption from a gas holder for heating: how to calculate + tips for minimizing

- Gas in a private house: how to arrange it, how to arrange it? and why gas along the border of the site

- Toilet flush cistern

- Categories and groups of classification of water supply systems

- Checking gas equipment at home: rules and terms

- Bellows hose for gas: description and connection recommendations

- How is thermal energy for hot water calculated?

Read with this

- How to properly install a hood for a geyser

- Rules for connecting a gas water heater in an apartment and private house

- Water column for a country house

- Why gas burns with a red flame on the stove: factors affecting the color of the flame

- Ceiling acoustics: “and a voice came from heaven...”

- Gas in an apartment: safety rules, signs and consequences of a leak, harm to the body

- Why does the air conditioner gurgle when not working when there is wind?

- Household gas analyzer. household gas analyzers for apartments with gas stoves. wireless gas leak sensor with valve

- Features of analyzing water from a well: when is it necessary and what is the cost?

- Dielectric coupling for gas. safety precautions