All people, sooner or later, have problems with home insulation. Insulating an apartment is quite simple. Things are more complicated with the house. The floor can be insulated using a “warm floor” system, and the walls can be insulated with a special material. But in order for the heat to remain in the room for a long time, heating to occur faster, it is necessary to insulate all sides of the room, including the attic. In this article we will talk about exactly this.

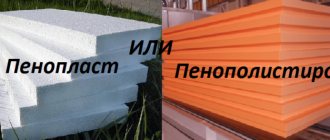

Modern technologies make it possible to insulate an attic using a variety of means. The most optimal of them, judging by the feedback from people and experts, is polystyrene foam.

Polystyrene foam is often used for reliable transportation, this indicates its strength, pliability, and lightness. In addition, the price of this material is affordable to any buyer. Many people think that this material breaks easily, but this is not entirely true. In order to break a layer of this material, you need to apply force and try to move a certain area. Agree, we don’t treat our walls and ceiling like that.

Read the topic : using polystyrene foam for wall insulation.

Is it possible to insulate an attic with polystyrene foam?

To insulate an attic with your own hands, the choice of building materials is based on the environmental component. Expanded polystyrene is a product of synthetic origin. When the plates are heated (+25-+30 degrees Celsius), phenol, acetophenone, and methyl alcohol are released. Inspecting authorities claim that the amount of substances complies with acceptable standards. Today, manufacturers are using new technologies for the production of synthetic insulation aimed at reducing the content of residual harmful products. To simplify the choice of polystyrene foam for the buyer, finished products are divided into 2 groups:

- Technical expanded polystyrene is used for work on facades, non-residential buildings, and in road construction.

- Household insulation can be installed with your own hands inside a residential or social facility.

However, there are restrictions on the use of polystyrene foam regarding the type of structure. The addition of fire retardants reduces the melting and combustion temperatures, but it is impossible to completely eliminate this property of the thermal insulation material. When using polystyrene foam to insulate an attic roof, experts recommend using non-combustible roofing and decorative finishing. And the electrical wiring must additionally be insulated with a corrugated plastic pipe or hidden wiring should be eliminated altogether.

Advice and recommendations from experts

In order for a residential attic to delight you with its comfortable conditions for many years of operation, you need to familiarize yourself with some of the subtleties when insulating it:

- small gaps between the insulation will improve ventilation; the cladding of the roof or walls can be supplemented with a waterproofing film. This coating will protect well from cold wind and condensation; carefully glue the junctions of the canvases.

Don't forget about windows and doors. Up to 30% of the heat escapes through these openings.

If the attic has a wooden window, seal the gaps between the walls and the frame. If there are cracks in the glass, seal them with tape, or better yet, replace the damaged panels with new ones. To eliminate drafts, you can use thick curtains and treat the doorway with special sealants or foam rubber.

Knowing how the attic is insulated with polystyrene foam, the pros and cons of other materials, various technologies for covering gables and ceilings, you can independently turn the attic into a residential and cozy corner.

Insulating an attic with polystyrene foam is an effective and inexpensive way to turn an attic into a room suitable for comfortable year-round living.

This article will discuss the features of the technology of thermal insulation of walls, floors and ceilings of an attic room using slab foam. You will learn the pros and cons of this material, and all the nuances of how the attic is insulated with polystyrene foam. Remember that polystyrene foam is harmless to human health.

Pros and cons of insulating the attic from the inside with foam plastic

Low-density polystyrene foam crumbles and breaks a lot.

The choice of polystyrene foam for attic insulation is often based on the low cost and light weight of the material with strict geometric shapes. However, expanded polystyrene has other advantages:

- The thermal conductivity coefficient is limited to 0.032-0.044 W/m*K, which is lower than some options for mineral insulation.

- The density of foam plastic has relatively low values, which is important for ensuring minimal load on the supporting sheathing and rafters, load-bearing structures and the foundation of the building. The low weight of the slabs also simplifies the DIY installation process, during which there is no need for special lifting equipment.

- Water absorption is 0.2%. This fact does not limit the use of polystyrene foam with respect to humidity indicators. This means that you can insulate a room, a bathroom, walls inside and outside the attic.

- Inertness to biological damage. The synthetic base of expanded polystyrene does not promote or support the development of bacteria, fungus, mold and moss.

- Ease of processing. To insulate the attic from the inside with polystyrene foam with your own hands, it is enough to have a construction knife, a hacksaw with a fine and fine tooth. Less commonly, an electric jigsaw or reciprocating saw is used to speed up the DIY installation process. The cutting of slabs is carried out without significant effort and quickly.

Important!

When choosing a thermal insulation material, you need to consider the coefficient of thermal expansion of the insulation. The mansard roof has a rafter support system. As a rule, wooden beams are used to organize the frame. Foam plastic is characterized by a lack of plasticity, which causes a low risk of cold bridges and eliminates mechanical impact on the sheathing.

Depending on the density of the foam, installation, the service life of synthetic insulation can be 10-15 years or more, up to 30. Extruded polystyrene foam retains its quality characteristics and physical parameters longer. The material also copes better with exposure to ultraviolet radiation, but protection is still required.

Along with the tangible advantages of expanded polystyrene, there are disadvantages that are important to consider before making the final choice of one or another insulation:

- The low vapor permeability of polystyrene foam causes poor breathability. These facts contribute to the formation of condensation on windows, walls and ceilings, and the accumulation of carbon dioxide in the room. Such consequences can be eliminated only by organizing a ventilation gap in the body of the structure, forced or natural ventilation of the internal space of the attic.

- Low resistance to sunlight. Often you have to carry out repairs with your own hands in stages; the insulation is left open for some time. Foam plastic, regardless of composition and density, will begin to change color and crumble within a month.

- The weak resistance of polystyrene foam to solvents must be taken into account during finishing work. Many chemically aggressive substances lead to the destruction of slabs almost instantly.

- The low strength of synthetic insulation leads to deformation of the slabs under the influence of any type of mechanical load. Under pressure, density and thermal conductivity change for the worse.

As a result of contact of polystyrene foam with acetone, the material is destroyed.

In addition to negative technical characteristics, disadvantages include the attractiveness of the thermal insulation material to mice and rats. They easily gnaw channels in foam plastic slabs for movement, warm burrows for hibernation, and nests for reproduction. This significantly increases heat loss on the attic roof.

Advantages and disadvantages of attic insulation with foam plastic

Any product has its advantages and disadvantages, the question is which side prevails?

Let's look at the advantages:

- light weight, which simplifies transportation, loading, installation;

- affordable price;

- strength;

- due to the fact that the material consists of particles tightly adjacent to each other, it does not allow heat to pass out;

- easy to process, which is very important for obtaining the desired shape;

- has good sound insulation;

- if it gets into fire, it begins to melt, but does not burn.

The disadvantages of this material are:

- reacts poorly to high humidity;

- mold may form on it;

- When ignited, it releases toxic fumes.

How to insulate an attic with polystyrene foam?

A variety of materials can be used to build a house. In all options, it is possible to insulate the attic floor with foam plastic.

Scheme for insulating an attic with foam plastic

The diagram shows how to properly insulate an attic.

Foam thickness for attic insulation

The risk of condensation and the level of heat loss depend on the choice of thickness of synthetic insulation. The thinner the attic structure, the larger the layer of foam that must be organized. When determining this parameter of slabs, the following criteria are taken into account:

- climatic features of a particular area;

- thickness of the attic walls;

- building materials from which the roof of the building is erected and finishing is carried out.

The choice of which polystyrene foam to insulate an attic roof is based on the density and location of the insulating boards. It looks like this:

- For a flat roof, the current figure is 35 kg/cubic meter. m, which corresponds to a thickness of polystyrene foam of 50-100 mm.

- The slopes of the attic roof are insulated with polystyrene foam with a density of 15 kg/cubic meter. m high, close to 100 mm.

- For the walls, thermal insulation boards with a density of 25 kg/cubic meter are used. m. As a rule, a thickness of 50 mm is sufficient.

There is a general formula for calculating the thickness of insulation. The value is obtained by multiplying the thermal resistance of the walls of a residential premises, characteristic of a particular locality, by the thermal conductivity coefficient of the selected thermal insulation material.

For example, for the north-west the thermal resistance limit is 3.08 sq.m.*K/V. A wall of 1.5 bricks has a resistance of 1.06 sq.m.*K/V. If we take expanded polystyrene with a conductivity of 0.039 W/m*K, then slabs 78 mm thick will be needed to compensate for heat loss.

Nuances of insulation

As for the attic, the insulation of the walls should not only prevent the penetration of precipitation, but also reliably protect the upper floor from the penetration of heat and cold from the outside. Cold air always sinks down, pushing out warm air, so the temperature in the ceiling area will always be several degrees higher. In any case, heat loss from the wall and roof will differ significantly, even if the thickness of the materials is approximately the same.

Moreover, due to changes in air temperature, condensation may form, which can negatively affect the operation of the entire structure. The attic ceiling is more vulnerable than other elements; for example, a certain temperature difference that caused condensation on the attic ceiling will not affect the surface of the walls in any way. Attic spaces are insulated according to more stringent requirements than other elements of the building.

Scheme of roof insulation with polystyrene foam.

Due to significant heat loss, proper insulation of the attic can significantly reduce the cost of material and related devices. In addition, modern insulation technologies can significantly increase the thermal insulation properties of expanded polystyrene, which will allow less use of the heating system. Insufficient insulation of various roof elements can lead to the formation of huge icicles, which, if they fall, can cause harm to human health. If you try to knock down icicles, the roof may be damaged. High-quality insulation work will allow you to avoid unpleasant moments associated with icicles. The rafter system must also be insulated, otherwise the entire structure will not have sufficient qualities and characteristics.

Before installation, it should be taken into account that the moisture content in warm air is significantly different from cold air, so the moisture contained in the air is released outside. Waterproofing material, which is installed in almost all structures, does not allow moisture to escape, which can lead to the formation of mold and mildew on the surface of the walls. Drops of liquid that may appear on the ceiling have nothing to do with it, but simply appear due to excessive condensation. In order to counter this unfavorable factor, the insulation is equipped with a layer. As a rule, it is located on top of the main structure. To remove moisture from the roof elements, an air cushion should be provided, which will serve as a kind of ventilation.

Converting an attic space into a residential attic while preserving the rafters and rafter system is one of the most common methods. To reduce the load on the load-bearing structural elements, extruded polystyrene foam, which has a low density coefficient, is installed on top. This method does not affect the rafter system and does not require any changes. Thus, wind can easily penetrate the structure of the insulation, but in order to maintain the thermal insulation qualities, windproof material must be laid on top of the base.

Basic recommendations for attic insulation with extruded polystyrene foam

- Thermal insulation qualities may be reduced due to moisture penetration into the insulation layer. To prevent this problem, you need to properly design the water drainage system, taking into account the angle of inclination of the slope. Installing roll materials on top of the rafter system is also suitable.

- To prevent a decrease in the various qualities of the material due to exposure to moisture from condensate, a vapor barrier material is used on the inside.

- For effective ventilation, the insulation is sheathed with vapor-conducting material from the outside, but in no case from the walls.

The rafter system of any attic space consists of elements placed at a distance of 0.5–1 m from each other. For high-quality insulation, the rafter space is filled with extruded polystyrene foam or mineral wool. The thickness of the insulation will be directly determined by its thermal conductivity coefficient, depending on which the thermal insulation qualities will depend. The rafter system can be insulated with one or several layers. If the insulation of the house is carried out immediately after construction, then the installation of insulation on top of the rafter structure begins from the rafter legs.

How to choose polystyrene foam for insulating an attic roof

Classification of synthetic insulation is carried out based on production technology. Material made by baking is labeled as PSB (foamed) or EPS. Extruded polystyrene foam PS or XPS is sold through the press. Regarding density and application, the following types of PSB thermal insulation boards are distinguished:

- S-15 - relevant for work with a mansard roof;

- S-25 - more often used for flooring;

- S-35 - foundation, utilities, facades in harsh conditions;

- S-50 - any structures with high mechanical load.

There is also technical polystyrene foam labeled A. It is used for foundation insulation. Synthetic material of class K is allowed only for interior work. It is better to insulate an attic with foam plastic under a soft roof from group C, since its strength characteristics are higher than other analogues in its group.

A gap of 10-15 mm is left between the frame and polystyrene foam, then it is filled with polyurethane foam

Basic properties of polystyrene foam as a material for insulation

Nowadays, stores offer a huge selection of different materials for insulating rooms, but one of the popular ones is polystyrene foam. It is not only easy to use, but also quite economical among other insulation materials, despite the fact that it is better known as a packaging material.

Styrofoam sheets are probably familiar to everyone

Polystyrene foam is a white material, cellular and lightweight, consisting of carbon and hydrogen atoms. Its density and specific gravity are characterized by very low values. But polystyrene foam has a high degree of thermal protection. It has been successful in construction for 70 years . Currently, there is not a single material similar to it at least partially. The durability of high-quality polystyrene foam has been confirmed by various tests.

How to prepare an attic for foam insulation

Due to the low vapor permeability of expanded polystyrene, there is a risk of condensation, which is detrimental to wooden or metal roof rafters and supporting lathing for thermal insulation. Therefore, it is important to first clean the structural elements and install protection. For this purpose, anti-corrosion or antiseptic compounds are used.

Important! You need to choose universal protective equipment suitable for work inside and outside the attic. They are environmentally friendly and resistant to variable operating conditions.

Before laying expanded polystyrene slabs, it is necessary to organize waterproofing. Since synthetic insulation is chemically unstable, fabrics and liquids without bitumen and solvents are used. If polyethylene or membrane-type materials are used, then they are attached to wooden rafters using staples and a construction stapler. To avoid damage, an additional thin beam is laid. Installation to the metal frame is carried out using glue. The overlap of the canvases is 10-15 cm using double-sided universal tape.

Tension and sagging of the protective material is allowed to a slight extent in order to prevent damage to the waterproofing fabric under the influence of temperature changes

Disadvantages of polystyrene foam

- This material also has a number of disadvantages:

- It crumbles well. Very often, in private homes, rodents appear in the attics, which can cause many problems for the owners. Materials such as polystyrene, unfortunately, are very attractive to mice.

- An event such as thermal insulation of a roof with foam plastic takes quite a lot of time if insulation occurs after the sheathing process. In this case, each slab must be cut and adjusted to size, which creates additional labor costs both for installation and for cleaning the room after it.

- With prolonged high humidity and lack of sufficient air exchange, a kind of black mold deposit forms on the foam. In order to prevent this, it is necessary to provide a gap of at least 2 centimeters during installation.

- The environmental friendliness of polystyrene foam is also questionable. Some believe that polystyrene foam can release toxic fumes into the environment. But this opinion does not have sufficiently strong grounds, so it is quite controversial.

- Also, roof insulation with foam plastic does not sufficiently comply with fire safety standards. At extremely high temperatures that occur during a fire, polystyrene foam can ignite. In other cases, the material melts.

Polystyrene foam cannot be called an environmentally friendly material

Work such as insulating the roof with foam plastic from the inside is carried out on a special frame or sheathing using self-tapping screws. The slabs are fitted end-to-end as closely as possible, and the seams between them are carefully foamed with polyurethane foam or sealed with sealant. This is done in order to prevent the occurrence of so-called “cold bridges”. Despite the moisture resistance of the material, it is necessary to lay waterproofing between the foam and the roof and leave a gap for air circulation.

Next, a finishing ceiling made of plasterboard or chipboard is mounted on top of the foam. Installation of thermal insulation of a flat roof with foam plastic is carried out by laying sheets of the latter on a flat, clean surface of a bitumen-polymer membrane. The foam is covered with geotextile on top and then covered with gravel about 5 centimeters thick.

“Green roofs” are created using the same principle. A reinforced coating is placed on the insulation layer, on top of which a profile membrane, geotextile and a layer of soil are alternately laid, into which ground cover plants with a superficial root system are planted.

How to properly insulate an attic with foam plastic

The living space of the attic requires insulation of all structures. According to the technology, the process begins with the treatment of the roof and ends with the floor. The step-by-step procedure is as follows:

- Expanded polystyrene slabs are laid with a small gap on the prepared base between the roof rafters or in the grooves of the sheathing. This is important because the thermal conductivity of building materials varies. Self-tapping screws and plastic dowels with a wide head are used as fasteners. An alternative option is special glue, liquid nails or solvent-free foam.

- Window openings in the attic roof are protected with waterproofing and insulated with polystyrene foam in the same way as walls.

- A vapor barrier sheet is laid on top of the expanded polystyrene and secured using construction staples and a stapler.

The vapor barrier fabric, by analogy with waterproofing, is installed without strong tension with acceptable sagging.

The final stage involves finishing the attic. It is carried out using leveling plaster, reinforced with fiberglass mesh. Another option involves organizing lathing for subsequent sheathing with plasterboard, plywood, boards, and OSB boards. The third option may be limited to rafters and a frame for insulating flooring.

Roof insulation with foam plastic: technology and nuances

It seems possible even for a non-professional to insulate a roof with your own hands. Before you begin directly insulating the roof, you need to have a clear idea of where the attic, residential area or non-residential location for the attic will be located. The consumption of insulation material depends on this.

Next you should take the following steps:

- select the appropriate material , suitable in terms of characteristics and meeting the requirements of a particular building, designate the scheme and order of work;

- Be sure to check the rafters for strength, quality, and possible fungal damage. If defects or moisture are detected, unsuitable elements must be replaced;

- To increase service life, treat all elements of the roof frame with an antiseptic , including wires, water pipes, rafters. Both antipyretic and antiseptic agents can be used as impregnation for wooden structures.

When all the preparatory work is done, you can begin to insulate the roof.

Advice from professionals

To minimize the likelihood of cold bridges, polystyrene foam on the attic roof should be laid in 2 layers. In this case, the arrangement of the plates should be staggered. Additionally, the joints should be filled with polyurethane foam and sealed with plumbing tape with low vapor permeability.

The peculiarity of attic insulation with foam plastic in cold regions is the thickness of the slabs, which can reach 150-200 mm. To reduce space loss, mineral wool with a low thermal conductivity coefficient is often laid on top of thin sheets of polystyrene foam. Such a combination of insulation can total 100-120 mm.

Any gaps between the foam boards and the sheathing are best filled with low-expansion foam. Such a building material will not exert much pressure when drying and will not deform fragile slabs. The mass will prevent heat leakage and condensation formation.

It is not recommended to use polyethylene film to waterproof insulation in the attic. In extreme conditions it lasts less than stated. At the fastening points there is a high risk of rupture when heated and during frosts. Insulating materials should be chosen with similar durability indicators, so that you do not have to repair and dismantle the entire finish.

Any sheathing material can be easily fixed to a wooden sheathing under foam plastic.

Common mistakes when insulating with foam plastic

It is advisable to insulate the roof with foam plastic in conjunction with the insulation of all walls of the building. However, if the roof is not insulated correctly , then soon the consequences of unprofessional insulation will clearly make themselves felt.

The most common mistakes that are important to avoid during the installation of insulation:

- the occurrence of gaps between foam plates. These gaps are cold bridges that appear during the cold season. In addition, they can cause moisture to form in the insulation;

- using polyethylene film as waterproofing . After a few years, its properties will be lost and cellophane will begin to allow moisture to pass through;

- Errors in calculating the thickness of the heat-insulating layer can lead to the appearance of depressions and failure of the seal of the insulation.

NOTE!

When insulating the roof of a house, it is necessary to carefully analyze and follow the installation technology and adhere to the rules of thermal insulation.

Correctly selected thermal insulation material and properly equipped roof insulation will keep the house warm for many years.

Advantages and disadvantages

The above physical indicators and the structure of foam plastic have formed pros and cons that are not quite traditional for thermal insulators.

Among the strengths:

- long service life - 20-50 years (such a significant difference is due to different densities of the material and type of additives);

- good thermal insulation properties;

- low cost of insulation of 1 m2 of area - 140-185 rubles;

- ability to maintain consumer properties in any region of Russia - withstands temperatures from -50oC to +75oC;

- simple insulation technology - the owner of the premises can perform all operations with his own hands;

- low density (specific gravity) allows you to insulate any house structure without load calculations;

- good adhesion with cement-sand and gypsum mortars. Sometimes, to increase the adhesion force, the surface of polystyrene foam is treated with a kitchen grater.

There are also disadvantages, but they can be successfully dealt with:

- flammability. Imported polystyrene foam is self-extinguishing - fire retardants have been introduced. Therefore, it is classified as flammability class G-1. In Russia, either the fire retardants are wrong, or the manufacturers add them in words, but most of the products burn well. Therefore, before buying domestically produced polystyrene foam, you need to set a piece on fire and then remove the flame. If the combustion stops within 4 seconds, you can buy insulation and forget about such a drawback as flammability;

- the second minus is directly related to the first - during the combustion process, harmful substances are released;

- No matter what manufacturers say, the styrene polymerization process cannot be 100%. Therefore, when the foam is heated above 30oC, unbound styrene begins to release. This is a harmful substance, especially for the female body. The problem is completely solved by good ventilation and regular airing of the premises;

- Under the influence of ultraviolet radiation (sun rays), the material ages intensively. It is simple to avoid destruction of the polystyrene foam structure under the influence of the sun: cover the insulation with sheathing, decorative plaster, or simply paint it with paint compatible with the material.

There are disadvantages that cannot be dealt with, but you can avoid such situations:

- melts on contact with most solvents, from paint to polyurethane foam;

- does not allow vapor molecules to pass through - completely vapor-tight;

- has low tensile and bending strength;

- is a favorite place for mice and rats to build nests;

- resonates household noises, which many consumers are not prepared for: they cannot understand why the noise load in the apartment increases after insulation with foam plastic. By the way, this is why foam plastic and metal tiles are incompatible on the roof: the sounds of raindrops falling on the roof are amplified.