Baxi are gas boilers with Italian roots. These are devices for creating a comfortable atmosphere, maintaining heat and creating a comfortable life. Baxi products are safe and environmentally friendly. By purchasing a boiler from an Italian brand, you get a silent assistant for maintaining heat in your apartment. The boilers are characterized by high productivity. The operation of gas equipment is simple; anyone can master the operation of a boiler, and the attractive price makes it possible to install high-quality equipment with limited finances.

Even if the pressure in the network decreases, this will not affect the quality operation of Baxi boilers. The operating features of the unit allow the use of liquefied natural gas for operation. Modern design solutions make Baxi products popular; boilers fit organically into different interiors: innovative shapes and bright design solutions make boilers a stylish detail in the room.

Knowing the series and model will allow you to select spare parts if necessary. The most popular models: Slim, Main, ECO, Nuvola (they come with a stainless steel boiler), Baxi Luna (Comfort Combi, Silver Space, Comfort).

The volume can be selected based on the characteristics of the room: the line of boilers includes super-compact models and units with a capacity of 80 liters. If the area of the room allows, the Italian boiler can be placed on the floor; in a small room, the device can be mounted on the wall. Based on the design, all models are divided into:

• double-circuit; • single-circuit.

WITH AGREEMENT

— 50%

Full discount on work when concluding a boiler maintenance agreement

Order

Many buyers who purchase heating equipment from foreign manufacturers rely on its good quality and often forget that Russian standards for electricity and gas supply do not always correspond to the parameters established for such equipment. It is this reason that explains the need to contact authorized service centers for servicing the Baxi gas boiler .

When Baksi boilers are faulty

You can fix the problem yourself if the cause of the problem is visible or if you don’t need a specialized tool or serious knowledge of the problem. When the cause of the malfunction is unclear, the owner does not have the appropriate education, it is better to entrust the repair of the boiler to a specialist.

Types of faults:

1. The operation of the burner raises questions: it does not turn on, works intermittently, and goes out. 2. The ignition process is difficult. 3. Trouble is suspected in the combustion chamber: the owner is frightened by popping noises. 4. The equipment is overheating. 5. The degree of heating of the coolant is far from maximum. 6. The boiler is working, but its operation has become noisier. 7. The sensor or other important element of the boiler is faulty.

Why do Italian boilers break down:

1. Moisture has penetrated: many devices do not tolerate foreign interference. 2. The water used in the heating system is not of the best quality. 3. The gas pressure in the gas pipeline system has undergone changes. 4. The electrical network has been overvolted. 5. The heating system is poorly installed.

When the boiler does not start, the owner should suspect improper installation; the phase and zero may be reversed; accumulated air often causes problems.

The burner flame is not the most powerful. When the pressure in the system is adjusted inappropriately, the gas valve modulator requires inspection by a specialist, the diode bridge is broken, and the specified problem occurs. The operating instructions will help you choose the optimal system parameters.

The startup is present, but the equipment quickly stops working. Low pressure is responsible for the malfunction. It is necessary to adjust the incoming pressure: the indicator should be below 5 mBar.

The coolant is not fully heated. You need to make sure that the pressure indicator on the gas valve is within normal limits.

The modulation mode fails. You need to call a technician: the board needs replacing, and so does the valve.

Temperature sensors provide inaccurate readings. Perhaps the elements have served their purpose. New sensors will delight the owner with accurate indicators.

Hot water supply is characterized by low heating. The three-way valve is acting up: either it is not working at all, or it does not open completely. Actions: after the system has cooled, the shut-off valves close and the hot water supply mode is activated. A valve failure is indicated by simultaneous heating of the heating system.

Popping noises are felt when igniting. These troubles are caused by: insufficient gas combustion (it is worth adjusting the minimum pressure), changing distance from the igniter to the gas supply (the optimal gap is 4-5mm), excessive draft (the damper will help reduce the draft).

Gap adjustment. You need to remove the front panel. The flap is removed from the inspection hole. An igniter is placed behind it. Unscrew the screw on which the igniter electrode is attached and bend the electrode. Return everything to its place and close the existing hole with a flap.

The coolant temperature drops quickly. There may be several options: filters require attention, radiators or pipes are damaged, clogged or frozen.

Common problems with Baxi gas boilers

| Problem | Possible reason | Solution |

| Crackling and noise during heating. | Most likely, the walls of the heat exchanger are covered with a thick layer of scale. | It is necessary to flush the system or replace the heat exchanger |

| The pressure drops and the boiler turns off. | Coolant leak or problem in the expansion tank. | It is necessary to find the cause of the coolant leak and eliminate it. |

| Error E01 | The fire does not ignite due to a loss of gas supply or a malfunction in the sensor. | Diagnostics and situational repairs. |

| Error E10. | Failure of coolant circulation - a drop or sharp increase in pressure. | |

| Errors E96, E97, E98. | Control board problems. |

Prices (includes on-site, diagnostics and repairs)

| Wall-mounted (electric, gas, condensing) boilers up to 40 kW, Floor-standing (gas, diesel, solid fuel) boilers up to 65 kW. | Cost, rub. |

| Boiler repair/maintenance with a 6-month warranty on work performed and installed spare parts. For each additional boiler in the boiler installation +50%. | 6 000 |

| Cleaning the boiler combustion chamber from soot deposits (added to the cost of repair/maintenance work) | 3 000 |

| Condensing wall-mounted boilers from 45 to 80 kW, Condensing floor-standing boilers up to 80 kW, Traditional floor-standing boilers from 65 to 300 kW | Cost, rub. |

| Boiler repair/maintenance with a 6-month warranty on work performed and installed spare parts. For each additional boiler in the boiler installation +50%. | 9 000 |

| Cleaning the boiler combustion chamber from soot deposits (added to the cost of boiler repair/maintenance work) | 4 000 |

| Cost of repair/maintenance work for boilers over 300 kW | by agreement |

| Condensing wall-mounted boilers from 80 to 300 kW, Condensing floor-standing boilers from 80 to 300 kW | Cost, rub. |

| Boiler repair/maintenance with a 6-month warranty on work performed and installed spare parts. For each additional boiler in the boiler installation +50%. | 11 000 |

| Note: The cost of work on objects located from the Moscow Ring Road in a zone from 50 to 100 km increases by 10%. The cost of work on objects located from the Moscow Ring Road in a zone over 100 within the boundaries of the Moscow Region increases by 20% | |

Simplicity and convenience are the strengths of Baxi products. With prolonged use, even such reliable equipment can fail. Repairing modern boilers requires special specialization and the availability of suitable tools. Thermostrim engineers have a solid base of knowledge and practical skills in repair work. That's why we guarantee you a positive result in 100% of requests.

Regardless of what model is installed in your home (Main, LUNA, Slim, Duo-Tec, etc.), we are ready to take on the repair of Baksi boilers. We reliably and promptly eliminate both “children’s” problems and more serious breakdowns.

Cleaning filters

Incoming filtering is necessary. If water is used as a coolant, the flow often contains fine sand, silt, scale, rust or metal shavings. Dirt entering the system can disrupt the operation of the input flow sensor, clog the heat exchanger, etc.

The filter and flow sensor are cleaned using ordinary running water and a brush with hard bristles. Next, before reinstallation, to soften the O-rings that prevent leakage, they need to be treated with silicone grease to achieve a tight connection.

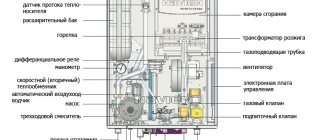

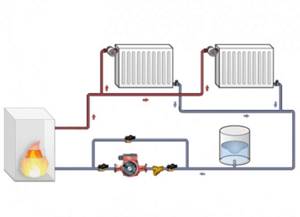

Operating principle

The combustion chamber of baxi boilers is made of metal. The outside is covered with a layer of thermal insulation. A copper heat exchanger is placed above the combustion chamber, and the burner is located under the combustion chamber.

When the air temperature in the room changes, the thermostat automatically starts, transmitting a switching signal to the pump, which creates a vacuum in the return pipeline. In this case, heated water begins to flow into the supply line of the heating system under a pressure of no more than 0.45 bar (if the pressure increases, the microprocessor sends a signal to the relay, the contacts close, and the burner ignites). The boiler starts with low power, which gradually increases until the coolant temperature reaches the set temperature. After this, the heating mode changes to modulation mode. As soon as the coolant temperature deviates from the set value towards a decrease, a signal is received from the temperature sensor, the fuel inlet valve opens, the burner is re-ignited and heats the water.

If at the beginning of operation the boiler power is too high, the burner automatically turns off and the system can be restarted only after three minutes.

When there is no need for heating, the boiler is switched on to DHW mode. In this case, cold water enters the secondary circuit through a three-way valve that shuts off the heating line. Fuel flows from the gas valve into the burner, gradually increasing power. When the water heats up, the temperature control mode is activated.

Do-it-yourself boiler cleaning

You need to drain the water and turn off the tap on the right. If the situation allows, it is better to get rid of water in the heating system. The Zhel device will help: it cleans the system. We connect the device to the Baxi pipes. Remove the cover of the device and fill in the cleaning liquid. Turn on the Zhel device. We work for several hours: we change the direction of the washing liquid. After two hours of cleaning, turn off the device and turn off the tap. When the liquid goes into the device, remove the hoses. We carry out connecting operations of the boiler and heating system. The described procedure will prolong the operation of the boiler, remove scale, and prevent blockages.

Cleaning the secondary heat exchanger

Again he resorts to the washing device. We perform connection operations, turn on Zhel. Close the gas tap and open the hot water tap. Turn off the cleaning device. The liquid will travel along a short circuit of the system.

Before choosing a model and installing a boiler, it is better to listen to a specialist. Baksi boilers have many advantages, but, like all equipment, they do not last forever, and the durability of the devices is not ideal. We assessed the extent of the breakdowns and described the basic steps required for DIY repairs. We hope that you will not regret your purchase and that your boiler will create a warm atmosphere for a long time. And if breakdowns occur, let them be minor and quickly fixable. It’s good when, with a minimum set of tools and in a short period of time, the trouble is eliminated and a warm atmosphere reigns in the house again.

Do-it-yourself cleaning of heat exchangers

To clean the primary circuit, drain the water from the heater. For these purposes, unscrew the tap on the body (usually located on the right).

Cleaning is carried out using Jelly using special liquids. The device is connected to the boiler through pipes, liquid is poured into it and connected to the network. Cleaning takes two hours, changing the direction of fluid movement manually. After this, the liquid is drained and the boiler is restored to its original state.

The secondary circuit is also cleaned using special liquids. Only in this case the gas tap is turned off and the hot water tap remains open. The cleaning liquid passes in a short circle.

Basic cleaning methods

The heat exchanger is cleaned in the following ways:

- mechanical;

- using chemical reagents;

- hydrodynamic;

- electric discharge.

Mechanical

The mechanical method involves manual cleaning using various auxiliary tools. This is the simplest and cheapest method that does not require the owners to spend money and time. However, its effectiveness leaves much to be desired. Mechanical cleaning does not provide a 100% guarantee that the problem will be corrected.

What you will need

To mechanically clean the heat exchanger you will need to prepare:

Refrain from using tools that have sharp edges. They can damage heating system components.

How to clean

We remove the part needed for cleaning and carefully treat its surface with a brush. To clean the internal surfaces of the part, use a brush or vacuum cleaner.

Using chemically active substances

Chemical cleaning is much more effective than mechanical cleaning, due to the removal of blockages in hard-to-reach places that cannot be reached with a regular brush. Advantages of the method:

- reagents cost money;

- chemicals are harmful to the human body and must be used extremely carefully;

- requires specific equipment, which you will have to purchase in a store or do it yourself.

What is a booster and how to mount it yourself

A booster is a special device that circulates chemicals inside the heat exchanger. To make a booster on your own, you need to prepare:

- pump;

- hoses with a diameter of 12 or 34 inches;

- container for chemistry.

We connect one end of the hose to the pump, and screw the other onto the heat exchanger. We screw the second hose to the outlet of the heat exchanger, and lower its free end into a container with chemicals. The pump must also be located in a chemical tank.

Depending on the type of pump, the chemical tank may require some modification.

How to clean a heat exchanger using a booster

When using a booster with heating element you will need:

- disconnect the boiler from the heat exchanger;

- attach hoses to it;

- fill the container with chemicals;

- turn on the booster.

Note! When using a booster without heating element, you will have to turn on the boiler at 1/3 power so that the liquid warms up to 45 o. This must be done very carefully, otherwise an accident may occur. If you are not sure of the final result, seek help from specialists.