Regardless of the brand of water heater and its cost, breakdowns will occur sooner or later. Most of them have nothing to do with the operating features, but it would be stupid to exclude the possibility of a malfunction due to the fault of the user himself.

Each water heater, due to its design features, has certain breakdowns, but most of them can be prevented or corrected independently. The main thing is to follow clear instructions and maintain maximum safety.

Causes of breakdowns

The most common causes of water heater malfunctions are the following:

- Sudden power surges in the network lead to burnout of contacts in the heating element, rendering it inoperable.

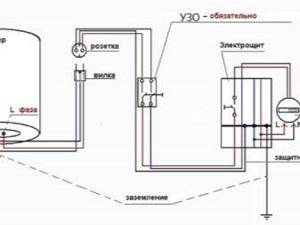

- Incorrect installation and connection, lack of grounding - the water heater is operated in conditions not intended for favorable operation, which significantly reduces its service life.

- Lack of maintenance - if the water heater is not cleaned of sediment that accumulates due to contaminated water, then sooner or later it will reduce efficiency, after which it will completely fail.

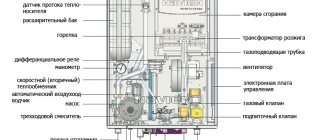

If we consider water heaters from the point of view of their design, then there are two types:

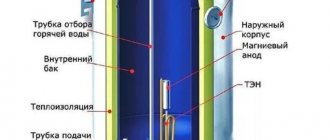

- Storage (boiler) - water from the general system is supplied to a storage tank, where it is heated to the required temperature and, on demand, discharged into a separate hot water supply pipeline. Heating is carried out using an electric heating element, and to prevent the development of corrosion, a magnesium anode is used, which needs periodic replacement.

- Flow-through - water is heated directly as the flow passes through the device. There are electric and gas ones, in which the heating power is much higher than that of storage ones.

Water heaters also differ in volume, power and brand. Cheaper models are made from the most affordable materials, but their service life is quite limited. A good and reliable option will cost the buyer a little more, but with timely cleaning it will last for many years.

Can I fix the problem myself?

Troubleshooting a water heater requires the user to have experience working with water heating equipment. This will help him not to confuse anything and actions to correct breakdowns will not cause even bigger problems.

If there is no such experience, then when dismantling various parts of the water heater, disassembling its parts and components, it is better to invite a specialist involved in the repair of devices of this class and brand. The measures are related to the fact that different models of devices from different manufacturers necessarily have significant design and functional features and their own specific functioning. This applies to both the appearance of the device and the features of the configuration, the layout of its internal parts and elements.

For example, one well-known company decided to equip its water heaters with connecting elements in the form of self-clamping clamps, while another uses nuts to connect pipes, and the use of anything else, in this case, will be useless.

In heating devices from other companies, the spiral of the water heating element is placed in a hole with a diameter of 65 mm. To attach it to the tank, special tools are needed, and the screwed-in bolts are so tightly connected to the nuts that it is simply impossible to unscrew them even if you try. As a result, when something in the device fails, it will not be possible to quickly open its case. In addition, all fastening parts, and there may be more than 12 of them, will have to be removed with a grinder, and the likelihood that by removing the bolts, you can also remove part of the body at the same time is very high. In addition, a boiler is an electrical device, and in order to work with it, you need to know which wire should be connected to which element. Not knowing and not following safety precautions when working with electrical devices can lead to dangerous consequences, the most harmless of which will be a short circuit in the electrical wiring.

If there are interruptions in the operation of the boiler, you cannot do without contacting specialists because difficulties are caused not only by the breakdown of parts of the device, but also by external factors that are in no way dependent on either the user or the device that he is trying to fix on his own.

However, it is necessary to carry out preventive maintenance of the device from time to time: change filters, inspect the internal tank for leaks and possible damage, check the integrity of the electrical wiring, at the slightest suspicion that the device is not working correctly. In the event of a breakdown, contact the service center to troubleshoot. Then the water heater will last a long time and it will be safe to use.

The water temperature does not correspond to the specified parameters

Significant deviation of water temperature from the specified parameters

The problem arises in two cases, when the water from the heater is either too hot (literally boiling water) at minimum heating values, or cold and heating does not occur at all. There is also an intermediate malfunction, when the maximum heater values are set, and the water is slightly warm. All problems deserve attention, the causes of which can be quite numerous.

So, let's consider a situation where the water heater, at maximum values on the relay, produces only warm water in the tap, which is preceded by the following possible problems:

- The heating element is covered with scale, it consumes more energy on heating, while the efficiency is at a minimum.

- There are problems in the central board that are blocking the relay signal to the desired temperature.

If the water heater visually turns on and supposedly works, but in fact only produces cold water, then the reasons may be similar to those stated above. When the temperature of the water is exceeded, the problem lies in a malfunction of the thermostat or thermostat, which is responsible for fixing the heating parameters set by a person and maintaining this temperature inside the water heater.

If the problem is related to temperature mismatch, you need to perform the following sequence of actions:

- Check the heating element for contamination and proper operation : disconnect the boiler from the mains, allow the water to cool and drain it as much as possible, then remove the protective cover at the bottom, open the valve and carefully remove the heating element. Using a multimeter, check the functionality of the element, which is fixed in the range of values 0.68-0.37 Ohm. If there is a break, the indicators will be unstable and will tend to infinity. If there is scale, it can be removed by soaking it in a special acid solution, which can be bought at any household store. Apple cider vinegar is an alternative.

- Take out the thermostat and evaluate its performance : disconnect the boiler from the network, drain the water, remove it from the wall. Find the thermostat (you can see in the instructions what it looks like and where it is located for a specific model) and press the safety button all the way. Next, the metal tube needs to be slightly heated with a lighter. If the thermostat is working, then when it heats up it will react and return the button to its original position. If this does not happen, then you should completely dismantle and replace the element with a new one.

Similarly, you should go through all available contacts with a multimeter, since there is a possibility of a break, which provokes a lack of proper operation.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

Before draining the water, you need to let it cool. If you don’t have time to wait, then the following trick will do: open the hot water tap to maximum, unplug the boiler. After about 5-7 minutes, the water in the tank will become slightly warm, which will facilitate the process of draining it.

Why does the boiler cool down quickly even though we recently bought it?

First, let's look at the simplest reason for a recent purchase. If you recently purchased a water heater and have not used it before, then we must warn you about some interesting points.

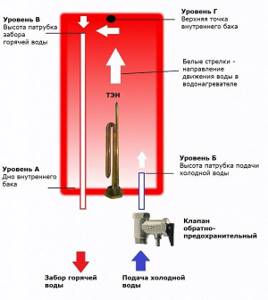

A good 80-liter water heater, fully heated (this can be understood by the indicator), should freely allow 3 adults to wash themselves in the shower, and at the same time the latter will no longer have hot water flowing. Why is that? We actually waste a lot of water when we bathe, so the system is designed in such a way that cold water is supplied from below, and hot water is taken from above (even if the supply visually comes from below). Therefore, when there is less and less hot water, some of it mixes with the lower layers of cold, and cool water comes out.

Even if you were told that now you can wash with almost five of you, you were deceived. Now many people are complaining about the insufficient power of their water heater, and it turns out that they were told fairy tales in stores.

Why does the boiler cool down quickly after moving or after reinstallation?

If you moved this water heater to a new apartment, or it was installed by “insufficiently qualified technicians,” there are some errors that may affect its operation.

- The most common reason why the boiler cools down quickly is incorrect connection of the water supply and outlet hoses. In this case, the water will heat up, but it will cool down much faster, since cold water will fill the system from above, and according to physics, will move down to the outlet. Therefore, after some time, you will no longer be able to wash normally, even though hot water will still be in the system.

- In addition, the concept of “water too cold” is often observed. In winter, the water entering the system is almost icy, and in summer it is slightly warmer. If before the three of you washed normally, but now the third one barely has enough time, know that this is the reason. If the three of us washed normally before, but now the first one doesn’t have enough, then most likely this is not the reason.

- It is also worth checking the pressure in the system. Often more cold water can be supplied, or rather the pressure can be much greater than necessary, and the drainage system can pump out warm and hot water to avoid rupture of the tank. This happens in extremely rare cases, especially if you installed the system using wizards. Although it is rare to find this, even if you installed it yourself.

- Sometimes, sudden cooling is possible due to the lack of shut-off valves at the hot water outlet. This is a common installation error, so if you did the installation yourself, you may want to take a look at this problem. In this case, hot water may partially go through the system to your neighbors if you live in an apartment building.

- The heating element is dirty inside. For the device to work properly, the tank must be opened and cleaned at least once a year. If it has not been cleaned for about 2-4 or more years (the period may be less due to the quality and type of water), the reason may be that a lot of sediment has accumulated on the water heating element, which interferes with normal operation. In this case, you just need to clean the water heater.

These are the main reasons why the boiler cools down quickly. Only a master can really try to solve the problem in this case, especially if the above methods did not help.

Boiler problems:

- the thermal insulation has burst or broken;

- the entire structure is installed on the roof (attic) of the house, so it easily cools down due to the external temperature;

- The water heater itself is defective.

But this happens extremely rarely. The reasons described above occur more often. You can solve it yourself if you understand the problem a little, but if not, then leave a request to the specialist.

Leak in tank

The problem of leak development is associated with corrosion of the metal, which is constantly in contact with water. If you do not change the magnesium anode, as required by the manufacturer, then after a couple of years you can see clear signs of depressurization. In 95% of cases, it will not be possible to eliminate this problem, since the design of the tank requires tightness, which can only be achieved in a factory environment.

A leak in the tank is almost impossible to fix on your own; a complete replacement may be required.

Self-repair is only appropriate if the leak appears exclusively from under the flange. This happens when the gasket, which creates a seal on the outside of the heating element, is worn out.

The sequence of actions in this case is as follows:

- Disconnect the boiler from the mains, let the water cool and drain it as much as possible.

- Remove the lid, place the container and carefully open the valve, removing it along with the heater.

- Inspect the rubber valve for deformations and abrasions.

- Replace it by first disconnecting it.

If drops of water collect along the contour at the bottom of the boiler, then this cannot be corrected. Craftsmen will tell you that there is also welding that will allow you to quickly and reliably seal the hole. But this is inappropriate in the case of closed-type boilers, since the design does not imply access to the outside of the internal tank. It would be appropriate to replace the water heater with a new one.

Valve leakage during water heater operation

If the water heater is connected to the network and heats water for a long time without significant water intake, then the cause of the constant leakage is most likely a faulty safety valve. The fact is that during the initial heating of cold water, its volume in the boiler will increase by about 2-3%. This excess liquid will be discharged from the tank. In the future, the boiler simply maintains the temperature of the hot water, so there should be no leaks, so the cause should be sought either in a breakdown or in a clogged safety valve.

A completely different picture should be observed with increased water consumption, for example, while taking a shower: the constantly leaving volume of hot liquid will be continuously replaced by cold water. But when it heats up, the excesses indicated above will begin to appear. Therefore, the flow of a certain amount of water from the drainage hole in this case is quite logical.

Safety valve device for water heater

And the third option is for a small, extended water withdrawal. For example, washing dishes or cooking. With such a flow rate of hot water, there should not be a constant leak from the drainage tube, but the periodic leakage of liquid drops will indicate the correct operation of the water heater.

Boiler does not turn on

If there is no heating when inserting the plug into the socket, there may be several reasons:

- The heating element has burned out or there are broken contacts, which occurs with frequent sudden changes in voltage in the network.

- The elements of the central board , which control the operation of the entire water heating system, burned out.

- Malfunction of the thermostat , which records false readings of water and eliminates the need to heat it.

What can and should be done in this case:

- Inspect the heating element and evaluate its performance using the device - disconnect from the network, drain the water and carefully unscrew the safety valve. If it is faulty, it needs replacement. This problem is most common in closed type water heaters.

- Go through the thermostat contacts: disconnect from the network, you don’t have to drain the water, remove the protective cover and ring all connections, including the central board. If the indicators are far from normal, then repair is required. If the thermostat can be replaced with a similar one yourself, then this will not work with the board. You'll have to call a technician, but he doesn't guarantee that the boiler will work.

You also need to check the serviceability of the plug. It often happens that the wire breaks and the contacts are compressed, forming a short circuit.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

It is better to allocate a separate outlet for the boiler, next to which no other devices will be connected to the network. This will reduce the risk of overheating and also eliminate the possibility of a short circuit.

Trouble-shooting

Having discovered a problem unit, you need to begin restoring the boiler’s functionality. The procedure depends on the specific reason that is interfering with the normal operation of the device. Let's look at the most common situations.

Scale clogged

Water heater clogged with scale

Scale is deposits of insoluble carbonate salts on the walls of water heating devices. It is found in kettles, washing machines, and water heaters.

The amount of scale depends on the hardness of the water. In regions with hard water, even after a year of operation of the boiler, the amount of salts deposited on the walls may be sufficient to completely block the lumen of the heating element tubes or significantly narrow it.

If scale causes the water heater to fail, repairs must be carried out in the following order:

- Open and remove the protective cover from the water heater.

- Unscrew the nuts holding the heating element in place and remove it.

Dismantling the heating element

Wash the boiler walls and heating element coil from carbonate deposits. Organic acid - lemon or oxalic acid - will help dissolve the hard crust. You can also use industrial products - anti-scale agents. Soak the part in an acid solution to free it from accumulated deposits.

Cleaning the heating element from scale

- Using a tester, make sure that the heating element coil has not burned out due to a violation of heat removal by scale.

- If the spiral is intact, assemble the device in the reverse order of dismantling.

If the heating element fails, you will have to look for a new one or buy a new boiler - you need to choose the most economical solution. If repairs require large financial expenses, it is more profitable to immediately purchase new equipment.

Failure of the pressure reducer

The pressure drops of the incoming water in the system can range from 2.5 to 7 atm. To compensate for surges, a special unit is installed at the boiler inlet - a gearbox. Its task is to ensure equal pressure at the outlet of the boiler and from the tap. If it falls due to a gearbox failure, it is necessary to adjust its operation or replace the broken part.

Low pressure in the main water supply also leads to a drop in pressure at the outlet of the water heating boiler or instantaneous water heater. Unscrew the hose and check the pressure level: if water comes from the main water supply in a thin stream or does not flow at all, you should wait, as the problem may arise due to repair work. If the pressure has not been restored within several hours, you should contact Vodokanal.

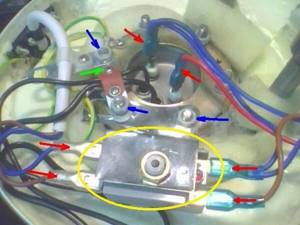

Thermostat failure

If the water leaving the boiler does not heat up enough or does not heat up at all, the cause may be a failure of the thermostat - it is responsible for maintaining a constantly high temperature. To carry out diagnostics, turn off the power to the boiler and remove the thermostat from the housing.

- Press the thermostat button.

- Heat the copper tip of the thermostat. If the node is working properly, the button should turn off.

- Test the electrical circuits of the thermostat using a tester.

Typically, a thermostat malfunction is caused by the overheat protection tripping. As a result of the operations performed, the device should work, and the problems will disappear after it is installed in place. If the tester shows an open circuit, you will have to replace the burnt out thermostat.

Faucet clogged

If water comes out of the boiler with sufficient pressure, but flows out of the tap slowly, the reason lies in the faucet being clogged with scale or rust. You will need to turn off the water, disassemble the faucets and thoroughly clean the filter mesh. You also need to inspect all the rubber seals and make sure that the valves are working properly.

The boiler body is electrocuted

If you accidentally come into contact with the heater, you may notice how it transmits a discharge. It may not shock much, but it is quite unpleasant. One reason is the direct contact of electricity with water. This happens due to a crack in the heating element, which is caused by accumulated scale. When the boiler is connected to the network, not only its body, but also the flowing water can carry a charge.

If the body of the water heater is electrocuted, then it is necessary to check the heating element

In this case, it is necessary not only to check the heating element and, if necessary, replace it, but also to ensure proper grounding of the electrical appliance. If this causes difficulties, then it is better to entrust the repair to a specialist.

It is extremely unsafe to use a hot water heater. Sooner or later this will provoke a global breakdown or cause health problems.

Water heater: Installation and use errors

In addition to possible breakdowns during operation, malfunctions often arise due to errors during installation and assembly of the boiler.

To prevent this, you need to know what points you need to pay attention to:

- Connection errors.

Improper connections to the inlet and outlet pipes may cause leaks or steam production. This negatively affects the operation of the water heater and can lead to breakdown. Therefore, it is necessary to carefully check all connections before starting work. - Errors when installing the thermostat and heater.

If such a flaw is allowed, then not the entire volume of water may be heated, but only some of it. Because of this, the water temperature will be much lower, although the thermostat will show a higher water temperature and turn off the heating. - Hull deformations.

If the thermostat is installed incorrectly, a vaporization effect may occur. This leads to increased pressure inside the water heater and deformation of the housing. - Bacterial infection.

Before a long break in operation, it is necessary to drain all water from the boiler. If this is not done, bacterial contamination of the container is possible. The water in it will “bloom” and acquire an unpleasant odor, which is very difficult to remove in the future. In particularly advanced cases, bacterial contamination may lead to tank replacement.

In addition to the above, there are many other causes of breakdowns, which are too long to list. Therefore, in order for the water heater to serve for a long time and without failure, you must follow the following rules.

Installation of equipment and general installation must be entrusted to professionals. Only in this case will all work be completed correctly, and in case of any problems, repairs will be made under warranty.

It is necessary to carry out regular preventive examinations. This will allow you to promptly clean clogged connections, descale the container, and prevent problems from accumulating.

Repairing problems that arise should also be entrusted to professionals. Only experienced workers can accurately diagnose the cause of the breakdown and eliminate it. Amateur intervention may make the situation worse.

If you follow these simple rules that are understandable to anyone, you can significantly extend the life of the product and reduce the cost of possible repairs. But despite this, many owners are trying to save a hundred or two and go to craftsmen who cannot provide high-quality repairs. Therefore, the boiler will break down again and again until it requires a complete replacement.

Dirty and foul-smelling water from the heater

If, when you turn on the hot water, something similar to kvass flows out of the tap, having a characteristic swamp smell, then it’s time to clean the heater. This situation occurs when sediment accumulates inside a closed tank and flows through the pipes. Visually this may not be noticeable, but debris tends to accumulate and settle not only on the heating element, but also on the walls of the boiler.

The problem should be solved in two stages:

- Place a filter at the cold water inlet: it will trap debris and dirt, as well as bacteria that can live in a closed tank system. The water will become much cleaner, and preventative cleaning of the boiler will be needed less often.

- Clean the boiler: you can pour special disinfectant solutions through the supply tube, then drain the contents into a bucket. There are a lot of special products to clean your boiler.

The cleaning procedure will not cause any particular difficulties. The sequence of actions depends on the chosen tool:

| Name | Quantity | Sequencing |

| Lemon acid | 20 g of powder for every liter of water | Mix the required amount of citric acid with 2 liters of water, then introduce the solution through the water supply hose. Plug in and set the maximum values on the relay. Let it boil for 3-4 hours, then open the hot water tap and completely drain the water from the boiler. |

| Vinegar essence | 10 ml for every liter of water | Vinegar should be introduced into the boiler through a hose, and then connect the hose to the pipeline. Set to maximum temperature and drain completely after 4 hours |

| Acidic solvents for cleaning boilers | Please refer to the instructions for proportions. | The product is poured into the boiler and left for 1-2 hours, after which the water is completely drained |

Why is the water heater not filling?

Filling the boiler is a simple matter at first glance

It is important to follow the correct sequence of this procedure:

- the hot water drain valve on the mixer to which the boiler is connected opens, then the cold valve of the general water supply;

- the liquid gradually fills the reservoir and displaces the air with a hiss;

- the water level in the tank rises, it begins to overflow into the pipe (level B in the figure);

- When a steady stream of water flows, you can turn off the mixer.

Diagram of water movement in the boiler

The water heater is full, only now you should turn it on. This is how it should be ideally. But it happens that the boiler suddenly does not draw cold water, although the water supply is working. What can affect this behavior of the heat exchanger?

Filter clogged

At the entrance to the boiler, the water is filtered to remove impurities. To do this, the design of the device has a mesh filter that traps debris and rust particles. The metal grate gasket becomes dirty and the garbage plug prevents the free flow of water. To resume normal filling of the boiler, you need to remove the plug from the flask and remove the mesh. Wash it in the same way as the mixer filter and return it to its place.

There are also replaceable filters with gel filler. Poor quality material can leak and clog the tubes through which water moves. If this is your case, then saving the situation will be very simple: you need to buy a normal filter. But you will have to try and thoroughly clean the water intake pipes with a brush.

Incorrect assembly

It happens that the cold water intake hose is connected to the heated water drainage point, and vice versa. Such a nuisance sometimes happens, especially if the installation was installed by a newbie. As a result, the functioning of the boiler is disrupted and water does not flow into it. The same can be said about an erroneous connection of a safety valve. A specialist will help solve the problem.

Boiler connection

Check valve faulty

To keep water in the boiler and prevent it from flowing back into the general water supply, a safety valve is built into the design of the device. It is located after the shut-off valve, at a short distance from the tank, and acts in one direction when drawing water. It is also designed to relieve excess pressure: when the water gets very hot, the valve locking device presses the spring. Excess fluid is released and the pressure stabilizes.

When worn out or when large particles get into the valve mechanism, it jams and does not allow water to flow into the boiler. It often happens that the chamber behind the disc spring becomes clogged with scale. You can return the unit to functionality by unscrewing the part, disassembling it into its components and thoroughly cleaning it. If the cleaning attempt is unsuccessful, the equipment should not be left without the valve.

Repair of instantaneous gas water heaters

Failures are most often associated with scale fouling of the heat exchanger, as well as a malfunction of the thermocouple. Repairing gas equipment yourself is strictly prohibited. To find the cause and eliminate it, you need to contact specialists who will do everything themselves.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

In order for the equipment to last as long as possible and not require expensive repairs, it is necessary to follow the rules of its operation, as well as promptly clean the internal elements from contaminants. Preventive cleaning is indicated once a year.

Weakness of the non-return safety valve

Water leakage through the valve drain pipe can be considered normal if a liter jar is drawn drop by drop from it over the course of a day. This is the excess formed when pressure increases from heating. But sometimes it is impossible to determine the amount of liquid flowing out, since it goes down the drain hose into the sewer. If the boiler empties unusually quickly, you may suspect a weak valve. In this case, you will have to install a new part, and in general it is recommended to change this important unit annually.

Water drips from the valve - this is normal.

It is forbidden to empty the boiler through the safety valve opening! Scale and sediment can clog the drainage pores and the mechanism will stop functioning.

- No matter how well the water heater is thermally insulated, heat loss cannot be avoided. So you shouldn't set the temperature regulator to maximum. If the water consumption is moderate, it is better to heat it to a medium temperature so that dilution is not required. Strong heating is desirable at a time when you need to take a shower and you will need to draw a lot of water. Lower temperature means less scale.

- If no one will be home for several days, the water heater should be turned off, but left full. But night shutdowns will not help save energy and will even lead to accelerated wear and breakdown of electronics, which are often forced to experience overloads.

- After a long period of inactivity, the musty water must be drained, the boiler must be rinsed and refilled. Warm up at maximum mode for two hours, this will help get rid of unpleasant odors and bacteria. When there is no need to use the boiler for a long time, for example, in winter at the dacha, it is emptied, dried well and kept warm.

- A useful element such as a magnesium anode will help reduce the formation of scale on the walls of the boiler. It dissolves over time and should be replaced about once a year. But this is a general recommendation, and in each specific case you need to think about whether to interfere with the operation of the equipment. The level of hardness and impurities in the water is different everywhere, but if the unit begins to crackle and heats up more slowly, it would be a good idea to disassemble the structure and inspect it from the inside.

Anode for water heater

- To soften the water, you can install a filter at the inlet of the boiler, the cartridge of which is filled with a special resin. This substance displaces magnesium and calcium ions, and sodium ions appear in their place. Another way to reduce water hardness is to install a hydromagnetic system. The magnet crystallizes the salts, turning them into sludge, which are then retained by the filter.

A properly installed and properly operated boiler can last up to 15 years. Its performance is influenced by various factors: from water parameters to the quality level of parts and components. In diagnostics and repairs, the “random” method should not be used; the main rule is to follow the requirements of the instructions.

Storage tanks capable of heating water to a certain temperature (in common parlance - water heaters or boilers) are most often installed in those rooms where there is no centralized supply of hot water, or there is a high probability of its shutdown. This device has not lost its relevance from ancient times to the present day. Thus, the ancient Greek mechanic Heron of Alexandria (second half of the 1st century AD) is rightfully considered the inventor of the boiler. The unit he created heated cold water with steam. Then they forgot about it, and therefore at the end of the 17th - beginning of the 18th centuries they were forced to reinvent the device. But, like any other household electrical appliance, even an advanced water heater can break down as a result of exposure to internal or external factors, as well as due to simple wear and tear of parts. All the reasons why hot water does not come from the boiler, as well as ways to eliminate them, will be described in this material.

General tips and tricks for DIY repairs

In order for repair work to be successful and not pose a threat to life and health, you need to:

- Inspect and replace parts only with the device disconnected from the network, after draining the water in any convenient way.

- Do not attempt to independently repair faulty parts that should be replaced with new ones.

- Carry out work based on the boiler structure diagrams, which are different for each specific model.

If ultimately the water heater does not work or is working with some problems, then it is better to call a technician who has some experience and can identify all possible causes.

Cleaning and Maintenance

If the boiler has not been serviced for a long time, a thick layer of hard sediment forms at the bottom of the tank, and the heating element becomes covered with a lime coat. You need to take it out carefully so as not to bend or tear the rubber seals. To do this, you need to lift the part and remove the sediment through the resulting opening. After this, you can remove the element.

When the internal parts are removed from the tank, you can easily inspect it and clean it of dirt. First you need to rinse the walls with a strong stream of water from the shower head. If there are deposits left, they should be moistened with a special product or citric acid solution, and then washed off.

The next step is to service the rubber gasket of the tank. It must be cleaned of deposits to ensure a tight connection with the heating element. If the seal is cracked, it should be removed and thrown away. Before installing a new gasket, the socket should be cleaned of rust, sanded and painted with waterproof paint. The inlet pipes should not be ignored. They also need to be cleaned of dirt and rust and the cuts straightened.

FAQ

The power indicator is at maximum, and the water in the boiler is not even hot, but slightly warm. What could be the reason?

There are several problems: malfunction or scale of the heating element, breakdowns in the relay or malfunction of the central board. A specialist who will diagnose all working elements will help determine the true cause (and there may be several of them).

The water quality in our region is not very good, so the magnesium anode has to be changed 1-2 times every six months. What is the alternative?

If magnesium anodes quickly dissolve and there is a risk of contamination of the heating element, then it is necessary to install a cleaning filter at the inlet of the cold water pipeline.

Sometimes the hot water from the boiler is electric. The grounding has been checked and is working properly, what could be the reason then?

It is necessary to inspect the heating element for cracks and chips. Often, if there is scale and annual salt deposits, its integrity can be compromised, allowing direct contact of water with the coil. The cause may also be faulty wiring or the inclusion of several household appliances in one outlet.

Is it necessary to periodically change the heating element or is this procedure forced?

The heating element must be replaced only if it is faulty.

In conclusion, it is worth noting that not all breakdowns can be fixed with your own hands, and in some cases it is better not to experiment at all and entrust the diagnosis to a specialist. All work must be carried out in compliance with safety rules, disconnecting the electrical appliance from the network. To prevent hot water from causing a burn, it should be drained only after it has been diluted with cold water.

Mixer dirty

The liquid will flow in a weak stream if the mixer spout

a traffic jam has formed. The pressure will be equally bad for both cold and hot water. To fix the problem, it is necessary to carry out a number of procedures.

- Close the riser to turn off the water.

- Carefully remove the mixer.

- Unscrew the spout from the general body.

- Remove the mesh and rinse it under running water. If salt deposits or heavy dirt forms, let it soak in a special cleaning solution.

- Rinse the faucet spout thoroughly and clean the insides of dirt using a brush.

- Reassemble the mixer in reverse order and install it in place. Don't forget to open the riser.

This procedure may take some time; alternatively, you can simply replace the clogged faucet with a new one. Experts recommend replacing worn parts every few years to avoid serious damage in the future.

How an electric boiler works and functions

The reason that the boiler does not heat water is most often a breakdown of the heating element.

The design of a water heater is similar to a thermos - in it, the water tank is protected from the environment by a layer of thermal insulation. This allows you to retain heat for a long time, even if the device is currently turned off. The main components that make up the heating installation:

- The base or body is the outer part of the device, on which there are mounting devices for mounting to the wall, and the filling is hidden inside.

- The coolant tank is made of metal, has a titanium or other anti-corrosion coating, inside there are elements for supplying, extracting liquid and the electric boiler itself.

- Supply and intake pipes with threaded connection.

- Thermal insulator is a polymer material between the body and the water tank, designed to reduce the heat transfer of the latter.

- The heating element is an electric heating element of dry or wet type, designed for different power depending on the volume of the tank.

- Heating control system - a circuit with a thermostat and a regulator, necessary for setting the operating mode of the boiler.

- Magnesium anode with protective action.

- Safety valve - relieves pressure in the tank when the water overheats and boils.

- Temperature and operating mode indicator.

An electric boiler is a device that is included in a continuous flow circulation system. Liquid enters the tank through the supply pipe at the bottom of the tank. The heated coolant is drawn from the top of the flask.

Checking the circuit with a tester

If the light on the boiler is on, but the water does not heat up, then it is likely that the heater, which we discussed above, is not working. Checking it at home is quite simple; you need to install the tester probes on the contacts of the heating element and look at the resistance on the display. For a working heater, the resistance can vary between 0.4-0.7, as shown in the photo below. If you see “1” on the display, it means a break has occurred and you need to replace the part with a new one, because it is almost impossible to repair it.

By the way, if the boiler is electrocuted or when it is turned on the RCD turns off by itself, then the cause of the breakdown is, again, in the heater from which the leak occurs. You can check the malfunction by connecting one probe to the contact of the heating element, and the second to the tube itself. You will see “1” on the display, the part is in good working order and there is no need for repair, a negative value or too high means replacement is required. We described in more detail how to check the heating element with a multimeter in a separate article.

Another reason why the boiler does not heat the water or, on the contrary, heats up too much, is the failure of the thermostat. You can check it in two ways - with a tester or a lighter.

Everything is clear with the tester, you need to follow a similar method, but as for the lighter, everything is more interesting. To begin, remove the thermostat and press the button on it (circled in the photo below). After this, the copper contact of the thermostat must be heated. If after some time the button returns to its original position (it is knocked out), the thermostat is working. If the thermostat does not work, you can repair a boiler that does not turn off or turn on by replacing this part with a new one. I would also like to note that to replace the thermostat on a water heater there is no need to drain the water. It is enough just to disconnect the equipment from the network and disconnect all the connected wires.

Also, sometimes there is a breakdown - the water heater display does not show the temperature or the display does not work at all. In this case, check all the elements of the circuit and if you do not find a break, most likely the control unit is broken. You will not be able to repair electronics with your own hands if you lack experience and knowledge, so you will have to take the electric water heater for repair to a service center.

please

Do-it-yourself air conditioner cleaning and maintenance. Currently, air conditioners are an indispensable attribute of almost any modern apartment. However, during operation, a large volume of air passes through climate control equipment, which contains dust, mechanical inclusions, and fluff.

Oven: types, selection criteria, functionality. In order to choose the right oven model that will fully satisfy all your needs, we will consider in more detail the operating principle, advantages and disadvantages of each device.

Causes of microwave oven breakdowns and methods for eliminating them. A distinctive feature of microwave ovens in comparison with other kitchen appliances is the high strength of the device. However, sooner or later, as a result of natural wear and tear of parts or non-compliance with operating rules, the device may fail.

Causes and methods of eliminating air fryer breakdowns. Currently, there are many household appliances that can facilitate the cooking process, saving time and effort. One of these indispensable kitchen assistants is the air fryer.

Maintenance Tips

To ensure that your water heater requires repairs as rarely as possible, it should be properly maintained. For example, it is necessary to periodically carry out preventive inspections of the boiler, and also follow the advice specified in the instructions.

The most common problem for water heater owners is scale. To prevent this phenomenon, it is first necessary to install a pre-filter on the water. If deposits are visible on the walls and pipes, they should not be cleaned mechanically. During this process, scratches are formed, which can later lead to corrosion. It is best to use special cleaning products to remove scale.

For example, in order to remove limestone from a tank and heating element, you can use a solution of acetic or citric acid. 100 percent water contains 3 to 10 percent acid. Moreover, the solution must be hot enough. The heating element is completely immersed in the solution using a container of suitable size, and the tank is simply washed. Washing machine cleaners are also suitable for removing plaque.

A magnetic transducer can help prevent the formation of scale deposits. You can also reduce the heating temperature in the tank to 60-70 degrees. At this temperature, magnesium and calcium salts do not boil.

It should be remembered that the service life of the magnesium anode will be significantly extended if it is cleaned in a timely manner and, if necessary, replaced. Moreover, replacement should be done once every six months.

It is also necessary to ensure that there is water in it before turning on the boiler. When the device is plugged in, the protective cover must not be removed. It is not recommended to use a water heater without grounding. It is also necessary to take into account that water heaters are not suitable for water supply systems in which the pressure exceeds 0.6 MPa.

If the water heater has an electronic display, then it may display basic error codes, which are best familiarized with, as sometimes they can allow you to significantly save on boiler repairs.

Most often you see three errors:

- "Vacuum" (E1). This means that the tank cannot be completely filled with water when the heating element is turned on. In this case, it is enough to turn off the heating element and wait until the tank is completely filled with liquid.

- "Sensor" (E2). This signal indicates that the temperature sensor is not working. In this case, you need to disconnect the water heater from the network for half a minute, and then restart the device.

- "Over Heat" (E3). Indicates that the water has heated to more than 95 degrees. To prevent damage, you must start the safety thermostat with the button.

To learn how to repair a Thermex water heater, see the following video.

Cleaning the water heater structure

A number of malfunctions of water heaters can be eliminated by cleaning, which, if desired, can be done independently. These include prolonged heating of water, the appearance of loud hissing sounds, a yellowish tint of water or the smell of hydrogen sulfide, as well as long-term operation for 2 years without preventive measures.

Turn off the power to the device, remove the cover of the lower part of the tank and the wires. Drain all the water from the inner container using a hose. Don't forget to turn off the cold water.

To remove the heating element, unscrew the bolts that are located under the tank cover at the bottom. Remove the heating element from the tank; if there are too many build-ups of rust and scale, this can also become a difficult task.

Excessive build-up can result from constantly operating the water heater at full capacity. If the heating temperature does not exceed 60°C, this will significantly extend the service life. The heating element removed from the tank must be cleaned mechanically.

Check the condition of the magnesium anode; it may require replacement. Then clean the tank of scale and debris and rinse. Before assembling the boiler, dry it, check the grounding and carefully strengthen the parts.