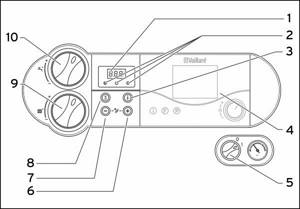

Features of operation and diagnostics

During connection, operation and maintenance of the Vaillant heating gas boiler, some malfunctions may occur. Models that have an electrical control system with a screen make it possible to understand what exactly does not work in a given situation.

To understand what to do in certain cases, let’s look at the common error codes for the Vailant gas boiler, and what needs to be done if they occur. If several errors occur at once, they are displayed alternately for approximately 2 seconds.

The icons may begin with the letter F (error) or S (status). Technical characteristics and codes that are specific to each specific model are specified in the operating instructions.

Procedure

Step 1

Perform a reset by pressing the button on the Vaillant control panel. Imported boilers are sensitive to the supply voltage, and if the network is unstable, they malfunction with an indication of some error. If it is false, it is easily reset.

Step 2

Bring the thermostat into working position. In Vaillant boilers, it is “cocked” manually by pressing the rod (painted red). If error f20 is caused by a pump malfunction or other reason, it will disappear. To access the overheating thermostat, you need to fold back the front panel - in most Vaillant models, a protective device (fuse) is installed at the heat exchanger outlet, under the NTC sensor.

Location of the NTC sensor of the Vailant boiler

Step 3 – diagnostics of signal circuits. Defects are determined visually: line break, insulation melting, short circuit - the causes of error f20 and emergency stop of the Vaillant boiler. The reliability of the contacts and the absence of oxides are checked.

Step 4 – testing the overheat sensor. It is easy to determine serviceability with a multimeter by measuring the resistance. In the initial state, the contacts of the working device are closed, R = 0. The protective thermostat cannot be repaired - it is replaced.

The last reason that causes error f20 is the electronic board of the Vaillant boiler. It generates a fault code based on a signal from the overheating sensor. It will not be possible to identify a defect on your own without diagrams, experience, or appropriate equipment. If the measures taken to eliminate error f20 are unsuccessful, you need to contact a service center. After replacing the board, the boiler's performance will be restored.

Did you like the article? A repost will be the best thanks.

The most common error codes for Vailant boilers

F5

Error F5 means a break in the external exhaust gas sensor. Possible reasons may be incorrect operation of the exhaust gas sensor, the plug is removed or the cable is damaged, or the spare resistor is installed incorrectly. The code is valid only for the mounted model Vailant Atmo.

5ER

If the display alternates between the water temperature and the 5ER (or SER) error, this is a reminder that it is time to service the device.

The user can set the frequency of how often this reminder pops up. The value is set in diagnostic item D.084 within the range from 0 to 3000 hours with an interval of 10 hours (the number 300 corresponds to 3000 hours). To completely disable this function, enter the symbol “—“ instead of the numeric value.

F15

Error F15 indicates a short circuit in the external exhaust gas sensor. Presumably, there is a short circuit with the sensor plug body, a short circuit inside the wiring harness, or the sensor itself is faulty. Only shown in Vaillant Atmo wall-mounted boilers.

F20

Error F20 (F20) indicates that a protective shutdown of the device has occurred due to the fact that the STB temperature limiter has tripped. It is triggered when the maximum permissible temperature is exceeded.

This can happen due to the fact that the ground contacts of the wiring harness with the housing are incorrect, or the NTC of the return or supply line is broken (weak contact). A breakdown through the ignition wire, electrode or ignition plug is also possible.

F21

Error F21 means an emergency shutdown of the GFA flame control machine.

F22

Error F22 (F22) indicates that a protective shutdown has occurred due to insufficient water. The reasons for this are a malfunction of the pump cable or toggle switch, insufficient water, the pump does not work or is blocked, or its power is too low.

F23

Error F23 detects an emergency shutdown due to too large a temperature difference between sensors located on the supply and discharge lines.

This happens for the following reasons:

- Very low pump power, why pressure drops on one side;

- the pump is blocked;

- The return and forward line NTC sensors are not in the right places.

F24

Error F24 signals an emergency shutdown if the temperature rises too sharply. This means the presence of air in the device, reduced pump performance, blockage, or very low pressure in the heating system. The gravity valve may be incorrectly connected or blocked.

F26

Error F26 means that the flow of the stepper motor gas valve is not detected due to a breakdown of the gas fittings. Perhaps the servomotor of the gas valve is not connected or broken, the connector is incorrectly inserted into the board, or there is a break in the wiring harness.

F28

Error F28 (F28) shows that the equipment did not turn on, a malfunction was detected when starting the device, attempts to ignite were unsuccessful.

There are a number of options:

- the device that controls gas pressure or the meter is broken;

- there is too much air in the gas, low pressure in the gas pipeline;

- error in the operation of gas fittings due to a non-working magnet or operator;

- one of the elements of the ignition system is broken: ignition plug, cable or transformer;

Boiler ignition electrode

- Electronic malfunction, such as interruption of the ionization current.

- dynamic gas pressure is too low;

- when operating on natural gas, a liquid gas coding resistance is used;

- breakdowns in gas fittings;

- The mass flow sensor (Venturi nozzle) has failed.

Gas flow sensor

F29

Error F 29 (F29) indicates that the burner flame goes out during operation and further attempts to ignite are unsuccessful. The fuel supply may be temporarily interrupted, the ignition transformer may fail, or the equipment may not be properly grounded.

F33

Error F33 (Ф33) reflects that the device for measuring pressure force does not turn on. After the fan is turned off, the pressure switch does not disconnect the contact. Relevant for the Vailant Turbo TEK PRO line.

S33

Error S33 indicates that the device is locked and put into a 20-minute standby state, and the heat exchanger frost protection mode has been activated. The reason is that the contacts of the air-gas path relay did not connect. This condition may appear in the Vailant 242 Turbo double-circuit boiler.

Gas boiler Vaillant turboTEC PRO 242

F36

Error F36 (F36) - the thrust stall sensor has detected the release of combustion products. Indicates that the thrust is too weak. Most likely, the chimney is clogged or the ventilation is closed. The solution to this problem is to clean the chimney, turn off the active hood above the stove and open the window.

F37

Error F 37 (F37) means a deviation in the fan rotation speed (too fast or slow). The pressure sensor may be broken.

F38

Error F38 means that the fan has failed and requires replacement.

F53

Error F53 indicates incorrect combustion settings.

Possible reasons:

F61

Error F61 indicates an error in the control of the gas valves. The cable harness connection may be damaged and a short circuit has occurred, or the gas fittings or electronic board may be faulty.

F62

Error F62 – time delay for turning off the gas fittings. It can be triggered if there is extraneous light inside (the control electrode does not indicate flame extinction).

F71

Error F71 indicates a failure of the temperature sensor in the supply line. It is probably faulty or is located too far from the supply line.

F72

Error F72 appears when the return or flow temperature sensor fails. It may be faulty or there may be a very large temperature difference in the forward or return line of the NTC sensors.

F75

Error F75 (F75) means that there is no pressure surge when the pump is turned on. There may be oxygen in the heating system or the pump or water sensor is not working correctly. To correct the situation as quickly as possible, the adjustable bypass is checked and the expansion tank is connected to the return line.

Gas boiler pump

SER

Error SER is the same as code 5ER (the letter “S” and the number “5” are equally displayed on the electronic display). After the problem has been resolved, the errors are reset by pressing the “Reset” button or turning the boiler on and off from the network.

Possible causes of the error

Leak

With error f22 there is no talk of a serious defect. But if, some time after filling the system with coolant, the pressure drops, the conclusion is clear: a microcrack has appeared in the circuit, through which liquid slowly and continuously leaks. The problem area may be on the main line (radiators, pipe connections, expansion tank) or in the Vaillant boiler. It is difficult to identify a defect due to the fact that water droplets from a heated surface evaporate intensively, rather than flow down, forming puddles. And if the coolant in the system is of good quality, no traces in the form of streaks remain in the area of the microcrack.

How to proceed . Wait until the pipe temperature reaches room temperature. There will be no more evaporation, and the location of the leak can be determined by looking at the stains on the floor and walking around the house. It is not difficult to decide how to repair a microcrack (soldering, cold welding, high-temperature sealant).

Air accumulation

When the boiler is operating, gas formation in the circuit occurs continuously. And the higher the Vaillant mode, the faster. With normally functioning air vents, bubbles are removed automatically. Incorrect operation of the device leads to the formation of a bubble, which impedes the circulation of liquid, initiating dry running of the pumping device. The result is the same - error f22 of the Vaillant boiler.

Vent the heating system

How to proceed . Vent the air wherever possible. You should not rely on the valves, since any of them can fail. There are many reasons: weakening of the spring, contamination of the channel, but the formation of a cluster of bubbles is inevitable. This also applies to the Vaillant boiler pump. There is a plug on the end of the device body. Unscrew the washer until a trickle of water appears, after placing the bath in place. The coolant is drained until clean liquid comes out, without air bubbles. With the measures taken, error f22 is eliminated.

Turn the washer to bleed air from the Vaillant circulation pump

Boiler pump

The 22nd fault code Vailant is evidence of incorrect operation of the pumping device. After bleeding the air, the error is caused by a problem with the pump itself.

What goes away on its own

- Impeller contamination. Mechanical cleaning, washing - and error f22 will disappear.

- Unreliable contact. Burning and oxidation of the lamellas leads to instability of the supply voltage. Hence the pump malfunctions. It is not difficult to check, clean, and make a tight connection.

Incorrect functioning of the pump is also caused by other reasons : deformation of the shaft or impeller, destruction of the bearing, contamination of the internal air removal channel. Repairing the Vailant boiler pump is impractical. And not only because of the search for a part, the need to disassemble the device: the shaft is not sold at retail, you need to order it. The nuance is that you will have to perform alignment, and it requires experience and time.

Recommendation : if an internal defect is suspected, install a new pumping device. Price from 9,700 rubles, the work is performed without contacting a professional.

Electronic board

This is the likely cause of error f22. In order not to waste time, you need to go to the menu (the algorithm is specified in the instructions for Vaillant) and look at the symbols on the display: the letter S and numbers. Using this code, an employee of the service organization, taking into account the boiler model, will give recommendations over the phone or accept an application. If the unit stops for this reason, the arriving technician will replace the board.

Did you like the article? A repost will be the best thanks.

Similar errors and malfunctions

Other malfunctions and solutions

If the reverse draft diode blinks, then either it is faulty, or the combustion products are not completely removed but enter the room. The repair instructions in this case are as follows: first you should clean the chimney, then check the quality of ventilation.

After this, you can replace the backdraft sensor. Initially, during installation, it is important to comply with all safety requirements. Quite often the gas burner becomes clogged and soot is deposited on it. It should be cleaned regularly to ensure full control of the flame level.