Advantages

The safe operation of furnaces is achieved by reliable bolted or welded connections of elements and assemblies.

The technological joints of the fireboxes are sealed with a ceramic seam (the products can withstand temperatures of 1200 °C without breaking the seal). Universal stove options are recommended for use in Russian or Finnish baths. The main advantages of Vesuvius stoves are described:

- ergonomic design;

- stylish design;

- increased efficiency - efficiency factor;

- specialized self-cleaning system;

- durable heat-resistant glass on the doors;

- increased fire safety.

The manufacturer launched 8 bath models on the market:

- "Rusich";

- "Scythian";

- "Vertical";

- "Lava";

- "Optimum";

- "Premium";

- "Russian steam";

- "Legend".

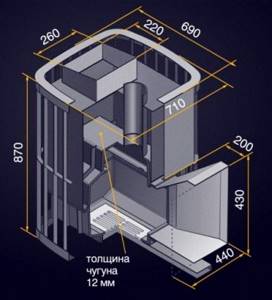

Cast iron stoves

Let's move on to cast iron products. Only the fact that there are 46 new models in the 2017 furnaces indicates the demand for this material. With the proper quality of the alloy and proper use, its resource is very long. The design of cast iron stoves is distinguished by the prefabricated body, weight, and heat transfer properties of cast iron.

All furnaces are assembled from three main parts, hermetically joined through a ceramic refractory cord using a bolted connection. The composite design is partly advantageous in that it makes it easy to handle its weight alone. The material’s resistance to deformation during heating and “damping” of temperature conditions make cast iron a very good choice for a sauna stove. In many ways, cast iron models are similar to their steel relatives.

The first of four model series is “Sensation”. The cast iron analogue of the “Rusich” line is practically indistinguishable in appearance, thanks to similar casings. A successful design is also identical because it produces the right ratio of heat and steam of the desired consistency and quality.

It is worth noting separately that the metal composition used allows us to speak about the resistance of cast iron to temperature changes and the absence of risks when water gets on the hot surfaces of the firebox. All of the above is backed by a 30-year warranty! Furnaces differ in whether they come with sealed or non-sealed doors, dimensions, depth of the fuel tunnel, or lack thereof. The difference between some models lies in the difference between the door latches. The weight of the stones placed in the heater is, on average, about 60 kg, and the power of the models in each series will allow you to serve steam rooms up to 30 square meters.

The cast iron analogue of the “Skif” model range is called “Legend”.

The shapes of the stone casings are identical, except for the continuous shielding sheet on the front side of the steel furnaces. The need for a front baffle was eliminated, thanks to the less infrared, harsh radiation of cast iron.

The “Hurricane” line is distinguished by its massiveness and closed heater. The weight of the stacked stone can reach 320 kilograms, and the stove 140. It is extremely important to take into account the total weight of the structure when arranging the installation site. The subsidence of the stove is fraught with a violation of the integrity of the chimney, and as a result, a fire. All 18 models have a heater above the firebox and differ in dimensions, combustion path and casings. The depth of the combustion tunnels varies from 20 to 25 cm, the diameter of the chimney of the products is 115 and 120 mm.

In the premium class there are two new products, where the facing panels are soapstone slabs. This is a material of natural, metamorphic origin, the melting point of which is in the range of 1630-1640˚C. The heat capacity of about 0.98 kJ/kg, ease of processing, chemical stability and a very low percentage of thermal expansion make the stone attractive for such purposes. Two small stoves “Legend Soapchlorite”, with heat-resistant and self-cleaning glass on the doors, for a steam room up to 24 sq. m. crowned with a fairly large selection of stoves from the Vesuvius company.

Video: Cast iron bath stoves Vesuvius Legend

Equipment Specifications

The maximum heating temperature of Vesuvius furnaces is 1200 degrees

The stove from the Vesuvius brand is distinguished by a system of pipes touching the firebox areas. They are placed so that when suctioned from the floor, cold air masses rise up and heat up. The manufacturer produces products with the following characteristics:

- wall thickness depending on the furnace zone - from 8 to 12 mm;

- air heating - from 60 to 150 degrees;

- long burning - from 7 to 8 hours after warming up;

- productivity - a small unit is capable of passing 4.5 m3 of air per minute;

- different steam room volumes – from 6 to 50 m3;

- combustion chamber volume – from 14 to 30 m2;

- maximum heating temperature of the product is 1200 degrees;

- standard chimney diameter is 115 mm;

- The depth of the firebox tunnel is 290 mm.

The models have a rounded shape, which promotes even distribution of heat throughout the room. The all-welded outer casing of plates is bolted together. For high-quality heating of stones, an external mesh or door is used. The manufacturer's warranty for the entire range of stoves is 35 years.

The Vesuvius Legend model is a reliable cast-iron version of a sauna stove. Design features and characteristics guarantee users increased efficiency - 80%. Cast iron options are characterized by accelerated heating of the room. The cast iron stove demonstrates resistance to temperature changes. Eliminating the slightest deformation at critical temperatures does not spoil the presentable appearance of the product.

The reliability of the stove is determined by the integrity of the seams. The volumetric mesh around the firebox holds 160 kg of material. With the same weight of the stove (160 kg), it is recommended to worry about a reinforced foundation. “Vesuvius Legend” lives up to its name and efficiently heats rooms from 10 to 28 cubic meters.

Choosing the type and size of foundation for the furnace

It is advisable to lay it out at the design stage. After all, if you act with a steam room already equipped, you will have to remove the floor, replace the damaged structure, then fix new logs or strengthen the old ones. What foundation options are there? If we are guided by current SNiPs, these are:

The dimensions of any of the options depend on the dimensions of the rooms, so this is always an individual indicator. The main thing is that there is a distance of 7-10 centimeters from the edge of the perimeter to the beginning of the walls.

The range of Rusich stoves has incorporated the experience and findings of professionals in the niche of bath heating equipment. The performance of the devices is surprisingly combined with thoughtful design. Some closed structures are equipped with glass doors.

According to reasonable consumer estimates, Vesuvius Rusich stoves are recognized as the most productive devices for accelerated heating of the bath. The models are equipped with large, ventilated, open-type heaters, and this design feature allows the stones to be quickly heated from all sides in a short period of time.

Advantages of Vesuvius stoves

You can cook food on the horizontal surface of the oven

The furnace is safe due to bolted or welded fastening of parts. The joints of the firebox elements are processed using a ceramic seam, which allows them to withstand high temperatures without damage. A Russian bath or a Finnish sauna is equipped with universal equipment, which has many advantages.

Durability

Cast iron is a material that does not deform at high temperatures, so the equipment has been in use for more than 30 years. Solid rectangular grates are located nearby and do not crack when heated. The stove does not corrode and therefore does not require heat-resistant painting or anti-corrosion treatment.

Versatility

The owner of a bathhouse, sauna, greenhouse or workshop can install a stove with good heat transfer. The equipment is easy to use and has a spacious firebox for firewood. For baths, a closed type of heater is suitable, which allows you to generate wet steam.

A water tank is not supplied with the stove, but the manufacturer offers to purchase a Vesuvius boiler for 55-125 liters.

For a summer cottage or country house for temporary residence, you do not need to purchase cooking equipment. The upper horizontal surface of the unit is suitable for cooking. The only condition is to use the right utensils. Cast iron utensils are compatible with stoves; they heat up evenly, preserve the taste of food and keep them warm for several hours.

The stove is capable of heating a room of 100-150 cubic meters

Forced convection technology ensures quick heating of rooms. Due to the channel system, air exchange is accelerated - the heater is capable of working in rooms with a volume of 100-150 cubic meters.

We suggest you familiarize yourself with: Blower for a metal stove

The stone container can hold up to 60 kg. The material is placed in the compartment between the casing and the firebox, heats up to 400 degrees and produces good steam. The blower and working area have a special configuration - the device operates for 2-3 hours after one fill of fuel.

The blower is designed as a pipe embedded in the loading hatch, due to which a single-door system is implemented. This allows you to light the stove faster and clean out the ash.

Silicone protection of the case prevents its deformation and rusting under the influence of moisture and high temperature.

Only firewood, bark, chips and shavings can be placed in the firebox. When using coal, the body overheats and the welded joints crack.

Easy to install

The Vesuvius cast iron sauna stove is sold fully assembled; it is simply placed indoors. To organize a fireplace in a workshop or country house, the products are covered with bricks, leaving holes on the side to remove warm air. Before installing the device, a chimney is equipped.

Results of operating the stove after the onset of cold weather

After the onset of cold weather, it became possible to evaluate the results of full operation of the device and slowly talk about the conclusions that emerged. At that time, the stove cost the author 15,300 rubles. The chimney is a little more expensive, more than 17,000 rubles. Now about the operation of the stove in severe frosts. She coped with the frost, but with great difficulty. The point here, apparently, was the volume of the firebox. But the frosts were severe, down to -30 degrees. When choosing a stove, the author was not guided by this temperature outside the window. There was a concept that a large firebox volume in relatively warm weather would cause excessive consumption of firewood - and this is true, but the heat did not increase. Another tile burst during use. The author tried to figure it out and it turned out that it was squeezed out by the fittings, which in turn should have strengthened the side wall of the furnace. Therefore, the sheet iron was deformed, square reinforcement was welded vertically to the entire height, but apparently the distance to the tile itself was violated. This conclusion was made because on the other side the distance was greater. Firewood was consumed very heavily during the cold winter period. And this despite the fact that ash wood was used.

"Skif" - slowly, but surely

Reviews from numerous users confirm the reliability of the Vesuvius Skif bath heating products. Compared to “Rusich”, a larger number of stones are loaded into the stove design, because here, instead of a casing, a reinforced three-dimensional mesh was installed. The increased volume of stone mass reduces thermal radiation from the metal body of the stove. To fill the grid, it is preferable to choose stones such as: white quartz or crimson quartzite, jade or jadeite, serpentinite or serpentine.

Design features of the furnace:

- the firebox area is separated from the ash pan by a grate;

- The grate is designed to continuously supply air flow to maintain active combustion.

For example, the Vesuvius Skif 16 panorama model is equipped with an extended panoramic door. Cozy gatherings in the circle of such a stove are conducive to intimate conversations, and the design, which is not quick to warm up, retains heat in the room for a long time. The modification can withstand a mass of stones - 130 kg.

Professionals recommend installing “Vesuvius” in the wall adjacent to the steam room and guest room. A thoughtful installation allows you to add an elongated combustion chamber to the design. A special development will allow you to simultaneously warm up a steam room and a relaxation room.

Buyers are interested in the all-welded design of the Vesuvius 22 stove. A solid and reliable model creates a comfortable atmosphere in the steam room. The oven does not heat up quickly. It retains heat for a long time after the end of the kindling; the loading stone mass reaches 150 kg. Chimney of standard sizes - 115 mm.

Popular furnaces with heat exchangers

Cast iron stoves are deservedly popular among lovers of Russian baths, but how are they combined with heat exchangers? As it turns out, they combine perfectly.

Cast iron stove

To get started, we recommend visiting the Petrozavodsk website. Among the products offered to visitors are components, among which there is a disk-shaped heat exchanger, apparently attached to one of the walls of the furnace. Thus, you can purchase both a stove and an exchanger at once. As an option, they also sell mounted tanks for the chimney.

Cast iron stove with heat exchanger for a bath. Photo source

Vesuvius stove

Vesuvius stove with heat exchanger for a bath

also provides the opportunity to simultaneously purchase a stove (and in its catalog you will find both steel and cast iron stoves) and a heat exchanger. The buyer is given a choice of three models - two “samovars” for the chimney, differing in capacity, and one rectangular heat exchanger, which takes heat from the stove wall.

photo of heat exchangers on the Vesuvius website

Stoves for baths "Termofor"

There is a message on the Termofor website that the manufacturer took into account customer preferences and produces the most popular models - Tunguska 16 and Tunguska 24 - with already installed heat exchangers, which require an external location of the storage tank. The material of the exchangers is high-quality food grade stainless steel, 2 mm thick. Depending on the buyer’s choice, the placement can be varied by installing it either on the right or on the left wall of the stove.

Useful video

Termofor sauna stoves with a heat exchanger may be built well, but there are negative reviews. Watch the video and see what it looks like:

Potbelly stove Mini

produces several types of wood stoves.

Potbelly stove

The potbelly stove from the Vesuvius brand is produced in the Mini modification and is intended for installation in a small room - a garage, greenhouse, attic. Structural steel 5 mm thick is used to manufacture the unit.

Advantages:

- beautiful details;

- comfortable handle;

- warms small rooms up to 100 m3 well;

- welded joints are invisible.

Minuses:

- there are no holes in the blower;

- produced without grates;

- There is no drawer or door to clean out ash.

Product weight – 20 kg, height – 450 mm, width – 300 mm, depth – 500 mm.

Stove-fireplace

The Vesuvius fireplace stove is produced in several modifications.

The Skif line includes 26 devices that differ in size. The stove body is welded, the firebox has a remote structure, and the ash tray slides out. The ventilation casing is made in the form of a mesh.

Series features:

- heating rooms with a volume of 6-40 cubic meters;

- possibility of laying up to 60 kg of stones;

- decorative design of the door (panoramic, made of heat-resistant glass);

- large capacity of the ventilation casing - stones heat up to 350 degrees;

- long-term heat accumulation.

Fireplace PK-01

The PC fireplace is manufactured by Vesuvius in corner and straight versions. Direct models include:

- PK-03 (224) – equipped with a cast-iron hob, fire-resistant door, and thin lining. After the first laying, the firewood burns for up to 5 hours. Equipment power – 12 kW.

- PK-02 (205) – produced with a hob and a combustion intensity control system. The stove is decorated with ceramic inserts. You can connect an electric fan to it. Power is 12 kW.

- PK-01 (270) – steel fireplace unit with a heat-resistant door. At the bottom of the firebox there are 3 cast iron grates. Using the blower, you can regulate the combustion modes. Device power – 9 kW.

We suggest you read: How to choose the right stones for a bath? Types of stones for baths

Corner models are represented by the PK-01 (220) series. The wood-burning fireplace is made of steel with soapstone lining (beige, red, marbled). Oven height – 843 mm, width – 752 mm, depth – 586 mm. Power is 9 kW.

Fireplaces are manufactured for a chimney with a diameter of 115 mm.

Sauna stoves

Legend

The Vesuvius brand stove, which is suitable for a bath or sauna, is also available in several series.

The Legend series is an open heater that weighs almost 160 kg. It is equipped with an extended firebox, which is suitable for heating rooms up to 28 m3. The devices are compatible with chimneys with a diameter of 115 mm and can be installed in steam rooms of 8-30 cubic meters.

Line differences:

- heating a stone mass weighing 210 kg from all sides;

- built-in converter casing;

- possibility of heating from a steam room or an adjacent room;

- firebox made of 3 elements.

Hurricane

The Hurricane series is distinguished by forged parts. Models 12 (260), 28 (270), 16 (205) and 28 (224) differ only in size. They heat from the steam room, an adjacent room. The units are designed for a steam room of 6-30 cubic meters.

Line differences:

- firebox of 3 elements;

- ceramic seam at the junction;

- operating temperature – 1200 degrees;

- closed heater;

- malleable convection ventilated casing.

The Standard modification is equipped with a leak-proof door DT-3.

Sensation

Several modifications of the Sensation series that are heated from a steam room or an adjacent room. The ventilated heater is designed for granite rocks weighing 60 kg.

Series features:

- rapid heating of stones up to 350 degrees;

- stability of temperature and steam production;

- removable outer casing;

- complete with cast iron door.

Optimum

The budget line Optimum with a firebox of 30x20 cm is made of metal 5 mm thick. The mesh-shaped casing holds 110 kg of stones. It is produced in two models with different types of firebox use (steam room, adjacent room).

Series differences:

- warming up a steam room with a volume of 6-14 square meters;

- cast iron grates;

- molded pattern on the door;

- ash pan in the form of a shovel.

Oven height – 58 cm, width – 50 cm, depth – 56 cm.

The Lava and Rusich series are stoves that are installed in a bathhouse or sauna. Manufactured with a cylindrical or rectangular casing. The rulers are similar in design:

- Rusich - modifications designed for 40 kg of stones provide light and dry steam. The rectangular firebox is reinforced at the top, rear (8 mm) and side (6 mm). The temperature of the stones increases gradually, without overheating. The steam room can be used in Hammam mode.

- Lava – available with fire-resistant glazed doors. The draft is adjusted using a damper. The weight of stones for laying is 50 kg.

The Rusich series includes 20 models, the Lava series - 23.

Lava Solid fuel boiler

Triumph

The Triumph line is made of cast iron. Model 180 T/O has a water circuit and a heat exchanger, model 180 is produced without it. The units are installed in rooms up to 180 m3.

Series features:

- equipment weight – 98 kg;

- oven width – 485 mm, height – 615 mm, depth – 505 mm;

- bolted connection of elements;

- processing joints using a ceramic cord;

- two cast iron elements 1 mm thick near the firebox;

- combustion chamber with a door made of fireproof glass;

- presence of combustion intensity adjustment.

Vesuvius brand water tanks for sauna stoves

The basic equipment used in Vesuvius stoves does not include water tanks. However, you can freely purchase a water tank of the same brand that suits you.

Rectangular tanks are available for sale, both pipe-mounted (55-80 l) and hinged (60-125 l). Millimeter matte stainless steel is used for their manufacture. The G3/4 fittings are located on the sides of the tank or on its bottom.

| Rectangular tank on a pipe | Mounted oval tank | Oval tank for pipe |

Oval contour-type tanks of vertical or horizontal placement (60, 90 l), oval-shaped pipe tanks are made of mirror stainless steel 0.5-1.0 mm. The tanks are equipped with filling holes and G3/4 fittings.

In addition, Litcom also offers heat exchangers that can be round or flat (6, 12 l). They are made of stainless steel 0.5-1.0 mm and have G3/4 fitting connections.

Installation features

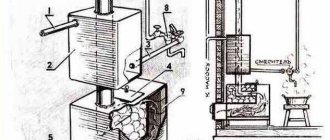

Installation diagram

The brand recommends involving specialists in the installation of equipment. If the owners have the skills or tools, self-installation is allowed. The process goes like this:

- Laying a red brick base to a height of 6 mm or a fireproof foundation made of 20 cm thick material.

- Removing the product from the wooden wall by 50 cm.

- Wall covering with metal sheet. In this case, the distance is reduced to 38 cm.

- Making a half-brick superstructure with preliminary cutting of the wire frame of the furnace.

The walls can be covered with slab apothecary bricks.

The manufacturer's instructions note the specifics of installation of a particular modification of the stove.

Legend Series

Installation work involves assembling the chimney taking into account the location of the rafters and load-bearing beams:

- Installation of ceiling trim in section. A hole 130 mm in diameter is made along the axis of the chimney with an angle of inclination along the corner of the roof.

- Fixation on the outlet pipe of a single-circuit, starting pipe or tank with sealing of the gap.

- Installation of further elements - tap through the boards with a mallet or hammer.

- Installing the throttle valve and putting the chimney on it. Passing the starting sandwich through the hole and organizing the support clamp.

- Laying heat-resistant heat-insulating material - basalt wool, mineral wool.

- Further assembly of the chimney using sandwich elements along the condensate line.

- Place a cone clamp on the chimney and tighten it further.

- Installation of the last sandwich and covering it with an umbrella-head.

After checking the strength, tightness of connections and draft, a test fire is carried out.

Sauna stoves

The equipment is located in the steam room, and the tank is located in the sink. For convenience, a samovar-type heat exchanger is used to heat the water. This increases the efficiency of the device and eliminates heat dissipation through the pipe.

We suggest you read: Bathing a newborn in a bathhouse

Fireplace installation

The units are installed in rooms with good air flow. The optimal height of smoke channels is 600 cm. The pedestal is made of non-combustible materials. To remove ash, a flood zone is created from a sheet of metal 40 cm in front of the firebox and 10 cm on each side. The distance from the fireplace to the ceiling is from 1.2 m.

Any equipment requires a competent and carefully thought-out approach. For experienced specialists or combustion professionals, correct installation will not take a lot of effort and additional costs for components. At the beginning of the installation stages, it will be necessary to provide a leveled platform for the stand made of non-combustible material with a thickness of 200 mm. For some users, it is preferable to install a fireproof foundation.

Homemade designs of different types

There are several common modifications of sauna stoves with a water tank. They are designed for rooms of different sizes and different operating conditions. We invite you to consider the options and choose the most suitable one.

Model "Skif"

Option #1: with heat exchanger and remote tank

Installing an external tank is a guarantee that the steam room will not be filled with unnecessary raw steam, because... the water does not boil ahead of time. The design is an improved potbelly stove, which has a special register for heating water in the firebox, and a heater above the firebox.

The most convenient option for arranging a heater is an open metal mesh or pocket. A closed pocket is not suitable, because... when steam comes out of it, the temperature is too high. This increases the risks for people in the steam room: you can get serious burns.

A sauna stove with an external tank can be purchased ready-made or made with your own hands. For its manufacture, sheet steel with a thickness of 4-5 mm is suitable. For the register and tank, it is better to take stainless steel. The tank must be mounted at a height of at least 0.5 m from the register, and connected to the register using pipes or hoses.

Scheme of a heater with a water tank

Option #2: heater from an iron barrel

To make a sauna stove with a water tank and a heater, you can use a used iron barrel. The main thing is that it is not leaky or rusty. To get a metal cylinder, cut off the upper and lower parts, then install a grate.

Part of the structure is filled with bricks. They are installed on the edge. 2/3 of the space will be occupied by the heater. All that remains is to install the chimney and bring it to the roof. This design has a serious drawback. If it is not covered with a lid, gases enter the steam room. If you cover it, you will have to remove the lid every time you need to add steam.

Scheme of a barrel furnace

"Vesuvius Premium" - justified expectations

The line of premium class sauna stoves includes modifications of 2 models - “Vesuvius Elite” (22 or 26) and “Russian Steam”. (they look alike in appearance). Grateful user reviews confirm the improved performance of the products when heating the air mass to 140 °C in rooms of 22 cubic meters. An important advantage of ovens is that the doors are equipped with reliable heat-resistant glass.

Wood briquettes, pallets or dried firewood are considered the best fuel option. The stylish design with an attractive coil lining is complemented by reliable damping of harsh thermal radiation from metal surfaces.

Basic options for installing a sauna stove

It is necessary to decide on the placement option at the stage of building the bathhouse. If you plan to move the furnace firebox to an adjacent room, then when constructing a dividing wall between the steam room and the dressing room, an opening is immediately installed in it. In the case of a completed reconstruction, it is quite acceptable to cut out the necessary window in the wall to remove the fire door.

Support the development of the channel! Subscribe so we write useful articles for you!

“Lava” - fireplace type sauna stove

The company's staff guarantees the buyer accelerated heating of a 40-kilogram mass of stones to 350 °C. After the end of the heating session, the stove maintains the temperature in the steam room for a long time. An accelerated heating firebox was specially developed for this model. Structural steel with typical values of 6–8 mm is used. In some places the thickness reaches 12 mm.

The combustion intensity of the selected fuel (dry firewood) is regulated using a movable ash pan. When the structure is carefully pulled out, the intensity of the flame increases. With proper selection of the location when closing the ash element, the user achieves smoldering firewood without extinction.

“Vesuvius Russian Steam” - a stove for a Russian steam room

The company's engineers worked conscientiously on the project and created a furnace to obtain the required air mass condition, which is inherent in the original Russian steam rooms. The characteristics of bath equipment allow you to achieve high humidity with the presence of “light” dry steam. Under these conditions, the temperature in the steam room does not exceed 50 -70 °C.

A reliable mesh heater is constructed around the stove. In addition to the reinforced external mesh, a special closed-type heater is provided in the upper part of the firebox. The designers have provided easy access when loading through a cast-iron door at the end (back) of the firebox. The parameters of dryness and lightness of steam are achieved by heating the stones selected for the closed heater - 400 °C.

Water is supplied through the cast-iron door into the closed heater - the required steam concentration is achieved. Experts in the Russian steam room claim that the true indicators of real steam are created when the temperature rises to 500 °C.

"Vesuvius Optimum" - a rational stove without frills

The budget model of the Optimum bath option does not suffer from excesses. The exclusion of unnecessary elements indicates a rational design:

- all-welded basket for loading stones;

- cast iron door with remote firebox:

- standard models are equipped with a forged basket;

- lightweight firebox is made of 5 mm metal;

- for the combustion tunnel - 2000 mm;

- the weight of stones placed in the basket reaches 65 kg;

- The furnaces were designed for rooms of 14 cubic meters.

Cast iron and steel stoves

The design features of cast iron bath units are identical to steel models. The design of the firebox is made in the cast iron format with a thickening of 12 mm and a longitudinal outer curb. The rib-reinforced housing is characterized by better rigidity and increases the intensity of heat transfer.

Cast iron stoves "Vesuvius" are available in 2 types - "Legend" and "Hurricane". The corresponding (11 and 3) modifications were designed for use in steam rooms; the variety of options allows users to easily select the model they like with different types of glass, an external tunnel or a water tank.

Tags: Vesuvius, oven, installation

« Previous entry