There are a lot of misconceptions circulating among people. In this review I will destroy one of the established myths. In the future, People's Windows will write more than one article on the topic of deception and dirty marketing. Now let's go.

When I start talking about insulating balconies and loggias, we often talk about foil penofol. Penofol is an elastic technical insulation in rolls.

It is a layer of foamed cellophane (polyethylene) with a silver film pasted over it. Available in different thicknesses from 1.5 to 12 mm. Rarely found on a self-adhesive basis.

One of the cooperators mistakenly called the silver layer foil. Then a rumor appeared that it was reflecting part of the spectrum back to the territory of the loggia. This preserves the heat inside the loggia and increases the efficiency of the insulation.

All these reviews are insanity. Let's sort it out in order. The first part of the misconception is that a layer of foil is glued to the insulation.

As we know, metal is opaque (does not allow sunlight to pass through). If we look through the thin foil from a chocolate bar at a light bulb, we will not see anything.

If we tear off the top layer of penofol and look at the light, we will find that it is not metal. This material is nothing more than wrapping paper for bouquets.

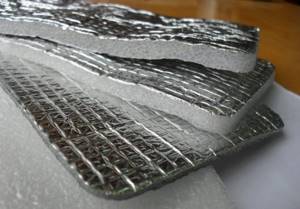

Here's another piece of evidence. This is a photo of a heated floor on a balcony.

From below, penofol is used as a substrate. The lower part of the heated floor consists of two copper bars. Plus and minus are the black graphite plates themselves.

If it really were foil, then the + and – would be immediately short-circuited. Such a balcony would burn down.

This once again proves that the coating has nothing close to metal.

The next thought is that penofol reflects the radiation that hits it and miraculously heats the room.

Penofol is attached to the floor or walls. If the wall cladding is made of plastic panels, then there is a chance that a hundredth of the light will reach there. If the wall cladding is made of clapboard, light will not reach the insulation. I’m already silent about the floor - there’s plywood, linoleum, laminate and no light gets there either.

If light does not hit the penofol, therefore, it cannot reflect anything. Because he has nothing to reflect.

If we talk about the role of penofol on the balcony, then its main merit is that it can be laid in the corners and covered with tape.

And eliminate the possibility of drafts on the loggias. This is the only purpose of using penofol on the balcony.

In the afterword, I’ll note that foil is found on foam foil. However, such material does not shine and is expensive. For this reason, it is the shiny fake that is praised on every corner. Attributing wonderful properties to it.

This is how the review turned out. I hope it was interesting for you.

When carrying out major renovations of premises, one of the most pressing issues is the issue of sufficient thermal insulation. As a rule, heating devices do not cope with the task; huge interpanel seams allow cold, noise, and moisture to pass through, which over time deteriorate the condition of the room. To protect your home from cold, noise, and high humidity, you need to purchase high-quality insulation.

Main characteristics of insulation

Let us first provide the characteristics of the most popular thermal insulation materials, which you should first pay attention to when choosing. Comparison of thermal conductivity insulation should be made only on the basis of the purpose of the materials and room conditions (humidity, presence of open fire, etc.). We have further arranged in order of importance the main characteristics of insulation.

Comparison of building materials

Thermal conductivity . The lower this indicator, the less thermal insulation layer is required, which means that insulation costs will also be reduced.

Moisture permeability . The lower permeability of the material to moisture vapor reduces the negative impact on the insulation during operation.

Fire safety . Thermal insulation should not burn or emit toxic gases, especially when insulating a boiler room or chimney.

Durability . The longer the service life, the cheaper it will cost you during operation, since it will not require frequent replacement.

Environmental friendliness . The material must be safe for humans and the environment.

Comparison of insulation materials by thermal conductivity

Economical . The material must be accessible to a wide range of consumers and have an optimal price/quality ratio.

Easy to install . This property for a thermal insulation material is very important for those who want to make repairs themselves.

Thickness and weight of the material . The thinner and lighter the insulation, the less heavy the structure will be when installing thermal insulation.

Soundproofing . The higher the sound insulation value of the material, the better the protection in the living room from extraneous noise from the street.

Properties of foil penofol

Despite the fact that the material is new, its properties have been used for a long time. Penofol was first used in America in the manufacture of spacesuits for astronauts. Later, Russia found the use of penofol as a building material.

The principle of operation of the material can be compared to a thermos

. It keeps the house warm in the winter and keeps the heat out in the summer. Penofol does not retain heat or coolness, it reflects them. This is a multilayer material that consists of foamed polyethylene, which has many pores filled with air. Covered on both sides with a layer of reflective foil. Sealed pores prevent heat transfer, and the foil reflects heat. The thickness of polyethylene foam is from 3 to 15 mm, there are types up to 40 mm thick. The polyethylene layer is connected to the foil using heat treatment. In addition to the function of heat reflection, penofol performs soundproofing and vapor barrier functions.

Comparison of insulation materials by thermal conductivity

Expanded polystyrene (foam)

Expanded polystyrene (foam) slabs

This is the most popular thermal insulation material in Russia, due to its low thermal conductivity, low cost and ease of installation. Polystyrene foam is produced in slabs with a thickness of 20 to 150 mm by foaming polystyrene and consists of 99% air. The material has different densities, has low thermal conductivity and is resistant to humidity.

Due to its low cost, expanded polystyrene is in great demand among companies and private developers for insulating various premises. But the material is quite fragile and ignites quickly, releasing toxic substances when burned. Because of this, it is preferable to use polystyrene foam in non-residential premises and for thermal insulation of non-loaded structures - insulation of facades under plaster, basement walls, etc.

Extruded polystyrene foam

Penoplex (extruded polystyrene foam)

Extrusion (technoplex, penoplex, etc.) is not exposed to moisture and rotting. This is a very durable and easy-to-use material that can be easily cut with a knife to the desired size. Low water absorption ensures minimal changes in properties at high humidity; the slabs have high density and compression resistance. Extruded polystyrene foam is fireproof, durable and easy to use.

All these characteristics, along with low thermal conductivity in comparison with other insulation materials, make Technoplex, URSA XPS or Penoplex slabs an ideal material for insulating strip foundations of houses and blind areas. According to the manufacturers, an extrusion sheet 50 millimeters thick replaces 60 mm of foam block in terms of thermal conductivity, while the material does not allow moisture to pass through and you can do without additional waterproofing.

Mineral wool

Izover mineral wool slabs in packaging

Mineral wool (for example, Izover, URSA, Tekhnoruf, etc.) is produced from natural materials - slag, rocks and dolomite using special technology. Mineral wool has low thermal conductivity and is absolutely fireproof. The material is produced in slabs and rolls of varying hardness. Less dense mats are used for horizontal planes; rigid and semi-rigid slabs are used for vertical structures.

However, one of the significant disadvantages of this insulation, like basalt wool, is low moisture resistance, which requires additional moisture and vapor barrier installations when installing mineral wool. Experts do not recommend using mineral wool for insulation of wet rooms - basements of houses and cellars, for thermal insulation of steam rooms from the inside in baths and dressing rooms. But even here it can be used with proper waterproofing.

Basalt wool

Rockwool basalt wool slabs in packaging

This material is produced by melting basalt rocks and blowing the molten mass with the addition of various components to obtain a fibrous structure with water-repellent properties. The material is non-flammable, safe for human health, and has good thermal insulation and sound insulation properties. It is used for both internal and external thermal insulation.

When installing basalt wool, you should use protective equipment (gloves, a respirator and goggles) to protect the mucous membranes from cotton wool microparticles. The most famous brand of basalt wool in Russia is materials under the Rockwool brand. During operation, the thermal insulation slabs do not compact or cake, which means that the excellent properties of low thermal conductivity of basalt wool remain unchanged over time.

Penofol, isolon (foamed polyethylene)

Penofol and isolon are roll insulation materials with a thickness of 2 to 10 mm, consisting of polyethylene foam. The material is also available with a layer of foil on one side to create a reflective effect. The insulation is several times thinner than previously presented insulation materials, but at the same time retains and reflects up to 97% of thermal energy. Foamed polyethylene has a long service life and is environmentally friendly.

Isolon and foil penofol are lightweight, thin and very easy to use thermal insulation materials. Roll insulation is used for thermal insulation of wet rooms, for example, when insulating balconies and loggias in apartments. Also, the use of this insulation will help you save useful space in the room when insulating inside. Read more about these materials in the section “Organic thermal insulation”.

Scope of application

The material reflects 97% of heat when installed behind a radiator

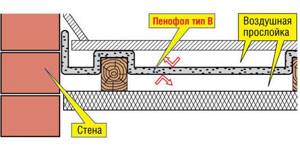

Penofol can be used as primary or additional reflective thermal insulation. As the main material, it is used to insulate walls from the inside, and in wooden houses for heated floors.

The material is used as additional thermal insulation in the design of residential and industrial premises.

The use of Penofol allows you to simultaneously solve several issues:

- reflection of dissipated heat;

- waterproofing;

- vapor barrier.

The material can be used not only for interior work - the insulation is also effective for insulating the walls of a house outside.

The scope of application of penofol extends not only to internal insulation, but also external. This type of insulation is also used for thermal insulation of residential premises, civil and industrial production:

- country house or apartment in a multi-storey building;

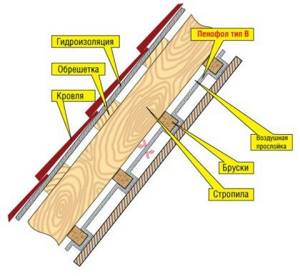

- roof;

- ceiling coverings;

- attics and attics;

- basement and basement structures.

- underfloor heating system (water, electric) and roof insulation;

- building facades;

- water and air pipes;

- insulation of refrigeration structures;

- ventilation and air duct system.

Sometimes the wall where the battery is located is covered with foil material. This is done so that the heat is not absorbed by the wall, but goes inside the room.

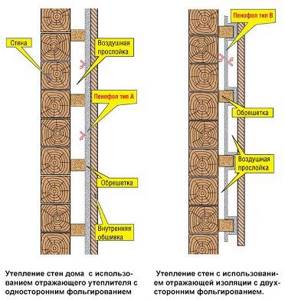

For domestic needs, three types of penofol are used: A, B, C. The scope of application of this material as a heat-insulating building material is very extensive: walls, ceilings, floors, insulation of concrete surfaces, loggias, insulation of wooden and frame buildings.

You can easily do the installation of penofol with your own hands without the involvement of specialists, the main thing is that the safety instructions are followed.

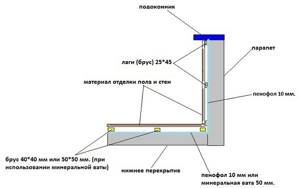

On the floor

Before you begin fixing the insulation, you need to prepare the base of the floor with a concrete screed. For this purpose, a liquid cement solution is used, which is poured onto the surface and leveled.

The following actions are related to the selected type of penofol:

- If type A penofol is used, then a fixing adhesive is applied to the foam in an even layer, after which the penofol is fixed.

- If type C foil material is used, then no adhesive is applied. This type of material is already equipped with an adhesive solution on the back of the building material. To prevent the waterproof adhesive solution from drying out prematurely, it must be covered with polyethylene. Before starting work, the plastic film is carefully removed, and then the foil material is laid out on the foam.

We suggest you familiarize yourself with what is better to build a bathhouse from, what material is cheaper

. The building material is laid in such a way that the foil overlaps the walls (about 5 cm), and the resulting joints are glued with aluminum insulating tape.

When installing a heated floor system, there are 2 main types of installation: the use of logs or concrete screed. Logs are used if a wooden floor will be installed on top of the insulation. In this case, wooden logs are installed along the floor on top of the heating elements.

The horizontal position of the beams must be controlled using a building level. Then a wooden covering is mounted on top of the logs. Thus, the foil material will heat up and transfer heat from below to the wooden coverings.

The second variation is to install a warm floor system under the tiles. In this case, the special heating elements are covered with reinforced mesh and filled with concrete mixture. For this type of installation it is necessary to use penofol type ALP.

For walls

To insulate internal walls, type B foil material is used. Its installation is more complex than other types of penofol, but this insulating material can create the most effective thermal insulation of a room.

Material with double-sided metal special coating is mounted as follows:

- Using dowels, you need to secure the bars to the concrete wall (thickness 1-2 cm).

- A layer of type B penofol is mounted on them using screws or mounting brackets.

- A plasterboard product is laid on top of the insulating building material, which is fixed to the slats with self-tapping screws. To leave gaps for ventilation, wooden blocks are installed on top of the insulating material, the thickness of which is similar to the previous slats. Then the drywall is fixed.

To avoid drafts, the joints of the foil product must be taped with damper tape. Instead, you can use penofol, which is cut into strips of the required width.

For the ceiling

Insulation of indoor ceilings begins with fixing a thin layer of foil material onto the base coating. Wooden slats are screwed onto the primary insulating layer, which act as a frame for the main insulating building material. The main thermal insulation layer is fixed on top of the slats using a construction stapler or screws. If it is necessary to install a third layer of insulation, then its installation is carried out similarly to the previous variation.

After carefully studying the technology for insulating ceilings, walls and floors, performing thermal insulation in rooms such as a balcony will not cause difficulties. In this case, the material must be laid on the rafters, and fastening must be done using staples. The main thing is that the insulating material for the balcony does not have much weight, otherwise an accident may occur.

The technology for installing penofol is no different from other types of insulation. But it is necessary to take into account the fact that fixing penofol to wooden surfaces both outside and inside is carried out only in the summer, and it is advisable that several hot days pass before starting work.

Comparison of insulation materials. Thermal conductivity table

Comparison of foam block, mineral wool and polystyrene foam by thermal conductivity

The table above comparing thermal insulation by thermal conductivity gives a complete picture of which material is best to use. All that remains is to compare the data from the thermal conductivity table with the cost of thermal insulation from suppliers. In this case, it is necessary to accurately calculate the required thickness of insulation when using various materials in order to select the required amount of material.

The use of penofol for insulating walls outside

Professionals believe that the external method of thermal insulation is much more effective than the internal one. External insulation is recommended if the house is wooden. For outdoor work, use perforated penofol. It will protect the room from wind and precipitation.

You can use external insulation of the house if you don’t want to start repair work inside or disturb the situation.

Penofol is placed between the building cladding and the wall. This type of work is performed in the warm season. The walls must be dry, temperature changes are insignificant.

Instructions for performing work

.

- Remove wall coverings. Treat the surface with an antiseptic. Pay special attention to the corners, the bottom of the wall - places that freeze more strongly, where mold and mildew most often form.

- We make a wooden frame, which we attach to the surface using self-tapping screws.

- We arrange the foil penofol, not forgetting to leave an air gap.

- Seal the joints with aluminum adhesive tape.

- After this, proceed to the installation of the outer frame for cladding the walls of the building with siding, corrugated sheets, and metal profiles.

Foil penofol can solve several problems

straightaway. It will protect your home from cold, moisture, extraneous noise, and keep you cool in the summer. At the same time, you will save on the amount of material, cost, at least reduce the internal space of the room, and install reflective, heat-insulating material without much effort and expense. By giving preference to foil penofol, you will never regret it, and the result of the work will delight you for a long time.

Properties of foil penofol

Penofol, which has no competitors, has excellent characteristics. Its flexibility allows it to fit perfectly on any surface. Among the variety of modern materials, penofol has gained the highest popularity. Penofol, like any building material, has its pros and cons. In this article we will analyze the advantages and disadvantages of penofol and its scope of application.

When renovating or building a house, almost all surfaces are finished: ceilings, floors, interior and exterior walls. This, as a rule, is the insulation of surfaces, as well as their steam, sound and waterproofing. But, if “sound” and “steam” don’t particularly bother developers, then everyone thinks about heat.

Construction markets offer a huge range of thermal insulation materials, the use of which is determined by their technical characteristics. A new material - penofol - appeared relatively recently. Let's try to understand whether it makes sense to give preference to this particular material.

Main characteristics of insulation

Let us first provide the characteristics of the most popular thermal insulation materials, which you should first pay attention to when choosing. Comparison of thermal conductivity insulation should be made only on the basis of the purpose of the materials and room conditions (humidity, presence of open fire, etc.). We have further arranged in order of importance the main characteristics of insulation.

Comparison of building materials

Thermal conductivity . The lower this indicator, the less thermal insulation layer is required, which means that insulation costs will also be reduced.

Conclusion

The optimal choice for insulating a balcony or loggia is penoplex. Mineral wool will allow you to get a comfortable room in terms of heat and sound insulation, but it is a more expensive material. If the balcony does not have high sound insulation requirements, then cheap polystyrene foam can be used to insulate it. The use of penofol and isofol in the combined insulation of a loggia will achieve the best results.

The correct choice of thermal insulation materials is the key to high-quality insulation and long service life of a balcony room as an additional living room.

Comparison of insulation materials by thermal conductivity

Expanded polystyrene (foam)

Expanded polystyrene (foam) slabs

This is the most popular thermal insulation material in Russia, due to its low thermal conductivity, low cost and ease of installation. Polystyrene foam is produced in slabs with a thickness of 20 to 150 mm by foaming polystyrene and consists of 99% air. The material has different densities, has low thermal conductivity and is resistant to humidity.

Due to its low cost, expanded polystyrene is in great demand among companies and private developers for insulating various premises. But the material is quite fragile and ignites quickly, releasing toxic substances when burned. Because of this, it is preferable to use polystyrene foam in non-residential premises and for thermal insulation of non-loaded structures - insulation of facades under plaster, basement walls, etc.

Extruded polystyrene foam

Penoplex (extruded polystyrene foam)

Extrusion (technoplex, penoplex, etc.) is not exposed to moisture and rotting. This is a very durable and easy-to-use material that can be easily cut with a knife to the desired size. Low water absorption ensures minimal changes in properties at high humidity; the slabs have high density and compression resistance. Extruded polystyrene foam is fireproof, durable and easy to use.

All these characteristics, along with low thermal conductivity in comparison with other insulation materials, make Technoplex, URSA XPS or Penoplex slabs an ideal material for insulating strip foundations of houses and blind areas. According to the manufacturers, an extrusion sheet 50 millimeters thick replaces 60 mm of foam block in terms of thermal conductivity, while the material does not allow moisture to pass through and you can do without additional waterproofing.

Mineral wool

Izover mineral wool slabs in packaging

Mineral wool (for example, Izover, URSA, Tekhnoruf, etc.) is produced from natural materials - slag, rocks and dolomite using special technology. Mineral wool has low thermal conductivity and is absolutely fireproof. The material is produced in slabs and rolls of varying hardness. Less dense mats are used for horizontal planes; rigid and semi-rigid slabs are used for vertical structures.

However, one of the significant disadvantages of this insulation, like basalt wool, is low moisture resistance, which requires additional moisture and vapor barrier installations when installing mineral wool. Experts do not recommend using mineral wool for insulation of wet rooms - basements of houses and cellars, for thermal insulation of steam rooms from the inside in baths and dressing rooms. But even here it can be used with proper waterproofing.

Basalt wool

Rockwool basalt wool slabs in packaging

This material is produced by melting basalt rocks and blowing the molten mass with the addition of various components to obtain a fibrous structure with water-repellent properties. The material is non-flammable, safe for human health, and has good thermal insulation and sound insulation properties. It is used for both internal and external thermal insulation.

When installing basalt wool, you should use protective equipment (gloves, a respirator and goggles) to protect the mucous membranes from cotton wool microparticles. The most famous brand of basalt wool in Russia is materials under the Rockwool brand. During operation, the thermal insulation slabs do not compact or cake, which means that the excellent properties of low thermal conductivity of basalt wool remain unchanged over time.

Penofol, isolon (foamed polyethylene)

Penofol and isolon are roll insulation materials with a thickness of 2 to 10 mm, consisting of polyethylene foam. The material is also available with a layer of foil on one side to create a reflective effect. The insulation is several times thinner than previously presented insulation materials, but at the same time retains and reflects up to 97% of thermal energy. Foamed polyethylene has a long service life and is environmentally friendly.

Isolon and foil penofol are lightweight, thin and very easy to use thermal insulation materials. Roll insulation is used for thermal insulation of wet rooms, for example, when insulating balconies and loggias in apartments. Also, the use of this insulation will help you save useful space in the room when insulating inside. Read more about these materials in the section “Organic thermal insulation”.

Insulation of walls and floors of premises, balconies and loggias

You only need to seal penofol with aluminum tape.

Modern insulating materials make it possible, with even a little experience, to insulate a room or balcony with your own hands. It is used as an additional one - the main insulation of a room or balcony is performed with penoplex.

Before attaching Penofol, all cracks or gaps must be filled with polyurethane foam.

In the same way, using Penoplex and Penofol together, they insulate the loggia.

We suggest you familiarize yourself with the correct installation of vapor barrier to insulation

Insulation scheme for a room or balcony:

- Level and prime the surface.

- Attach foam insulating panels.

- Attach Penofol strips with the reflective side to the room.

Penofol strips are tightly joined together and sealed with aluminum tape.

To complete the finishing of the walls, you will need a frame for plasterboard or plastic panels. When insulating the floor, a reinforcing layer is made and filled with screed.

Under heated floor

To avoid damaging the penofol, a reinforced mesh is placed under the screed

Warm floors, water or electric, require mandatory thermal insulation. Penofol is considered the most popular material. It is laid directly on the ceiling with the foil side up. The thickness of Penofol under a warm floor is chosen so as not to raise the surface too much.

Inside a wooden house, it is effective to use foil insulation Penofol for walls in all rooms. When installed on walls or ceilings, it is placed between two layers of sheathing made of beams, at a distance of 2 cm from each. You can fasten it with a furniture stapler or small nails. The insulation is fixed to the sheathing joint to joint. The joint line is additionally insulated with aluminum tape.

The lathing is needed to attach drywall so as not to damage the penofol

The internal sheathing is used to fasten panels or sheet materials that will be painted or wallpapered.

Penofol is not used to insulate the facade of wooden houses - the material “does not breathe”, and the wood will collapse due to accumulated moisture.

The use of all-foam polyethylene in wooden houses and outbuildings has another advantage - due to its small thickness, rodents do not live in it. There is such a problem when using polystyrene foam or mineral wool.

What is penofol

The material belongs to a new generation of ultra-thin polymer insulation, manufactured using foaming technology. In this case, we are dealing with polyethylene foam welded to a layer of reflective aluminum foil.

Thanks to the manufacturing technology, the small pores inside the penofol have a closed structure, which is why the insulation practically does not allow water vapor to pass through. According to the manufacturers, the foil layer is designed to reflect the flow of infrared heat coming from inside the premises. There are 3 main types of penofol:

- with one layer of heat-reflecting foil (type A);

- the foil is welded to the insulation on both sides (type B);

- on one side of the material there is foil, on the other there is an adhesive layer (type C).

Note. One of the latest innovations is single-sided (type A) perforated penofol. Many tiny holes are made in the insulation to make it vapor permeable.

The scope of application of penofol is thermal insulation from the inside of houses and apartments, including balconies and loggias, as well as any industrial premises. The insulation is offered in thicknesses of 3, 4, 5, 8 and 10 mm. To finally understand all the properties of the material, we suggest that you familiarize yourself with its technical characteristics presented in the table:

How to attach

The basis for penofol is polyethylene, which, unfortunately, has very weak adhesion to construction adhesive solutions.

Mechanical methods are used for fastening: self-tapping screws with a press washer, stapler brackets, clamping strips, fixation under the sheathing. When laying on a horizontal surface under a screed, fastening is not necessary at all.

All joints and fastening points where the material has been stitched through are sealed with special tape made from thick aluminum foil or a polymer base coated with aluminum. This will restore the tightness of the insulation layer and give additional strength to the insulation.

Foil self-adhesive

However, manufacturers provide an even better option. The self-adhesive surface of foam foam “type C” makes installation on any clean, prepared surface extremely simple. One side of the material is completely covered with an adhesive composition with the same properties as regular tape, covered with a protective film.

It is enough to prepare the surface, clean, degrease and, if necessary , prime it so that it does not accumulate dust.

How to insulate with penofol

It should be noted that insulating anything (a wall, ceiling or roof) with penofol is really quite simple. If you follow the manufacturer's instructions, then to achieve maximum efficiency it is necessary to provide an air gap of 1.5 to 2 cm wide on both sides. To create such a gap, rolled penofol will have to be attached to wooden sheathing strips attached to the base.

That is, first you need to take 20 mm thick planks and attach them to the wall vertically or horizontally at intervals equal to the width of the penofol roll. If the house is wooden, then the planks are fastened with self-tapping screws; for brick or concrete bases, dowels will be required. Then strips of the required length are cut from the roll and attached to the planks with staples from a construction stapler.

Important. Unlike various thin films, the installation of penofol sheets is carried out not overlapping, but end-to-end. In this case, the foil side should be facing inside the room, and the joints should be carefully taped with aluminum tape.

When the layer of thermal insulation made of penofol is fixed and taped, the same strips are installed on top of it with your own hands to provide an external air gap. They are attached with self-tapping screws to the previous sheathing, and the outside is lined with plasterboard sheets or other finishing methods are used. Please note that a vapor barrier film is not laid, since there is no need for it; penofol itself is a vapor barrier.

It must be said that in practice, few people follow the instructions; usually penofol is attached directly to the wall or ceiling, and the air gap is made only on one side. This reduces the thermal insulation properties of the material, and further we will tell you why. When thermally insulating roofs or inclined walls of attics, installation of penofol is carried out by attaching it to the lower planes of the rafter boards. This means that the space between the rafters is filled with other insulation, since thin polyethylene alone will not be enough.

Important. If penofol can replace a vapor barrier, then under no circumstances can it replace waterproofing. You cannot lay it in the under-roof space in front of mineral wool; a diffusion membrane is needed there. It does not allow water to pass through, but also does not prevent the passage of vapors escaping from the cotton wool.

Floors in wooden houses are also insulated with foamed polyethylene, laid between the joists. Again, waterproofing is laid first, then slab insulation, and penofol on top. Putting it at the very bottom or in the screed is pointless; compression causes the material to cease to be heat-insulating. Although in practice such errors can be encountered often.

Another area of application of penofol is the insulation of balconies and loggias, where the material is laid as a second layer after more serious insulation materials - extruded polystyrene foam or polystyrene foam. The installation method is still the same: first, the sheathing bars are placed, polystyrene slabs are laid between them, and polyethylene foam is attached on top. After this, interior finishing is carried out.

Note. Perforated penofol is used as insulation for the walls of a wooden house in cases where it is necessary to ensure vapor permeability of the structure.

What is it needed for

The main feature of penofol is the presence of a heat-reflecting screen. It is indispensable for insulation:

- walls and ceilings as part of multilayer enclosing structures;

- balconies and loggias;

- pitched roofs, attics and attics;

- utility rooms and outbuildings;

- greenhouses;

- heat-reflecting screen as part of a heated floor system;

- niches with an installed heating radiator;

- air conditioning systems for freezing units;

- pipes and lines with refrigerant or coolant within the permissible operating temperatures.

It is used for effective and unique waterproofing properties as part of a roofing pie. H only from the inside of the attic or attic. Covering all the advantages, penofol is ideal for arranging insulated heat-efficient rooms: greenhouses, incubators, vegetable stores, for protecting basements and semi-basements.

Thanks to the hermetic closed structure of polyethylene foam, penofol has good soundproofing properties. Basically, it absorbs shock sound and vibration well, but is less resistant to high-frequency sounds and noise.

As an underlay for flooring, as well as under a thin screed, it will absorb the sound of footsteps or impacts on the floor.

Floor insulation. Under the screed

When insulating floors, penofol is used as a substrate for all types of screeds, wet, semi-dry, dry, bulk or made with any sheet material, as well as as a substrate for all types of floor coverings.

This is facilitated by the high compressive strength of the material and the dynamic modulus of elasticity is much higher than that of any other insulation.

Floor insulation scheme

Polyethylene ensures the strength of air bubbles, which in turn provides uniform shock absorption to any distributed loads.

Taking into account the horizontal distribution of penofol, it is not necessary to attach it additionally to the base.

When installing a heated floor or fixing a reinforcing layer, any damage to the surface of the penofol should be minimized so as not to violate the integrity of the foil layer.

Balcony insulation

For insulating a balcony, penofol is an ideal thermal insulation material. In conditions of extremely limited space, it will be necessary to subtract only 20 mm from each fence in order to insulate the room with penofol, taking into account the required gap between the insulation and the finishing to form a closed air chamber.

Two installation options are used:

- Uniform laying of the material end-to-end over the entire insulated surface and installation of sheathing for further finishing on top of it;

- First, a sheathing made of 40x40 mm timber is attached, and then insulation is distributed in each cell, extending onto the sheathing elements.

In both options, there is no need to use adhesives or a large number of fasteners. In the first case, the insulation will be securely pressed to the base by the sheathing, and in the second case, it is enough to attach the penofol under the very base with a stapler to the same sheathing.

The choice of the optimal option is determined based on the required load capacity of the sheathing and the weight of further finishing.

Benefits of penofol - debunking myths

Manufacturers and sellers of penofol attribute wonderful thermal insulation characteristics to this insulation, which is actually a myth.

Also, installation diagrams with air gaps, one of which we described at the beginning of the previous section, can be considered misleading the buyer. How the manufacturer proposes to insulate floors and roofs is shown in the figures:

In fact, the presented schemes are nothing more than another way to improve the thermal insulation of external fences using air gaps, since penofol’s own resistance to heat transfer is absolutely not enough.

This can be easily checked by taking as a basis the best thermal conductivity indicator from the technical characteristics table - 0.037 W/m2 °C. Next, we take the canonical formula and determine the thermal resistance of a material 4 mm thick:

- δ – penofol thickness in meters, taken 0.004 m;

- λ is its thermal conductivity coefficient, equal to 0.037 W/m2 °C.

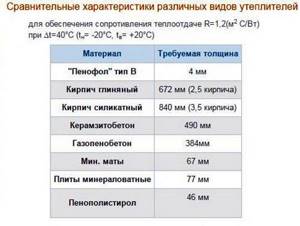

We get R = 0.004 / 0.037 = 0.11 m2 °C/W. Now look at the comparison table, which is presented on the same resource as the technical data. It says that 4 mm of penofol can easily replace 77 mm thick mineral wool or 46 mm thick polystyrene foam.

This means that, for comparison, it is necessary to determine the thermal resistance of a 77 mm mineral wool layer (its thermal conductivity is 0.05 W/m2 °C):

Rminwool = 0.077 / 0.05 = 1.54 m2 °C/W, which is 10 times more than that of foamed polyethylene.

Hence the conclusion: the presented comparative table is a pure fake. The data given in it is unreliable, and although the material is a good insulator, it is not better than others. The reason is that it is too thin, although its thermal conductivity is equal to extruded polystyrene foam.

Against this background, all other advantages of penofol fade. However, there is another myth - about the reflection of infrared heat back into the room thanks to the foil surface. But none of the manufacturers explains what the foil will reflect behind the interior trim. After all, infrared radiation spreads across open space; it will not pass through drywall or other obstacles.

What is really good about penofol is its low cost and ability to act as a vapor barrier together with other insulation, as evidenced by reviews on the forums. In addition, it is easy to install and the process does not take much time. You can also note the durability of the insulation, reaching 50 years, provided that it is located inside the building and not outside. By the way, it is better not to use penofol for external insulation of walls; it will be of little use there. You should not use it for thermal insulation of a bathhouse, like any polymer; when heated to 100 ° C, the material will begin to release harmful substances.

Specifications

A significant part of the thermal energy is distributed in the form of radiation, and therefore the heat-reflecting surface of penofol allows not only to slow down heat loss, but to turn the heat back into the room in winter or prevent it from coming from outside in the hot summer.

The layer of foamed polyethylene acts as a strong and durable base for the aluminum screen, and at the same time copes with thermal insulation in the usual way, increasing the thermal resistance of the fences. That is why it is difficult to compare penofol with traditional insulation using a simple calculation.

Aluminum, even of this thickness , does an excellent job of reflecting up to 97% of thermal radiation , while foamed polyethylene provides thermal insulation in the classical way, preventing convection heat transfer.

| Characteristic | Unit. | Type A | Type B | Type C |

| Operating temperature | ºС | -60..+100ºС | ||

| Thermal reflection coefficient | % | 95-97 | ||

| Coefficient of thermal conductivity | W/m*K | 0,037-0,049 | 0,038-0,051 | 0,038-0,051 |

| Water absorption by volume | % | 0,7 | 0,6 | 0,35 |

| Specific gravity at 4 mm thickness | Kg/m3 | 44 | 54 | 74 |

| Dynamic modulus of elasticity under load 2kPa | IPA | 0,26 | 0,39 | 0,26 |

| Vapor permeability | Mg/m*h*Pa | 0,001 | ||

| Compressive strength | MPa | 0,035 | ||

| Specific heat | J/kg*K | 1,95 | ||

To compare penofol with other materials, it is more clear to use the value of the total heat transfer resistance R under equal operating conditions and a difference between external and internal temperatures of 40ºС.

For example, penofol 3 mm thick Type B (double-sided foil) according to tests creates a resistance equal to 1.173-1.064. Similar resistance is provided by:

- 1.7 m of concrete;

- 77.40 cm of expanded clay concrete;

- 11.70 cm wooden beam (oak);

- 55.0 mm mineral wool (stone);

- 42.2 mm EPS;

- 36.0 mm polystyrene foam;

- 31.7 mm polyurethane foam.

The numbers are impressive, but such results can only be achieved if operating rules are followed and provided that the main source of heat transfer is radiation. Simply put, in the absence of active convection air flows in a heated room.

Introduction

If you are planning to insulate a balcony, then first of all you need to find the most suitable materials. The stores offer a large selection of insulation materials. Among them there are time-tested and modern, affordable and more expensive. Which one is best for your balcony?

The most important parameter of any insulation is thermal conductivity. The smaller it is, the better. Low thermal conductivity means that the material will retain heat in the room. Porous materials with low density have this property. The air they contain is the best heat insulator.

Very often, insulation materials are quite voluminous: the thicker the layer, the better the effect. But this is inconvenient for a balcony, because there is not enough space on it. It is necessary to insulate all walls, floor and ceiling; finishing materials also take up space. Therefore, for a balcony it is preferable to choose insulation that effectively saves heat in a small volume. Weight is no less important. The peculiarity of repairing and insulating balconies is that it is extremely undesirable to make them heavier.

Izolon or penofol: which is better?

Penofol can be compared with only one group of thermal insulation materials of the Izolon brand, namely “heat-reflecting insulation IZOLON”.

The ISOLON company offers insulating materials based on polyethylene foam (ISOLON 100) or cross-linked polyethylene foam (ISOLON 500) with aluminum foil or lavsan applied on one side.

When comparing Isolon 100 and penofol, there is no significant difference in properties and method of application, so the final winner will have to be determined by availability and cost. The only advantage of Izolon is that the range has been expanded with sheet material with a thickness of 15 to 50 mm.

Thermal reflective insulation based on Isolon 500 is made from cross-linked polyethylene foam, which gives it much greater strength and a slightly lower thermal conductivity coefficient. Depending on the frequency of foaming (5-40 times), the compressive strength at 10% deformation ranges from 0.011 to 0.15 MPa.

In most cases, it is enough to use penofol, however, Izolon makes it possible to use heat-reflecting screens in cases where the performance characteristics go beyond the limits permitted for penofol.

Polystyrene foam, polystyrene foam and penoplex

Foam plastic has been used for insulation of balconies and other premises for a long time, about 50 years. It consists of polystyrene foam balls glued together. The material is produced in the form of slabs of different sizes, thicknesses and densities. The higher the density, the more durable the insulation will be. Let us list the main advantages of polystyrene foam.

- Polyfoam is very light and has low thermal conductivity, which makes it suitable for insulating balconies. It is better to use sheets 3 cm thick.

- It is easy to insulate a balcony with polystyrene foam, since it is affordable and easy to find in any city.

- The material is moisture resistant and does not grow mold.

- Working with polystyrene foam is not difficult. The slabs are cut with a knife and laid effortlessly.

- High-quality foam plastic will last 50 years or more without loss of properties.

Now let's look at the disadvantages of polystyrene foam.

- Polystyrene foam is a flammable substance. During combustion, it releases toxic substances along with smoke. There are also self-extinguishing varieties, but they are much more expensive.

- The material is easily destroyed under the influence of solvents, acetone, gasoline and other substances. Some types of foam or glue can also dissolve it. So choose carefully which one to use.

- Although moisture-resistant, the material is still quite hygroscopic and requires additional vapor barrier.

Polystyrene foam is a popular material for insulation

Expanded polystyrene is close in chemical composition to polystyrene foam, but is produced using more modern technology. It has a very dense structure due to smaller bubbles. The thermal insulation properties of expanded polystyrene are higher than those of polystyrene foam, but its price is also higher. Otherwise, the properties of these materials are similar. Expanded polystyrene is produced in the form of sheets with a step, with the help of which they are attached to each other. This creates a warm seam.

Penoplex is extruded polystyrene foam with uniform cells no more than 0.2 mm. It is produced in slabs, the thickness of which is from 2 cm. This is a new generation of insulation. It is stronger than polystyrene foam and has better thermal insulation. Moisture resistance is also high: after lying in water for a day, the tile will pick up no more than 0.5% water. This material is perfect for insulating a balcony both outside and inside.

Application and installation

This material can be used as an independent insulation material or in combination with other materials. You can simply glue it to wooden walls under the finishing and in this way you will significantly increase the thermal insulation characteristics of the building.

Penofol can be used not only for insulating walls; it can be used to insulate warm floors and ceilings. Installation can be done by yourself without the involvement of specialists.

To attach to a wooden wall, you can use glue, a stapler or nails; the seams must be taped with aluminum tape so as not to violate the integrity of the insulation layer. The reflective side of the material should be directed towards the room.

Foil penofol is used to insulate hoods and air ducts; this is easy to do, as it is very elastic. Another advantage is that installation can be carried out at any time of the year. To carry out installation you do not need to have special equipment.

Between penofol and other finishing materials, it is necessary to leave a gap for ventilation so that moisture does not accumulate. If we talk about the service life of this insulation, we must remember that it is based on polyethylene foam, and its service life is more than 200 years, so penofol will last for decades.

Advice: for insulation you can also use the “old-fashioned method”, namely, an environmentally friendly and economical method.

Mineral wool and polystyrene foam are often used for thermal insulation.

Despite the fact that this material has many advantages, like any other insulation, it also has some disadvantages:

- it does not have sufficient rigidity, so it cannot be glued with wallpaper or plastered;

- some people nail penofol with staples, but in this way its thermal insulation characteristics deteriorate; it is better to use special glue or rolls with a self-adhesive base;

- For complete wall insulation, the use of penofol alone will not be enough; it must be used in combination with other materials.

If during the installation of the specified insulation you accidentally cut it, then it’s not a big deal. The specified place must simply be sealed with aluminum tape.

This material is also suitable for installing heated floors; for this you need to use penofol A-LP or regular A-03, but you need to lay a film under it.

I know that penofol is a good insulation product, but I still have questions for the experts.

I would like to know about its use as insulation under linoleum in an old wooden country house. There is simply no point in buying something expensive... the house is quite old, we only use it in the summer and autumn, but still the floor is always cold. Insulating building materials are becoming increasingly popular nowadays. Their scope has expanded significantly. When you come to a store or market, it is difficult to understand the assortment of samples offered. In this article we will talk about modern insulating material - foil foam.

Polyurethane foam (PPU)

Polyurethane foam is usually applied by spraying using special equipment. Sometimes foaming filling is used. This material has many varieties. For example, the well-known foam rubber is also polyurethane foam. But for thermal insulation, more rigid and durable polyurethane foam is used. Polyurethane foam also consists of this substance and is applied in a similar way. But foam from a balloon forms only half of the closed cells, and professional insulation forms more than 90%, so it is better able to insulate. The advantages of PPU are as follows.

- This material is one of the most effective insulating materials. It is superior to expanded polystyrene in its thermal insulating properties. Hardening in an even layer without seams or joints, it eliminates the appearance of “cold bridges”.

- Hard polyurethane foam is not afraid of water, which cannot penetrate into closed cells.

- Polyurethane foam does not require fasteners, which can also reduce the thermal insulation properties. The insulation hardens quickly, firmly adhering to almost any surface and filling all the cracks.

- PU foam can be applied to surfaces of various shapes, which makes it possible to insulate complex objects.

- The material is environmentally friendly and does not burn well.

- The service life is approximately 30 years.

There are not many disadvantages of polyurethane foam, only two.

- Application requires special installation. You need to contact specialists to insulate your balcony.

- If the surface of the polyurethane foam remains open, it loses its properties under the influence of ultraviolet radiation. It is necessary to cover the insulation with finishing materials.

Polyurethane foam - reliable insulation

Advantages and disadvantages

The use of penofol has its advantages:

- The small thickness of the material allows you to create reliable thermal insulation of the room.

- Installation of building materials does not require special skills or special tools. Working with this material is much easier than with other types of insulation.

- The material is environmentally friendly, which makes it possible to use it for storing food.

- Fire safety. This building material belongs to the class of fire-resistant materials.

- Ease of transportation. The thickness of the product allows the insulation to be rolled up, which allows it to be transported in the luggage compartment of a car.

- Excellent sound insulation. Mounting penofol on top of the frame of building structures provides good insulation of extraneous sounds.

Penofol has not only positive qualities. There are also disadvantages to using this building material:

- The insulation is soft. Because of this, this product is not used for finishing plastered walls. When lightly pressed, the material bends.

- To fix the insulation you will need special adhesives. It is not recommended to nail it to the surface, because in this way penofol loses its thermal insulation qualities.

Penofol and isolon

Penofol is insulation made of polyethylene foam, covered on one side with foil. The thickness of the material is only a few millimeters, but it will successfully replace 10 cm of mineral wool. Thermal energy is reflected from the foil layer and remains in the room. This creates the effect of a thermos: the room is warm in winter and cool in summer. Penofol can also be used as a moisture and vapor barrier. The material is so thin that it is convenient to combine it with other insulation materials. Efficiency increases, but thickness remains almost unchanged.

Izolon is also made from gas-foamed polyethylene and has similar characteristics. But the technology for its production is more complex. It has greater strength and the reflective surface is smoother. There are other similar materials, including self-adhesive ones. All of them are durable, environmentally friendly, chemically resistant and are perfect for insulating a balcony. Available in roll form. Sections of insulation are fastened with metallized tape so that the reflective layer is not disturbed. Do not confuse which side to lay the material. The foil layer should face the inside of the room.

Foil polyethylene foam reflects heat

What it is?

Penofol is a two-layer heat-insulating building material, which can be made from one or 2 layers of foil applied to a base layer of polyethylene foam. Depending on the type of product, the density and thickness of the foam may vary. Utilitarian and inexpensive insulation is in great demand among buyers, because it has high performance characteristics.

A layer of foil, the thickness of which is 20 microns, provides penofol with excellent heat-reflecting qualities.

This insulation is used in everyday life and industry as the main insulating material or as an auxiliary thermal insulation layer.

Penofol is used as the main insulating material in cases where it is necessary to insulate a room with normal heat loss and where there is a powerful heating source (bathhouse, sauna, underfloor heating system in a wooden house). As an additional insulating building material, penofol is used to create complex heat insulation in residential and industrial premises, and such premises must be equipped with vapor barrier and waterproofing.

Mineral wool

This is an accessible and inexpensive material. There are several types of mineral wool: slag, stone and glass wool. The latter can pose a health hazard, so you must work in special clothing. The starting material (slag, rock or glass) is melted and formed into fibers. Tile wool is easy to install, but for rolled wool it is necessary to construct a sheathing.

- The material retains heat well.

- Mineral wool is fireproof.

- It is affordable and is on sale everywhere.

- Has high sound insulation properties.

Mineral wool has a number of disadvantages, due to which it is undesirable to use it for insulating a balcony or to use it only to a limited extent.

- The insulation is quite bulky and, together with the sheathing, takes up a lot of space.

- Mineral wool gets wet easily and quickly, including absorbing moisture from the air. Once wet, it becomes heavy and loses its heat-protective properties.

- If the cotton wool is not covered well enough, its fibers can become airborne, which is harmful to health.

There are many varieties of mineral wool

Insulation Penofol

In the insulation department of any construction supermarket there is a place allocated for penofol. Thin rolled material with a foil surface attracts attention, but its appearance does not always answer the question of where it can be used.

However, it successfully occupies a whole niche in the field of home insulation, where conventional insulation materials, such as mineral wool or expanded polystyrene, will not help adequately cope with the task.

Glazing and preparatory work

It is clear that it only makes sense to insulate a glazed balcony. The type of glazing should be “warm”: PVC profile with double glazing and hinged doors. The basis for the structure is often brick or foam block masonry. In terms of weight and thermal conductivity, foam blocks are better than bricks, so you should opt for them. Before starting insulation work, it is necessary to seal all cracks and joints with foam. Also note that the insulation layer may cover the window frame. To prevent this from happening, use an expansion or additional profile.

Source

Insulation of interior walls

To prevent the walls from becoming covered with fungus and mold from moisture entering from outside, you need to insulate them using foil foam. It is better to use penofol types A, B and C. The choice depends on the installation method and the expected result. Type A

used as an additional layer of insulation.

Attached to the main insulation to protect against moisture. Type B

is used as the main thermal insulation material.

Type C

can be mounted on a wall base.

To fasten penofol indoors, use a stapler. The thickness of the material is 4–5 mm. If the house is very cold, you first need to insulate the walls with polystyrene foam and cotton wool.

Carrying out installation work:

- A frame is first made on the wall using wooden slats. The slats should be no more than 15–20 mm thick. Leave an air space of about 2 cm on both sides of the foam foam for the material to work effectively. The frame beams are attached at a distance of 1 m from each other.

- Check the condition of the electrical wiring and apply additional insulation if necessary. Aluminum foil material has good electrical conductivity. Penofol should not be allowed to come into contact with exposed wires.

- Attach penofol to the wooden frame using a furniture stapler. Cut the strips and lay them end to end, sealing the seams with aluminum tape. Make sure there is no overlap at the edges. Condensation may drain when steam is formed.

- A frame with an air “cushion” of 2 cm is mounted on penofol and fastened with plasterboard panels, plywood boards, sheets that can be puttied, painted or wallpapered.

Ceiling insulation

. We fasten the first cut strip along the wall in the middle of the ceiling. We begin to lay penofol from the strip to the corner. Having reached the corner, nail the edge of the last strip. Do this procedure on the other side of the strip and nail the edge. Do not forget to constantly smooth the foam foam on the ceiling.

The wall surface does not need to be pre-prepared; it does not need to be processed.

What to glue it with?

A correctly selected adhesive solution for foil material does not yet guarantee a successful installation. For a quality connection of materials, it is necessary that the surface to be glued be carefully prepared. All defects, irregularities, and various debris must be eliminated.

To improve adhesion, materials made of metal, concrete and wood can be treated with a special primer solution.

Concrete floors and walls are leveled, cracks are sealed, and metal products are treated with an anti-corrosion agent.

Adhesive for foil insulation can be either specialized or universal. You can also use liquid nails, double-sided tape, or a thin layer of foam. The choice of glue depends entirely on the purpose of the surface and its further use.

The adhesive composition must correspond to the performance indicators of the insulating material:

- permission for indoor use;

- the toxicity of the solution should be 0;

- high resistance to adhesion;

- the glue must withstand temperatures in the range of -60 to +100 degrees.

If insulation is carried out externally, then the adhesive solution must be resistant to water vapor and liquid.

In order for penofol to be reliably glued to the surface, the glue must be applied to the side that does not have a foil layer. The adhesive solution is applied evenly, without gaps. The edges of the panel are carefully coated with glue so that the foil material does not come off during operation.

Before you start fixing the penofol, you need to wait 5-60 seconds for the glue to dry slightly. This ensures better adhesion to the products. Penofol is pressed to the surface, holding it, and smoothed out with special care.

If the insulation is glued in pieces, then the joints are additionally glued.

Basic properties and performance characteristics

Safety and environmental friendliness

Durability and stability in operation

Resistant to rot and fungus

Patented interlock technology

Flexibility and lightness

Thickness up to 150 mm

Main technical characteristics

Due to its physical properties, Tepofol® is a unique heat-, moisture-, steam-, hydro-, and noise-insulating material, which replaces a whole range of materials used in the construction and operation of residential, sports and industrial facilities. The material has low thermal conductivity and good elasticity, which allows the formation of a homogeneous thermal insulation shell of an object of any geometry.

- Appearance of products Not allowed: cracks, chips, cuts in the coating

- Density, kg/m3 16 - 25

- Compressive strength at 10% linear deformation, kPa, not less than 16

- Effective thermal conductivity coefficient, NPE type “B” (with two heat-reflecting layers) 0.028

- Thermal conductivity in dry condition at a temperature of 25±5°С, W/(m*K), no more than 0.039

- Thermal conductivity after 100 cycles of freezing and thawing in a dry state at a temperature of 25±5°C, W/(m*K), not more than 0.042

- Water absorption during full immersion for 28 days, %/volume, no more than 0.96

- Vapor permeability, mg/m*h*Pa 0.0001

- Operating temperature range, °C -60 - +80

- Longitudinal tensile strength, kPa 81.55

- Impact noise insulation, dB, not less than 24

- Standardized sound insulation level (reduced impact noise index 10 mm), dB 54

- Service life *subject to storage and operation rules Unlimited*

Thermal insulation materials Tepofol® made from non-crosslinked polyethylene foam have the necessary certificates confirming the compliance of the products with modern quality standards.

Still have questions?

Enter your phone number and our specialist will call you to answer all questions, calculate the price and discount amount

By clicking on the button, you consent to the processing of your personal data and agree to the privacy policy.