In order for a house made using frame technology to be fully exploited in Russia on a year-round basis, it is important to take care of its thermal insulation. In this case, absolute insulation of the frame house is required: ceiling, walls, ceilings, roof and floor. There is a lot of work, but knowing how the process is carried out, you can try to do it yourself: select the material and install it.

Why is insulation necessary?

By itself, a frame house cannot provide the required resistance of the roof, walls and ceilings to heat leakage from the premises. Living in such a house is uncomfortable; the air temperature in the rooms does not meet the standards. In addition, dampness and even mold appear on the walls.

In order to live in a house without fear for your own health, the thickness of its walls must differ from that of a summer house. Winter frame houses are more serious buildings. In addition, with insufficient insulation, heating costs increase sharply, which will not please residents.

Spray insulation

To some extent, this technology is reminiscent of applying plaster on beacons - vertical slats are placed on the walls at a level, between which polyurethane foam or ecowool is sprayed.

A frame house, insulated on the outside with polyurethane foam, is ready for façade finishing. Source mirstrojka.ru

After the polyurethane foam “hardens”, its excess is cut off with a special hand-held electric cutter or electric saw. You can either install façade panels on top or apply a layer of decorative plaster.

How to insulate?

There are different requirements for insulating walls, roofs and ceilings. For example, when insulating a floor, special attention is paid to the strength and rigidity of materials. For the roof it is important to choose lightweight thermal insulators . When insulating walls there are no special requirements; the following types of heat-insulating materials can be used:

- mineral wool (slabs and mats);

- Styrofoam;

- extruded polystyrene foam (penoplex);

- polyurethane foam (foam).

The installation technology of all these materials is similar; only mineral wool has differences, but this will be discussed later.

Each material has its own advantages and disadvantages, but all of the above types are modern insulation materials with a high degree of efficiency.

Insulation materials for thermal insulation of timber walls

Recently, many effective insulation materials have appeared, which are produced on the basis of advanced technologies.

One of these modern materials is Penoplex, produced by a Russian company in the form of thermal insulation boards. "Penoplex" is a type of foamed extruded polystyrene foam prepared using special technologies. The panels are durable and highly resistant to moisture. This material does not have the ability to absorb moisture, is not afraid of dampness, and is not a medium for the development of bacteria, mold and other microorganisms.

Penoplex slabs, due to their high strength, can be laid both vertically and horizontally. The structure of their surface allows the application of plaster.

Penoplex insulation is a material that has a uniform structure, which consists of small, closed cells (0.1-0.2 mm in size).

The main properties of PENOPLEX boards are:

- low thermal conductivity

- low vapor permeability

- no water absorption

- high compressive strength

- Resistant to fire and biodegradation

- ecological cleanliness

- simplicity and convenient installation

- durability

When using Penoplex boards, you should know that this material, like other types of extruded polystyrene foam, has low chemical resistance to substances such as:

- Aldehydes (formaldehyde, formaldehyde)

- Aromatic hydrocarbons (benzene, toluene, xylene)

- Ketones (acetone, methyl ethyl ketone)

- Esters (diethyl ether), do not use solvents with ethyl acetate, methyl acetate,

- Gasoline, kerosene, diesel fuel

- Polyester resins (epoxy resin hardeners and coal tar cannot be used),

- Oil paints.

Penoplex is resistant to the following chemicals:

- Acids.

- Salt solutions.

- Caustic alkalis.

- Bleach.

- To alcohol and alcohol dyes.

- For water-based paints.

- Ammonia, carbon dioxide, oxygen, acetylene, propane, butane.

- Fluorinated hydrocarbons (freons)

- For cement and concrete mortars.

- Animal and vegetable oils, paraffin.

Important! PENOPLEX boards should be used only in the temperature conditions recommended by the manufacturer. If the range of recommended operating temperatures is exceeded for a long time, the slabs may lose their mechanical and thermal insulation properties and change their dimensions

With Penoplex insulation, you should use only adhesive solutions approved by the manufacturer. Products containing acetone, ethyl acetate, etc. lead to softening and shrinkage of extruded polystyrene foams.

Another modern insulation material, polyurethane foam, is used to insulate the walls of a log house using the spraying method.

The main advantages of this method:

- The thermal insulation system based on polyurethane foam is not susceptible to rotting and bacteria.

- The material has a long service life, during which it retains its thermal insulation qualities.

- Does not support combustion.

- Has noise-insulating properties.

- A simple way to apply heat-insulating material.

- Does not require additional fasteners.

- Environmentally friendly.

This insulation method can be used for thermal insulation of walls, plinths, and foundations.

The easiest way to insulate a log house is with polystyrene foam, but this material has low fire-fighting properties. And since wood itself is a flammable material, many experts do not recommend using foam boards to insulate wooden walls.

Therefore, the best option for insulating a timber house would be mineral wool, glass wool and other non-flammable materials.

Important! Before starting thermal insulation work, the outside walls of a timber house must be treated with fire retardants (agents that reduce the flammability of wood) and antiseptics (preparations that protect wood from rotting, fungi, mold, insects)

Calculation of material thickness

The thermal insulators listed in the previous paragraph have approximately the same thermal conductivity values, which means that their thermal insulation abilities are also comparable. A frame house for long-term living must be properly insulated, and for this you will need to select the thickness of the heat insulator. The value depends on the climatic region. For most of the country, a layer of 100 mm can be used.

Calculation of insulation for the walls of a frame house

In order to live in a house with maximum comfort, a full thermal calculation is performed. To do this, it is not necessary to study mountains of regulatory documentation and delve into the principles of calculation.

Now there is a simple program “Teremok”, which performs a full calculation based on regulatory documentation. With its help, the thickness is selected in a few minutes. You can install the program on your computer (free and open access) or use the online version.

To calculate you will need:

- thickness of all layers except insulation;

- thermal conductivity of all materials.

The thermal conductivity of the insulation is indicated by the manufacturer. For wood, take 0.15 W/m*ᵒC (pine across the grain). The internal and external cladding is also taken into account (for mineral wool, the external cladding located after the ventilated layer does not need to be taken into account). Once the thickness has been selected, you can buy the material and get to work.

Which construction material to choose

The timber does not have to be of square or rectangular cross-section; timber with a rounded surface is also widely used in construction. The price of lumber can vary significantly, but choosing the cheapest option is not always justified; it can simply result in big problems in the future.

For construction, the following type of timber can be used:

solid - the cheapest option, it is obtained from tree trunks. And the main disadvantage can be considered large deformations of the house. The main difficulty at the production stage is to achieve acceptable humidity. If there are no special problems with a cross-section of 15x15 cm (it’s enough to just keep it in the drying chamber), then larger sizes, for example, 25x25 cm, are more difficult to dry;

if your budget allows, then it’s better to go with laminated timber. It differs from a solid one in that it is assembled from several boards, which are glued along the entire length. Due to this, it is possible to achieve the required level of humidity, and the profiled surface will make the joint of the individual beams very strong and reliable.

Winter houses made of laminated veneer lumber have much less shrinkage. And if it is recommended to wait about 1-2 years before starting interior decoration, then laminated veneer lumber allows you to remove this pause. Shrinkage does not exceed 0.5-1.0%, and the likelihood of cracking is reduced to a minimum.

As for the length and thickness, the dimensions can vary over a wide range. Typically, the thickness of glued beams is up to 30 cm, and the minimum value is 7.5 cm; the length, as a rule, does not exceed 12 m.

How to insulate?

According to the technology, thermal insulation material is placed in the gaps of the wall frame. Load-bearing wall elements can be made of wood or steel. The work is carried out in several stages.

Preparatory

It will not take much time, but will significantly increase the quality of work. Before starting work, the wall frame is cleared of construction debris, dirt and dust. Next, the walls are inspected for the presence of protruding fasteners that could damage the insulating material. Protruding nails are driven in with a hammer.

All cracks in the frame are insulated with polyurethane foam. The moisture content of the wood is checked; if the wall frame elements are damp, they should be dried with a hair dryer. Next, the next stage of work begins.

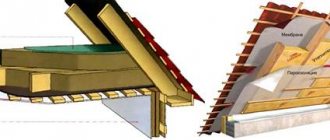

Waterproofing and vapor barrier

Protection of the wall frame from moisture is required in the following places:

Scheme of vapor barrier for walls of a frame house

- resting the wall on the foundations (at the junction of elements made of materials of different properties, horizontal waterproofing);

- on the outside of the wall, on top of the insulation to protect against atmospheric moisture;

- A vapor barrier is installed on the inside of the wall to protect against moisture coming from inside the room (warm steam).

Vertical waterproofing and vapor barrier is especially necessary when using mineral wool, since of all the wall materials presented above, it has the highest degree of water absorption. Also, do not neglect these measures when insulating with polystyrene foam and polyurethane foam. Perhaps the only material that can cope with moisture on its own is penoplex.

Thermal insulation

The insulation is installed between the studs of the wall frame. The distance between the load-bearing elements is selected so as to ensure easy installation, namely:

- 580 mm clear between mineral wool posts;

- 600 mm for polystyrene foam and extruded polystyrene foam;

- for polyurethane foam, the distance does not matter much.

Methods for insulating frame houses

First you need to decide on the type of thermal insulation. It can be internal, external, as well as insulation of the floor, ceiling, etc.

What you need to know about external insulation

This insulation option has the following advantages:

- Additional protection of walls from deformation.

- The insulation absorbs sudden temperature changes, thereby extending the service life of the building.

- Makes walls smoother, making it possible to use various facade finishing materials.

External insulation can be:

The first method is the most common and economical; this work can be done without the help of specialists. A gap is created between the insulation and the cladding, which serves as ventilation. Thus, the condensate accumulated in the insulation is blown out by a stream of air. This technology extends the life of the building.

The second method is to glue the insulation to the wall, and then attach it to the dowels. We apply several coatings on top: reinforcing, intermediate and decorative. However, without experience it is impossible to perform “wet” insulation.

Important information about insulating a house from the inside

Internal insulation of a house has a number of advantages:

- the ability to perform work in any weather and season;

- You can install thermal insulation yourself;

- provides good sound insulation.

- condensation may appear on the wall, under the insulation;

- the wall does not warm up well, which leads to dampness;

- reducing the area of the room;

- the materials used are harmful to health;

- At the junction of the insulation there are gaps through which cold will penetrate.

Insulation of a panel house for winter living, choice of materials and technology

In the first case, the insulation is attached to the facade with glue, a reinforcing mesh is glued over the insulation and facade plaster is applied. In the second case, the thermal insulation is attached between the guides made of bars, then the insulation is covered with a vapor barrier film and sheathed with siding.

Insulating a garden house with polystyrene foam from the outside

Insulating a garden house from the inside

In addition to insulating floors and walls, do not forget about protection against heat loss through doors and windows in the summer house.

Window openings, especially window slopes and window sills, require careful insulation. It’s good if you have a small vestibule, then the cold will not penetrate into the house, but it is better to insulate the front door in a country house. For this you can use dermantin, padding polyester and furniture nails.

Insulating a garden house with mineral wool from the inside

Eternal questions of choice. What should you pay special attention to when choosing insulation?

Proper insulation of a frame house for winter living makes it durable, strong and reliable. For a frame house, materials are suitable that have:

- Low thermal conductivity is the amount of heat passing through a material. The lower this indicator, the longer the heat is retained inside the room.

- Fire safety - resistance to high temperatures. For frame houses, it is better to use insulation with the flammability grade - NG.

- Low water absorption - the amount of moisture passed through. The lower this indicator, the better the quality. With high liquid absorption, thermal conductivity increases, the material freezes and loses its properties.

- Do not shrink over time - the insulation must maintain its density. When shrinking, cracks are formed through which cold air passes.

- Environmentally friendly - should not cause harm to health and emit harmful substances.

Choosing the optimal insulation

Mineral wool heat insulators are the most acceptable option for insulating a frame house. The materials are made from different raw materials, which determine the basic characteristics and scope of application. The general advantages of all types of mineral wool include: light weight, fire safety, resistance to pests and the necessary vapor permeability.

The main disadvantage of fiber insulators is hygroscopicity. To preserve the insulation properties, mineral wool needs high-quality vapor and waterproofing.

Basalt wool - environmentally friendly and fireproof

The main component of the insulation is rocks of volcanic origin: basalite, diarite and basalt. Stone wool is a completely non-flammable material that can withstand temperatures of 1000 °C. The heat insulator retains its physical properties for 40-50 years. The main advantages of basalt-based mineral wool:

- low thermal conductivity – 0.36-0.42 W/m*C;

- resistance to mechanical stress;

- good noise insulation characteristics;

- resistance to temperature fluctuations.

The insulation contains hydrophobic additives that ensure rapid removal of moisture. Basalt heat insulator is produced in slabs, the density of the material is 35-50 kg/cubic. m. The disadvantage of stone wool compared to fiberglass counterparts is less elasticity and susceptibility to rodents.

Glass wool – elasticity and moisture resistance

The basic components of the heat insulator are broken glass and sand. The addition of binding components makes it possible to form rolls from the finest glass fibers. Approximate dimensions of the mats: thickness – 100 mm, width – 1200 mm, length – 10 m.

It is equally important to calculate what density of insulation should be used. For thermal insulation of frame buildings, this glass wool parameter should be at least 15-20 kg/cu.m. m.

Features of glass wool:

- high elasticity – the material easily takes on and quickly restores its given shape, which is very convenient during installation;

- vibration resistance;

- not susceptible to mold and unattractive to rodents.

Like rock wool, fiberglass is fire resistant. However, in comparison with the previous insulation, glass wool loses on several points:

- Unsafe material - installation is carried out in a respirator and protective clothing. The fibers are very fragile and when cutting, a lot of “glass” dust is released.

- Shrinkage of the heat insulator - over time, the risk of the formation of cold bridges increases.

Ecowool – versatility of use

A new word in the segment of thermal insulation materials is ecowool. The material is 80% recycled paper. Additional components: boric acid and sodium tetraborate. Minor ingredients provide protection against microorganisms and reduce flammability.

Useful: Design and application of sandwich panels

Distinctive features of ecowool:

- Ecowool is a loose insulation material, and therefore the technology for its application is fundamentally different from working with sheet mineral wool. To create a thermal insulation layer, special equipment is required - a pneumatic inflatable device.

- If the walls of a frame house are insulated poorly, there is a risk of ecowool shrinkage , which can lead to the formation of uninsulated zones.

- The material is not recommended for use near open fire sources, fireplace pipes and chimneys. A protective layer of basalt foil-clad fireproof mats or fencing made of asbestos-cement slabs is required.

The main advantages of ecowool: environmental friendliness, the ability to insulate hard-to-reach places and high sound insulation qualities.

“Warm wood” - an alternative to mineral wool

This group is represented by mats and boards made of wood fiber materials . The technical and operational characteristics of the insulation are at a fairly high level:

- good thermal insulation - thermal conductivity is comparable to that of mineral wool;

- preservation of the structure even when wet - the properties of the insulation do not change when absorbing moisture in a volume of 20% of its own weight;

- high strength and excellent sound insulation – protection from impact and “air” noise;

- sufficient density and elasticity - the insulation is attached between the frame posts without additional fasteners;

- environmental friendliness of the material and safety of installation work.

Wood fiber insulation “breathes” and helps maintain a comfortable microclimate in the house. The disadvantages of a heat insulator include: high cost and flammability.

So which insulation is better for a frame house?

A frame house is a wooden building that, without insulation, is suitable only for seasonal (summer) living; otherwise, high-quality thermal insulation will be required. The vapor permeability of the material used must be higher than that of the wood from which the frame is made.

The best insulation option for frame houses would be: basalt wool. As a last resort - ecowool. And the least suitable are polystyrene foam, polyurethane foam and extruded polystyrene foam.

I build it myself - I guarantee 100% quality

I do all the work personally, I have my own team

At first I was involved in roofing, but I have been building frame houses for more than 12 years now.

Building materials without extra charge

I will bring all the materials to you at the purchase price (compare my estimates)

99% of satisfied customers who recommend me to friends

in 17 years there was only 1 warranty case (fixed within 2 days) You can safely search for reviews about me on the Internet by the name of the site or by Mikhail Stepanov

How to insulate a house

Thermal insulation of a frame house is an important and complex stage of construction. You need to fill every millimeter of free space so that cold air does not enter through it.

Insulation of walls outside

There are two ways to install insulation in a frame house. In the first case, thermal insulation is installed during the construction process, in the second - on the completed building.

In the first case, we lay the thermal insulation in a checkerboard pattern between the frame components. This method helps prevent cold bridges in the thermal insulation layer, and also saves free space both inside and outside the building.

If insulation was required after the house was put into operation, then a layer of thermal insulation is placed on the surface of the facade. Material in slabs with a thickness of about 5 cm is suitable for this.

How I install insulation:

- First I do the preparatory work. I check the condition of the walls (if the house has already been in use), remove everything unnecessary from the facade of the building (nails, screws, etc.). I seal all the cracks and irregularities with polyurethane foam. If there are damp areas on the façade, I dry them with a hair dryer and also eliminate the cause of these consequences.

- When insulating a house during construction, I cover the inside walls with chipboards. Afterwards I put a vapor barrier film.

- Next I lay down the insulation. Each subsequent layer must overlap the junction of the previous one. The total number of layers depends on the region and its climate.

- After finishing work with the insulation, I put a windproof membrane on top and secure it with a stapler.

- I'm doing the sheathing. It serves as a ventilation opening between the membrane and the cladding.

- I attach particle boards to the sheathing.

- I am doing the façade cladding.