The logic of designing residential buildings, cottages and baths largely depends on the functional purpose of the buildings. Recently, the method of frame house construction has become very popular: it is fast, relatively cheap and, at first glance, very simple from the point of view of thermal insulation. However, the fashion for using certain schemes does not help to find universal construction solutions, since they simply do not exist. What is good for the home may not be suitable for the spa area. Let's consider the insulation of the main surfaces of a frame bath and try to determine the feasibility of using various types of thermal insulation and other technological elements that form the necessary microclimate in the steam room.

Features of heat transfer of a frame bath

Frame buildings belong to inertia-free thermal systems, that is, to houses with low heat capacity. What is the meaning of this parameter? It reflects the ability of building components to accumulate thermal energy. Accumulated by the walls and foundation, heat is released into the room, ensuring, on the one hand, slow cooling of the space when the heating is turned off, and on the other hand, slow heating to the required temperature.

Frame sauna is economical and prefabricated

A house built on the principle of a frame filled with thermal insulation heats up quickly and cools down just as quickly. There are no strong (in the traditional sense) walls, and the insulation for a frame bathhouse does not transmit energy well, but it also accumulates it in itself poorly.

During operation of the heating system, the level of heat saving of such an object is very high and is usually close to the standard of a “passive house”. However, the need for constant heating brings serious inconvenience to permanent residence in buildings of this type. But no one lives in bathhouses! The heating rate of the steam room is much more important here. It is for such objects that low inertia is rather a positive factor than a negative one.

Kinds

We have already said above that we are always talking about an overlap, and it can be formed in various ways. It would be more accurate to say that there are two most common ways to create these floors.

Grazing

When the budget is not too large, there is an option to reduce construction costs by creating a deck as a floor.

IMPORTANT! This option is only suitable if there is a cold attic above, to which no one will particularly climb.

Read more about insulating a deck ceiling here.

The reason the rule is so strict is that the decking is not designed to support a lot of weight. Because the flooring boards have only two support points on opposite walls. And the greater the distance between the walls, the more fragile such a structure will be, and the boards themselves will tend to sag under their own weight.

ATTENTION! Therefore, a flat ceiling in a steam room of a bathhouse is made only if the distance between the walls does not exceed 2.5 meters.

As you can see, the limitation is quite significant. If you have a rectangular steam room with dimensions of 2 by 3 meters, then it is clear that the flooring can be laid on walls, the distance between which is 2 meters, not 3.

The ends of the boards, as you already understood, are placed on the walls. But how exactly does this happen?

The support for the flooring boards can be a mauerlat - a wooden beam that is fixed to the top of a wall made of block material (brick or cellular concrete, or cinder blocks). In the case of frame construction, an analogue of the Mauerlat is the upper strapping beam.

But what if a log house or bathhouse is being built from timber? In this case, to lay the boards in the ceiling crown, a recess is made, a longitudinal niche, which the master cuts out with an ax. And this is not the simplest action, although the construction of such a ceiling itself, of course, is considered very simple.

ADVICE! The recommended depth of insertion of the board onto the mauerlat or into the groove of the ceiling crown is at least 5 cm.

The boards that are used to create a floor ceiling are usually 5 cm thick. Since we are talking now exclusively about the steam room, it is better to give preference to non-coniferous boards. Because resin is released even at 40 degrees.

However, boards are not everything. They need to be insulated from steam and moisture, and also insulated using those types of thermal insulation that will be most effective for a given case.

A complete diagram of the floor ceiling (what it looks like is shown in the picture above), below is a video with an explanation:

Many craftsmen do not limit themselves to simply laying flooring. They strengthen it with the help of transversely laid bars or boards placed on edge. This ensures the necessary rigidity and eliminates the possibility of displacement. In addition, it is more convenient to lay insulation in the resulting “sections”. Fastening is done with self-tapping screws from below, from the steam room side.

Hemmed

Where there is more money or the size of the steam room does not fall within the size restrictions given above, bathhouse owners rely on a false ceiling.

BY THE WAY! For those who make a two-story bathhouse, there is simply no other option.

So, what is a false ceiling? In general, it is called that for a simple reason: it is “sewn” to the ceiling beams. And ceiling beams are rigid structural elements stretched and fixed in the walls. By sewing up the space between them, we create a strong and reliable ceiling that can serve as a floor on the side of the upper room.

Beams appear at the stage of wall construction. Whereas the filing begins closer to the finishing stage, but not at the finish line, of course. Because you need to first secure and insulate everything.

This video explains the design of a hemmed version of a bathhouse ceiling. However, the description ends with laying the insulation, but if there is a living space or a warm attic on the second floor, then the floor will be laid on top of the insulation.

Thermal insulation of walls

In accordance with the design of the wall sandwich in frame housing construction, the insulation of bathhouse walls is not external or external. It is internal because it is a filling of honeycombs created by vertical posts made of thick boards or timber.

Filling the voids

Of course, we are talking about the main insulating layer. Mineral (basalt) wool is most often used. But not because it is the “warmest material,” but for a number of other reasons:

- Fire safety. Wood frame is the most flammable wall structure. Therefore, filling with non-combustible stone wool greatly reduces the risk of fire.

- Vapor permeability. To reduce the level of moisture condensation from the air inside the wall sandwich, the principle of increasing the vapor permeability of layers is used: the value of the parameter should increase in the direction from the inner surface of the walls to the outer one. Rolls and mats made of mineral fibers have higher vapor permeability than internal wooden cladding. This increases the resource of the wooden frame by preventing rotting and the formation of fungal mold.

- Price issue. Firstly, cotton wool is cheaper than EPS boards and sprayed polyurethane foam (PPU). Secondly, when using cotton wool, you can avoid the expense of ventilating the wall sandwich. Thirdly, you can save on installers’ labor costs: insulating a frame bathhouse with your own hands using this scheme is a simple matter, since all the materials used are quite light.

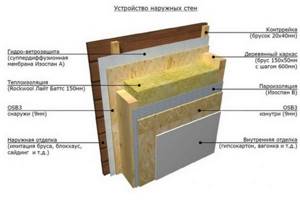

Diagram of a frame bath

Since there is no windproof traditional wall material, the sandwich uses special windproof Isoplaat boards, made from fine softwood powder impregnated with moisture-proof compounds (resins and paraffins). These slabs also serve as structural rigidity for the walls. When using mineral wool, a sandwich for insulating bath walls looks like this (from the inside of the steam room to the outside):

- decorative finishing made of solid wood (lining, tongue and groove, or regular board cladding);

- vapor barrier membrane (for example, foil material);

- a layer of stone wool;

- waterproofing membrane;

- Isoplaat windproofing;

- decorative cladding with a high level of vapor permeability.

It should be noted that even without external cladding, high-quality wind protection retains its properties for 5 - 10 years. A special feature of insulating walls in frame baths using mineral wool is the installation of large thicknesses of insulation (up to 150 - 200 mm depending on the climate zone). A common technique is to combine rolled and slab materials, forming 2 layers of insulation.

Theoretically, EPS or PU foam can be used instead of cotton wool, but certain design tricks are required to protect these materials from exposure to temperatures above + 75 °C. Firstly, the stove is not located closer than 1.5 m to the wall. Secondly, it is mandatory to use foil reflective materials with their own insulating layer. Moreover, a ventilated gap of 1.5 - 3 cm must be maintained between the foil insulation and the insulation board.

Otherwise, the structure of the sandwich is the same as already described.

The greatest difficulty is the arrangement of powerful ventilation capable of drying the air inside the frame. This measure makes the insulation scheme using EPS and PPU significantly more expensive. Therefore, foamed polystyrenes and polyurethanes are practically not used in baths of this type.

External insulation with EPS boards is possible. In this case, instead of windproof materials such as Isoplaat, the frame is sheathed with OSB sheets, onto which a slab of foamed polystyrene foam is glued on top.

What is the best way to sheathe the frame?

In Russian baths they often use a wooden frame.

The lathing takes on the functions of ventilation. The gaps will prevent moisture from accumulating on the surface of the timber and insulation. Ventilation gaps provide good air exchange, where there is no room for dampness or fungus.

Fastening is carried out vertically. To insulate the walls of a bathhouse, not all types of thermal insulation can be used.

It is prohibited to use flammable cheap polystyrene foam or polystyrene foam.

Expanded clay and ecowool are not suitable due to the fact that they quickly become saturated with moisture and lose their working properties.

The best insulation options:

- basalt wool;

- kaolin wool;

- vermiculite

Photo: wall construction of a frame bath

The outside of the frame structure can be finished:

- siding;

- decorative plaster;

- edged board;

- half beam;

- clapboard;

- croaker;

- tiles;

- block house;

- plastic panels.

The cladding with a block house that imitates a log looks beautiful.

For interior work, lining is considered a universal ceiling and wall material. It is convenient for her to sheathe the steam room and dressing room. The lining does not heat up and is easy to install. To decorate the shower, choose ceramic tiles or moisture-resistant wood.

It is forbidden to paint or varnish the finish in the steam room, otherwise when heated it will begin to release toxic substances that are harmful to health.

It is allowed to use moisture-resistant plasterboard for covering the walls in the locker room. OSB and MDF boards are suitable for the same purposes.

The procedure for internal lining of the bathhouse is given in more detail in the section below.

Insulation of ceilings and floors

There are practically no specific differences between the insulation of ceilings in frame baths and the work in buildings of other types. On flat ceilings, the main insulating layer is installed from the inside of the steam room, and in the case of hemmed ceilings - from above, from the side of the under-roof space.

On the inside, a reflective layer (foil material) and a thermal insulator located behind it (mineral wool or EPS boards) are used. Regardless of the type of insulation, there is an air gap between the infrared screen and the main layer. On the side of the under-roof space, the wool is protected by a waterproofing membrane.

When installing the bath floor, do not forget about the drain

False ceilings can be insulated with the same materials as floor ceilings, but bulk mixtures (most often eco-wool) are usually preferred for their installation.

Insulation of the floor in a budget frame bathhouse is carried out, as a rule, using cellular self-growing concrete. In more expensive buildings, options are possible for installing a heated floor on the ground, providing a concrete screed on top of an EPS layer. A finishing plank floor made from a jointed “magpie” is laid on the concrete, which is the subfloor.

Main advantages of thermal insulation

An insulated frame bath allows you to significantly save on heating. Therefore, the money spent on insulation and vapor barrier pays off over time. A thermally insulated bathhouse warms up to the desired temperature faster and cools down more slowly, “holding” steam better.

Gentle temperature conditions can significantly increase the service life of the heater. Wooden structures of an insulated bathhouse are less susceptible to rotting. There is no doubt about the feasibility of insulation; all that remains is to choose the right material and carry out work using the appropriate technology. To do this, you can hire specialists or do everything yourself.

Application of DIY insulation

The second most commonly used insulation for frame-type baths are compositions based on sawdust and shavings. Processed in a certain way, the material is poured in portions and compacted. A sandwich wall using sawdust has the following structure (from the inside to the outside):

Insulating a bathhouse with sawdust

- plank cladding;

- kraft paper (no air gap);

- sawdust with a layer thickness of 10 cm;

- kraft paper;

- plank cladding.

The boards play the role of both a strength frame and decorative cladding. Reflective screens are usually not used, since the default option with sawdust should be the simplest structurally and inexpensively.

Pre-treatment of sawdust involves soaking it in a lime solution. Lime gives the material moisture resistance and is quite effective in fire protection.

If the work is carried out in the warm season, there is no need to dry the limestone chips before installation. Evaporation of excess moisture occurs quite quickly after backfilling.

In operation, processed sawdust has proven to be the same effective material as mineral wool, but lacking one of its main disadvantages - high hygroscopicity. To insulate floors, sawdust is used in the composition of cellular concrete. Treated sawdust is poured into natural coffered false ceilings in a layer of about 200 mm with moderate compaction. The top layer is covered with a waterproof membrane.

What rules must be followed

The insulation of the bath occurs according to its own rules. And it depends primarily on how the building was erected. For example, it is enough to insulate a bathhouse made of blocks or bricks from the inside. A bathhouse made of solid timber must be caulked well. If the bathhouse is a frame extension, it also has its own characteristics. A frame bath is insulated according to its own rules. However, in order for the insulation to fulfill its role one hundred percent, it is necessary to ensure waterproofing and vapor barrier of the internal layers of the frame wall.

Three stages that you should pay attention to when forming frame walls:

- waterproofing

- vapor barrier

- insulation

Frame building wall

Waterproofing prevents moisture from getting inside the walls. If it is not made well, the material, especially if it is mineral wool, will absorb moisture and lose all its thermal properties. In this case, the moisture inside will get on the wood, and after a while the timber will begin to rot, and mold and mildew will grow along the wall.

Waterproofing material

Vapor barrier is the second important point; it removes excess moisture into the room, as a result of which drops of condensation that can form at the dew point do not harm the wall

Particular attention should be paid to the ceiling. Why him? Because the warm and moist air that is in the frame bathhouse rises upward under the influence of physical laws, which is why the ceiling of the frame bathhouse should be additionally protected

We install the vapor barrier with our own hands from the side of the room.

Vapor barrier membrane

If you didn't use foil insulation, you can add an extra layer of foil to the ceiling and walls. To do this, we shoot it onto small bars fixed to the surface. Choose thicker foil, which is more durable. The foil will create a thermos effect.

Foil for walls

Another rule when building a frame bath is the processing of the wooden frame, which is done with your own hands. Fire protection is used for this purpose. A frame bath is a room with increased fire hazard, so additional fire protection should not be neglected. Excessive moisture in a frame bath leads to the appearance of rot and mold on wooden elements if they have not been treated with a septic tank in two or three layers.

Wood processing

Summary

By thermally insulating frame-type spa areas according to one of the described schemes, you can get a relatively inexpensive, but very effective version of a steam room with easy achievement of high temperatures and intense steam generation. The main attention requires careful consideration of the issues of vapor barrier and prevention of condensation of atmospheric moisture inside the sandwich walls. The inhibition of the development of undesirable microflora depends on this, ensuring the sterility of procedures and extending the service life of the wooden frame of the bathhouse.

More