Work on insulating a house made of foam blocks is necessary to improve the characteristics of the building and extend its service life. This building material is lightweight, has good noise absorption and other advantages. But the blocks are exposed to negative environmental influences and require careful protection.

Insulating your home is a very important step in preparing for winter.

Features of foam block houses

Foam block is a lightweight building material with a cellular structure.

On its basis, inexpensive premises with a good degree of heat and sound insulation are built.

The main advantages of foam block houses include:

- Increased thermal insulation. Cellular surfaces of aerated concrete or foam concrete have minimal thermal conductivity. This allows you to reduce heat loss during the cold season and protect the building from overheating in the summer.

- Ease. The weight of 1 m³ of foam concrete ranges from 300 to 1200 kg, depending on the series. This factor reduces the requirements for the quality of the foundation and makes construction work less expensive.

- Minor water absorption. Foam blocks are produced using the following technology: the initial raw materials are poured into molds, and closed pores appear in the final product, preventing the penetration of liquid from the outside. To check the hygroscopicity of a material, simply immerse it in a container of water.

- Long service life. The cellular blocks are based on concrete, which provides additional strength. Therefore, over time, the building becomes more reliable.

- Flame resistant. According to the fire resistance class, the material is one of the most fireproof.

- Compliance with environmental regulations. The feedstock includes sand, water, cement and foam formers. During operation, the blocks do not emit harmful substances or toxins.

- Ease of communication. Due to the porous structure, making holes for pipes or wiring inside the blocks is quite simple.

Foam block houses have increased thermal insulation and a long service life.

When reviewing the advantages of foam block houses, it is important to analyze the negative sides. Among them:

- Probability of house shrinkage.

- A number of problems when installing fasteners in the wall.

- The need for reinforcement and finishing with special compounds.

- Fragility.

Which aerated concrete does not need to be insulated?

Buildings made of 300 mm aerated concrete can be operated without insulation. At the same time, heating costs will increase many times over, so most homeowners opt for thermal insulation.

However, insulation of a gas block is not always required, and sometimes it is even strictly contraindicated. The answer to the question whether it is necessary to insulate 300 mm aerated concrete will be negative in the following cases:

- The building is not residential, it is classified as industrial or warehouse.

- The house is located in the south, where the required thermal conductivity coefficient is below 1.25.

In other cases, residential buildings made of aerated concrete blocks require insulation.

Is it necessary to insulate houses made of foam blocks?

Residents of warm regions do not need to insulate buildings made of foam blocks, because... the material itself has a good degree of thermal insulation. But due to the specifics of the Russian climate, it is better to carry out additional insulation of the building.

In addition, under unfavorable climatic conditions and other related factors, foam concrete begins to absorb condensate and freezes. To eliminate all problems, external thermal insulation should be performed.

There are several reasons explaining the importance of proper insulation of foam concrete structures:

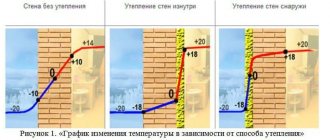

- Due to the porous structure of the structure, steam passes through. In the absence of an insulating layer, the dew point will be inside the material, which will shorten its service life.

- High-quality insulation reduces heating costs.

Experts advise additional insulation of the building.

You can refuse to perform thermal insulation work if the building will not be used during the cold period.

But exterior finishing is mandatory, since under the influence of negative environmental factors the walls can become unusable.

So what will external insulation of a house give if it is carried out?

The purchase of thermal insulation material will certainly lead to an increase in construction costs, but this will provide a number of advantages:

- If you skillfully calculate the properties of insulation and wall thickness, you can reduce the mass of the overall structure and save on the foundation.

- The low level of thermal conductivity of the walls will reduce fuel costs.

- A wall made of foam blocks will be protected from destruction, which will ensure the longest service life of the structure.

Many experts in the construction industry believe that the insulation process for foam concrete structures is an irrational exercise. But in most cases, they fanatically overestimate the properties of foam concrete (it is good, but not ideal), so it is possible, and even necessary, to increase the ability of walls with the help of insulation.

What materials to use

When choosing insulation, you should consider the method of its application. Builders insulate housing in 2 ways:

- from the inside;

- outside.

For external thermal insulation

To protect the building from heat loss from the outside, vapor-permeable materials should be used. If the condensation that accumulates inside the structures cannot escape, the walls will begin to become damp and lose their attractive appearance. The following solutions can be considered as facade insulation:

- Mineral wool. The material has high vapor permeability, but if installation rules are not followed, it can shrink. Certain varieties are used only in conjunction with a protective finish. Mineral wool should be isolated from the destructive influence of wind and other external factors that spray small particles. In addition, it absorbs moisture and is not suitable for installation in cold weather.

- Ecowool. The insulation is made from cellulose with the inclusion of various chemical additives that increase the room’s resistance to fire and aggressive compounds. Cellulose wool is spread over the surface in a wet state using special devices. Therefore, it will not be possible to complete the work without the help of specialists.

Mineral wool is a fibrous inorganic insulation material.

For internal

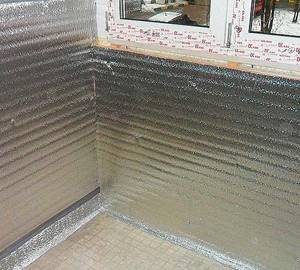

Thermal insulation of walls from the inside is used as a supplement to the outside, and also in cases where it is impossible to insulate the building from the outside. For example, the method is suitable for protecting a loggia or balcony from the cold.

When choosing the optimal materials, you can use both vapor-permeable and vapor-tight solutions. In the first case, the building stops “breathing”, so it is necessary to provide an effective ventilation system.

Vapor-permeable options include mineral and cellulose wool, and vapor-tight options:

- Styrofoam. It is an affordable and high-quality insulation with a degree of thermal conductivity from 0.032 to 0.04 W/m*K. Like other products with a polymer base, polystyrene foam is subject to combustion even if it contains fire retardants. When exposed to high temperatures, the material releases toxins.

- Penoplex. This is foam plastic produced using a special technology. Compared to classic material, it has an increased safety margin, longer service life and thermal conductivity. The only drawback of the material is its high cost. Therefore, it is not always justified to use it for internal insulation.

- Polyurethane foam. It is distributed like liquid foam using a special device. It has minimal thermal conductivity - from 0.019 to 0.058 W/m*K. The disadvantages of the material include limited service life and high cost.

Polystyrene foam is an affordable and high-quality insulation material.

Insulation technologies with different materials

Depending on the thermal insulation material, the insulation features of the building may vary. Also, depending on the type of insulation, different installation technologies are used.

Foam plastic

In most cases, polystyrene foam is used for external processing. But if it is impossible to carry out work outside, it is allowed to install the stove indoors. To do this, select the option with the appropriate marking. Before starting work, you need to prepare a number of tools and materials, such as:

- thermal dowels with nails;

- glue mixture;

- reinforced composition;

- fiberglass mesh;

- primer;

- dye.

Polystyrene foam is used for external processing.

The length of thermal dowels is calculated according to the following principles: the approximate length of insertion of the fastener into the surface is added to the thickness of the insulation. The softer the material used to make the façade or interior walls, the longer the dowel you need to choose. For insulation of concrete buildings, 5 cm is enough. If the dwelling is made of shell rock - from 7 cm.

The nail is used to wedge the “fungus”. The cells of the fiberglass mesh are treated with alkali-resistant impregnation, which prevents the destruction of the mesh. The finishing putty is chosen based on personal preference.

First you need to dilute the glue, following all the recommendations. Next, the composition is distributed over the wall using a spatula with an 8 mm tooth. The slabs are placed in a checkerboard pattern, and dowels should be driven through the holes and nails inserted into them.

Then a reinforcing layer is applied to the insulation. It is leveled, and the joints are covered with a spatula. A fiberglass mesh is laid on top.

Mineral wool

Mineral wool can be laid in 3 ways:

- Using the “well” method. Mineral wool is placed between the facing layer and the wall.

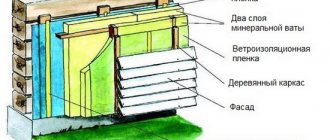

- Frame technology. Builders call this method “dry” or “ventilated” and consider it universal. The insulation is tightly placed in a metal frame and fixed using umbrella dowels and adhesive. Due to the presence of a special gap between the thermal insulation material and the wall, air exchange is always maintained in the voids. This prevents condensation.

- "Wet" installation. Well suited for buildings made of brick, aerated concrete or foam concrete blocks. Mineral wool slabs are applied to the surface and secured with glue and dowels. If all the rules are followed, the surface becomes almost uniform, without seams or gaps.

Mineral wool is well suited for insulating a foam block house.

Penoplex

To insulate a building with penoplex, you should prepare suitable fasteners and follow the instructions. First, you need to clean the coating from dirt and coat it with a primer. Then the foam boards are attached to the wall using an adhesive solution and dowels. All voids and joints are sealed with polyurethane foam. Next, the first plaster layer with mesh is distributed, and after that the second. At the last stage, finishing and fastening of the facade decor are carried out.

For insulation, foam boards are attached to the walls.

Expanded polystyrene

To insulate a room from the inside with polystyrene foam, you must do the following:

- Get rid of the old coating on the walls and antifungal impregnation.

- Put the surface in order, insulate the window openings.

- Attach polystyrene plates in niches behind heating radiators for better heat transfer.

There is no need to use additional fasteners for polystyrene foam boards.

Drywall is used as finishing material.

Insulate the room from the inside with polystyrene foam.

Instructions for external insulation

External insulation of buildings made of foam blocks is carried out in 2 ways:

- “wet” installation method;

- through a ventilated façade.

Each option has both positive and negative sides.

"Wet" facade

To decorate the outside of a house with your own hands cheaply and efficiently, you can use the “wet” facade technology. To carry out the work, you need to prepare facade mineral wool, adhesive for insulation, plaster mesh, disc dowels, facade primer and finishing materials.

The thermal insulation board is glued according to the following instructions:

- First, apply a primer to the surface, and then prepare the glue and distribute it over the back side of the insulation.

- The first slab is glued to the wall and aligned in different planes. The work starts from the bottom corner and is glued in rows.

- The second row is slightly shifted in relation to the first, adhering to the chess principle. It is important to ensure the evenness of the installation using a building level.

Use the “wet” façade technology.

The next stage involves installing dowels. First you need to drill a hole in the slab 5-7 cm longer than the length of the dowel and insert fasteners there. A nail, which comes with the kit, is driven into the formed opening.

At the last stage, all that remains is to reinforce the insulating material and finish it with plaster.

Ventilated façade under siding

The ventilated façade option does not imply wet work, so thermal insulation can be done both in warm and cold periods. In addition, this finishing technology ensures maximum strength and durability of the coating. But the costs of installing insulation increase by 20-30%.

To insulate a room under siding, you should use the following materials:

- panels and additional elements (corners, film);

- wooden beams with a section of 50x50 mm;

- a layer of protection from wind and moisture;

- insulation.

Siding finishing technology ensures maximum strength.

Algorithm of actions:

- Secure the frame. The timber is cut according to the height of the walls and fixed in a vertical plane in increments of 30 cm or 60 cm. Since the foam block does not have a large margin of safety, the racks must be fixed with extreme caution.

- Carry out insulation and vapor barrier work. At this stage, you should distribute the insulation boards and secure them with 1-2 fasteners. Then attach a moisture and wind protection film to the material, as well as wooden slats to create a ventilation gap.

- Install siding. To install it, you need to secure a base strip along the bottom line of the skin. Decorative corners should be provided in the corners to serve as guides. The first panel is tucked into the corner and aligned with the starting bar. Then the material of the second row is joined to it.

When is insulation necessary?

If we are talking about a wall made of blocks with a thickness of 375 mm, then such a structure will be quite capable of retaining heat. All you need to do is install the outer cladding yourself .

But this is only a general rule. In reality, it's not that simple. In addition to thickness, what also matters here is how well the masonry was made and whether heat escapes through its seams.

Heat can escape through the seams between blocks

An important factor is the strength of the material used. The higher it is, the worse the thermal insulation properties of this product will be.

But this is particular. At the same time, there are also common cases when insulation of a foam block house is simply necessary.

Let's list them:

- the use of high-density foam blocks in the construction process - it is denoted by the Latin letter “D”. In this case, we mean the value of this parameter equal to 500 or higher;

- the width of the blocks is less than 300 mm - in this case, the building constructed from them will also have to be insulated;

A house built from such elements cannot do without insulation.

- if the load-bearing frames of buildings are filled with foam concrete products;

- You will have to think about how to insulate a wall made of foam blocks even if the builders made mistakes - for example, using ordinary cement mortar for masonry rather than special glue. It is also a mistake to create thick seams.

The seams should not be thick

Instructions for internal insulation

Internal insulation of buildings made of foam blocks is carried out using 2 technologies:

- "wet" method;

- under dry plaster.

"Wet" method

This principle is practically no different from the “wet” façade method used for external insulation. The main thing is to cover the reinforced surface with putty, and not with decorative plaster. Then the walls need to be finished with paint, tiles, decorative stone or other material of interest.

With the “wet” method, the reinforced surface is covered with putty.

When using the “wet” method, mineral wool, penoplex or foam plastic are chosen as insulation.

Dry plaster

Dry plaster means drywall, which is fixed to the frame. A vapor barrier film or penofol is placed between this material and the heat-insulating boards to prevent the insulation from getting wet. But if polyurethane foam is chosen to insulate the house, then there is no need to install additional vapor barrier. The material is completely protected from condensation.

The principle of insulation is to distribute foam over the surface of the walls. The composition itself has good adhesive properties, so it combines well with concrete.

The specifics of applying foam are accompanied by some difficulties. If you do not use professional equipment, you will not be able to insulate your house.

Dry plaster protects against condensation.

We insulate the walls from the inside

When using this method, you may encounter the following problems:

- destruction of foam concrete walls due to temperature changes (dew point inside the wall);

- condensation on the walls indoors - you need to use a vapor barrier and install a false wall;

- the appearance of cold bridges in places of contact with ceilings;

- internal insulation requires the use of insulation with improved environmental characteristics;

- risk of rodents appearing inside the insulation.

Stages of insulation of ceiling and floor

To protect a foam block building from cold and other adverse influences, additional insulation should be provided for the ceiling and floor. It is recommended to use a concrete floor in such houses, installing a sheathing of wooden beams before laying. Expanded clay is poured inside this structure, and then a concrete base. Insulation after hardening is carried out using linoleum, parquet boards or other suitable coatings.

It is necessary to carry out thermal insulation of ceilings if you need to insulate the living part of the room.

Favorable time for work

Foam blocks are delivered to the construction site in sealed packaging. If the building is erected in a short time, then after completion of the work the blocks will retain moisture and insulation will become impractical.

This reduces the vapor permeability of the object, and under the influence of frost, condensation will be directed to those places where the partial pressure is lower. Once moisture interacts with the interior finishing, it will begin to accumulate in the walls, causing wet spots to appear. As a result, the foam concrete will begin to freeze, and the insulator will rot.

If a house is being built in the spring, then it needs to be insulated at the end of summer. In this case, the block will have time to dry completely, and the work efficiency will be higher.

Tips and tricks from professionals

In order for thermal insulation work inside or outside the house to be completed properly, you should follow the recommendations of specialists and not deviate from the step-by-step guide. The foam blocks themselves do not allow steam to pass through, so the accumulation of moisture can cause the material to become damp. To get rid of condensation indoors, you need to provide a high-quality ventilation system. For rooms made of cellular concrete, mineral wool or expanded polystyrene slabs are used as an additional protective layer.

A properly insulated house made of foam blocks will have a comfortable microclimate all year round and will last as long as possible.

How to insulate

Since the foam block does not have very high strength, it is necessary to use lightweight materials for its finishing.

Outside

The most commonly used insulation materials for external walls of a house:

- Mineral wool. This is an inexpensive material with high thermal insulation characteristics. It is vapor permeable, so moisture does not linger inside the blocks, has a long service life, and is not flammable. The material must be well protected from moisture, otherwise its characteristics are reduced, and you must work in a respirator.

- Expanded polystyrene (foam plastic). This material is not afraid of high humidity, it is frost-resistant, and has an affordable price. Please note that polystyrene foam deteriorates when exposed to sunlight, so it requires additional coating.

Inside

If you decide to carry out the above work inside the house, then first decide whether it needs to be done.

Foam concrete has high heat and sound insulation characteristics, and if you additionally insulate it from the outside, then there is no need to do this inside.

Materials

Indoors, it is best to use fiberglass or basalt wool as insulation, and so that you can lay it yourself, it is recommended to take it not in rolls, but in slabs.

Cork

This material not only acts as insulation, but can also be used as a finishing coating.

Before using it, the walls must be properly leveled using plaster; they must be clean and dry. The only drawback of cork is its high cost.

Penofol

If you insulate walls made of foam concrete with it, then about 95% of the heat will remain indoors. Thanks to the presence of foil, heat returns to the room.

The slabs are laid tightly, and all joints are taped, after which you can begin installing the finishing material.

Polyurethane foam

This is a foam material, with the help of which all cracks and voids are sealed, so cold bridges do not form.

This material hardens within 20-30 seconds after application and will serve for at least 50 years.