Often, due to problems with good stove makers, the presence of brick or clay, people have to replace old brick stoves with metal ones. What does this mean?

First, let's figure out what a metal stove is. This could be a cast iron stove or a long-burning stove. It can be completely steel, or cast iron, or have a cast iron firebox.

There are models with ceramic (or soap chloride) lining. All this is reflected both in the price and characteristics of the stove. So, for occasional heating of a garage or workshop, even the simplest potbelly stove will do. If we are talking about a house, then it is better to take a stove with a higher efficiency

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE >>>

ADVANTAGES AND ADVANTAGES OF METAL OVEN.

They are not afraid of temperature changes and long breaks in the furnace, and do not require acceleration fires after downtime. That is, for those who come to a country house only for the weekend during the cold season, this is the best option. Moreover, such ovens heat the air very quickly.

Another advantage is the relatively low cost (when compared with a brick oven). Again, to install such a “hot heart of the house” you do not need to make a foundation or hire a stove-maker.

Compact dimensions allow you to place the metal stove almost anywhere. But observe the fire safety clearances, this is very important (the exact distances are indicated in the installation instructions). However, if the room is extremely compact, the indentations are sometimes reduced. And fire safety is ensured with the help of protective screens. The walls are fenced off with steel sheets, but not tightly, but with a 2-3-centimeter air gap. There is also a gap of 3-4 cm between the edge of the sheet and the floor. Thus, the metal, when heated, increases the convective movement of air near the wall. This protects the wall from overheating.

Last but not least, a factory-made metal stove may have a fire safety certificate. This means that it is much easier to obtain permission from firefighters to use it (provided that the installation was carried out exactly according to the instructions).

Conclusion

Everyone makes the decision to choose a stove for a brick or iron bath independently. It is clear that metal construction is cheaper . It takes up little space and can be installed independently. But for those who want to experience all the delights of a real Russian bathhouse , it is advisable to choose a brick stove. It is quite good, allows you to steam without having to monitor the temperature, and is also healthier than iron.

If you were able to make a decision, then take a stainless steel metal stove, it is inexpensive and practical.

Features of metal stoves

A cast iron fireplace is made almost entirely of cast iron. The material has high heat transfer, thanks to which the stove quickly and evenly distributes heat in the house. The design consists of a chimney, a body and a firebox with thick walls, which is closed by a transparent door with heat-resistant glass. Improved models are complemented by heat exchangers for the operation of water heating.

The cast iron stove is connected to a regular exhaust pipe. Models that are technically complex require more painstaking work: connecting to a pipeline, creating a brick cushion, and bringing out a pipe. Simple fireplaces are better in terms of connection, but improved options open up more opportunities, including getting hot water at any time of the year without connecting to a general water supply system and purchasing expensive heaters.

Which sauna stove is better, cast iron or steel? Cast iron or steel?

“I share the opinion that for a bath there is nothing better than a cast-iron stove. This is the most heat-resistant, heat-intensive and wear-resistant material that can withstand extreme fluctuations in temperature and moisture,” says commercial director Artem Zhiglov.

A cast iron stove takes a long time to heat up; for example, at 20 degrees below zero it will take about 3.5 hours to fire it up, but it retains heat longer. Such a stove will last on average about 30 years. Unless in commercial baths and saunas, where it works every day, the service life will be shorter.

“In the manufacture of Siberia stoves, we use cast iron of a special alloy; its composition is close to the SCh-10 grade, but with its own nuances. Now there is a lot of Chinese cast iron on the market. But cast iron produced in China and cast in Russia are two different materials,” says Zhiglov.

The firebox in the Siberia cast iron stove is made of separately cast elements, connected to each other by bolts and sealed with a heat-resistant cord. This design allows you to look inside after a few years and see how the metal behaves in order to prevent burnouts. But you should only disassemble the stove if there are problems with its operation.

The brittleness of cast iron is a myth. The interlocutor describes the tests that one of the stoves withstood - it was beaten with a sledgehammer, covered with snow, melted red, and then extinguished with a fire hose. No damage appeared.

The Siberia bathhouse is also available in steel. The advantage of a metal stove is that it heats up quickly; in winter it will take about two hours to create a comfortable temperature of 60-80 degrees. But to maintain heat, it will have to be heated more, which means more wood will be consumed.

“The service life of a standard steel stove is up to 10 years, then it can’t be used, you have to look for a replacement. And replacement is like a repair; you have to disassemble everything, from the heater to the chimney,” warns Nikita Dorovsky, head of the Hephaestus retail chain of stores.

Cast iron stoves “eat” everything - wood, brown coal, hard coal, coke. Steel stoves are usually heated only with wood, but Siberia stoves are designed so that brown coal can also be used. This option is very popular in some regions, for example, in Kuzbass.

By the way, about firewood. An important parameter here is the size of the firebox. “In Sibir we have provided a capacious and deep combustion chamber (42 centimeters excluding the external channel and 70 centimeters including the external channel), this allows the use of long chopped firewood as a fuel source,” notes Zhiglov.

The comfort of time spent in a steam room and the benefits obtained from it depend on many factors, primarily on how correctly the sauna stove is selected. It is simply impossible to unequivocally answer the question which heater stove for a bath is better: heat generators for a bath are designed for the types of available fuel, and their power is calculated depending on the size of the steam room.

Content

- Types of sauna stoves video

- gas stoves

- electric ovens

- wood burning stoves

- Brick oven and its advantages video

- Metal sauna stoves video

- How to choose a sauna stove

- Operational safety is a very important point

Types of sauna stoves

First of all, all types of sauna stoves are divided according to the type of fuel used. There are three options:

- traditional option - firewood,

- natural gas,

- electricity.

gas stoves

Although the use of gas as fuel for a furnace is the optimal option, which does not require fuel loading, removal of combustion products, or manual adjustment, a serious obstacle to its widespread use is the difficulty of developing an individual project and a rather complex and expensive connection procedure.

electric stoves

This type of heat source is different:

- interesting modern design,

- possibility of operation without installing a chimney system,

- the ability to automatically or manually regulate the temperature and maintain it at the desired level for a long period of time,

- There will also be no need for fuel storage.

At the same time, installing an electric unit will require the involvement of specialists who have access to perform work of such complexity. During the operation of the furnace, the cost of paying for the electricity used will also increase significantly.

wood burning stoves

It is much easier to acquire a wood-burning stove for a sauna. This option is preferred by true connoisseurs and experts in bath procedures. Depending on the material of manufacture, such stoves are divided into metal and brick. The stability of the amount of heat they emit is ensured by the large mass of the brick stove; the emitted heat is softer and more comfortable than that coming from a metal stove. The main disadvantage of brick structures is also associated with their large mass - it causes thermal inertia and increases the heating time of the steam room.

Brick kiln and its advantages

To make a rational choice of a sauna stove, you should consider in more detail the advantages and disadvantages of its varieties. If we take into account national traditions and the efficiency of the stove, then preference will be on the side of models built from brick. In addition, a brick stove, due to the large thickness of the masonry, will be less fire hazardous. Its walls will not heat up to such a temperature as to cause a fire from overheating.

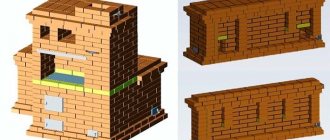

Among the disadvantages of brick options, the complexity and relatively high cost of its construction should be noted. You will need a solid foundation, a well-founded design drawing, and masonry in strict accordance with it. The stoves are built from baked red brick, which is slightly shortened in length. Because of this, the dimensions of the stove are reduced to 74x74 cm.

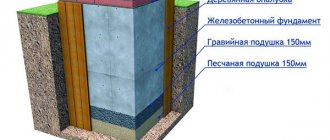

The stove is installed on a foundation; its dimensions should exceed the dimensions of the base of the structure by about 10 cm. The under-furnace equipped from below is covered with wooden blocks and a brick vault. The oven is used to store equipment. Then a layer of roofing material is laid which will act as a waterproofing material. It will separate the foundation from the brickwork.

Checking the correctness of the masonry using a plumb line, construct a protective wall in five rows. Then a sand-clay mortar is mixed - it can withstand high temperatures that cement cannot withstand. The solution is mixed as follows: take 2 parts of sifted sand for 1 part of fatty clay. In accordance with the order, the stove itself is erected, tanks and grates are installed. Galvanized wire is used to attach the door to the firebox. If the stove is built according to all the rules, it will be economical and safe.

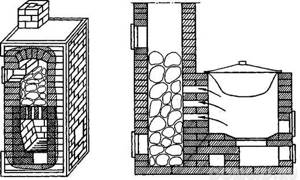

The design of sauna brick stoves can be different - with or without a chimney, respectively, they will be heated in white or black. The optimal option can be considered to build a furnace closed with a brick casing and equipped with cast iron plates for stones and for the tank.

If the size of the bathhouse allows, then you can design the construction of a brick stove with a closed heater (an open heater for the stove was used in the old days, when bathhouses were heated in black). The closed type of heater involves installing a container for laying stones above the firebox. Hot air passes through the stones, heating them to a temperature of about 400 degrees. A water tank with a capacity of up to 80 liters is located under the heater. In this case, the heat from the firebox does not evaporate through the pipe, but effectively works to heat the room - you can use the steam room 1.5 - 2 hours after lighting the stove. If the weight of the stones in a closed heater reaches 250-300 kg, then several families can use the sauna in turn - the high temperature in the steam room will be maintained for several hours.

Birch, aspen or oak firewood can be used as fuel. Mica must not be allowed to enter the firebox - its heating causes the formation of carbon monoxide, which poses a danger to human life.

Metal sauna stoves

Wood-burning stoves have a lower cost than metal ones, but building a brick slab is not a simple matter, requiring the hands of a craftsman. Finding it is not always easy. Most likely, it was this reason that served as the rapid popularization of metal sauna stoves. Such stoves produce good quality steam, they are easy to use, and their appearance is quite aesthetic and attractive.

The material for the manufacture of the metal plate is heat-resistant alloy steel containing about 12% chromium or cast iron. Stoves made of cast iron are heavier than steel ones, but lighter than brick ones; they heat up quite quickly and retain heat better than steel ones.

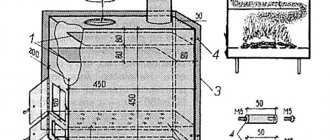

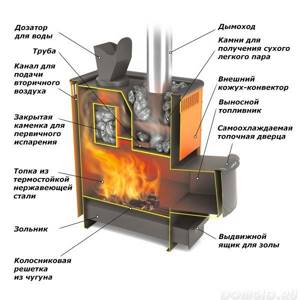

By design, metal furnaces can be closed, i.e. bricked or open. The latter produce stronger steam, but heat the room much faster. Combined stoves require the presence of two valves, a blower and a grate for stones. The advantages of metal structures are compactness, lack of smoke, and quick heating of the room.

The designs of metal sauna stoves can be very diverse; they can be made from barrels or scraps of pipes, steel sheets, and can be positioned vertically or horizontally. There are options when the heater, firebox and water tank are located in different rooms of the sauna house.

Most often, consumers prefer the option of a metal stove with a closed heater or a built-in one.

How to choose a sauna stove

To make the right choice, you should consider the following parameters of heat generators for a bath:

- quality of the steam produced,

- convective design,

- presence of a combustion tunnel,

- design power.

Steam Quality – The best choice would be a stove that produces light steam with minimal moisture content. Staying in a steam room with light steam does not cause difficulty breathing and does not increase blood pressure. Light steam is a finely dispersed structure obtained when water comes into contact with stones heated to 500 degrees C. But in this case, the air temperature in the steam room will rise to 110 degrees, using a broom at this temperature is dangerous - you can get thermal burns.

In order not to provoke the occurrence of such a situation, the wood-burning stove is equipped with a steam generator - a chamber made of metal and installed on the side of the firebox. It warms up faster than stones; upon contact with it, water turns into light steam.

Convection exchange. In order for the air temperature in the steam room at floor level and under the ceiling to be more uniform, it is necessary to ensure high-quality convection. It will also help warm up the air faster; you can start using the steam room 40-50 minutes after kindling. The selected version of the sauna stove should allow you to maintain a temperature in the steam room of about +45 degrees at floor level and +80 at the ceiling. Depending on the preferences of the bathhouse owners, you can plan a higher temperature.

The convective design of a sauna stove is characterized by the presence of a gap between the firebox and the tray with heated stones, which ensures the movement of heated air.

Fuel tunnel. Its presence in the stove design is due to the need to preserve oxygen in the steam room - it is taken from other rooms of the bathhouse, which have a much larger cubic capacity than the steam room. The presence of a fuel channel allows you to get rid of dirt and dust that inevitably enter the room when loading firewood. Equipping the combustion tunnel with a viewing fireplace glass significantly increases the aesthetics of the appearance of the stove.

Estimated power. Correct calculation of power is extremely important - an underestimated figure, just like excess power, will create serious problems during operation. Fortunately, the buyer does not need to intensively study the basics of heating engineering - all calculations are made by stove manufacturers; you just need to take the time and familiarize yourself with the data entered in the tables. the choice of a suitable model should be made taking into account a small power reserve, a maximum of 25%, because the quality of insulation of walls and ceilings in each bathhouse is different.

When choosing a sauna stove option, consider the following points:

- When choosing a stove, the availability of free space for its installation is important.

- You should also take into account the dimensions of the washing room and steam room, how many people can steam in them at the same time.

The choice may also be influenced by the desire to receive dry or wet steam. Particular attention should be paid to the possibility of quickly warming up the steam room.

Operational safety is a very important point

Since the operation of the stove is associated with the combustion process, care should be taken to comply with standards during its construction and compliance with fire safety rules during operation. Brick laying must be done with high quality, and the recommended clearances must be observed during construction:

- the distance between the floor and the ash pan should be about 20 cm,

- from the floor to the bottom of the smoke circulation - from 2 m 20 cm to 2 m 80 cm,

- from the top of the heat-intensive stove to the ceiling should be at least half a meter, for a non-heat-intensive stove - about 1 m (when calculating the distance, the protection of the ceiling is taken into account).

To prevent fire from falling sparks, the surface of adjacent walls and floors should be protected with metal. The use of birch firewood will help to protect the combustion process in terms of sparking - they burn hot and do not spark when burning.

Furnaces powered by gas fuel are no less dangerous; if the rules of construction or installation and operation are violated, they can be explosive. Electric heaters have a lower fire hazard, but their operation is quite expensive.

In addition to technical parameters, the stove must have a pleasant aesthetic appearance - after all, it will be the center of attention of people who come to relax in the bathhouse.

In order to make the correct and rational choice of a sauna stove, in addition to the advantages and features of each type of stove, you should take into account the size and layout of the sauna house, the number of rooms in it, the overall design, and your individual preferences. If choosing a design still causes difficulties, it is better to consult a qualified specialist on this issue.

Author: Sergey and Svetlana Khudentsov

10

Which stove is better, cast iron or steel, for a summer residence? Manufacturers of cast iron and steel stoves

To choose a stove for heating and cooking, you need to carefully study the compliance of the range offered on the market with your requirements, as well as the installation standards in a particular room.

We invite you to get acquainted with the most famous manufacturers who supply cast iron and steel stoves to specialized showrooms in the country, and also directly sell their own products through online stores. This list of manufacturers is provided for your reference. Be careful! Regardless of the brand and presence on the market, the history of the company and its product range, as well as the cost of a certain product item, the quality can be either really high or extremely mediocre. Therefore, the guideline when choosing is compliance with standards and declared technical characteristics, which we personally recommend that you check them on site before purchasing! Today, the following names of companies that we represent are increasingly noticeable: Nordica, Dovre, Harvia, Vermont Castings, Ardenfire, Bullerjan, Rud, Wamsler, Ecozhar, Novaslav, Mriya, Meta, Termofor, Teplodar, Hephaestus, Konvetika and many others. In the catalogs of these companies, as well as those not presented in this article, you can find convection boilers, standard or lined fireplace stoves, stoves with a water circuit, cooking and heating units made of cast iron and steel, as well as inexpensive potbelly stoves, if necessary heat a garage, workshop, small veranda. Make your choice wisely, because there are indeed many low-quality products on the market. And, be sure to listen to the recommendations of experts!