Properly selected and installed insulation allows you to improve the microclimate in the room, because... It helps keep you warm in winter and cool in summer. The formation of additional thermal insulation is economically beneficial, because Helps reduce heating and cooling costs.

Thermal insulation materials on the market differ not only in characteristics, but also in areas of application.

Insulation materials are an extremely popular product on the market of thermal insulation materials. Regardless of what field of construction you work in, insulation materials can be used in both civil, private, and industrial construction. We offer an extensive line of Isoroc insulation. The material is based on mineral wool. Environmentally friendly raw materials, processed using modern equipment, fully comply with GOST standards. This means: you get European quality at an affordable price. The truth of these words is confirmed by the experience of leading developers: Isoroc thermal insulation was used in the construction of the largest construction projects in Russia.

We offer an extensive line of Isoroc insulation. The material is based on mineral wool. Environmentally friendly raw materials, processed using modern equipment, fully comply with GOST standards. This means: you get European quality at an affordable price. The truth of these words is confirmed by the experience of leading developers: Isoroc thermal insulation was used in the construction of the largest construction projects in Russia:

More recently, another interesting fact was revealed. It turns out that the integrity of superthin basalt fibers is not damaged by the radiation environment. Therefore, Isorok mini-plates began to be used as thermal insulation for nuclear industry buildings.

ISOVENT-N

Isoroc Isovent-N is a mineral wool insulation based on stone fiber. The material is made from natural components of igneous rocks of the basalt group.

Non-flammable hydrophobized mineral wool slabs based on stone. Intended for use in civil and industrial construction as unloaded heat and sound insulation of horizontal, vertical and inclined building envelopes of all types of buildings, including low-rise and cottage-type individual buildings; middle layer in three-layer lightweight masonry (layered, well); inner layer for two-layer insulation in curtain wall systems with an air gap; heat and sound insulation of technological equipment with a temperature of the insulated surface from minus 60 to +400°C.

Installation features

Under the screed, Izorok slabs are laid tightly next to each other, without gaps.

Features of the installation of Izorok slabs and rolls for surfaces of various classes are manifested in the requirement to adhere to certain rules. They depend on the conditions in which this material is supposed to be used as a heat insulator. However, in any case, its use is permissible only in combination with vapor and waterproofing.

Cement floor screed

Installation of insulation on a floor base begins with preparatory operations, which include the following steps:

- The screed is cleaned of accumulated layers of dirt.

- All cracks found on the floor are sealed, followed by leveling its surface.

- A waterproofing layer is installed, on top of which Izorok mats are laid.

When laying them, you will need to ensure that the workpieces are positioned close to one another without noticeable gaps.

Another waterproofing layer is laid on top of the thermal insulation, on which a reinforcing mesh is then placed. The laid reinforcement is filled with cement screed. When carrying out this work, it is important to take into account that the total thickness of the coating increases noticeably.

Insulation of external walls of frame structures

Before purchasing Izorok slabs, their total volume is calculated based on the fact that two layers of protective material are formed. Work on their installation is carried out in the following sequence:

- A sheathing based on wooden slats or a metal profile is attached to the walls.

- During installation, the distance between the individual elements must match the dimensions of the insulation boards.

- The laying is organized in such a way that the slabs in the layers are arranged in a checkerboard pattern, with the blanks of the second row completely covering the joints of the previous one.

To fix the outer sheets on the walls, fungal-type piece hardware is used, hammered in at 5 points. Waterproofing is installed on top of the insulated surface, providing reliable protection for the coating being formed.

Insulation of flat roofs

For roof insulation, Isorok material with a high density is selected, laid on a base of reinforced concrete slabs or metal profiles. Work order:

- A vapor barrier layer is installed to prevent moisture from entering between the layers of the heat insulator.

- The edges of the protective film must be folded under the insulation, which does not allow vapors to penetrate into it.

- With multi-layer installation, the joints of the slabs are located with a slight offset.

- For the top layer, a material of higher density is selected than for the bottom coating.

- Waterproofing is installed on top of the insulation.

Isoroc insulation is a reliable and high-quality material used in a wide variety of production areas. Due to the ease of installation and accessibility, this type of heat insulator is constantly in demand among professionals and people engaged in construction at an amateur level.

ISOFLOOR

ISOROC's assortment includes various thermal insulation building materials. Including Isoflor. This building material can be used to solve a wide range of problems. From us you can purchase Isoflor both wholesale and retail. We are a product manufacturer. Therefore, our price for Isoflor does not contain any unreasonable markups. It is significantly lower than most resellers. In this section you will learn useful information about the properties of building materials and the terms of cooperation with us.

ISORUF V

The use of rigid Izoruf V slabs as an insulating material (alone or together with Izoruf N slabs for the bottom layer) seems to be the most rational option for thermal insulation of a load-bearing roof. Before the advent of this material, a layer of rigid insulation had to be first placed on the roof structure, followed by a cement screed, and only after that could waterproofing be installed. This inevitably led to a heavier structure and forced the construction of more powerful supporting structural elements. The total cost of construction increased.

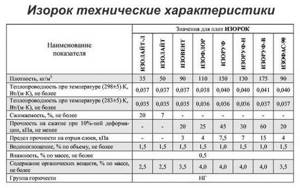

ISOROC mineral wool: technical characteristics

The sizes of ISOROC slabs are different, the most important characteristics of thermal insulation are thermal conductivity in the range of 0.033 - 0.07 W/(m K), material density from 40 to 150 kg/cub.m., compressive strength up to 55 kPa. Increasing the density of Rocklight basalt wool leads to greater strength of the material and increased thermal conductivity. Isorok brands can be divided into several groups depending on their purpose.

Table Technical characteristics of thermal insulation Isorok

Isorok Izolight-Lux and Izolight-L are used for processing structures without loading the thermal insulation.

Isovent and Isovent-L are used for insulating facades under siding and ventilated attics of houses.

Izoflor, Izokor-S and Izokor-K can withstand heavy loads and are used for insulating floors.

Izoruf N, V and Izoruf NL are intended for flat roofs of garages with a cement screed device.

Izofas is used by builders for the facades of houses with subsequent plastering of the surface.

The use of Izorok roll insulation in construction is varied - insulation of horizontal surfaces, sloping roofs, pipelines and other communications. Isoroc is significantly superior to polystyrene foam in terms of fire and environmental safety; in terms of thermal conductivity characteristics, ISOROC is not inferior to analogues from other manufacturers. All materials are durable.

Technical characteristics of Izorok products

ISORUF-NL

Thermal insulation is the most important stage in the construction of a facility for any purpose, and today many types of materials are offered for this work, each of which has certain characteristics and properties. The Isoroc company, which has been working in the field of manufacturing heat and sound insulating materials for a long period, offers Isoruf slabs for the installation of a reliable and effective thermal insulation structure. Izoruf can be classified as a unique energy-saving material that is made using the latest technology.

Universal heat insulator ISOFLOOR

This material from the manufacturer Izorok contains non-flammable stone wool, which also has a high level of moisture resistance. The form of the material is presented in the form of plates. Thanks to this heat-insulating product, it is possible to reduce the amount of heat loss from various types of foundations (concrete or reinforced concrete structures, self-leveling, electric, water floors and similar structures).

The cost of this insulation product is 130 rubles per square meter.

PP-60/-80

PP-60/-80 are non-flammable mineral wool slabs based on stones with water-repellent and dust-removing additives. Designed for use as unloaded thermal and sound insulation of pitched roofs, floors, ceilings, internal partitions, light frame structures, three-layer lightweight walls of low-rise buildings made of brick, aerated concrete and other blocks, for thermal insulation of equipment and pipelines with an insulated surface temperature of - 60 C to + 400 C.

P-125

P-125 are non-flammable mineral wool slabs based on stones with water-repellent and dust-removing additives. Designed for use as unloaded heat and sound insulation of horizontal, vertical and inclined building envelopes of all types of buildings, including: in three-layer lightweight masonry (layered, well); frame walls and partitions; attics and interfloor ceilings, for thermal insulation of equipment with a temperature of the insulated surface from -60 °C to + 400 °C.

Areas of application of insulation

Insulation materials of the Izorok brand are characterized by the fact that they are used not only in construction, but also in other areas. In their classic form they are used:

- for internal thermal insulation and insulation of floors (interfloor ceilings);

- for the purpose of protecting attics and roofs of buildings;

- for soundproofing premises in apartment buildings.

When choosing products suitable for specific purposes, the density of the insulation material used must be taken into account.

Due to their ability to retain heat well, they are used for thermal insulation of various utilities, including centralized water supply and heating systems.

ISOVENT-SL

Isoroc ISOVENT-SL is a non-flammable hydrophobized mineral wool slab based on stone. Designed for use as heat and sound insulation of horizontal, vertical and inclined building envelopes, including: in three-layer lightweight masonry (layered, well); suspended facades with an air gap (ventilated facades) with single-layer insulation and as an outer layer with a two-layer insulation scheme, for thermal insulation of equipment with a temperature of the insulated surface from -60 to +400 ° C.

Information about the manufacturer Isorok

The date of appearance of the Russian brand “Izorok” is considered to be 2000, when a large association was created on the basis of the Tambov Mineral Insulation Plant. The further development of this production was supported by investments coming from a number of foreign companies.

Over time, Isorok mineral wool has become a very popular product, in demand in most areas of construction technology.

To expand the volume of mineral wool production, the association needed:

- significantly expand its production areas;

- acquire modern equipment that allows you to automate the work process;

- master new technologies for waste-free production of insulation products.

Thermal insulation Isorok is made on the basis of the finest fibers from a melt of mineral rocks, the individual components of which are held together by a special binder. The need to comply with all the subtleties of the technological chain stimulated the concern's engineers to constantly improve this process. Today it belongs to the undisputed leaders of the Russian market of insulation materials.