Foam is quite often used in the construction process. It is often chosen as insulation for the walls of private houses and other buildings. When using material for thermal insulation, possible cold spots, which are often located in the area of the seams, must be excluded. If present, adjacent areas should be sealed. The ideal layer is considered to be one without existing seams, through which heat will not escape and cold will not be able to enter the room. Foam can provide the walls of a house with these beneficial properties.

Penoizol

Despite the complexity of the process of mixing the liquid components of the insulator, foam insulation between walls is a fairly popular method of insulation.

It's all about cost. Polystyrene foam is cheaper than polyurethane foam, practically not inferior to it in terms of its technical characteristics. However, when practicing independently, such equipment requires certain skills and knowledge. It is necessary to know how much it is necessary to increase or decrease the performance of the compressor unit when working on different sections of the walls. In addition, the components are mixed in certain proportions, which also need to be known. At the same time, experience in performing such operations is also important - filling voids requires care and experience, since if the process is not carried out correctly, you can not only create a poor-quality layer, but also destroy fragile structures

If you do not have experience in such operations, it is better to pay attention to other methods of insulation

Insulation technologies

Installation of polyurethane foam can be done in one of two ways:

- spraying;

- filling.

Let's look at each technique in more detail.

Thermal insulation by spraying

Installation for spraying polyurethane foam

Installation of insulation by spraying is carried out using special installations, into which two main components are supplied from separate containers - polyol and polyisocyanate. Then the ingredients enter a spray gun, where they are mixed and applied under high pressure to the surface to be insulated.

Types of foam insulation

Foam insulation may differ in its structure and composition. We can distinguish the main types of material for insulating walls and windows:

- Penoizol. It contains aldehydes, which are harmful to health, although manufacturers often claim the opposite. It dries much longer than polyurethane (complete drying time can reach three days). Typically used for insulating attics, load-bearing walls and structures. Can be purchased in the form of ready-made slabs or as a liquid composition.

- Ecowool and foam concrete. Can be purchased in liquid form, most often used for pouring foundations. They are practically not used when finishing facades due to their significant weight, which puts a large load on the walls. In addition, the high cost often speaks against this material.

- Polyurethane foam. Suitable only for sealing seams, joints, holes, since it does not allow moisture and steam to pass through, and this is a critical point for insulating material. When interacting with air, its volume increases twenty times, while there is a minimal amount of air bubbles inside. Can be purchased in convenient small-volume containers that have a significant shelf life.

- PPU or polyurethane. The most common option, which is considered the most universal. Polyurethane insulation is very effective as thermal insulation for facades. It consists of two components; they must be mixed by machine immediately before application. The foam expands thirty to forty times from its initial volume, and small balloons form inside. Due to this, high-quality insulation of the house is achieved.

How does Russia insulate itself?

When property owners are faced with the question of insulation, they have to choose between polystyrene foam, mineral wool or basalt fiber.

Recently, pouring penoizol into the ventilation gap of brickwork has become popular. This once again confirms the fact of blatant technical illiteracy of both customers and performers. The components of Penoizol contain a large amount of water, which remains in the material for a very long time, negating the thermal insulation properties of Penoizol. When drying, Penoizol cracks, forming straight bridges of cold.

In general, people without special education (and these are the absolute majority), when faced with the problem of insulation, use everyday logic. The essence of this logic is to compare insulation with winter clothing. Which is fundamentally wrong.

What do we wear in winter? Sheepskin coats and down jackets.

What protects us from the cold? An air layer that is located between the fibers of wool, down or padding polyester.

Mineral wool and basalt insulation consist of almost the same fibers, and if they are sewn into fiberglass, then this is a real down jacket.

The analogy is inaccurate.

We periodically take off our clothes, excess moisture evaporates, and it is impossible to remove the insulation. Insufficient thickness of the insulation leads to freezing and accumulation of moisture, which destroys both the insulation itself and the surface, which turns from heat-insulating to heat-conducting, which further aggravates the situation. But property owners don't know about this. In 90% of cases, the insulation is not available for control. Some actions begin only after the appearance of mold and mildew.

Why is this happening? Air is the best insulation after vacuum. But STILL air. If the structure of the insulation is such that air flows pass through it, such “insulation” must be protected from saturation with moisture. For our climate, the thickness of such insulation should be at least 20 cm, with double protection and an air gap in front of the outer cladding. 5-7 cm of hard polyurethane foam is sufficient without additional measures.

Foam plastic (expanded polystyrene)

- Article about teaching staff

- Comparison and calculations

Consists of granules foamed under the influence of high temperature.

Thanks to its low cost, it has gained popularity, especially in the Samara region, where one of the largest PPS production plants is located.

Density - from 15 to 40 kg/cub.m.

Thermal conductivity coefficient - 0.04 W/m*

Moisture absorption coefficient - 3-5%

Effective service life is from 5 to 10 years.

It is used everywhere, from insulating balconies to facades of multi-storey buildings.

Almost all modern new buildings are insulated with 10 cm thick EPS, followed by finishing with facade plaster.

Why? Because it's cheap. And because the construction company is then not responsible for anything.

Minvata

Consists of mineral fibers glued together.

It is also a very popular insulation material, also due to its low cost. The main disadvantages of mineral wool are its fragile structure and the presence of formaldehyde in the adhesive base. It is a poison and an allergen. In terms of thermal conductivity and service life, it is worse than its competitors.

Density - 10-25 kg/cub.m.

Thermal conductivity coefficient - 0.045 W/m*

Moisture absorption coefficient - 25-40%

Effective service life is from 2 to 5 years.

It is mainly used for insulating the roofs of houses, small structures such as trailers, cabins, and modular structures of any size.

Why? Again, because it's cheap. And again, because then no one is responsible for anything.

Basalt insulation

Consists of ultra-fine fibers obtained from basalt rocks.

The main advantage of the material is its non-flammability. Formaldehyde is also present.

Density - 15-50 kg/cub.m.

Thermal conductivity coefficient - 0.04 W/m*

Moisture absorption coefficient - 15-30%

Effective service life is from 5 to 8 years.

It is used everywhere, especially in the construction of frame wooden houses.

So what material is free from the main disadvantage of sheet and roll insulation?

Technical characteristics of polyurethane foam

Let's look at what polyurethane foam is. This material is considered one of the best for insulating aerated concrete and other surfaces. Foam of this type has both advantages and disadvantages, which can manifest themselves both during operation and in the future.

Typically, the main components of foam are special combinations of polymers. Initially they are in a liquid state, but after being applied to the surface when interacting with air, the foam hardens almost instantly, filling the pores and forming a very dense and reliable layer.

Positive properties

Let's consider the main advantages of using polyurethane foam for wall insulation. There are quite a lot of them, which explains such a high degree of demand for the material among builders and people who started insulating walls.

- Very high degree of sound insulation. As a rule, foam today is even better than extruded polystyrene foam at isolating a room from extraneous sounds. This applies to both external and internal insulation. In both cases the effect will be achieved. Only natural cork material can compete with foam in terms of sound insulation.

- Absolute degree of environmental friendliness. This property allows you to use polyurethane foam for any purpose, even for sealing cracks in the walls in a children's room. The foam does not emit any toxic substances even when exposed to external factors.

- Polyurethane foam is relatively resistant to negative environmental factors; it is a non-flammable insulation material. She is practically not afraid of rain, wind, or extreme heat. The polymer composition gives the polyurethane foam greater stability, especially high if a protective layer of plaster is applied on top of it.

- Polyurethane foam is quite easy to work with. It has good adhesion - it adheres perfectly to almost any surface, it can even be applied to metal panels. Has the ability to expand several times. As a result, even a large crack can be filled with a small amount of liquid foam.

- The degree of thermal conductivity of foam is considered one of the minimum among other materials for insulating walls in a house. This allows it to retain heat in the room and keep air and moisture out. And fire resistance protects the house from fire.

Disadvantages of polyurethane foam

But there are also disadvantages to using polyurethane foam. Of course, there are not as many of them as advantages, but still they must be taken into account. This will allow you to avoid mistakes and make the right choice.

- Polyurethane foam is not resistant to ultraviolet radiation. As a rule, after sealing cracks and cracks, additional materials should be applied on top or finished with slabs. This will protect the foam from exposure to sunlight, which causes the destruction of polymers in the structure.

- Another disadvantage is the cost. Now on the building materials market you can find many types of foam, which differ from each other in their characteristics. But usually even a small bottle of foam is not cheap. And when working with damaged walls and large areas, you will have to buy a lot of foam at once.

So, if you carefully weigh all the pros and cons, you can choose a good polyurethane foam that will serve for a long time and will firmly protect the inside of the house. Taking into account all the subtleties described above will not allow you to make a mistake.

Foam for wall insulation: types and features

To insulate walls, modern craftsmen use various materials and technologies. They have significant differences among themselves, but they are all designed for the same purpose - to make the thermal insulation of the house as productive as possible.

IMPORTANT!

Polyurethane foam is considered one of the most effective materials used for insulation . This material will best protect against cold air entering the building.

Liquid foam for wall insulation is called polyurethane foam (PPU).

All the necessary ingredients are mixed at the factory and the composition required for polymerization is kept under high pressure in cylinders. In order for the foaming and hardening reaction to occur, contact of this composition with oxygen is necessary.

Insulation with polyurethane foam

Is it worth insulating walls with foam? Of course, it’s worth it for one simple reason - polyurethane foam is an ideal material for this purpose, and besides, it performs another very important function - sound insulation.

What is foam insulation? This is a special pliable mass that, when interacting with air, tends to foam. This composition has a fairly strong and elastic structure. To spray it, cylinders, pneumatic devices and other devices are used.

Today, when constructing frame-type houses, the areas between the “sandwich panels” are filled mainly with foam insulation.

Polyurethane foam

From a technical point of view, everything will be much simpler here. The composition will be mixed from two ready-made components and the whole process will be much easier. It is necessary to observe the proportions of liquid compositions entering the mixer and monitor the pressure provided by the compressor

The rest of the precautions will be the same as in the previous case - you can easily destroy fragile brickwork with foam, which can expand forty times

The cost of the material in this case will be higher, but it is easier to work with and the quality of the insulation will be at a high level

It is important to ensure that the voids are filled evenly. At the same time, during the polymerization process, this composition will release significantly less formaldehyde compounds than in the situation with penoizol, and the time for complete hardening of the foam will be reduced several times

Regardless of the chosen option for foam insulation, you need to remember that there are no harmless compounds of this kind. All of them will release formaldehyde during the polymerization process. Therefore, while the foam dries, it is better to leave the house empty and not live in it. It will take a couple of days or even a week, but you are guaranteed to protect yourself and your loved ones from poisoning. In this regard, penoizol performs worst of all, which can dry in open spaces for up to thirty days - depending on the proportions of mixing the components and the quality of the raw materials.

How they insulated my wall with foam insulation and how it all ended

Good afternoon to my readers.

I've been absent from the blog for quite some time. And all because events have unfolded over the past two weeks that have occupied all my thoughts and time. This is what I will talk about in today’s notes. With the beginning of summer, the family resumed debate about insulating the furthest room in the house. It really is a couple of degrees colder. True, the wife claims that she is also pulling from somewhere in the upper corner. I don’t feel any drafts, the wall is just cool. Be that as it may, it was decided to insulate the walls. The disputes were regarding the technical side of the issue.

Insulating the outside of the house with mineral wool followed by siding was rejected due to the lack of the required amount of money for this type of work. Insulation from the inside, also with mineral wool, vapor barrier and covering the walls with plasterboard, was the last thing I considered (it risks a total renovation of the room, the presence of suspended ceilings and a reduction in the usable area of an already small room). And here, like a lifesaver, an advertisement from a newspaper about insulating houses (as well as all conceivable building structures) with foam insulation .

For reference. Penoizol is a polymer foam, a kind of liquid foam (components: water, foaming agent, acid, hardening resin), which is used to fill cavities in building structures, between walls. Many advantages and few disadvantages. And so on and so forth... I won’t describe it for too long. Those interested can type in the search (Yandex knows everything) and see what kind of animal this penoizol is.

That's it, I think. This is salvation for me! I called the ad, talked, found out in advance what the insulation was, how the work was carried out, prices, and so on. The next day, a representative of the “insulation” team arrived and inspected the scope of work on site (that is, my house), estimated the volume of work and we parted, promising to call as soon as he had time free from regular orders.

And then at the end of July comes D-Day. An installation crew of three people drives into the yard in a GAZelle, which carries all the props necessary for the work. A compressor, piles of coiled watering hoses, wires, buckets, watering cans, a large rusty barrel... it all looked like a bunch of junk. Honestly, I somehow imagined everything a little differently, but you never know. Maybe I just don't know anything about the latest nanotechnology.

The work didn't work out right away. Something was constantly getting lost, something didn’t work or broke along the way. Either the extension cord is burned out, then the compressor does not produce the required pressure, then the bucket is leaky, then the taps are leaking... in short, everything is not thank God. They agreed that they would go home to repair the compressor (as soon as they do it, they will come). Two days later they arrive with a new compressor, well, now things will go smoothly. I suspected something was wrong when all the workers had been running after each other for more than half an hour, turning the taps on the pressure gauges and blowing into the hoses. Well, I ask. But the problem is, the mixer and all the filters in it are clogged, just clean it and rinse it with acetone. In short, they untwisted the ill-fated mixer, jumped into the car and rushed home. On the third visit, the solution refused to foam properly, they say the foaming agent had deteriorated due to the statute of limitations. Let's go get the foam concentrate. I was already getting tired of this, but my wife grabbed my hands, begging me not to kick them out, as I had planned. Because no one else in our little town is engaged in such a cunning occupation and there is no one else to work with. Okay, this will be their last chance.

The last chance was provided for a very long time. Where they disappeared to for a week and a half remained a mystery to me until the very last day. Their phones stubbornly did not answer, all their accessories were in the gazebo and I began to get more nervous than usual. When, one fine sunny morning, they answer the call and, as if nothing had happened, they declare that he was driving to Belarus to get a car and they had no time. And now they are rested and ready to continue working.

In response to my angry reproaches and indignation, the workers began to sniffle offendedly and considered themselves unfairly offended. Silently they unsheathed their vacuum cleaners and pumps, mixed the paste and got to work. I sit next to them and watch their activities. It doesn't seem to be suspicious yet. Foam pops and cheerfully climbs out of the holes in the wall, which the craftsmen quickly plug with their fingers and newspapers. Two hours later, when a third of the holes in the walls had been used and plugged, the workers informed me that they say that the water has run out. The water used was not just any kind, but river water, hard, so that it would not foam so abundantly. And the barrel, as luck would have it, remained on another farmstead in a neighboring city. We'll come tomorrow, bring fresh river water and finish it all. I just nodded silently, because I was simply tired of swearing.

Installation of lathing and applying foam yourself

It is necessary to screw an aluminum profile to the ceiling and walls in vertical rows. Next, the sheathing is strengthened using horizontal jumpers (0.5 meter increments). Don't forget to screw the profile around the perimeter of the window doorway.

In order not to stain pipes and communications, they need to be covered with film.

Installing the sheathing

Rules for applying foam insulation in cylinders:

- First of all, you need to take care of safety precautions.

- Then you need to spray a small amount of automotive silicone grease onto the mounting gun.

- Next, you need to insert the can onto the gun and screw it tightly.

- Now you can apply the mounting foam to the desired location.

- The can must be removed from the gun and cleaned with a special compound.

- If the foam is not completely used up, you need to wash the valve located on the cylinder with a cleaner.

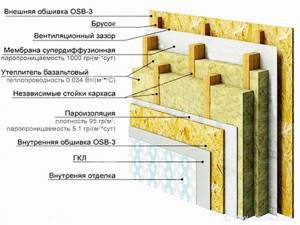

wall pie

Construction of a wall “pie” of a frame house:

- interior decoration;

- vapor barrier layer;

- insulation;

- frame stand;

- windproof layer;

- transverse lathing;

- vertical lathing;

- external finishing.

If you plan to insulate the premises from the inside, you need to carry out all the work in stages. One of the main issues that you should pay special attention to is the correct placement of the vapor barrier film in the thermal insulation “pie”.

Vapor barrier can be made from:

- reflective film;

- diffusion membrane;

- steam condensate film.

When installing a vapor barrier material, you need to take into account one important point: it must be mounted on top of the insulation on the room side. If you plan to insulate the wall with polyurethane foam, then you will not need a vapor barrier.

Cost of paving slabs

Many factors can influence pricing. For example, ordinary domestically produced tiles cost approximately 500 rubles. for 1 sq. m. Imported products are more expensive, but not much - about 500-700 rubles. for 1 sq. m. Elite options cost approximately 1,500 rubles.

The cost of work also depends on the types of additional activities. Creating a path on crushed stone or sand costs approximately 1000 rubles. for 1 sq. m, and installing tiles on concrete costs approximately 1,200 rubles. Installing curbs costs an average of 300-600 rubles, the price depends on the characteristics of the material.

The most budget option is installation on an existing base (approximately 500-800 rubles). Another way to save money is to make paths in your dacha with your own hands from paving slabs. Let's look at this option in more detail.

Standard gray brick tiles and beige-orange paving stones allow you to create an interesting pattern

More expensive and beautiful look of embossed paving slabs

Using paving slabs on a garden path

Standard gray paving slabs on country house paths

Where can it be used?

You can insulate with polyurethane foam both residential or industrial buildings (inside or outside), as well as window or door openings, as well as fill voids formed in the walls when laying communications and pipes. The miracle sealant easily fills even small gaps, preventing the formation of insidious drafts. Walls, floors and ceilings can be easily insulated. It protects the tree from rotting and fungal mold. Iron – from corrosion.

The environmental friendliness of the sealant allows it to be used even in such matters as insulating a nursery. Therefore, if we return to the topic of our article: “Is it possible to insulate a house using polyurethane foam? “- the answer will be definite. It is possible and even necessary! Of course, the high price of polyurethane foam sealant may scare you away, but the advantages mentioned above will definitely be worth the money you spend on insulating your home. However, one should not forget about one nuance - the use of this type of insulating material makes the insulated room almost airtight, which means that the building or room must have well-thought-out ventilation so that problems of stuffiness or stale air do not arise.

Polyurethane foam is suitable for insulating hangars, garage doors, garages, facades, windows, as well as balconies and bathtubs. Using the material, you can insulate the area between the walls between the brick and the block. Waterproofing with it from the inside and on the roof is more reliable.

To learn how to insulate a balcony with polyurethane foam, see the following video.

What is the best way to insulate a building with foam - from the outside or from the inside?

It is difficult to give an unambiguous answer to this, but we will try to do so. One of the varieties of liquid foam, penoizol, is used for thermal insulation of frame buildings . This material fills the air gaps between:

- external and internal walls;

- wall and plastic panel;

- a wall and a sheet of drywall;

- subfloor and floor covering.

Insulation outside and inside

Using polyurethane foam, slabs made of solid thermal insulation materials are fixed, and the seams between them are also filled with foam.

Some homeowners use foam to insulate the facade of their building.

Polyurethane is used to eliminate minor defects on walls.

You will get an equally good result if you insulate the walls of frame-type houses, the roof, the attic, the facade of the house, as well as the basement and lower floor with polyurethane foam.

Material selection

Before purchasing insulation, you need to check the composition and manufacturer, and compare several products. For example, European foam compositions for covering walls have very high parameters, but are expensive. Cheap nameless Chinese products are often of poor quality or very harmful.

Domestic manufacturers indicate the composition in full, in Russian, have quality licenses and produce affordable products.

Among the Russian brands, Khimprom, Elastokam, Dau-Izolan, Uretan, Vladipur, KhimPostavshchik Don stand out with constant demand and good quality.

Factories are subject to technical standards, and product quality is constantly monitored.

Foam insulation is the most preferred material, as it forms a seamless layer that serves its intended purpose and is subject to further finishing. You need to understand the principle of use and application in order to obtain high-quality thermal insulation.

The principle of using foam insulation is clearly shown in the following video:

Peculiarities

In order to insulate the walls in any home, it is best to use polyurethane foam. This type of foam hardens very quickly, which allows you to get a dense surface in a matter of hours that separates the interior of the room from external temperature changes, drafts and moisture penetration.

The main characteristics of foam include:

- heat resistance - the material can withstand heating up to eighty degrees;

- capable of letting water through if necessary;

- possibility of providing vapor barrier;

- high level of strength;

- increases in volume after application.

When using this material, you don’t have to worry that the wall structure can easily ignite, because the foam resists this in every possible way. With all the positive aspects of this material, there is also one negative aspect. It concerns the ability to freeze. If you foam something in a closed space, it will not freeze. In addition, the high cost of this product does not allow everyone to use foam to insulate walls in the house.

With constant contact with the aquatic environment, this material begins to deteriorate and eventually becomes completely unusable. Application of foam requires good ventilation, which means that certain conditions must be created for work

This material has low vapor permeability, so it is important to provide forced ventilation in the room

When applying foam with a thickness of four or more centimeters per square meter, you will need to use one balloon

In order to be able to do the work correctly and without risk to health, it is important to work using a pneumatic gun. This is special equipment that helps to spray foam evenly over a specific surface.

Such a gun mixes foam with gas and delivers it to the surface, evenly spraying where it is needed. Using such a device, you can independently adjust the intensity of the foam supply for more comfortable work. It is very convenient to use a pneumatic gun, but not everyone resorts to it due to the high cost of such equipment.

When applied to the surface, the foam does not form any seams, which is convenient and aesthetically pleasing. This material has minimal thermal conductivity. An important indicator is its environmental friendliness - when used, no harmful substances are released into the air. Any impact on the foam will be painless for it; it only reacts poorly to ultraviolet radiation.

When insulating a room, it is advisable to take care of sound insulation, which foam also does well. In addition, it has good adhesion to the surface. The foam is easily applied to uneven surfaces, while the formation of air pockets is completely eliminated. Rapid hardening allows you to continue working within 24 hours. Foam for wall insulation is a universal and convenient option, with the help of which even a non-professional can do everything well and efficiently, most importantly, follow safety precautions.

Cylinder assembly

It is best to carry out insulation with this type of insulation in small areas, because its use in large areas is not always economically feasible.

The reason here is that polyurethane foam is sold mainly in small volume containers, approximately 200 and a maximum of 750 ml.

The largest of them are inexpensive, but they are enough to process only 1 square meter. m of any surface, but taking into account that the layer will be applied no thicker than 8 cm.

After insulation with this material, the thermal insulation of the surface will be several times lower in comparison with the use of the other two types of foam. The reason is that in such insulation half of the cells remain open, whereas in the same polyurethane foam the number of closed pores reaches 90%.

The process of foaming polyurethane foam occurs due to the fact that it is supplied to the surface under high pressure.

In addition, this process intensifies after the material reacts with moisture in the air.

The use of this insulation is common for sealing both window frames and during the installation of doors. It is also advisable to insulate the walls of a small area, for example, a loggia or closed balcony.

This insulation has a more complex composition than classic polyurethane foam.

It is produced in the form of slabs, which is somewhat similar to classic polystyrene foam.

Being in this form, it is more protected from external factors for storage and transportation.

But to bring it into a liquid state at the point of use, a special device is used. It not only melts penoizol, but also mixes it with resin. When insulating walls using such insulation with your own hands, you use a special construction gun.

Foaming begins inside this device and then it is applied to the surface, where it hardens after 15 minutes. For the material to completely harden, you need to wait several days.

Due to the fact that it has a long period of complete hardening, brick-type walls are most often insulated with foam insulation. The material is also often used for thermal insulation of formwork, as well as for insulation of frame houses.

Good to know: due to the fact that the composition of penoizol includes urea and formaldehyde, a significant number of people believe that this insulation is harmful to health. In fact, this is not so, all these components are removed, so the material is harmless to people.

Purpose

The KMZ-012 minitractor was initially aimed at widespread use in agriculture and public utilities. According to experts, the debut model of the 0.2 traction class, in terms of its main indicators, is as close as possible to the parameters of budget analogues of foreign production.

The popularity was also contributed by the moderate price range, high level of reliability, maintainability and durability of the machine as a whole. The expectations of Kurgan machine builders were fully justified; the mini tractor became in demand not only in the domestic tractor market, but also in the CIS republics and neighboring countries.

Advantages and disadvantages of use

- The structure of the foam allows it to penetrate into the smallest spaces, thanks to the reaction that occurs when interacting with air.

- This material has a high level of thermal insulation. After complete hardening, it forms a monolithic coating that has no seams. No rigid insulation can do this.

- The foam does not cause significant load to the walls of the house and other structures, having a completely insignificant weight when frozen.

- Almost all types of foam after final hardening are absolutely harmless to human health and the environment.

- Basically, before finishing work with foam, no additional actions need to be performed. You just need to apply it and wait until it dries completely. This process will take a little time.

- The porous structure of the material increases sound insulation.

- When using it as insulation on the walls of a house, the construction of additional frames and other structures will not be required. The foam has a high level of adhesion and perfectly connects to the required surface.

- Most foam products work well with metals. When foam is applied to a metal surface, a protective coating is formed that prevents corrosion.

The disadvantages of foam include its high cost, which is an order of magnitude higher than other finishing materials that are used as insulation.

Foam is an effective material that creates a reliable and seamless thermal insulation coating on the walls of houses and other structures. This product appeared not so long ago, but is already quite popular for insulating facades

Each type of foam product has its own advantages, which should be taken into account before purchasing, based on the needs and scope of their application.

Which liquid insulation to choose?

As is known, long-term or improper storage significantly worsens the properties of materials, especially liquid insulation.

In this regard, when choosing a composition, you should first of all pay attention to the date of its manufacture. In addition, it is recommended to give preference to well-known brands that have proven themselves, because the effectiveness of the entire thermal insulation system depends on the quality of the liquid insulation

In order to ensure the quality of liquid insulation produced in the form of paint, experts recommend:

- Check the weight of the bucket - the lower the density of the composition, the higher its heat-saving properties. Therefore, if a ten-liter plastic bucket weighs more than 6.5 kilograms, then you should not purchase such a composition.

- Check the paint against light, as light microspheres rise up. Therefore, the thicker the top layer of insulation, the better its thermal insulation characteristics.

- Rub a small amount of paint with your fingertips - a good material should feel a large number of rough microgranules. The absence of such an effect indicates low quality of the product.

- Make sure the composition is white - a change in color indicates gross violations of the technological process. However, this rule does not apply to paints with mineral color additives.

It should be noted that in this case you should not focus on the cost of the product, since some manufacturers deliberately sell low-quality products at inflated prices in the hope that the choice stereotype will be triggered.

Polyurethane foam

From a technical point of view, everything will be much simpler here. The composition will be mixed from two ready-made components and the whole process will be much easier. It is necessary to observe the proportions of liquid compositions entering the mixer and monitor the pressure provided by the compressor

The rest of the precautions will be the same as in the previous case - you can easily destroy fragile brickwork with foam, which can expand forty times

The cost of the material in this case will be higher, but it is easier to work with and the quality of the insulation will be at a high level

It is important to ensure that the voids are filled evenly. At the same time, during the polymerization process, this composition will release significantly less formaldehyde compounds than in the situation with penoizol, and the time for complete hardening of the foam will be reduced several times

Regardless of the chosen option for foam insulation, you need to remember that there are no harmless compounds of this kind. All of them will release formaldehyde during the polymerization process. Therefore, while the foam dries, it is better to leave the house empty and not live in it. It will take a couple of days or even a week, but you are guaranteed to protect yourself and your loved ones from poisoning. In this regard, penoizol performs worst of all, which can dry in open spaces for up to thirty days - depending on the proportions of mixing the components and the quality of the raw materials.

Conclusion

Foam insulation can be used for walls made of various materials, including aerated concrete, blocks and reinforced concrete panels. Therefore, they are used for insulation of private cottages and apartments. Before giving preference to any one type of foam, consult a specialist.

If you have decided to insulate your house with liquid foam, this is the right intention. Always try to buy raw materials from the best domestic and foreign manufacturers. This way you will be able to avoid premature wear of structures.

1 Features of the material and work performed

Liquid polyurethane foam is a fairly good and reliable insulation material. The most widespread in this industry is the so-called polyurethane foam insulation.

In order to use it to carry out insulation with your own hands, you first need to put on special protective clothing.

After this, the process of insulation by spraying can begin. The presented polyurethane foam has one key feature - it hardens quickly.

Next, the insulation should fill the space located between the rafters in a short time. The same applies to vertical beams fixed in the wall of the house. The presented material is characterized by:

- Resistant to high temperatures (up to +80°C);

- Ability to pass water;

- High vapor barrier properties;

- Mechanical strength;

- The ability to increase volume is similar to that of liquid insulation Corundum.

Polyurethane foam, which provides reliable thermal insulation of the walls of the house, can also be actively used as a seal for cracks when installing plastic windows.

Polyurethane foam is made on the basis of polyurethane, and therefore it exhibits fairly high fire-resistant properties.

There is one significant drawback - it is not recommended to fill closed, unventilated spaces with such polyurethane foam.

In such an environment, the material is not able to completely harden. Thermal insulation using polyurethane foam is a fairly reasonable construction solution.

Foam for wall insulation

If you do this yourself, the working surface will become monolithic, it will not have seams or joints. The average capacity of the cylinder is 600-700 milliliters.

As a rule, one cylinder is enough to insulate 1 square meter with a thickness of 4-8 centimeters. Before starting work, the cylinder containing the insulation is inserted into a special gun.

The trigger is pressed and a tight stream of insulation flies out of the cylinder, which must be directed at the wall. After 24 hours the foam hardens completely. Using a pneumatic gun is rational when insulating objects with your own hands such as:

- External walls of apartments;

- Balconies with insulation for external walls;

- Loggias;

- Window;

- Foundations;

- Pipes.

1.1 Types of insulating foam

The presented insulation materials are currently quite widespread and are presented in the form of a wide range of products. It could be:

- Polyurethane foam;

- Two-component polyurethane foam;

- Penoizol;

- Liquid insulation for walls.

Polyurethane foam for walls is an insulation material presented in the form of a one-component polyurethane prepolymer, which can be easily applied with your own hands.

The process of spraying the substance itself occurs with the participation of a balloon. The insulation is supplied externally using the energy of compressed gas.

This is not the best insulation for walls, since after the substance expands and hardens, a layer is formed, which is a structure consisting of open cells.

This significantly increases the thermal conductivity and moisture absorption level of the insulation. In order to solve local problems associated with insulation, it is quite possible to use such foam.

The process of insulating a wall from the outside with foam

But in order to carry out major insulation of walls, other types of thermal insulation materials are needed. For high-quality wall insulation, it is recommended to use two-component polyurethane foam.

In this case, the mixture foams as a result of a chemical reaction between its components. During this process, the insulation material increases in volume many times over.

This substance hardens within a few minutes. The internal structure of the material consists of 90 percent closed cells.

Thanks to this, foam, like sprayed polyurethane thermal insulation Polynor, has a low coefficient of indicators such as thermal conductivity, vapor permeability and moisture absorption.

Two-component polyurethane foam is now recognized as the most effective thermal insulator. Penoizol is in many ways similar to polyurethane foam, but has a fundamentally different chemical composition.

It belongs to a subtype of carbamine-formaldehyde foam. When such material is applied to the wall, the process of mixing hardener resins occurs, and foam is formed due to pressurized air.

Thermal insulation of a house using foam

Thermal insulation work is one of the most important stages of construction.

This applies to technical structures and residential buildings. High-quality insulation can significantly reduce energy costs and extend the service life of walls and finishing materials. Thermal insulation with polyurethane foam (PPU) came to the construction market recently, but quickly gained popularity among specialists and customers. This technology can significantly reduce the time required to carry out work. Polyurethane foam can be used as insulation on any surface, as it has high adhesion rates and has virtually no restrictions.

Wall insulation can be done in three ways:

The method is selected based on the individual characteristics of the premises and calculation of the cost of work. But each of the listed methods has its own characteristic nuances that must be taken into account. Spraying and insulation with slabs is carried out both outside and inside the house. And the filling is carried out in the air space between the parts of the partition, which is specially left at the construction stage.

1. Spraying technology.

Thanks to its high adhesion, polyurethane foam instantly adheres to the base and creates a uniform layer in which there are no areas of cold inherent in most types of thermal insulation. Insulation with foam by spraying is carried out using special equipment. It can be professional, and is used repeatedly, as well as disposable, which is quite suitable for DIY work.

If it is necessary to insulate a small room, for example, a loggia in an apartment, foam from ordinary cylinders is often used. It is slightly different in consistency, but at the base it contains the same polyurethane. The application technology is similar to spraying with professional devices used by specialists, but it is much slower due to the low pressure in the cylinder. Polyurethane foam has a higher cost, but it is offset by the fact that you do not need to buy equipment.

- As a result of expansion, it completely fills the insulated area.

- There is no need to level the walls before application.

- High speed of work performed.

- Relatively high cost.

2. Filling technology.

If the house is at the construction stage and polyurethane foam is chosen, a special wall design is required, which provides an internal empty space where the foam is filled. But even if the house has already been completely built, thermal insulation is possible through special technological holes that are drilled in several places and foam is injected through them. The device supplies insulation through hoses inserted inside the wall. After the material has completely hardened, dense thermal insulation is obtained, eliminating air chambers.

- Has the highest rates of efficiency and energy saving.

- The interior space is completely preserved and no additional exterior finishing is required.

- Do-it-yourself insulation with polyurethane foam by filling is impossible without specialized equipment.

- Injection through holes does not prevent the formation of air bubbles inside.

- The pressure that polyurethane foam creates during expansion can damage walls if the house is made of poor quality materials.

Foam is presented not only in a liquid state, but also in the form of finished slabs. Insulation is carried out by gluing segments to the surface and fixing them with dowels with a wide head. Unlike spraying, this process does not require special equipment and can be done with your own hands.

To prevent the insulation from accumulating condensation, before installation the surface must be treated with impregnations that prevent the appearance of mold and mildew. This should be done regardless of which side the house is insulated from. At the final stage, polyurethane foam from a balloon is filled into the seams. Thus, the thermal insulation becomes monolithic.

- Lowest cost among other methods.

- Ease of installation.

- Insulation with polyurethane foam boards is not as effective in terms of energy saving.

- The house needs decorative finishing.

- For installation, it is necessary to first level the surface, otherwise the insulation will lie unevenly.

- Foam in slabs has a lower degree of durability.

Penoizol has a similar structure to polyurethane foam, but differs in technical characteristics. According to the standards, in premises with increased requirements for fire and environmental safety, such as:

- Public places.

- Kindergartens and schools.

- Medical institutions.

Insulation with polyurethane foam is prohibited due to the easy flammability and toxicity of products released as a result of combustion. This applies to both the slab and liquid versions. Fire safety rules allow the use of polyurethane only in private construction or in the construction of non-residential premises.

In turn, penoizol meets all standards and has no restrictions on use. It is made on the basis of a complex chemical compound - urea-formaldehyde. This is a white porous material with a lot of air bubbles. The main advantage of spraying penoizol over polyurethane is that it does not support combustion at all, and at high temperatures it breaks down into carbon dioxide, nitrogen and water. The absence of toxic emissions allows the use of this insulation in any premises, regardless of their intended purpose.

Advantages and disadvantages of foam insulation

Thermal insulation with foam has its advantages:

- Fast processing of even large areas.

- Does not require the installation of lathing, additional profiles, hydro- and vapor barrier films and membranes.

- Does not rot, does not contribute to the growth of mold and fungi.

- It is classified as highly flammable, does not burn, but melts.

- When interacting with metal, it creates a dense anti-corrosion coating.

- Seamless uniform surface with good heat-saving characteristics.

Foam is not a new method of insulation. But, unfortunately, it is not as studied as mineral wool or polystyrene foam - it is difficult to talk about such indicators as environmental friendliness and durability. However, there are several disadvantages inherent in this particular type of insulation:

- Afraid of direct sunlight.

- Does not withstand constant contact with water.

- The original product is not cheap and requires special application conditions.

- A special suit made of tarpaulin, gloves and a respiratory mask with goggles are required.

- Due to the low level of vapor permeability, a thermos effect is created inside the room, so a forced ventilation device is needed.

In search of reliable and safe insulation, builders sometimes use the most unconventional materials and methods. The effectiveness of foam spraying has been proven and does not require large investments or labor costs.

The main thing is to be careful when working and not to leave treated surfaces without a final protective coating.

Features of works on insulating facades with polyurethane foam

Insulation of the facade using polyurethane foam is carried out by spraying. Liquid polyurethane foam is poured into a tank and, using a pneumatic spray gun connected to a compressor, the mixture is applied to the facade under pressure. As it cools, it turns into foam, which fills all the cracks on the facade and then hardens. To ensure good adhesion, the walls must be cleaned of dirt and dust before application. Since the foam does not form a uniform surface, after the polymerization process is completed, the master carefully cuts off the excess so that the cladding can be made with plaster.

Analysis of the material in comparison with analogues

Modern technologies offer many options for insulating facades. Compared to other thermal insulation materials, liquid polyurethane insulation has very high thermal conductivity levels. For example, a layer of 1 cm of polyurethane foam has the same thermal conductivity as 5 cm of mineral wool or 30 cm of reinforced concrete.

Distinctive features of materials

- quick insulation of both small and large areas;

- there is no need to install an additional base, profiles, membranes, vapor and waterproofing films;

- are not subject to rotting and mold formation;

- have a high degree of fire safety (not flammable, but can melt);

- interacting with metal, they provide a corrosion-resistant coating;

- have a uniform seamless structure;

- optimal heat-saving characteristics.

Therefore, it is difficult to talk about environmental and operational parameters.

Among the disadvantages of foam insulation, it is worth noting the following:

- do not tolerate exposure to sunlight;

- waterproofing properties are not ideal

- This material requires compliance with application conditions: you need a special canvas suit, gloves and goggles with a mask.

- Due to the rather low degree of vapor permeability in the room, a thermal effect is formed, so it is necessary to ventilate the room well.

For example, if we compare thermal conductivity, polyurethane foam is much superior to penoizol (the coefficient of the first is 0.019 W/m-k, and the second is 0.040 W/m-k). The density of the material characterizes the ability to operate under loads. Penoizol indicators are about 15 kg/m3, the density of polyurethane is approximately 25 kg/m3.

During standard operation, PPU insulation and penoizol are approximately the same (service life is about 50 years). In terms of price characteristics, polyurethane foam costs approximately 30% more than penoizol.

Thus, when choosing foam insulation, you need to take into account specific parameters for each individual situation.

Watch the video, which uses the example of a specific brand to discuss the features of working with foam insulation in cylinders:

Popular equipment, cost and characteristics

High-performance universal installations for spraying foam coating at a professional level cost hundreds of thousands of rubles. It makes sense to purchase them if you plan to open a thermal insulation business. They won't pay for themselves on just one house.

Household-grade devices are cheaper; they are divided into two classes:

Disposable

This is a factory assembled unit with charged components. Her virtues

- minimal preparation for work and ease of use;

- low price;

- After use there is no need for washing and preservation.

- fixed volume of composition and, accordingly, area covered during use;

- An accurate calculation of the purchased kits is necessary - there may not be enough or there may be extra ones left.

It makes sense for novice craftsmen who do not want to waste time dealing with settings, refueling and maintenance of a reusable unit.

Rechargeable

This is a full-fledged complex for applying viscous coatings, which, unlike professional ones, has limited productivity and resource. They allow you to independently choose the type and density of the mixture, and charge the strictly required amount into the cylinders.

ProtonHome

- A popular rechargeable unit costs from 25 thousand rubles.

- allows you to spray coatings of any density,

- productivity - 2 kg of mixture per minute, which corresponds to 25-30 m2 with a thickness of 2 cm.

- the cost per square meter of coverage is approximately 560 rubles, the lowest among analogues.

- Cheapness results in the absence of fine adjustments of process parameters.

- A good choice for beginners.

Home installation Proton Home

Air-Light

A more productive (up to 4 kg of mixture per minute) universal rechargeable unit allows you to work both with built-in cylinders and to remove components from 100- and 200-liter barrels. Equipped with a frame and wheels for easy movement around the construction site. It is wise to purchase if large volumes of foam insulation are expected

Cost - from 80 thousand rubles.

Mobile installation AirLight

Foam Kit 600

Kit for applying 56 m2 of coating, disposable, pre-configured.

Disposable Foam Kit 600

Costs from about 35 thousand rubles, the kit includes everything you need to apply the composition charged into the cylinders, including replacement nozzles for the gun and protective gloves.