Korean heating equipment is reliable, as confirmed by experts and users. But it happens that she also refuses to work. Navien gas boiler repair statistics show: in 80–90% of cases, problems that arise can be dealt with on your own . The article deciphers the symbolism of errors appearing on the display and gives recommendations for troubleshooting.

Photo of the main panel of the Navien boiler

* Navien gas boilers are available in different modifications: convection (with atmospheric burner), turbocharged, condensing. The malfunctions that arise are identical for all types of heating equipment of this brand. Therefore, errors appearing on the display are interpreted in the same way, with rare exceptions.

01E

The code indicates overheating. To prevent boiling of the coolant and thermal deformation of parts, the automation stops Navien until the cause is eliminated.

Check

- Extract temperature sensor (heating). If the signal line is not damaged, it is tested for operation.

- Circulation pump: does not function correctly or has stopped. It is necessary to ensure the integrity of the connecting wires, the reliability of the contacts and the presence (correspondence to the nominal value) of the supply voltage. These are the most common reasons that cause an error on the boiler display. A problem with the pump may arise due to the lack of free movement of the impeller. Salt deposits on the blades and shaft oxidation are the result of increased hardness of the pumped medium and poor quality water treatment.

- Presence/absence of plugs in the heating circuit. You should not rely on valves installed on radiators that automatically remove air from the system - dust and dirt often clog the channel, and the device does not perform its function. Try to bleed it manually: if water comes out, then the Navien error is caused by another reason.

Overheating of the boiler occurs due to a decrease in the coolant circulation rate. This is also possible if the heat exchanger is clogged (error 16E ).

Following recommendations from the category “in everyday life, on your own” will not give the desired effect. Even if you manage to prepare the special solution/solution correctly, you will not be able to completely clean the cavity of the device. The liquid circulation channel has a complex configuration - in the workshop, washing is carried out under pressure.

The boiler does not heat water

This video is the solution to your problem!

Watch to the end and you won’t need to call a specialist.

It is impossible to survive without boiler houses in the climatic zones of Russia. Moreover, this also applies to the warmest regions, Sochi, Anapa and Rostov-on-Don. Winters are still harsh and people cannot survive without heating. Therefore, it will definitely not be possible to do without heating systems and hot water. And only boiler houses can provide the city with all this. Today we will look at the reasons why the boiler does not heat the water - how to solve this problem and what to do about it......

They are very different. It all depends on the heat source. It can be either steam or water. They may vary by location. If the house itself decided to build its own boiler room, then a specially separate room in the house can be allocated for it. Or extensions are made to the house for these purposes. One of the main requirements when constructing boiler houses is good ventilation.

If the boiler operates with steam, then very high demands are placed on the quality of water purification, and then steam. Therefore, it will definitely not be possible to manage such boiler houses without a whole complex of cleaning installations. This also includes AquaShield electromagnetic softeners, which are highly valued by boiler house employees today.

If a gas boiler suddenly stops heating water, the reasons may be different, but most often when using water from a central water supply without softening units, the cause may be limescale deposits. Moreover, it is hard and difficult to remove. The table shows possible signs of the reason why the boiler stops due to scale formation.

| Reason for boiler shutdown | Signs |

| High rigidity | Heating the bottom of a gas boiler, but at the same time weak heating of the water A sharp increase in electricity or solid fuel consumption White-gray coating on the bottom of the boiler The boiler does not heat the water to a certain temperature Poor pipe capacity Increased electrical conductivity of heat |

Other reasons for boiler shutdown are simpler. A piece of scale may also get stuck in the pipe and block normal operation, and a crack in the gas boiler may also contribute to the shutdown. But in these cases there will definitely be no scale residues on the walls of the equipment. If the boiler room does not have boiler water softeners or treatment facilities installed, then the root cause will of course be water hardness. If the treatment plant is standing and the equipment has been checked recently, then most likely this is not the problem.

If the video did not help you, then try installing anti-scale filters (polyphosphate or electromagnetic) in front of the boiler. Because Hard water and scale are the root cause of malfunctions and breakdowns of gas boilers!

In any case, if there is no cleaning in the system, then you will have to urgently address this cause and solve it. For boiler houses there is a whole range of water softening devices that are suitable:

- AquaShield;

- Ultrafiltration and conditioning for steam boiler houses;

- Ion exchange for economical consumers of gas boilers

The most wasteful process of cleaning and softening will be in steam boiler rooms. There you will have to remove not just all organic and inorganic impurities. Even dissolved gases will have to be removed. Degassing is quite troublesome and costly. But the operation of the boiler depends on the quality of the steam. This is where membrane softeners work to make the water completely isolated.

Many consumers of gas boilers choose AquaShield for the simple reason that it does not require maintenance and does not require spending money on it. But its biggest advantage for boiler equipment was and remains the ability to remove old lime deposits even in the most difficult places. Usually, to eliminate such residues, the equipment needs to be unscrewed, the parts need to be soaked in aggressive acidic environments and kept there for up to two hours. But even after boiler treatment of water, it is necessary to clean the surfaces with metal brushes or cleaners. If your gas boiler does not heat the water to the required temperature, then the reason is scale deposits. The electromagnet does all this work without damaging the surface, at the molecular level.

02E

Pressure drop in the heating system. The error indicates a leak in the circuit, the boiler itself or installed devices (hydraulic accumulator, filters).

Check

- No puddles on the floor. Particular attention is paid to the joints.

- Circulation pump. Deformation of the blades and their damage affect the speed of fluid movement, hence the error on the boiler display.

Navien circulation pump

Tips and tricks for use

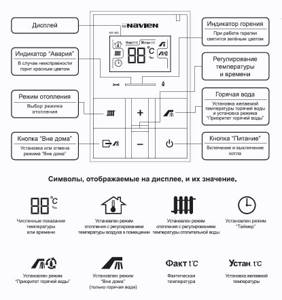

The algorithm for adjusting the heating capacity of the installation depends on the type of gas burner device. Units with electronic control - according to a given mode, the thermostat is turned on, which operates in a unit with a room temperature sensor. The adjustment is automatic; the thermometer monitors the temperature inside the room.

After it drops below the set limit, the thermostat sends a signal to start the burner device, or the regulator increases the gas flow through the valve. Usually the thermostat controls the temperature in one room, but if shut-off devices are installed in front of each heating device, the temperature will be controlled in all. The burner can be adjusted manually through the gas valve, which is especially important for atmospheric units with open fireboxes. Changing the mode is done in the menu on the control panel.

03E – no burner flame.

Check

- Condition of shut-off valves. The Navien error can be caused by user inattention - the valve blocks the pipe.

- Shut-off valve lever position. When it is triggered, the gas supply channel is blocked and the boiler stops; this can also happen in the absence of the owners.

If in fact there is a flame, the cause of the error is the ionization sensor: contamination of the electrode or its incorrect position, damage to the signal line, short circuit.

Error 27

Error 27 informs about an open or short circuit in the APS air pressure sensor circuit.

How to resolve error 27

1. Check the APS air pressure sensor.

If a circuit fault is detected, replace the APS sensor. 2. If there is no commutation between the APS sensor contacts and the control unit connector, disconnect the APS sensor connector from the control unit connector connector, and then connect them again for normal contact. 3. If the control board is faulty or does not work correctly, restart the boiler; if it fails again, replace the control board. Now you know the error codes that a navien boiler can produce. Contact us for high-quality repairs of your Navien boiler.

27E

An error typical for Navien atmospheric models. Caused by a malfunction of the air sensor (APS) or lack of communication between it and the boiler board.

Other codes are also displayed on the Navien display. But almost all such malfunctions are associated with the boiler’s electronic board. The only thing you can do yourself is to make sure that the contacts are tight and correct the connectors on the module. It cannot be repaired, especially at home.

Navien boiler control panel

Useful tips

- Before removing the casing of the Navien boiler and trying to solve the problem with it yourself, you should make sure that the warranty for the sample has expired (according to the mark in its passport). If it works, you need to call specialists from a service organization - you won’t have to pay for repairs.

- The risks of Navien errors can be minimized by proper arrangement of the heating system: power supply to the boiler via a UPS, high-quality water treatment, filters on the pipes of connected communications. Plus – professional installation of equipment.

- Navien boilers break down extremely rarely. If errors appear on the display, you should immediately check the corresponding sensors and connecting wires. In 85% of cases, the reason is precisely in them or in external factors (mismatch of parameters of house systems; for example, pressure in the main line).

The documentation for Navien heating installations contains scant information, including information on errors that appear. the user to contact an affiliated service center in case of problems with the operation of the equipment. This must be taken into account when calling a specialist. It’s not a fact that this department has manuals for repairing Navien boilers!!!

Repair instructions for gas boilers Navien

Basic boiler settings are carried out simultaneously with the initial installation.

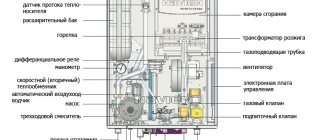

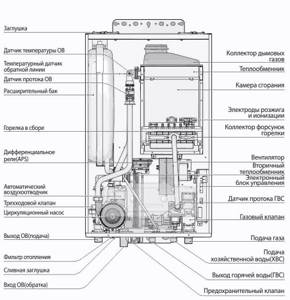

Connection is made to all necessary communications and systems:

- Gas supply.

- Water supply.

- Connection of the direct and return pipelines of the heating system (OB, coolant).

- Connection to the power supply network.

- DHW supply system (distribution to distribution points).

The initial setting of the boiler is carried out using DIP switches and a resistor that regulates the gas supply (pressure). They are located on the unit control board.

IMPORTANT!

Self-tuning of Navien gas boilers is strongly not recommended. To perform this procedure, you should invite a specialist from the service center.