Technological and production aspects

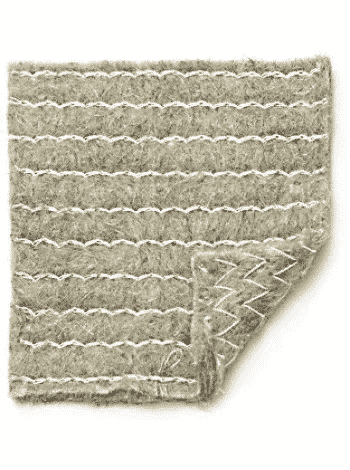

Linen felt and flax batting are made using the needle-punched method. In the first case, the fibers are tangled to bind the felt texture, resulting in a dense fabric without foreign inclusions (there is no nylon, cotton or other substances in the composition). The production of flax wool is based on stitching the catonin flax base with cotton or nylon thread. The density of flax wool is lower than that of linen felt, but according to the standard it should not be less than 500 g/m².

Ecoterm - a modern environmentally friendly insulation based on flax fiber with bicomponent polyester thread in a ratio of 7 to 3 - is bonded under temperature influence into a homogeneous and shape-stable slab.

The main forms of production of flax insulation are in slabs , rolls and mats . The technology for producing linen boards requires the use of starch to glue the fibers together or exposure to high temperatures. To ensure fire resistance, borax is added to the composition and the surface of the insulation is treated. Flax-based thermal insulation in rolls is available up to 160 cm wide. Tape flax tow for insulating wooden houses is made from fiber flax raw materials and is cleaned of impurities using a carding machine. After longitudinal polarization of the fibers, gray flax tow appears as a ribbon 1 cm thick and 15 cm wide .

Kinds

There are several types of linen insulation, which can be distinguished depending on what raw materials they are made from and what their structure is.

- Felt tape. The material consists of field flax fiber. Once collected, the fibers are processed so that they come in different lengths. Then, they are sorted using a carding machine. The fibers used for strip felt must be long; all the rest are used to make construction tow or tile material. Linen insulation is considered the most environmentally friendly and harmless material. It is very easy to use and its installation does not require special knowledge and skills, and all installation work can be carried out at any time of the year. Linen insulation does not mold and does not attract birds.

- Lnovatin. This eco-friendly material is produced on a carding machine using needle stitching technology. The catonin layer is stitched using nylon or cotton thread. However, flax wool has a lower density than felt, so it is better to lay it in two layers.

- Insulation made of flax in slabs. This material consists of sheets with increased density. They cover the walls of houses, various partitions, even roofs. But most often it is used to insulate frame houses, because thermal insulation materials allow the walls to breathe.

- Tow made of flax. This natural material is an example of a type of flax insulation. With its help, construction processes are greatly accelerated, since installation work is easy and simple. Tow is one of the interventional insulation materials. However, it can also be used for thermal insulation of doorways and windows or as an additional means for sealing joints between sheets of insulation, which is the main one.

But such insulation is very popular with birds, who build their nests in the soft fibers of flax, so houses should be built very quickly. This insulation has a low price and a variety of sizes.

- Flax-jute. This organic insulation is a combination of two types of raw materials - jute and flax. These components come in equal proportions, but some manufacturers make insulation with a predominance of one or another component. Flax-jute combines all the qualities of the materials from which they are made, and is also characterized by durability and elasticity.

You can choose any of all the proposed options. The main thing is to know where and under what conditions it is used.

Ecoterm - modern thermal insulation from Belarus

The eco prefix was chosen for a reason: the material really does not contain potentially harmful impurities - phenols, formaldehydes, etc. This type of insulation based on flax and polyester is widely used in “green” technologies in the construction of houses. Ecotherm is designed for thermal and sound insulation of unloaded building structures, and it can be mounted on vertical and horizontal surfaces. The slabs are elastic, the fiber springs, fills voids, and fits tightly. The material is suitable for installation between rafters, in frame spaces, between open beams - anywhere where additional fasteners are not required.

In terms of technical characteristics, Ecoterm is superior to other types of insulation in some areas (see table).

| Characteristics of Ecoterm | Indicators |

| coefficient of thermal conductivity | from 0.038 to 0.04 W/(m K) |

| sound absorption level | 0,98 |

| water permeability | absorbs liquid well, dries quickly, does not change structure |

| vapor permeability coefficient | 0.4 mg/(m h Pa), suitable for insulating baths and saunas |

| density | from 20 to 34 kg/m³ |

| temperature tolerances | minus range is not limited, no more than +160°C |

| fire resistance | fire retardant treatment |

| chemical interactions | Ecoterm does not react to construction chemicals |

| biological factors | the material does not rot, is not a medium for microorganisms, fungus and mold |

| environmental friendliness | does not emit harmful substances when burning, safe for allergy sufferers |

| life time | more than 60 years under manufacturer's warranty |

Insulation for frame houses

In the construction of a frame eco-house, heat and sound insulating materials produced exclusively on a natural basis are used. Natural insulation for the walls of a frame house can significantly reduce the level of audibility of even the loudest street noise.

Also, sound insulation in a frame house several times increases the possibility of maintaining a comfortable temperature in residential and domestic premises when the temperature outside drops.

For insulation and sound insulation of walls, ceilings and roofs.

The dimensions of the mats are 1000*600*50/100 mm.

The package contains 8 mats with a thickness of 50 mm (4.8 sq.m.) or 4 mats with a thickness of 100 mm (2.4 sq.m.).

Packaging volume 0.24 cubic meters

For insulation and sound insulation of walls, ceilings and roofs.

The dimensions of the mats are 1000*600*50/100 mm.

The package contains 8 mats with a thickness of 50 mm (4.8 sq.m.) or 4 mats with a thickness of 100 mm (2.4 sq.m.).

Packaging volume 0.24 cubic meters

For insulation and sound insulation of walls, ceilings and roofs.

The dimensions of the mats are 1000*600*50/100 mm.

The package contains 8 mats with a thickness of 50 mm (4.8 sq.m.) or 4 mats with a thickness of 100 mm (2.4 sq.m.).

Packaging volume 0.24 cubic meters

Universal insulation made from hemp (hemp) is intended for insulation and sound insulation of walls, floors and roofs.

The dimensions of the mats are 1000*600*100 mm.

The package contains 4 mats with a thickness of 100 mm. (2.4 sq.m)

Packaging volume 0.24 cubic meters

Universal insulation made from hemp (hemp) is intended for insulation and sound insulation of walls, floors and roofs.

The dimensions of the mats are 1000*600*50 mm.

The package contains 8 mats with a thickness of 50 mm (4.8 sq.m.).

Packaging volume 0.24 cubic meters

Insulation and sound insulation of any surfaces.

Packaging volume 0.25 cubic meters.

Ecoplanet is the official dealer of Izolna (“IZLNA”) in the Northwestern Federal District of the Russian Federation.

Insulation and sound insulation of all types of surfaces

Packaging volume 0.24 cubic meters

Density: 30 kg/cub.m

Moisture-resistant windproof wood fiber board for external and internal insulation of walls and floors. Sheet size 2700*1200 mm.

For external and internal insulation of walls and roofs of houses. Sheet size 2500*600 mm.

Moisture-resistant board for external and internal insulation of walls and roofs of houses. Sheet size 2400*600 mm.

The material consists of virgin cellulose without dye !

Does not burn!

The material meets international quality standards.

Moisture-resistant wood fiber insulation board for walls and roofs.

Wood-fiber bitumen board, resistant to external influences. Used under planken.

Designed for plaster

Wood fiber bitumen board for heat and sound insulation.

Wood fiber bitumen board for heat and sound insulation.

Insulation and soundproofing of premises

Price per sq. meter - 510 rubles

Insulation and soundproofing of premises

Price per sq. meter - 881 rubles

Internal wall insulation

Internal wall insulation

Insulation and sound insulation of the roof, external walls and internal partitions, floors and ceilings.

Production of materials for thermal and sound insulation of houses

Eco-products sold in our company are made from flax, hemp, eelgrass, coconut and wood fibers. Such insulation for a frame house reliably protects all vertical and horizontal surfaces from the penetration of cold and extraneous noise.

The price of environmentally friendly insulation for a frame house is from 260 rubles. per sq. m.

Fastening materials to walls, ceilings and floors is done in different ways:

- using staples or tape (roll insulation);

- tongue-and-groove type (insulation boards);

- using fasteners (dowels, washers, etc.).

You can buy insulation for a frame house on our website. The company's managers will select the best insulation option for your home. Free consultations by phone from 10 a.m. to 6 p.m. Moscow time.

Features of flax insulation

Flax is an annual bast crop with thin fibers (20-50 pieces per stem). In turn, the fibers consist of porous, up to 150 cm long, individual “hairs” (10-40 each), enclosed in a flexible shell. Thus, a flax stem can be fluffed into 200-2000 simple cellular structures, which perfectly retain heat and absorb sound waves traveling through the air.

In its pure form, flax cannot be used for insulation - it cakes quickly due to the presence of a hard trunk and is susceptible to rotting. Therefore, primary processing in the form of creasing and scuffing is necessary to free the fibers from the fire.

However, even in this form the fibers quickly cake. Therefore, synthetic substances (sintepon) are added to them, which are responsible for the elasticity of the fabric and its volume. To combat putrefactive microflora, a heat treatment method is used, as a result of which all microorganisms die - the material becomes biologically pure. But this does not mean that flax will not begin to deteriorate over time. Two factors contribute to this:

- starch (an excellent base for the development of pathogenic microorganisms) - added to mats for gluing fiber;

- constant dampness in a room with flax insulation.

In addition, we should not forget about the high degree of flammability of flax fiber, which requires treatment of tapes, canvases and mats with fire retardants. These points need to be taken into account when purchasing linen insulation.

Is it really as environmentally friendly as they say?

The cost of flax insulation is very high. Therefore, to promote a product on the market, you need features that should stimulate sales growth. Among them is the absolute environmental friendliness of the product.

This advertising move is confirmed by the quality mark awarded by the EU Commission to environmentally friendly building materials. In this regard, we note that for the most part all construction products made from flax from Western companies have this mark. What about in Russia? After all, we buy mainly domestic products.

Let's try to find out whether linen insulation is really environmentally friendly. For analysis, it is necessary to know the composition of the insulation. And here questions arise. If boron salt was used as a fire retardant, and starch is the binder, then there is no doubt about the environmental friendliness of flax insulation.

But to improve consumer characteristics, chemical binders are increasingly being used instead of starch (in some brands up to 30%). In this case, there is no need to say that the products are natural, although manufacturers claim the opposite.

Fire flax as insulation

Linen insulation can be purchased on the Internet or a hardware store. Insulation of a house plays an important role in its arrangement. This stage is the determining factor in the comfort of your stay in the building. Therefore, more and more types of different insulation materials are appearing on the construction markets. One of these varieties is considered to be flax insulation. This material is made from natural plant fibers and is absolutely safe for health. Therefore, it is loved by most adherents of environmentally friendly products.

Advantages of flax insulation

Linen insulation is made from the plant of the same name - flax. It has a pleasant smell and will allow you to insulate your home without harming your health.

Linen insulation is a new generation of insulation. It does not require additional quality checks, as it is made from environmentally friendly ingredients.

Most modern insulation systems, one way or another, affect your health. For example, seemingly safe glass wool spreads small and sharp particles. They enter the lungs and can cause asthma attacks. It’s not worth even talking about polystyrene foam; this material releases toxins, which, according to unverified data, can lead to oncology.

Flax is devoid of all these shortcomings. But it has a number of advantages.

Among the advantages of flax insulation, it is worth noting good thermal insulation qualities and long service life

Advantages of linen insulation:

- Linen has antiseptic properties. Therefore, fungus and mold will never appear on walls that are insulated with this material.

- Insulation made from this material does not cause allergies, which is especially important if small children live in the house.

- The thermal insulation qualities of flax will not go away if it gets wet.

- Linen material does not have the ability to become electrified.

- The heat capacity of flax is high. In summer, it prevents heat from entering the house, and in winter, on the contrary, it retains heat.

- The sound insulation properties of linen material are at a high level.

- Linen slabs cannot harbor mice and rats. This is especially important for private houses.

- You can easily attach linen insulation to the walls. At the same time, it will not crumble and emit dust.

- Natural flax insulation prevents condensation from forming. This quality is especially important in the winter season.

- Linen insulation is made on a natural basis. Therefore, it does not emit substances hazardous to health and can be used to insulate internal walls.

- It has a very long service life. Manufacturers assure that it can be used for 75 years.

Ecolene is an excellent insulation material for insulating the interior walls of a house. Such thermal insulation will not make you worry about the health of your loved ones.

Disadvantages of linen insulation

Linen insulation has a lot of advantages. However, this fact does not detract from its shortcomings. In order not to regret your choice later, you also need to get acquainted with them.

The disadvantages of linen insulation are not so significant, however, it is precisely because of them that this wonderful material is still not very popular.

People do not always have the opportunity to insulate their homes with linen material. It's all about his shortcomings. Let's get acquainted with them.

Disadvantages of linen insulation:

- Linen insulation has a high price. It is more expensive than most other insulation materials.

- Also, many complain about the narrow range of use of such material. For example, they cannot be used to insulate roofs or be used for outdoor work.

- In combination with wooden walls, such insulation will quickly absorb moisture. Because of this, the material may begin to rot.

- When stretched, this type of insulation can tear.

- If linen insulation is used in rooms with high humidity, it will have to be treated with a special moisture-proof impregnation.

- Despite appropriate processing, flax insulation can become the main component of a fire in the event of a fire.

Linen insulation can be laid on any dry surface

Linen is a good material for insulation. Despite its shortcomings, it is considered one of the best options. Indeed, in most cases you will not have to deal with the disadvantages of flax.

Types of linen material

Linen has been used for making fabrics and clothing since ancient times. Previously, shirts, dresses, bags and other wardrobe items were made from it. Such clothes did not have a bad effect on the body and looked beautiful.

Taking advantage of the experience of our ancestors, modern people also began to sew linen clothes. And having noticed the unique properties of this fabric, they began to think about using it in construction. It turned out that flax not only retains heat, but also prevents heat from penetrating into the house. Few materials can boast such properties. Therefore, they began to make insulation from flax.

It may seem to you that the property of flax not to allow heat to pass through is an advertising campaign by manufacturers of linen insulation. To make sure that this is not the case, in the hottest weather you can wear a linen dress or a long-sleeved shirt (the linen should be thick enough), after walking for several hours, you will notice that you feel hotter in a regular T-shirt than in such clothes with a long sleeve. sleeve.

Linen insulation is produced in different variations. We are talking not only about the shape of the insulation, but also about its texture. Let's see what products are used to insulate houses.

Types of flax insulation:

- First of all, it’s worth talking about linen wall insulation. They can be sold in the form of mats, strips, rolls or slabs. Each of the options is quite convenient, and here the choice depends more on your preferences. Many people choose mats.

- There are also linen insulation materials for sealing cracks. This is flax tow and sanitary flax. Tow is quite narrow, but it rolls out well and is hammered into walls; it is used for insulating houses made of ordinary timber. Plumbing flax has different sizes and is used for buildings made of profiled timber and calibrated logs.

Source: https://vashslesar.ru/uteplenie/kostra-lna-kak-uteplitel.html

Advantages and disadvantages

All building materials have their advantages and disadvantages. Linen is no exception. According to reviews on the forums, the advantages of this type of insulation include:

- high thermal insulation properties - the thermal conductivity coefficient is only 0.03-0.040 W/(m*K), which is only slightly inferior to polyurethane foam, is on the same level as polystyrene foam and is superior to mineral wool;

- durability, confirmed by practice - the service life is 50-100 years (manufacturers indicate the figure 50, but in practice, when dismantling wooden buildings, linen insulation was in working condition for 75-100 years);

- vapor permeability, allowing the walls to “breathe”, removing excess moisture from the room to the street;

- increased hygroscopicity, which on the one hand is a negative property - it gets wet quickly, on the other hand, flax-based insulation, like wood, regulates the humidity regime in the room: when there is an excess, it absorbs steam molecules, when there is a deficiency, it releases, and dries very quickly. The big advantage of this property is that no vapor barrier is required. Consumers do not need to worry about frequent but short-term wetting of flax, because... after drying, all characteristics are fully restored. The only thing that can happen is darkening of the fibers;

- possibility of installation by surprise, without the use of glue and dowels. Such installation became possible after manufacturers began to make mats slightly larger in width and length (2.5 cm) than the standard dimensions of the lathing cells or the distance between the lags (beams);

- environmental safety, not only in relation to homeowners (not an allergen, does not emit harmful and toxic substances when heated and burning), but in general flax absorbs CO2 when grown, is completely decomposed, can be reused, and is a renewable resource;

- good soundproofing characteristics, but only sound waves traveling through the air are absorbed. Linen is practically useless against structural and impact noise;

- simple and safe installation - all work can be done with your own hands without the use of special clothing. The problem only arises if the mats need to be adjusted to size - flax fiber does not cut well.

Material characteristics

Linen insulation is made from natural raw materials - appropriately processed technical flax fibers. It is characterized by the following main parameters:

- Thermal conductivity determines the ability of a material to retain heat. The lower the indicator, the better the material. The thermal conductivity coefficient of linen insulation is about 0.038 W/mK. This is an analogue of mineral wool.

- Soundproofing. Sound absorption ability. Flax is superior to mineral wool by a third.

- Vapor permeability. The ability of insulation to remove water vapor and not accumulate moisture in its volume. This reduces the risk of mold and the development of harmful microorganisms. Breathable insulation helps create comfortable climatic conditions in the protected area.

- Fire resistance. Flax itself is highly flammable. As part of the insulation, it is impregnated with substances that stop combustion. The smoke released during smoldering does not contain toxic substances.

- Specific gravity. Based on the insulation model, it varies in the range of 15-85 kg/m3

Separately, it should be noted that the material is environmentally friendly. It is made from natural raw materials and uses a minimum of harmful substances during production. The design service life of the insulation is set at 75 years. It can be reused.

Types of insulation

The construction industry offers consumers several types of linen insulation:

- tow;

- felt (linen);

- batting (linen);

- mats (slabs).

Tow. Tow is a waste from the processing of flax and other bast crops (hemp, jute, etc.), resulting from the scutching process. Consists of coarse, short, tangled fibers, heavily contaminated by fire. It has been used in construction since the beginning of flax cultivation to produce textiles.

It is mainly used for inter-crown insulation of log houses. But it can be found in the openings of doors and windows (instead of polyurethane foam), as well as in the joints of slabs of the main insulation, for example, polystyrene foam.

Felt. The definition of “felt” has nothing to do with linen insulation, because the word arose to define a dense non-woven material made from wool. But manufacturers of a similar material made from flax fibers could not come up with an independent name for dense non-woven tapes. So they began to call their products linen felt.

The product is made from long fibers using needle-punched technology - this is when special barbed needles form a fabric, holding it together with its own fibers. Used as inter-crown linen insulation.

Batting. Batting is another type of non-woven fabric. It differs from felt in that nylon or cotton thread is used to hold the flax fiber layer together. It is used in the same way as felt, but with one difference: it is laid in two layers. This requirement is explained by production technology - the insulating tape has a low density. Total about 500 g/m2.

Mats. Insulating mats made from flax fiber are produced using starch, which serves as a binder between the fibers. In many industries, mats are additionally stitched with silk or cotton threads. Thermal insulation material is produced in the form of rolls and slabs 5 and 10 cm thick. It is used to insulate various building structures.

Attention: in materials about linen insulation, another type is called: flax-jute. However, using the term “flax-jute” to define insulation as an independent type consisting of a combination of flax and jute fibers is incorrect. It would be more correct to say that other types of bast crops can be added to flax fibers. After all, the so-called “flax-jute” insulation is produced in the form of felt, batting and mats. Therefore, it is impossible to say that this is an independent type of heat insulator.

Features of flax

Hundreds of years ago, plant fibers were used as inter-crown insulation in the construction of wooden houses and baths. Today this method is also in demand - in many places you can find a log house caulked with tow. The latter is nothing more than a product of secondary processing of flax.

Materials made from short plant fibers are also becoming popular. Such products are produced in the form of mats or rolls with a thickness of 50-100 mm, and their density varies from 25 to 50 kg/cube. m. Modern linen insulation is distinguished by high manufacturability, tape uniformity, eliminating the need for additional caulking, durability, and good thermal insulation properties.

The material is convenient for work - it is easily fixed by surprise due to its elasticity. Natural insulation does not have high fire-resistant properties, but this issue is solved by manufacturers in different ways - some add boron salts during production, others treat the finished surface with fire-retardant solutions or additives.

Installation

Installation of slabs begins with adjustment and measurements. The joining will be reliable if the width of the slabs is 10-20 mm greater than the distance between the beams and joists: then the material will fill the space and be securely fixed without fasteners, which will help to avoid gaps and deterioration of the insulation.

The insulation layer should not be interrupted in the area adjacent to the wall.

cutting

After measurements, the slabs are cut. By the way, cutting does not cause problems - the material does not break or crumble, maintaining clear edges. It is better to use special knives with wave sharpening, an electric hacksaw or a small band saw. An ordinary bread knife will also work if it does not bend and is thick enough, as well as a hand saw with fine teeth.

When the insulation is 5 cm thick, it can be cut with large sewing scissors. Cutting can also be done through packaging. If you decide to work with a power tool or a hacksaw, then the plates can be placed on a stand for convenience. For an even cut, the slab should be lightly pressed down with a board and cut along it.

Criteria for choosing linen insulation

When choosing the optimal insulation, you must rely on several criteria. First, you need to take into account factors indicating the quality of the product. Secondly, you should select the type of material that will suit your needs. Features of choosing flax insulation:

- The main indicator of quality is the availability of certificates of compliance with sanitary and epidemiological requirements. Ask the seller to provide you with all necessary documentation.

- The color of linen insulation ranges from gray-greenish to brown.

- The structure of a high-quality heat insulator is strong and elastic, and does not crumble.

- Pay attention to the packaging of the material - it must be intact so that direct rays of the sun and moisture do not fall on the insulation.

- A universal flax insulation material is considered to be a material based on short fiber and tow. It is cleared of impurities and fractions. The presence of a large number of impurities significantly impairs the thermal insulation qualities and strength.

- If you plan to insulate a house made of profiled timber, then choose a heat insulator 2-3 millimeters thick and with a density of up to 300 grams per cubic meter. For insulating a house made of rounded logs, material up to five millimeters thick and with a density of 500 grams per cubic meter is suitable. Buildings made of timber must be insulated with insulation up to 10 millimeters thick and with a density of up to 800 grams per cubic meter.

- Linen wool is convenient to use for insulating walls, ceilings, roofs, floors, and ceilings. Tow is suitable for sealing roof gaps and cracks in openings. Choose felt if you need to insulate a house made of profiled timber or calibrated logs.

Problems and prospects of linen thermal insulation

The quality of linen insulation is influenced by many factors that have nothing to do with the integrity of the manufacturer. This is a real problem in the green building materials industry. Thanks to its environmental image and appearance, flax will always have success in the market, fueled by its relative scarcity due to weak harvests and numerous myths about the antiseptic properties and durability of the material.

The industry needs further research and application of new technological solutions. In the end, there is still no uniform quality control for bast fibers, which allows manufacturers to bring “whatever” to the market.

Price and manufacturers of flax insulation

There are many manufacturers of flax-based thermal insulators both in Russia and in neighboring countries. Give preference only to those that have proven themselves and have positive reviews. Among them are the following companies:

- HORSE

. Russian company producing flax insulation. As a rule, it specializes in the production of slabs. It grows raw materials on its own plots and uses innovative technologies in its work. It produces linen boards under the Ecoteplin brand. This is a universal heat insulator. There are also specialized products - “RosEcoMat Wall”, “RosEcoMat Roofing”, “RosEcoMat Floor” and other names. The average price is 5,500 rubles per cubic meter. - Artemis

. A new Russian company that produces Val Flax linen boards using German equipment. In addition to flax, they contain a semi-synthetic fastening component. The price of the package is about 1200 rubles. - Isolina

. Company from Finland. Works in collaboration with the research center, constantly improving the technical characteristics of products. It produces all types of inter-crown and tile insulation based on flax. The price per cubic meter is on average from 4,500 rubles.

Advantages and disadvantages

The growing popularity of linen thermal insulation boards is easily explained, because they have many advantages:

- safety, environmental friendliness, absence of allergies among residents;

- excellent heat-insulating and sound-proofing abilities;

- resistance to the appearance of harmful microbes, natural antiseptic properties;

- resistance to deformation, temperature shifts;

- durability, absence of subsidence, destruction and dust release - you do not have to regularly change the insulation on the walls or roof;

- light weight - does not put a load on the structure;

- non-electrostatic – flax removes electrical charge;

- ease of operation (even a beginner can handle it);

- variety of species.

Important! The disadvantages include the high price of the material, as well as the fact that birds love it - you will have to act faster to immediately complete the finishing.

Brief instructions for installing linen insulation

Working with natural insulation is very simple. The tools you will need are scissors, a knife, and brackets for fastening. We carry out installation according to the following scheme:

- We take measurements if tile or roll material is used. If you plan to install it on a horizontal surface, then you do not need to use fasteners.

- If you need to cut the insulation, take a regular knife or scissors. In this case, it is not even necessary to first take it out of the packaging.

- If you are insulating a wooden building during the construction process, then we cut the material into strips of the required length and width and lay it between the logs. We join the tapes and fasten them with staples.

- If you are insulating the joints of an already constructed building, you should use a chisel to push the tow or tape deep into the inter-crown space.

- Plates and sheets of linen thermal insulation are perfectly fixed even without fasteners. To do this, we install them spaced between the rafters or joists.

- If the surface has a slope, then we additionally equip the sheathing to allow moisture to erode out.

- If the building will be exposed to moisture, it is recommended to protect the insulation with a vapor-permeable membrane. We overlap it by 10 centimeters and seal the joints with tape.

Watch a video review of flax insulation:

Linen insulation is excellent for insulating so-called “green” or “eco” houses built of wood. They are environmentally friendly, have good technical characteristics and are durable. Also, flax-based tile material is used for insulation of ordinary brick and concrete buildings.

Insulation of the floor with linen underlay.

This is perhaps the easiest way to insulate. The underlay is laid on a subfloor, concrete or wood, and a finished floor (parquet board, laminite, or carpet) is mounted on top. Linen underlay is ideal as insulation for floors under linoleum. It resists the cold quite effectively, eliminating the discomfort of a cold floor. The linen backing has the highest heat and sound insulation characteristics in its class.

In terms of thermal insulation indicators, it is 4 times superior to cork substrate, and in its efficiency it is second only to heated floors, which consume a lot of energy resources.

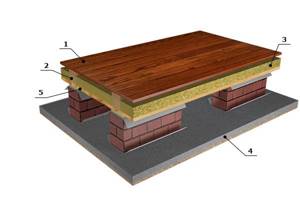

Floor insulation using joists

The most common, simple, and effective method is to insulate the floor using joists. It applies to both floors on the ground and those built on concrete slabs.

Insulation of floors using joists on the ground

Thermal insulation work begins with soil compaction. Then they make a backfill of crushed stone. Next, brick columns are installed in increments of 2 * 0.5 m. Waterproofing is laid on the columns, then wooden logs. Optimally, a log section of 120, 150 or 200 x 50 mm is sufficient. At the bottom of the joists, support bars are placed on the sides, on which a roll of boards or OSB boards is laid. The insulation is placed between the joists.

Method 1 Insulation with Zhivaizol construction insulation. The floor insulation is laid between the joists, on a wooden slab, in two layers, 100 mm high, with overlapping seams. Inter-crown insulation is laid on top of the floor beams before the floor is installed, which significantly reduces creaking.

Method 2 Insulation with flax fiber. The fiber is developed manually and laid between the logs on a wooden roll, to the entire height of the beam, at the rate of 8 kg of fiber per 1 sq.m., with a beam height of 200 mm. Inter-crown insulation is laid on top of the floor joists, before installing the subfloor, to reduce squeaks. The advantage of this method of insulation, along with high environmental friendliness and durability, is the price.

Buy flax fire in Kyiv, prices, photos

The result of processing bast crops, in particular flax, is long and short flax fibers, and the process itself is accompanied by the formation of fires - waste from the woody part of flax stems.

Flax flax consists of wood particles 1-10 mm long and 0.3-1.5 mm thick.

Being a waste product of primary processing, firewood has found wide application both as a separate finished product and as a raw material for further production of products.

Where is flax fire used?

- Insulation of floors and attics. It should be noted that as a fire insulation it has a number of positive qualities: natural material, low thermal conductivity.

- Kostra serves as a raw material for the production of pressed slabs (kostroplits), which are widely used in construction as a heat and sound insulating material, and in the furniture industry. The strength and rigidity indicators of such boards practically correspond to those of similar products made from coniferous wood, and in terms of shrinkage and warping properties they are superior.

- Pellets from fires are a source of fuel that does not lose its relevance among segments of the fuel market.

- Shredded to 2 mm, kernels are used as a component in the production of cardboard.

- Kostya is used as insulation in agricultural greenhouses, retaining moisture and heat in them.

The company, a manufacturer of inter-crown insulation made from natural flax fibers, offers flax fire for sale at an affordable price.

For questions regarding delivery, payment or performance properties of products, you can contact our company’s specialists

Ukrainian language story - go

Construction tow is a coarse, short, tangled fiber, a waste product from the primary processing of flax and other bast crops. Such fiber is unsuitable for spinning and is heavily contaminated by fire.

Construction tow is a traditional material that has proven itself in construction. Tow has long been used to insulate wooden houses as a heat-insulating material. Despite the development and creation of modern inter-crown insulation, tow continues to be in demand and is widely used in construction for insulating wooden and panel houses, in particular for sealing the distances between the crowns of wooden log houses, sealing wooden and window blocks, filling voids, and air conditioning ducts.

Construction tow is a good option for caulking a wooden house. Thanks to high-quality caulk work, wooden houses retain heat and sound insulation better. In cases where the house is built from rounded logs or profiled timber, it is better to use tape inter-crown insulation, since it compacts evenly.

Construction tow consists of fibers from bast crops; accordingly, flax tow is made from flax fibers. As a rule, construction tow is made from flax fiber No. 2 - No. 4. The number corresponds to the length of the fibers. Such fibers are not suitable for spinning. Natural fibers are combed using a carding machine, and are additionally cleaned from brome, which is the wood of the flax stem. The quality of the material depends on the length of the fibers and the degree of their purification.

The advantages of construction tow over polyurethane foam is, first of all, that it does not glue adjacent surfaces and, accordingly, prevents possible shrinkage of buildings in the future.

The material has all the advantages of flax:

- prevents the occurrence of fungi;

- has bactericidal properties;

- tow is very durable;

- no static electricity charges arise on flax fibers;

- Construction tow does not contain any hazardous or harmful components to human health, unlike mineral insulation materials.

During storage, moths do not attack tow, the material does not weather or crumble.

Source: https://mezhventsovuy.com.ua/kostra-lna.html

Rules for choosing linen insulation

The main criterion for choosing linen insulation is its quality, which in turn is determined by the following parameters:

- Raw materials

. The best option would be to use a material that is made from short fibers and flax tows, obtained by combing long flax fibers. Such processing of raw materials helps remove excess impurities. A large number of them worsens the appearance of products and creates obstacles to achieving the optimal density of the material. In addition, the presence of impurities leads to the destruction of thermal insulation over time. - Density and thickness of insulation

. Their ratio must be taken into account depending on the area of application of linen thermal insulation. For a log house made of profiled timber, in which the crown joints are made with high precision, a material with a density of 250-300 g/m2 and a thickness of 2-3 mm is suitable. If rounded logs are used for walls, these figures increase respectively to 500 g/m2 and 4-5 mm. To insulate houses made from ordinary timber, insulation with a density of 700-800 g/m2 and a thickness of 8-10 mm is used - Uniformity of material density

. It should not be more than 10%. Otherwise, the compaction of the cracks between the beams or logs in the log house will be uneven.

The most popular manufacturers of linen thermal insulation are two companies:

- Ecotherm (Belarus)

. Ecoterm universal linen insulation is suitable for almost all structures, with the exception of its use as thermal insulation for cement screed. The material is produced in slabs that are quite elastic. Fitting tightly to the base, they provide it with excellent insulation. The size of the slabs is 1200x600x50 mm, there are 12 pieces in a package, which corresponds to 8.64 m2 of coverage. Price per package - 1700 rubles. - ThermoLEN (Russia)

. This brand produces linen insulation in the form of slabs and rolls. Pack of 9 pcs. slabs Rolled inter-crown insulation ThermoLEN does not contain toxic impurities, it is environmentally friendly and can be used for insulation of frame houses.

How to choose high-quality flax-based insulation

Here are the criteria by which the quality of linen insulation should be assessed:

- Raw materials. The most acceptable option is short fiber No. 2-6 plus flax toils after using a carding machine. Any impurities, for example, sackcloth or nylon, over time lead to the destruction of thermal insulation, a decrease in density, and deterioration in appearance.

- The density of flax insulation - the denser the material, the better the quality . Experts also take into account the ratio of density and thickness of the insulating layer. Please note the indicators given in the table are acceptable for different types of houses.

| House type | Insulation thickness | Insulation density |

| from profiled timber | from 2 to 3 mm | 250-300 g/m² |

| from rounded logs | from 4 to 5 mm | 500 g/m² |

| timber house | from 8 to 10 mm | 700-800 g/m² |

- To properly seal the cracks, it is necessary to maintain uniform density of the layer. The parameter should not exceed 10%.

When it comes to choosing between different types of linen insulation, we recommend understanding their differences based on your needs. Thus, the dimensions of tow cannot exceed 15 cm in width, but it is loose and flexible, pliable for manual manipulation: it can be crushed, stretched, compressed. Linen batting is more expensive than tow , but there is a large selection of tape widths, and this flax-based material is universally suitable for any type of wooden house. If you choose modern Ecoterm, you will receive a material that is easy to install and resistant to deformation , but its cost is higher than its analogues.

Useful: House insulation with Ecowool: blowing methods, cost, pros and cons

Which one to choose?

When purchasing warm clothes, you need to imagine the properties of their insulation. In addition, it is important to know how long it will last and what problems you may encounter during operation.

Sintepon

sintepon-1

sintepon-2

Lightweight, voluminous, inexpensive material for many years was the only synthetic insulation for winter and demi-season items. It is made from polyester fibers in two ways: by gluing the fibers or by heat sealing. The first method produces a non-ecological product, while the second produces a short-lived product. Sintepon is 4 times thicker than Isosoft, loses volume after washing, and quickly falls off. In addition, the body in synthetic clothing does not breathe, outer clothing does not retain its heat. It is not suitable for severe frosts.

Thinsulate

thinsulate-1

thinsulate-2

The warmest and most expensive synthetic material. Its structure consists of extremely thin fibers. When creating Thinsulate, American scientists tried to replicate the design of the best down of the northernmost duck - the eider. The resulting insulation surpassed the natural original. Thinsulate is 1.5 times warmer than natural down. Thin, flexible, lightweight material is used to make not only suits for extreme professions - astronauts or polar explorers. It makes wonderful fashionable clothes. Thinsulate has a three-dimensional fiber configuration, it quickly restores its shape and does not deform when washed. This is the only synthetic material that can withstand machine washing at 400C and spinning at 1000 rpm.

Holofiber

hollofayber-1

hollofayber-2

This patented trademark is essentially a type of padding polyester, but differs from the latter in its excellent consumer characteristics. Holofiber insulation provides warmth at air temperatures down to -25°C. It is environmentally friendly, has low density and light weight. It holds its shape well, but is slightly flexible. It is suitable for sewing sportswear, but it is unlikely to make a fashion item. All characteristics are similar to Isosoft, but differ from it in lower cost.

Goose down

gusini-puh-1

gusini-puh-2

In terms of heat-protective properties, this insulation is close to Isosoft, but it belongs to natural materials. Down fibers are extremely mobile relative to each other. This causes difficulties when washing and drying. The down filling absorbs moisture, and in humid weather it becomes heavier and does not warm well. In addition, natural material can become a breeding ground for mites and cause an allergic reaction.