Coal ash as a fertilizer: properties and rules of use

- View the full image

Coal ash

What does coal ash contain and what properties does it have?

Types of coal fertilizer

What crops are fed with coal fertilizer?

Norms and application features

Benefits of Coal Ash

Ash has been used as fertilizer since the days of the first vegetable gardens.

It is publicly available, inexpensive, and easy to use. But the introduction of coal ash into the soil cannot be carried out without control. With such fertilizing, you need to follow certain rules and proportions, and also take into account what plants and types of soil it can be used for. Despite all the usefulness of ash elements, it must be taken into account that not every ash is suitable for fertilizer. A coal combustion product taken from a contaminated or radioactive area should not be used, because it accumulates harmful substances that will be consumed by plants.

Pros and cons of slag insulation

The positive features of insulation with slag fillers are:

- fire resistance;

- high speed of insulation;

- low price;

- ease of installation.

There are also negative aspects Among them:

- heavy weight of insulation. Today, slag insulation is the heaviest insulation. Their use requires a good foundation (if walls are insulated), durable structures (if floors and ceilings are insulated).

- some fillers absorb moisture, so the insulation must be well moisture-proofed.

Environmental friendliness of slag

The porous structure of the slag retains heat well.

The material in question is industrial waste. Understanding whether slag is harmful as insulation is important already at the beginning of designing a house.

The insulation technology and places where the backfill is used do not provide for direct contact with humans. Dust and gaseous emissions do not penetrate into the rooms, so they are not able to cause harm to health.

When purchasing, you must require a safety certificate. Some slags emit radioactive background.

What does coal ash contain and what properties does it have?

Coal soot can be produced by burning hard or brown coal. Accordingly, it will differ in the proportions of the chemical composition, which contains a small amount of:

- Calcium, which is necessary for plant development. It takes part in carbohydrate-protein metabolism, therefore it is very useful for young crops with active growth. Calcium is also necessary for plant roots; it helps absorb other microelements found in the soil. This element is able to influence the acidity of the soil by binding certain acids.

- Potassium, which is part of cell sap and takes an active part in photosynthesis and carbohydrate metabolism. It activates enzymes and affects the quality of vegetables and fruits.

- Phosphorus, which acts as an energy source for plants. It participates in the metabolic processes of the plant body and has a direct impact on the degree of maturity of fruits and seeds, and, consequently, on the quality and quantity of the harvest.

- Magnesium, which is part of chlorophyll and affects photosynthesis. The plant signals a lack of this element by yellowing leaves and their falling off.

- Sodium, which promotes the transfer of carbohydrates, and a sufficient amount of the element helps to increase plant resistance to pathogenic environmental factors and low temperatures.

However, ash fertilizer is used quite rarely, because the minimum content of useful substances enters the soil in a state that is difficult to access for consumption by plants - these are silicates, which under the influence of high temperatures fuse and form glassy masses.

Types of coal fertilizer:

- Coal ash. This fertilizer is rich in silicon oxides, the content of which often exceeds 50%, so it is often used to drain and loosen wet, heavy clay soils. Coal fertilizer improves the structure of homogeneous soils, increases their moisture carrying capacity and fertility. In addition, this fertilizer contains virtually no chloride compounds. The use of coal tar fertilizer is unacceptable for sandy soils and soils with high acidity, since the high sulfur content is converted into sulfates and contributes to an increase in acidity. In this regard, coal fertilizer is recommended to be combined with calcium-containing, ammonium and organic fertilizers (bird droppings and manure).

- Brown coal ash. Brown coal is produced under the influence of high pressure on plant masses, which are saturated with phosphorus, potassium and other mineral compounds. This fertilizing is used as a mineral fertilizer, which enriches poor soils with microelements. Unlike coal ash, brown coal ash reduces the acidity level of the soil, improves its structure and saturates it with boron, manganese, copper, molybene, zinc and other components, which helps increase productivity. Brown coal crumbs contain glumic acids (about two percent) and are the raw material for the production of glumates (fertilizers), which have high physiological activity that helps improve the agrochemical properties of the soil and stimulate the activity of earth microorganisms. Glumates also prevent the leaching of useful elements from the soil.

What crops are fed with coal fertilizer?

It is recommended to apply coal ash when growing crops that actively consume sulfur. It is added to grow quality:

To increase the yield of these crops, the combustion product of coal is combined with gypsum. For nutrient-demanding crops, fertilizing with rock ash will not bring any benefit, because it contains an insufficient amount of nutrients for them.

Crushed coal slag is added during digging of the trunk circles of fruit-bearing trees.

With regular fertilizing with coal ash, fluorine and potassium accumulate in the soil, because the ash retains its usefulness in the soil for five years. But for the effectiveness of the use of such fertilizer, it is necessary to combine it with organic matter.

Brown coal ash and flour are often used in the production of substrates for seedlings of cucumber and tomato crops. To do this, mix one part of peat and sand and 5% of crushed brown coal. The beneficial properties of such ash remain in the soil for three to five years. Lignite ash is effectively added to compost of fine straw, grass and sawdust.

Price and manufacturers of slag wool

Many large manufacturers of mineral insulation are gradually abandoning the production of slag wool. Those that still produce it have a limited range. The following domestic manufacturers of this insulation are worthy of attention: CJSC Minvata, LLC, LLC Thermal Insulation Products Plant. In addition, local representative offices of large brands, such as Rockwool, Isoroc, produce a series of thermal insulators for technical purposes based on blast furnace slag. The price of slag wool is about 500 rubles per package.

Norms and application features

Coal ash is added to loamy and heavy loamy soils in the fall in small quantities - it is recommended to apply no more than three kilograms per hundred square meters. To increase the effect, such a fertilizer should be combined with ammonium nitrate and organic matter, because by binding ammonium with sulfur ions, the loss of nitrogen compounds is reduced.

Rules for adding coal ash:

- in heavy and clayey soils, ash is introduced to a depth of twenty centimeters

- Due to leaching by precipitation, it is recommended to add ash before winter

- Coal ash is used in dry form and as solutions (100 grams of the element per 10 liters of water), but the solutions contain a reduced amount of useful elements

- Ash is stored exclusively in dry rooms, in tightly closed containers. When moisture gets in, the usefulness of the fertilizer is lost.

- simultaneous application of ash and nitrogen-containing fertilizers is not recommended

- ash can be used to stimulate seed germination. To do this, prepare an ash infusion, which must be kept for 24 hours and the seed material must be soaked in it.

It should also be taken into account that coal fertilizer contains sulfites, which are toxic to plant crops, but under the influence of oxygen they undergo oxidation and acquire beneficial properties. As a result, the combustion products of coal should not be added immediately; the ash residue must be sifted and dried on the floor in a dry place for at least a week and a half. After which the slag is stored in a well-closed container.

The rate of application of brown coal ash fertilizers per square meter is 3-5 kg.

An excess of such fertilizer will slow down the development of crops and increase the level of strontium in the soil. It is recommended to use lignite derivatives - glutates at a rate of 50-60 grams per square meter, and for crumbs - no more than 12 grams. Excessive application of these elements leads to inhibition of vegetation and destruction of beneficial microorganisms, which negatively affects the composition of the soil.

Insulation with sawdust

Another accessible, inexpensive natural material is sawdust. They have been used to insulate ceilings since time immemorial; for many, this option was the most convenient and effective. The correct use of sawdust made it possible to make thermal insulation incredibly durable: there are cases when such a coating lasted for more than a hundred years.

Since sawdust is a natural material, it is completely safe, but is highly susceptible to external influences. Wood shavings are afraid of fire, cannot tolerate moisture, and rodents and insects appear in them. Due to dampness, it begins to rot, and all its beneficial properties quickly disappear. In order for the ceiling insulation with sawdust to have the maximum effect, you need to do everything correctly.

If sawdust is simply poured between the floors, it will quickly settle and draw moisture from the air. It would be more reliable to mix wet sawdust with a small amount of cement, and then, compacting it, spread it in a thick layer in the attic. This method is very economical, easy to implement and effective.

Benefits of Coal Ash

If ash is used correctly and in the right proportions, then such a fertilizer will have virtually no disadvantages. Experienced gardeners prefer ash fertilizers due to a number of advantages:

- Safety and naturalness. Ash does not harm the human body, does not emit an unpleasant odor and does not cause skin irritation.

- Cheap and accessible. You can make coal ash yourself, purchase it at specialized retail outlets, or take it from friends who heat with coal. Fertilizer is used economically and can be stored for a long time.

- Protective properties. Coal ash is a good preventative against plant pests. Sprinkling ash on the soil around the plants stops the attacks of snails, slugs, ants, wireworms, flies and whites.

- Preventing diseases caused by fungi. To do this, plants are sprayed with an ash solution.

There is an opinion that coal combustion products are harmful to the human body because they may contain heavy metals and radioactive elements. But plants develop quite actively in the presence of these elements. This opinion is partly true. The accumulation of harmful substances in plant tissues is possible when the level of application of such fertilizer in the soil is exceeded, that is, if more than 5% of the total volume of soil is applied.

Coal derivatives are used everywhere and are of agricultural importance for farmers in many countries. Unlike wood, it contains more calcium, sodium and copper salts and less potassium and phosphorus. Therefore, coal combustion products are indispensable when applied to acidified areas of soil to normalize their acidity, especially when planting potatoes and tomatoes. Solanaceous crops from such fertilizer are saturated with copper, which resists late blight.

If you follow the standards for applying coal ash and do not overdo it in this matter, the accumulation of harmful substances is not observed, which means it is not capable of causing damage to the human body.

More information can be found in the video:

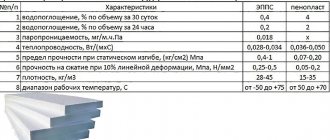

Main technical characteristics of blast furnace slag

When insulating, the main indicator is thermal conductivity . According to GOST and SNiPs, the thermal conductivity coefficient of crushed stone from blast furnace slag is 0.21 W/(m°C).

For comparison, let’s take the thermal conductivity of medium-hard mineral wool. It is 0.0326 W/(m°C). This suggests that when insulating a building structure, the layer of slag crushed stone should be thicker than the layer of mineral wool:

- Flakiness . The indicator characterizes the volume of smooth and angular elements in the filler. If the bulk of the filler consists of smooth grains, then it reduces the percentage of adhesion of the material to each other, as well as to the binder solution. The indicator is applicable only for bulk materials, such as slag insulation.

- Strength - characterizes the level of pressure and mechanical load that is maximum allowed on the filler. Slag insulation is stronger than mineral wool and polystyrene foam. Due to their rigidity, they are not prey for rodents. In this regard, insulation outperforms mineral wool, polystyrene foam, and polyurethane foam.

- Frost resistance . The parameter characterizes the number of frost cycles that the filler can withstand without changing its technical characteristics and properties. According to GOST, modern insulation materials must have a rating of at least F15 (i.e. 15 cycles). Manufacturers of all types of insulation adhere to this standard.

- Radioactivity - characterizes the class of radiation emitted. There are 3 classes, in the construction of residential buildings the 1st class is used, this applies to insulation of any type.

- Density _ This parameter shows the mass of filler per unit volume. Slag insulation is heavy insulation. Their density on average ranges from 300 to 1000 kg/m3. This is several times higher than the density of other insulation materials.

For example, the density of mineral wool averages 50-125 kg/m3. Thus, when insulating, it is necessary to take into account the high density and, accordingly, the heavy weight of the slag.

The characteristics of the filler fraction deserve special attention . The following levels are distinguished:

It is recommended to use medium-sized slag as insulation. Very small and too large elements are not beneficial in thermal insulation .

Is it possible to bring coal slag into the garden?

Winter is over, and with it the heating season. As a result, a pile of slag was formed after burning coal together with firewood in the furnace.

So the question arose: where to give all this goodness? Wood ash, as you know, can be poured into the garden and is even useful, because it is a fertilizer and even fights some types of pests, in particular it helps well against aphids and various flea beetles, which often grow on cabbage, radishes and other garden plants. What to do if wood ash is obtained together with slag from burnt coal? Here the question arises whether such a mixture can be added to the garden, whether it will be harmful to the various types of crops that we grow in the garden. I’ll immediately make a reservation that I did not find a clear answer to this question - since many are against introducing coal slag into the garden, a consequence of the content of heavy metals, but no one could give specific examples and studies that would confirm the harmfulness of the introduced slag. Of course, coal slag should not be brought into the garden. But since our slag contains a large amount of wood ash, and the super-harmful properties of the slag have not been studied, I think that such slag can be added to the garden. Many people write that they have been pouring slag from the furnace into the garden for decades and the yield is very good, and the yield of potatoes and tomatoes increases quite significantly. One woman writes that her mother poured slag from the furnace into the garden this way all her life, and now she is 90 years old, has eaten from the garden all her life and has never been sick. Others argue that slag is poison and under no circumstances should it be poured into the garden.

In the United States of America, a study was conducted in which coal slag was used instead of fertilizers for several years. As a result, there was an increase in the yield of many vegetable crops, and the tomato yield increased by 70%, the potato yield increased by 80%. At the same time, no harmful substances were found in the vegetables studied. In India, in this way (adding coal slag) the rice yield was increased by 34%.

It’s April 9, and the first greenery has already appeared in the garden - the spring onions are already gaining strength, you can cook pies with eggs and green onions. And also treat with ash to prevent aphids and fleas.

Types of slag

Metallurgical

They are divided into slags of non-ferrous and ferrous metallurgy. Ferrous metallurgy slags include:

- Blast furnace slag , obtained by smelting cast iron from iron ores. Its properties depend on the melting conditions used to produce fuel melts and flux additives.

- Steelmaking . They are produced in open-hearth, converter or electric furnace production.

- Ferroalloy . Types of ferroalloy slag are divided into subtypes with a predominance of the element that was added to the molten steel to obtain the ferroalloy, and this can be cobalt, chromium, manganese, molybdenum, silicon, etc.

Non-ferrous metallurgy slag : these include waste from copper, nickel, lead and zinc production.

Phosphorus

They are obtained as waste from the production of phosphate fertilizers. Used in the production of pumice or mineral wool. It is added as an additive to cement only if concrete products made from such cement go through the stage of high-temperature steaming.

Ash

They are a residue from the combustion of hard coal and oil shale. They are not used in practical use in residential construction due to the high content of radionuclides in them, but can be used in the production of paving slabs or if they are used as fillers for asphalt mixtures, where the possible formation of dust will be bound by resinous fractions. The method of cooling these slags immediately after their formation is also important: if cooling occurs with water, that is, quickly, a glassy structure is formed, which is more stable than the microgranular one obtained with slow, natural cooling.

LiveInternetLiveInternet

—Categories

- ACTORS (528)

- ACTORS 2 (80)

- BE BEAUTIFUL (31)

- GREAT ACTORS (136)

- FAITH. ORTHODOXY (146)

- FAITH.ORTHODOXY-2 (96)

- VIDEO (21)

- WWII (76)

- EVERYTHING FOR CHILDREN (152)

- EVERYTHING FOR YOUR DIARY (43)

- KNITTING (120)

- CROCHET (88)

- KNITTING (43)

- KNITTING.MITTENS (10)

- KNITTING.CHILDREN (105)

- KNITTING.SOCKS (35)

- KNITTING.Booties (51)

- KNITTING.FOOLS AND SLIPPERS (75)

- KNITTING.HATS (38)

- DIETS (94)

- ZhZL (340)

- PAINTING (55)

- CONSPIRACIES. RITES. (190)

- HEALTH (400)

- TOYS FOR CHILDREN (41)

- INTERESTING (495)

- INTERESTING ABOUT ANIMALS (38)

- HISTORY (176)

- HISTORY (CONTROVERSIAL) (21)

- HISTORY OF THINGS (60)

- HISTORY OF THE RUSSIAN STATE (555)

- HISTORY OF Rus' (208)

- HISTORY OF RUSSIA.SLAVS (61)

- CINEMA (66)

- COOKING (21)

- COOKING DISHES FOR HOLIDAYS (37)

- COOKING. SAUCES (18)

- COOKING. DISHES WITH APPLES (1)

- COOKING.WINE.TINCTURES.LIQUES (211)

- COOKING.BAKING (182)

- COOKING.BAKING WITH CARROTS (20)

- COOKING.BAKING WITH Cottage Cheese (88)

- COOKING.BAKING.PANCAKES (87)

- COOKING.BAKING.BUNS (96)

- COOKING.BAKING.CUPCAKES (22)

- COOKING.BAKING.EASTERS (70)

- COOKING.BAKING.MANNIKA.RUGS (13)

- COOKING.BAKING.COOKIES (166)

- COOKING.BAKING.NON-SWEET COOKIES (10)

- COOKING.BAKING.MEAT PIES (64)

- COOKING.BAKING.PIES NOT SWEET (103)

- COOKING.BAKING.SWEET PIES (119)

- COOKING.BAKING.PIES.WHITES.CHEBUREKI. (67)

- COOKING.BAKING.DOUGH (73)

- COOKING.BAKING.CAKES (182)

- COOKING.BAKING.NO-BAKE CAKES (21)

- COOKING.BAKING.BREAD (120)

- COOKING.BAKING.BREAD MAKING (11)

- COOKING.BAKING.CHARLOTTE (18)

- COOKING. COOKING IN POTS (13)

- COOKING. PREPARE SNACKS (205)

- COOKING. COOKING POTATO DISHES (87)

- COOKING. COOKING PORridge (18)

- COOKING. COOKING MEAT (87)

- COOKING. COOKING MEAT. MINCED MEAT (86)

- COOKING.COOKING MEAT.BEEF (11)

- COOKING.COOKING MEAT.CHICKEN (200)

- COOKING.COOKING MEAT.GIBLE (73)

- COOKING. COOKING MEAT. PORK (161)

- COOKING. COOKING MEAT. SALTED LAD (34)

- COOKING.COOKING MEAT.Kebabs (86)

- COOKING. COOKING VEGETABLES (165)

- COOKING.COOKING DUMPLINGS.Dumplings.MANTY (21)

- COOKING. COOKING PILAF (4)

- COOKING. COOKING FISH (76)

- COOKING. COOKING SALTED AND MARINATED FISH (57)

- COOKING. COOKING WITH MUSHROOMS (19)

- COOKING. COOKING SOUPS (54)

- COOKING.DESSERTS WITH KEFIR (5)

- COOKING.WINTER PREPARATIONS (240)

- COOKING. WINTER PREPARATIONS. EGGPLANT (43)

- COOKING.WINTER PREPARATIONS.MUSHROOMS (20)

- COOKING.WINTER PREPARATIONS.Zucchini (60)

- COOKING.WINTER PREPARATIONS.CABBAGE (39)

- COOKING.WINTER PREPARATIONS.CUCUMBERS (87)

- COOKING.WINTER PREPARATIONS.PEPPERS (16)

- COOKING.WINTER PREPARATIONS.SWEET (69)

- COOKING.WINTER PREPARATIONS.TOMATOES (171)

- COOKING.CASSORES (6)

- COOKING.MULTICOOKER.MICROWAVE. (51)

- COOKING.DRINKS (31)

- COOKING.EASTER (33)

- COOKING. IS THIS PRODUCT USEFUL (74)

- COOKING. USEFUL CULINARY TIPS (22)

- COOKING. LENTEN DISHES (29)

- COOKING.SALADS (180)

- COOKING.FISH AND SEAFOOD SALADS (46)

- COOKING.CHICKEN SALADS (76)

- COOKING.SALADS WITH MEAT (40)

- COOKING.SALADS WITH VEGETABLES (35)

- COOKING.SWEETS (118)

- COOKING.CHEESE DISHES (6)

- ICONS (62)

- FAVORITE TUNES (49)

- MYSTIC (22)

- MYTHS, PARABLES, TALES. (12)

- WE REMEMBER YOU 1. (458)

- WE REMEMBER YOU 2. (299)

- WE REMEMBER YOU 3. (231)

- FOLK SIGNS (68)

- FOLK RECIPES-1 (629)

- FOLK RECIPES-2 (221)

- FOLK RECIPES. HONEY AND BEE PRODUCTS (36)

- A LITTLE ABOUT EVERYTHING (99)

- SINGERS (116)

- SONGS I LISTEN TO (91)

- CONGRATULATIONS (21)

- SIGNS (5)

- HANDCRAFTS (86)

- GARDEN.VEGARDEN (924)

- GARDEN.VEGARDEN.EGGPLANT (71)

- GARDEN.VEGARDEN.PEAS. (15)

- GARDEN.VEGARDEN.PLOT DESIGN (46)

- GARDEN.VEGETABLE GREENING (48)

- GARDEN.GARDEN.ZUCCHES,PUMPKINS. (54)

- GARDEN.VEGARDEN.CABBAGE (82)

- GARDEN.VEGARDEN.POTATOES (72)

- GARDEN.VEGARDEN.STRAWBERRY (173)

- GARDEN.VEGARDEN.ROOT CROPS (162)

- GARDEN.VEGARDEN.SHRUBS AND TREES (204)

- GARDEN.VEGARDEN.ONIONS.GARLIC (323)

- GARDEN.Vegetable garden.CUCUMBERS (185)

- GARDEN.VEGARDEN.PEPPER (159)

- GARDEN.VEGARDEN.SEEDLING (335)

- GARDEN.VEGARDEN.SEEDS (23)

- GARDEN.TOMATOES (469)

- GARDEN.VEGARDEN.EXOTES (75)

- TIPS FOR THE HOSTESS (263)

- POEMS (585)

- POEMS ABOUT WAR (9)

- PHOTOSHOP (6)

- FLOWERS (92)

- FLOWERS.BINDOWWIND (3)

- FLOWERS.HOME FLOWERS (145)

- FLOWERS.CLEMATIS (37)

- FLOWERS.LILY (73)

- FLOWERS.BULB (99)

- FLOWERS.PERENNIALS (201)

- FLOWERS.ANNUALS (148)

- FLOWERS.PETUNIA (55)

- FLOWERS.PEONIES (44)

- FLOWERS.ROSE (83)

- FLOWERS.TULIPS (14)

- FLOWERS.PHLOXES (21)

- FLOWERS.CHRYSANTHEMUMS (6)

- FLOWERS.EUSTOMA (20)

- SEWING (93)

- YOU NEED TO KNOW THIS (111)

- HUMOR (99)

COAL ASH AS FERTILIZER

Wednesday, January 13, 2021 14:57 + to quote book

Coal ash is used relatively rarely as a fertilizer, since it contains few nutrients, and even those are in a form that is inaccessible to plants. At the same time, this product of coal combustion cannot be considered absolutely useless for garden needs. I will tell you about ways to use it on a personal plot in this article.

Coal ash ranks last in nutritional value compared to ash obtained from burning all other types of fuel. For example, the ash of birch logs contains lime - 36.6%, potassium - 13.3, phosphorus - 7.1, and the ash of lowland peat: lime - 18.0%, potassium - 1.45, phosphorus - 3, 14. At the same time, in coal ash the content of these substances is 2.2, 0.12 and 0.06%, respectively. In addition, all the substances contained in it are in a form that is poorly accessible to plants - in the form of silicates, which during the combustion process stick together into a glassy mass.

However, such ash is rich in silicon oxides, the amount of which sometimes reaches 60%. Thus, this substance can be successfully used as a replacement for sand to drain and loosen wet and heavy clay soils. This helps to improve the structure of garden soil, increasing its moisture capacity, and, accordingly, fertility. Another positive property of coal ash is that it contains virtually no chlorine.

Due to the fact that coals often contain a lot of sulfur, sulfates can accumulate in the ash. That is, coal ash does not normalize the acidity of the soil, but shifts its Ph to the acidic side. In this regard, its use on sandy and acidic soils is impractical.

Solonetzes are a completely different matter, during the process of reclamation of which gypsum, which is essentially calcium sulfate, is introduced into the soil. On such soils, ash sulfates displace carbonates during chemical reactions and form soluble salts. They are removed from the top fertile soil layer during irrigation. As a result, a decrease in soil salinity is observed. Among other things, the sulfate ion partially neutralizes the alkaline reaction of solonetzes. It is worth noting that it is still recommended to use coal ash on neutral and slightly acidic soils, and preferably with the parallel addition of calcium nitrate, ammonium carbonate and bicarbonate, bird droppings and mullein.

Coal ash as a fertilizer is good for crops that are active consumers of sulfur, such as mustard, onions, various types of cabbage, garlic, legumes, radishes, rutabaga, horseradish. By the way, to increase the quantity and quality of the harvest of these plants, the beds with them are even specially gypsumed (fertilized with gypsum). However, it makes no sense to add this type of ash to vegetables that have high requirements for soil nutrition, since it is generally poor in the nutrients they need.

On loamy and heavy loamy soils, the soil is topped up with coal ash in late autumn and in small quantities - no more than 3 kilograms for every 100 square meters. m. plot. If wood ash is not allowed to be combined with nitrogen-containing fertilizers (ammonium nitrate, manure), then coal ash can and should be used, since sulfur ions bind ammonium, thereby reducing the loss of valuable nitrogen. Thanks to this property, it is also not forbidden to add it to compost, but only after preliminary sifting to remove baked pellets.

Types of material

The following types of insulation are obtained from waste from metallurgical production and the energy industry:

- domain;

- metallurgical;

- fuel and coal.

Different types are used to insulate structural elements of a house.

Domain

The material is obtained by smelting cast iron. The composition includes the remains of rock, fluxes and fuel ash. The pieces are very porous, the material is free-flowing.

In private construction, the fine (heavier) fraction is used to fill cavities in walls or to screed concrete floors. The large fraction is light in weight and is suitable for backfilling attic floors.

This type of raw material is used for the production of slag heat-insulating materials.

The most suitable for insulation is slag pumice, which has good heat and sound insulating properties. It also goes into filler for cinder blocks.

Metallurgical

Metallurgical slag can create excessive stress on the foundation

This type most often includes waste from nickel and copper smelters and steel mills.

The material consists of sintered pieces of various fractions. They contain a lot of metal oxides, which is why the mass of the composition is large.

Fuel

The raw materials for production are the remains of fuel oil and coal burned in boiler houses. The fraction and properties depend on the type of combustion (chamber or layer).

Residues of fuel are hygroscopic, so before filling they must be dried for at least 2 months without exposure to precipitation.

It is used for filling cavities in brick walls or under concrete screed on floors and ceilings.

Coal

Coal slag is formed as a result of the combustion of coal and the occurrence of high-temperature reactions with the inorganic components that make up its composition. It is highly durable, as the ash content is up to 4%. The amount of unburned fuel is up to 20%, depending on the combustion method and chemical composition.

Features of coal slag are:

- volume fraction of the crystalline phase up to 80%;

- types of oxides in granules: aluminum, silicon, calcium;

- According to their chemical composition, they are super-acidic, basic and acidic.

Charcoal: how to obtain fertilizer

Charcoal is the remains of wood obtained after the combustion of raw materials with minimal access to oxygen.

At home it is done like this:

- Wood is poured into an iron barrel.

- The raw materials are set on fire and wait until the fire burns out completely.

- The remaining blackened pieces are removed from the container and used for their intended purpose.

This product has a number of positive qualities. It is capable of:

- can be stored for a long time without entering into chemical reactions or decomposing;

- absorb a large amount of liquid and aluminum oxides (is a good absorbent);

- convert nitrogen contained in the air into forms available for absorption by plants;

- regulate soil moisture due to water absorbed during rains;

- activate the biosphere of the top layer of soil.

Due to its porous structure, coal fertilizer:

- has low weight;

- capable of feeding large areas with a minimum amount.

Floor insulation using slag

When building a house, proper floor insulation is always the developer’s area of special attention. The entire heat flow is directed to the residential part of the building through the walls, as well as through a large floor area. During construction work, the developer insulates the basement in such a way that the temperature at the base of the floor is at the same level as the air temperature in the living area. Its fluctuations within a range of about 2°C are permissible. For floors, the heat absorption coefficient is very low. For flooring and subsequent insulation of the floor, you need to prepare the necessary tools and materials:

- nail puller;

- axe;

- mites;

- chisel;

- hacksaw;

- roofing felt;

- wooden blocks 2-3 cm thick;

- level;

- slats;

- rule;

- antiseptic;

- drill;

- hammer;

- insulation;

- nails;

- pencil.

Dry floor screed installation diagram.

When carrying out floor insulation, the work is carried out in 3 stages: first, work is carried out on the subfloor, then the insulating material is installed, and the work ends with the finished floor. It is possible to use a layer of waterproofing laid before the process of creating the subfloor.

Laying slag as a heat-insulating material is done on top of the subfloor. Insulation involves creating a gap of 15 cm from the insulation layer. Insulators must be treated with all responsibility: they must have high performance, be durable, and be easily cut to the required size.

Using charcoal in the garden

The substance in question is used to increase the fertility of humus. The amount of fertilizer applied to the soil depends on the composition of the soil in a particular garden plot.

In some American states, a method of soil cultivation is practiced in which the amount of coal additives used reaches 45-50% in relation to the surface of the cultivated plot of land.

Application area

The high-carbon product absorbs moisture and prevents the leaching of nutrients from the soil. This product should be scattered on fields located in close proximity to water bodies. Coal additives retain mineral fertilizers on the site and prevent pollution of nearby lakes and rivers.

In a warm bed and in flower beds, a layer of charcoal allows you to “pull” excess moisture from the root system of plants. It is recommended to lay it at the very bottom. Layers of coal pieces and ash are transferred:

Large pieces of coal are used for the drainage layer in greenhouses and greenhouses. Coal fertilizer scattered on the beds should have a fraction of 3 to 7 mm. Solutions and infusions are prepared from ash and dust residue.

Charcoal is used as a fertilizer and a means to protect indoor plants. Flower growers can purchase a charcoal mixture of suitable quality in specialized stores. Ash is also obtained independently by burning suitable raw materials.

Charcoal can be added to the bottom of the seedling boxes. Here it will work as drainage and fertilizer at the same time, and will also protect the plantings from putrefactive bacteria. Coal dust is used to stimulate the germination of seed. To do this, the layer of raw material is watered with warm water. After the liquid is completely absorbed, the seeds are placed on the coal bed.

When and how to fertilize the soil?

Charcoal ash as a fertilizer is added to the soil when planting plants that do not tolerate high soil moisture (cacti, orchids).

The ash remaining after burning coal is used to powder the leaves of garden crops (eggplant, cucumbers). This measure helps protect the crop from pests.

Loamy soils are fertilized in the fall with coal dust and ash. Fertilizer is evenly scattered over the surface of the beds at the rate of 3 kg per 1 sq.m of land.

The best result is observed after using fertilizers together with ammonium nitrate and organic matter.

A vegetable garden with clay soil is evenly sprinkled with ash, coal, compost, manure, and then dug up so that all fertilizers are covered with a layer of soil 10 to 20 cm thick.

In the south of Russia, the Salsky steppes have a hot and dry climate, so in the summer the ground cracks and becomes covered with a thick crust after watering. Charcoal here needs to be buried to a depth of 10-15 cm: under these conditions it will help retain moisture and act as a soil loosener.

To prevent rain from washing away nutrients, fertilizers are applied before the onset of frost.

Finely crushed coal is used in dry form, and solutions are prepared from coal dust. Raw materials are stored in a place protected from moisture.

Coal contains impurities that, in their pure form, are harmful to plants. When interacting with oxygen, sulfites oxidize and acquire safe forms.

Coal components should make up no more than 5% of the total usable soil area.