Owners of private houses with basement insulation from the inside can supplement the useful space of their home not only with a spacious basement. If desired, they can also equip an attic - a room under the roof (essentially the same attic, only landscaped).

Insulated attic from the inside

If various workshops are usually located in the basement, then the attic often serves as another bedroom. However, in order for it to be fully used as a living space during the cold season, it is necessary to take care of insulation. And the best solution to solve this issue is PPU - or sprayed polyurethane foam.

1Features of attic insulation

Installing insulation for the attic from the inside, as well as insulating a well from concrete rings, is a much more complex and time-consuming task than insulating an ordinary room. The difficulty lies in the following factors:

- lack of horizontal overlap on top - that is, insulation will have to be done directly along the inner surface of the roof, which usually has a triangular shape; low temperature in the attic in winter; moisture may get inside, onto the surface of the insulation (this happens when the roof is damaged) - which not every insulator can withstand.

For these reasons, the use of most other materials, if possible, will be a very, very difficult task.

By the way, regarding the relevance of the process itself: thermal insulation of the attic from the inside is needed not only in cases where it is planned to equip a living space. Even if you are not going to use the attic in any way, it still needs to be insulated.

The reason is simple: the lack of insulation leads to the fact that the temperature above the ceiling (that is, in the attic) in winter will tend to the street temperature. In addition, it is quite possible that it will also be damp inside - since the roof covering often has leaks (and if not, they can appear over time).

Spraying polyurethane foam between the joists from the inside

As a result, moisture from natural precipitation will seep into the attic, spoiling its microclimate.

Dampness, in turn, can lead to the appearance of fungus and mold, and they can appear not only in the attic itself, but also from the inside, in the living quarters of the second floor. This problem is especially relevant for owners of wooden houses with polystyrene foam - after all, wood is most “afraid” of contact with water.

Advantages

This material does not allow moisture to pass through, which is very important for achieving normal humidity levels in the room. High humidity is an indicator of improper installation of systems for heating the room: for example, steam heating radiators or heaters. The lack of thermal insulation leads to the melting of snow on the roof, which causes its icing, and - as a result - cracks and other damage to the roof form.

PPU retains heat perfectly. When using polyurethane, the owner receives a normal microclimate in the attic (optimal level of temperature, humidity and air speed in this room), protection from sudden and high temperature changes, as well as preventing dampness of structures. In addition to the above advantages, there are several more:

- fire safety and versatility;

- environmental cleanliness;

- noise absorption and bactericidal properties.

Adhesion

The advantages of using polyurethane foam also include the fact that it is able to adhere to any coating, regardless of whether it is reinforced concrete or wood. The most popular property of this material is, of course, low thermal conductivity.

Flaws

Despite all the advantages that this material has, it also has some disadvantages. First of all, at high temperatures, polyurethane foam can lose its primary appearance - in particular, color under intense exposure to solar radiation.

2About the material and its features

Now it’s important to touch on the properties and characteristics of the polyurethane foam itself. The use of sprayed insulation is a relatively new word for our market, but this technology quickly began to replace outdated mineral wool and foam insulation.

By the way, every person has seen polyurethane foam in one of its forms more than once - this is ordinary foam rubber used for padding upholstered furniture and entrance doors. Foam rubber is the so-called elastic polyurethane foam, and is not suitable as insulation.

Another form of polyurethane foam is rigid.

These products are presented in the form of slabs, indistinguishable in appearance from extruded polystyrene foam. However, as mentioned above, it is very difficult to insulate an attic from the inside with slab insulators, so we will only consider spraying technology.

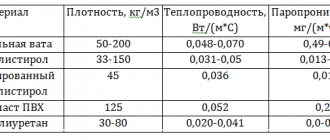

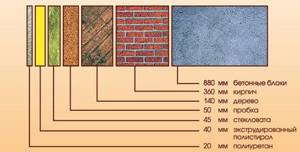

Brief characteristics of modern heat-insulating materials

Today, so many different thermal insulation materials are produced that it is very difficult for some consumers to understand. Manufacturers often take advantage of this, and with the help of not entirely honest advertising, they artificially inflate the prices of their products. Let's look at some of the most striking examples.

Mineral wool from basalt volcanic rocks

Mineral wool from basalt volcanic rocks

It sounds tempting, not everyone understands, but attractive, that’s what manufacturers call their products. The phrase “environmentally friendly” is always added to these words, and the consumer is ready to pay a lot of money. At the same time, they are silent that basalt volcanic rocks consist of 60-80% ordinary glass, and the rest is impurities that are removed during production.

Rockwool stone wool

In principle, their products are ordinary, long-known glass wool. Due to the use of “free” glass, the cost of mineral wool should be much less than the cost of glass wool. But advertising does its job; due to its action, the price increases significantly.

Stone wool slab

Glass wool

Previously, glass wool was difficult to work with; it caused quite unpleasant irritations on the skin. Outdated technologies did not allow making fibers very thin. The thick glass fibers were strong enough to damage the upper layers of the skin. Now technology makes it possible to reduce the diameter of glass fibers to 6 microns; to the touch such products are no different from cotton wool.

Characteristics of glass wool

But the buyer reacts negatively to the word “glass wool”; manufacturers do not use it today. A striking example of expensive ordinary glass wool is the Izover brand. An unclear word and the absence of “glass” allows manufacturers to increase the price of their products made of ordinary glass.

Glass wool Isover

What do we recommend? For attic insulation, mineral or glass wool is an excellent material in all respects, but you should not buy fashionable, well-promoted brands. Their performance indicators do not quite correspond to the high price. There is an opportunity to buy glass wool - take it, the quality is no worse than the most fashionable names, and the cost is thirty percent cheaper. Any mineral wool is safe for health, unlike other modern thermal insulation materials.

Another tip on mineral wool. It can be rolled or pressed.

Minvata. Rolls and slabs

Insulating an attic with rolled mineral wool will cost approximately one and a half times less than with pressed wool. The thermal conductivity of both options differs by no more than twenty percent. Think before you start insulating the attic in the bathhouse.

A few words about polystyrene foam, polystyrene foam, polyurethane foam and ecowool

These are the so-called “budget” thermal insulation materials, the average price is one and a half to two times lower than that of mineral wool. The main common disadvantage is that they release chemical compounds into the air. The quantity of these compounds is regulated by sanitary authorities, but they are necessarily present in one percentage or another.

Styrofoam

Very technologically advanced, easy to cut, not afraid of moisture. But he is afraid of rodents; after a few years they can “grind” the foam sheets into powder, it will crumble and, as a result, the quality of thermal insulation will decrease.

Styrofoam. Texture Table of foam characteristics

Expanded polystyrene

Expanded polystyrene

The “sibling” of polystyrene foam, universally used, has slightly increased physical strength.

Polyurethane foam

The most “harmful” insulation, it is not recommended for use in residential premises. The main advantage is that it is applied in liquid form to any complex surface. After cooling it forms an impermeable coating.

Ecowool

It can also be sprayed and can be used for insulation in hard-to-reach places in finished buildings. It is made from wood processing waste and waste paper, and is impregnated with antiseptics to slow down the decay process. Moreover, here “eco” is understood only by advertising agents of production companies.

Ecowool

Application of ecowool

We hope that this knowledge will allow you to consciously select materials for attic insulation; we are sure that additional knowledge has never hurt anyone. Now we can talk about the technology for performing work on insulating the attic above the bathhouse. We will look at the two most common options - mineral wool and foam sheets were used as insulation.

2.1 Characteristics and advantages of the insulator

First of all, you need to pay attention to the quality characteristics of polyurethane foam. The parameters are as follows:

- thermal conductivity coefficient like PSB S 35: about 0.025-0.03 W/mK (about one and a half times lower than that of mineral wool and foam insulation); density: from 30 to 200 kg/m³; service life: up to 40 years (this figure can differ - different companies promise different durability).

In fact, it is now difficult to say exactly how long sprayed polyurethane foam will effectively last - since it began to be used in our country relatively recently, and the “age” of most objects insulated with it does not exceed 4-5 years. However, the conditions carried out in laboratories prove that it actually begins to lose its properties after more than a dozen years.

The process of insulating the attic from the inside using polyurethane foam

Typically, the density of the material for insulating residential buildings is about 60-80 kg/m³, however, if necessary, this indicator can be changed. This is done by changing the proportions when creating the polyurethane foam itself - the material is prepared right at the work site, by mixing two components.

It goes without saying that the higher the density, the more effective the insulator and the higher its price. You can save money in the following way: initially, a layer of dense polyurethane foam is applied to the surface of the roof from the inside - it will better protect the structure from possible contact with moisture. Then, a less dense (but cheap) composition is sprayed onto it.

Another – third – layer of glass wool and mineral wool is sprayed on top of it, with the same density as the first. Thus, a kind of “pie” is obtained: with a denser insulator around the edges and a less dense one inside.

Regarding flammability: the material is classified as non-flammable.

When in contact with an open fire, it smolders, but does not spread the flame. However, there is a downside: when the threshold of +500 degrees is exceeded, it begins to release compounds dangerous to humans. However, this is typical for most other heat insulators, so this point cannot be called a significant drawback.

But among the significant advantages of polyurethane foam are the following properties:

- resistance to moisture, and absolute - even with frequent exposure to water, the material will not react in any way, will not begin to deteriorate or mold; the material is not interesting to rodents or insects; in normal condition, the material does not harm humans in any way (unlike, for example, mineral wool) ;lightness - which is very important for both the roof and the attic floor; in addition to retaining heat, polyurethane foam also insulates sounds quite well - which is very important for the roof (for example, this will reduce the noise from rain drumming on the roof).

If necessary, the properties of the insulator can be further improved, as when insulating a house with mineral wool under siding - for this, components can be added to its composition during preparation that will increase the resistance of the material to high temperatures.

What is construction polyurethane foam?

In comparison with elastic compounds of polyols foamed with air and/or carbon dioxide (foam rubber), construction polyurethane foam is a rigid material with a density of 30 - 150 kg/m³. However, it is not rigidity that is the main difference between insulating polyurethane foam and foam rubber, but the structure of its pores. In construction foam, up to 98% of the pores are closed, so the material does not absorb water and conducts heat poorly (due to the gas filling of the chambers - the pores).

Polyurethane foam - a new generation of insulation

Polyurethane foam, sold in spray cans, also belongs to insulating polyurethane foams, but its percentage of closed pores is lower (about 80%). In general, the higher this indicator, the higher the energy efficiency of the insulation. Polyurethane foam has the lowest thermal conductivity coefficient among all insulators currently used in construction. For the best two-component systems, the parameter value does not exceed 0.019 - 0.021 W/m*K. This is 30% less than samples of high-quality extruded polystyrene foam (EPS), which have a coefficient of 0.028 W/m*K.

Polyurethane foam is a material with stable properties. Its characteristics have not changed for many decades. However, it is destroyed when exposed to ultraviolet radiation, so it requires protection from it. The minimum required protection can be achieved with conventional painting.

2.3 Spraying technology

Insulating an attic with polyurethane foam probably has only one significant drawback: using such insulation with your own hands is impossible for most people. The reason is the high cost of special equipment - the installation with which polyurethane foam is applied to the surface.

The simplest compact model costs approximately $2000-2500 (the same cost for insulating the blind area around the house), so purchasing it for treating one building is unprofitable. In addition, the operation of such an installation requires some experience, and the correct preparation of the insulation itself is also not a task for an inexperienced person.

Let's consider the sequence of work stages:

- The attic room is completely emptied of contents. Insulated surfaces are completely cleaned of finishing materials, thermal insulation, dirt, dust, mold. If possible, detected leaks, cracks, holes in the roof must be repaired. Logs are installed on the insulated surface. Polyurethane foam is prepared on site. Between the logs The composition is sprayed. After the first layer has completely hardened, the next ones are applied if necessary. After applying the required number of layers along the joists, the facing material is installed and further finishing is carried out.

As you can see, in addition to the insulation, the thermal insulation layer does not contain a waterproofing layer - it is simply not necessary, due to its resistance to moisture. This reduces both time, effort and money for work.

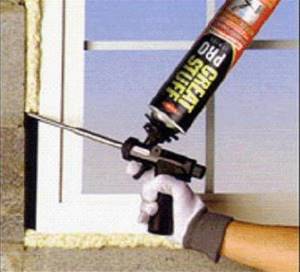

Construction foam

Insulating the loggia with foam

This material belongs to the category of polymers and is polyurethane foam, which is in a liquid state under pressure in a metal container. After application, the polyurethane foams, expands and then hardens.

In order for the foam to take its final form, it contains an isocyanate, which interacts with atmospheric humidity and polymerizes the polyurethane after the foam leaves the cylinders. Isocyanates are substances toxic to the human body; therefore, insulation of buildings with foam is carried out with the obligatory observance of safety precautions - special clothing, respirators, etc.

Note! The toxicity of isocyanates in this case is directly proportional to the insulated area - the larger it is, the correspondingly higher the level of harm to health. When inhaling vapors from hardening foam, general intoxication or acute respiratory tract diseases may occur, and if it comes into contact with the skin, allergic reactions may occur.

Foam as insulation for brick walls

After polymerization has completely taken place, the foam composition loses its toxicity and does not pose a threat to human health. Construction foam can be of two types - one-component and two-component, which differ from each other in composition.

One-component construction foam for insulation consists of a complex composition of various components, the polymerization of which is carried out within 8 hours after spraying. Available in pressurized cylinders.

Two-component insulation foam has a faster polymerization period - in most cases, the curing period ranges from 4 to 15 minutes. The foam components are contained in two cylinders, which are mixed using an activation lever. Its price is slightly higher than its one-component analogue.

Note! It should be noted that the foam used to insulate plastic windows is classified as non-professional and, accordingly, its composition and characteristics are somewhat different from the material described above.

Non-professional foam for window insulation

Advantages

- Good adhesion. The level of adhesion (degree of adhesion) of the foam is at a very high level, which allows it to be used for insulating surfaces such as concrete, metal and others. This property also makes it possible to insulate ceilings, vertical surfaces and surfaces with a negative slope;

- Solid structure. Since the insulation layer is applied by spraying, there are no seams on its surface, which prevents freezing of individual areas and the formation of “cold bridges”, which are inevitable when using a prefabricated structure;

- Extension. After application, the foam tends to increase in volume (the degree of increase depends on the selected class), which in some cases is necessary. If the surface has a relief structure and hard-to-reach voids that are difficult to insulate using sheet insulation, the foam will completely fill all the cracks and voids;

Note! When foaming deep niches, it is imperative to take into account the degree of expansion of the foam, since an excessively large amount of it can lead to deformation of the insulated structure.

Insulating foam in section

- High degree of thermal insulation. The degree of thermal insulation of polyurethane foam, with equal thickness, is practically not inferior to foam insulation or mineral wool;

Flaws

- Aging. Over time, the polyurethane foam coating undergoes degradation and aging, which leads to disruption of the structure and deterioration of thermal insulation properties. Officially, its service life is about 15 - 20 years, but under the influence of various factors (heating, high humidity, exposure to ultraviolet radiation or an oxygen environment), this period can be significantly reduced;

- Low vapor permeability. Polyurethane foam with a closed-cell structure is a vapor-permeable coating, and therefore its use is advisable only when insulating metal and concrete surfaces - insulating wooden structures can lead to their rotting;

- Low fire safety. Polyurethane foam belongs to the category of moderately flammable materials with a high smoke coefficient - the fumes released during combustion are highly toxic. Based on this, insulation of this type needs to be treated with fire-resistant coatings that reduce its flammability;

2.5About the advantages and disadvantages of technology

The technology for applying insulation discussed above may seem unfamiliar to the reader. Not surprising - after all, for those who have not encountered thermal insulation work, the idea is probably limited to gluing foam plastic or unwinding a roll of mineral wool.

In fact, this method is many times simpler, but at the same time more effective and convenient than the same polystyrene foam or mineral wool. The list of obvious advantages of the technology includes:

- the use of a thin layer of insulation (due to minimal thermal conductivity) - which is very important from the inside; no need to level the surface being treated; no need to create a complex multi-layer “pie”; minimal time for surface treatment (on average, in 6-8 working hours, 1 person can cover about 100 m²); monolithic insulation (that is, the absence of any seams); covering structures of any shape.

The first point is a fairly significant advantage. Indeed, when working from the inside, the main problem is the loss of free space, which can reach considerable values. For example, if you insulate the floor using expanded clay, be prepared to raise it by about 20-30 cm, thereby making the room smaller.

When insulating walls with polystyrene foam, you will have to lose about another 10-15 cm. Polyurethane foam is much more economical in this regard - the effective insulation layer is approximately 3-5 cm.

The second and third points will be appreciated by those who have tried to independently insulate any surface using polystyrene foam or mineral wool. Compared to spraying, this is a much more labor-intensive and lengthy process that requires not only time, but also attention.

If there is even a slight difference in height, the foam will no longer lie flat. Well, you have to work with mineral wool wearing gloves, a respirator and goggles.

It goes without saying that saving time is also a significant advantage. When creating a floor screed, you would have to wait several days until it hardens. And simply creating a heat-insulating “pie” is also not a quick procedure.

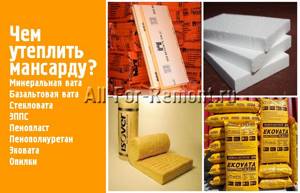

When it is necessary to insulate the attic from the inside, most homeowners choose mineral wool or expanded polystyrene (foam). The fact is that these are the most common types of insulation in Russia and, moreover, they can be installed independently.

At any construction market or Do-It-Yourself format store (Obi, Leroy Merlin, etc.) they will always offer to buy both mineral wool and polystyrene foam. But this does not mean at all that mineral wool and sheet insulation made from foam polystyrene are the best and most effective for attic insulation. Polyurethane foam is superior to them in terms of characteristics, and even more so in terms of manufacturability.

Some nuances when insulating

I would like to highlight some points that some do not consider necessary to take into account. But they are important because they guarantee your safety and the best quality of insulation. It all starts with the little things, so we recommend that you stick to what is written below.

Firstly, we are talking about overalls for insulating the attic. The worker performing insulation with polyurethane foam must protect himself from contact with the skin, eyes or respiratory organs of the chemical. To do this, use a special suit, gloves, a respirator and safety glasses. If there is no special suit, then you can use another type of clothing with the same qualities.

Secondly, it concerns the mixing of polyurethane foam components. You need to adjust everything so that the two components of polyurethane foam are mixed in an ideal 1:1 ratio. In addition, thorough mixing is important. If the ratio is not observed, the performance of the insulation is reduced.

These rules for attic insulation are simple, but quite important. Don’t neglect them, and then you will fully feel the beauty of polyurethane foam insulation.

How to choose material for attic insulation

Properly selected insulation is half the success in insulating an attic roof. The second half of the success of the idea comes from the professionalism of those involved in insulating the attic from the inside. There are a number of criteria that should be taken into account when selecting thermal insulation material:

- Thermal conductivity. It should be minimal, ideally no more than 0.05 W/m2. Hygroscopicity. This parameter should also be kept to the possible minimum. The less the material absorbs moisture, the better. Weight. Choose insulation with low weight and density to eliminate the load on the roof when installing thermal insulation. Safety. Opt for insulation that does not support the combustion process. Tendency to deformation. It is also better to exclude it: do not buy thin, soft rolled materials, which over time will lose their shape, settle, exposing the upper part of the roof. Frost resistance. Must be high, because the insulation will have to take on temperature changes. Service life of attic roof insulation. The more, the better - this is obvious .Thickness.Calculated taking into account the climatic characteristics of the region, the thickness of the roofing pie and walls of the house, as well as a number of other factors known to professionals.

Performance characteristics of polyurethane foam: pros and cons of the material

A large assortment of materials for thermal insulation complicates the selection process, but at the same time allows you to select insulation with ideal parameters for a particular object, taking into account its operating conditions, purpose, as well as the type of building materials from which the walls, ceilings and other structural elements of the building are constructed.

Therefore, when choosing polyurethane foam for your home, you need to take into account all the positive and negative properties of this insulation.

So why is polyurethane foam used less often for attic insulation?

Largely because polyurethane foam is difficult to lay on your own. This is because initially polyurethane foam consists of 2 liquid components. Moreover, as a rule, it is supplied in 200 liter barrels.

Two barrels weigh approximately half a ton. When an ordinary person finds out what polyurethane foam is in its raw form, he prefers “not to mess with polyurethane foam” and use what is “clearer and simpler” for attic roof insulation, i.e.

mineral wool or PSBS. And this is a mistake, the understanding of which will come later. Moreover, you will have to pay for this mistake in all subsequent years.

In fact, there is nothing supernatural about insulating an attic roof with polyurethane foam. To do this, you will need a special machine for applying polyurethane foam.

The task of the device is to pump raw polyurethane foam from barrels, dose it in the required ratio, and feed it through hoses into a special gun, where the two liquids meet and a chemical reaction begins. After which the air-liquid mixture is sprayed onto the insulated surface.

Therefore, it is problematic to carry out attic roof insulation with polyurethane foam on your own. It is necessary to hire specially trained people or buy such an installation yourself.

Why not, if in addition to insulating the attic from the inside, you can apply polyurethane foam to the walls, roof, foundation, floor, ceiling, etc.

etc. You can completely insulate your own home.

And it will be cheaper than ordering insulation work from the outside. You can then start your own small business and insulate the attics of others. We recommend watching the presentation from the conference on PPU in Novosibirsk about the possibilities of using polyurethane foam.

But, if it seems difficult to buy a machine for spraying polyurethane foam and master this type of work, then a person chooses an accessible and, by the way, cheap (but not at all the best!) method. In other words, buy mineral wool or polystyrene foam and lay it yourself.

Cheaper is cheaper, but you are not going to live in such a house for a year or 3.

PPU will be more expensive if compared momentarily. But, if we compare in perspective, taking into account heating costs, then in three years the costs for polyurethane foam and mineral wool will be equal, and then the one who insulated with mineral wool will go into a severe minus, and those who insulated with polyurethane foam will actually save. Therefore, before choosing this or that insulation, it is recommended to arm yourself with at least minimal knowledge about the resistance of building materials to heat transfer.

Of course, we can be called biased in our desire to offer polyurethane foam for insulating the attic from the inside.

Still, the SovTech company is the number 1 seller in Siberia of this type of gas-filled plastic. But the point is not even that we are promoting polyurethane foam, in the end, if your attic is not insulated with our polyurethane foam, then we will survive it. It’s not us who have to live in the house and it’s not us who have to pay for heating in the winter.

Simply, our many years of experience in construction work in Siberia shows that we cannot save on thermal insulation. Savings at the construction stage of a ruble will come out to 10 rubles in expenses later, during operation.

Before choosing PUR foam, we naturally used both mineral wool and polystyrene foam (and are now ready to use it if the customer insists). Therefore we can compare. The following outlines the main disadvantages of insulating an attic roof with mineral wool, when compared with polyurethane foam.

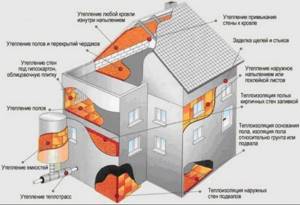

Why insulate the attic?

High-quality attic insulation provides the home owner with a number of tangible benefits:

An additional room can be arranged under the roof.

- ✓ Heating costs are reduced in winter. It has been proven that most of the heat escapes into the atmosphere through the roof.

- ✓ You can live in the house all year round.

- ✓ The rafter system will be protected from moisture contained in warm air. The wooden parts of the roof will retain their quality longer.

- ✓ Not every attic can be turned into a living room. If the height of the roof along the ridge is below 2.5 meters, then the attic will only serve as a utility room.

Traditional attic insulation

Disadvantages of attic insulation with mineral wool:

Firstly, it is placed in the cells between the rafters.

This means that it can be laid indented from the rafters, at an angle or vertically. Over time, the insulation sheets will sink slightly, shrink and a void will appear, i.e.

place to freeze. In order not to overpay for heating, you will have to additionally insulate the attic or re-do the roofing. In short, save money and plan your time.

Secondly, the required insulation thickness is 200 mm, plus wind protection, plus vapor barrier, plus padding of bars. If you look at this method of insulating an attic roof as a whole, it is obvious that there is an increase in costs for materials and work, and with questionable quality at the end.

Thirdly, laying insulation on part of the floor often leads to the suction of cold air under the attic baseboard, and builders often do not cover the end of the horizontal insulation. And as a result, problems arise such as cold below the wall, high condensation, air movement from the floor to the ceiling, additional condensation on the ceiling and increased humidity.

All such “delights” can be avoided if the attic insulation is carried out with liquid polyurethane foam.

How much does it cost to insulate

The cost of the work depends on the roof insulation scheme. Multi-pitched roofs are best insulated by filling the space between the rafters. The cost of applying polystyrene foam varies depending on the distance of the object, the area of application and the thickness of the applied layer.

With an area of up to 50 sq.m. roof layer thickness ranges from 5 to 10 centimeters. The price for applying insulation accordingly ranges from 800 to 1600 rubles per square meter. And, for example, with an area of 300 sq. m or more, the price per square meter starts from 350 rubles. That is, the price difference is more than double. Therefore, it is necessary to first determine the volume of insulation and the total area, and only then find out the price of the material.

You may be interested in information about what to choose for insulation: polyurethane foam or polystyrene foam.

Read about the technology of wall insulation with polystyrene foam here.

We also bring to your attention an article about the advantages and disadvantages of extruded polystyrene foam.

Attic roof insulation with polyurethane foam

Stages of insulating an attic roof from inside the room

When insulating an attic with polyurethane foam, the thickness of the foam should be 10 cm. As a rule, this is the value obtained as a result of thermal engineering calculations for the West Siberian Plain. It is better to spray polyurethane foam between the rafters on the hemmed ceiling, and then attach waterproofing sheets to the rafters on top.

It is better not to spray polyurethane foam on the attic roof, as it changes its size depending on the season (winter-summer).

Due to the precipitating suspension of material, application work is better done outdoors than indoors. When applied correctly, a homogeneous, approximately even surface of the foam is obtained on top of the ceiling covering. The layer is no thinner than 10 cm, thickening towards the rafters for better insulation and greater adhesion (sticking) to the rafters.

In terms of flammability, foam burns worse than wood. But the sheathing and rafters are wooden... On the topic of flammability of polyurethane foam and other insulation materials, read on this page sovte.ru.

Polyurethane foam for attic insulation is also good because, in addition to thermal insulation, it performs the functions of vapor barrier, wind protection and sound insulation. PPU does not have cold bridges through cracks or fasteners, because...

There are no cracks or fasteners. PUR foam is applied in a uniform layer from above, along a vertical wall and goes horizontal to the wall of the building. In the summer it is cool in such an attic, and in the winter it is warm.

Features of equipment for spraying polyurethane foam

The high pressure unit includes:

- A generator, usually powered by a diesel engine.

- Compressor.

- Feed pumps (each component has its own pump).

- The central unit, called the dispenser. The uniform supply of both PU foam components, as well as maintaining the required temperature, depends on it. The unit control unit is installed on the dispenser.

- Spray gun and hoses. The hoses from the compressor to the supply pumps are called supply, and the connecting pumps to the dispenser are called recirculation. The gun also comes with 2 hoses, combined into a common sleeve for ease of use. Direct mixing of the components occurs in the gun.

- Personal protective equipment, which includes a special suit and a respirator. Sometimes the respirator is made in the form of an insulating helmet.

Types of PPU installations

In addition to stable operation and strict maintenance of operating parameters, a good installation should provide protection against bypass resulting in material loss. The cost of equipment that provides high-quality PU foam coating, depending on productivity, ranges from 200 to 800 thousand rubles.

Vapor barrier

The fact is that the insulation has low thermal conductivity, while actively absorbing moisture and “breathing”. If there is no vapor barrier, warm indoor air passes through the insulation and condenses in the area of contact with the roofing pie. Condensation in the form of water droplets penetrates the insulation - hence dampness, mold, and the loss of the insulator’s ability to retain heat.

If you use mineral wool for insulation, aluminum foil or already foil insulation will help solve the problem of vapor barrier in the attic.

Pros of using PPU

Insulation of PPU floors allows you to get excellent strengthening results. Thanks to the positive properties of the material, the structure becomes stronger, and its elements are protected from exposure to various environments. The material also has a high level of sound insulation.

Another important advantage of PPU is cost minimization. For example, its transportation becomes much cheaper. Substances are contained in liquid form. When they are released from the container to the outside, they interact with the air and foam is formed. The material hardens very quickly, which allows you to create a reliable protective layer.

If extruded polystyrene foam is used for insulation, 400 sq. m. you will need to use about 20 cubic meters of EPP. When using polyurethane foam you will need only 16. The savings are about 20%.

In addition, the slabs are inconvenient to use when it is necessary to insulate the ceiling. Such protection from the cold will not be very reliable. Often the roof is a structure with a large number of projections and differences. When using polyurethane foam, it is possible to insulate structures of any complexity. The substance will easily penetrate into any place, and then form a protective layer that can last more than 50 years.

Another property of polyurethane foam is that it is thermally inert. Many materials have the ability to retain heat in summer and not eliminate cold in winter. Polyurethane foam ensures preservation of coolness in summer and warmth during frosty periods. For this reason it is quite popular.

Important! The use of polyurethane foam allows you to additionally waterproof the floor. This allows you to create reliable protection against moisture.

Thanks to the use of polyurethane foam, rot and mold do not appear on the wooden parts of the structure. This is due to the low water absorption coefficient. Even immersed in water, polyurethane foam will absorb no more than 3% moisture in 24 hours. When using polyurethane foam, work is carried out very quickly. Using a sprayer, a layer of material is applied to the roof in the amount needed for a specific area.

Waterproofing

The purpose of waterproofing the outside of the insulation is to prevent moisture from entering the insulation in the event of a roof leak. For this purpose, it is better to use special membranes with vapor-proof properties. Such membranes are more expensive than conventional waterproofing, but in fact they will repeatedly justify the costs.

By the way, closed-cell polyurethane foam lacks the ability to absorb and retain moisture, which makes it an excellent solution for attic insulation. Adhering tightly to the attic ceiling material, polyurethane foam does not leave gaps or voids into which moisture could enter.

So, let's summarize. Proper attic insulation is based, figuratively speaking, on “three pillars”:

- thermal insulationwaterproofingvapor barriers

Sprayed polyurethane foam solves all three problems simultaneously, which makes it so far the most practical material for insulating an attic roof.

We will help you select and calculate the amount of material, taking into account the area and type of your attic, and give recommendations for use. We will calculate the cost of services for thermal insulation of the attic roof and walls using our specialists.

Parameters of sprayed insulation

When insulating buildings, it is recommended to apply foam from the outside. Otherwise, there is a high risk of freezing and damage to the integrity of the wall. In this case, it is necessary to finish the walls so that nothing interferes with the application of the material.

Roof insulation can also be done from the inside. Roof materials are usually designed to withstand constant freezing, so no problems are expected in this regard. The foam is applied directly to the inside of the roof or frame.

Insulation with polyurethane foam requires a large layer thickness for high efficiency. According to standard specifications, at least 3 cm is required. However, most often, 5 cm is made. This is due to the location of the dew point in the wall of the house. This approach allows you to avoid the accumulation of excess moisture, which can lead to damage to the integrity of the wall.

Why is thermal insulation necessary?

If you neglect thermal insulation and limit yourself only to heating the attic, then the following situation may arise:

- In winter, warm air will quickly leave the room, which will entail significant financial costs.

- When warm air comes into contact with the roof, the snow on it will melt and form ice and icicles, which can lead to damage to the roofing.

- In cold weather, condensation will form on the inner surface of the roof, leading to rotting of the elements of the rafter system.

- In the summer, the room will heat up intensely to such an extent that living in it may simply become impossible.

Insulating an attic from the inside is a more difficult task than insulating ordinary rooms:

- The need to apply insulation not only to vertical surfaces, but also to roofs that have a negative angle of inclination.

- There is a high probability of moisture from the roof getting onto the insulation and getting it wet.

- Possibility of carrying out work only in the warm season.

All these problems are eliminated by insulating the attic space with polyurethane foam.

Applying insulation to the roof from the inside

Advice from professionals

PPU insulation is considered a complex technology. It is better to entrust the work to hired specialists. If you decide to master this “art” on your own, you should listen to the advice of professionals:

- When mixing polyurethane foam with water, the ratio is 1:1.

- If the working mixture has darkened, the proportions are not maintained correctly. The properties of the insulation will deteriorate.

- When insulating in the middle zone of the attic, the thickness of the polyurethane foam is applied at least 15 cm.

- Insulation is best done in warm weather, when the air temperature is above + 10 o C.

- During spraying, moderate humidity is created in the attic. Excess moisture is not allowed. The insulation can peel off from the surface or harden with large air bubbles.

- During operation of spraying equipment, ventilation is provided in the attic.

- Spray foam from a gun, moving from bottom to top. The nozzle is removed from the insulated surface at a distance of 50 cm.

- In one pass, a layer of the required thickness is immediately sprayed. You cannot use a gun to return to areas of foam that have not hardened.

Upon completion of work, the equipment is washed. If polyurethane foam accidentally sticks to the body, carefully remove it with a solvent.

The most common spraying of polyurethane foam is used:

- When insulating floors on the first floors of residential buildings and in basements.

- During the insulation of building roofs; in such cases, depending on the type of roof and whether people will walk on it, different brands of polyurethane foam are used, differing in density.

- Insulation work for vegetable stores; in order to save money, it is possible to use low-density polyurethane foam.

- Low-density polyurethane foam (from 20 to 30 kg/m 3 ) can also be used for attic insulation work, but in this case a thicker layer (from 12 to 15 centimeters) is required.

- Standard grades of polyurethane foam, when applying a layer of 5-7 centimeters, are used to insulate the walls of residential buildings. If we are talking about houses made of wood, it is advisable to use vapor-permeable grades of material, which will ensure air flow to the wood.

- To fill ventilation gaps in residential buildings, you can use polyurethane foam with a minimum density (15 kg/m3).

- Using this material, the foundations of any premises are insulated.

- The material is also suitable for insulating pipelines, but in such cases the brand and thickness of the layer are determined based on how hot the pipes themselves are and what temperature would be optimal for them in order to avoid premature failure.

Prices for spraying polyurethane foam per m2

Sprayed polyurethane foam, core density 8-12 kg/m 3, open cell.

Sprayed polyurethane foam, core density 30-35 kg/m 3, closed cell.

Work on pouring polyurethane foam into the cavity, open cell density 8-12 kg/m 3.

Work on pouring polyurethane foam into the cavity, closed cell density 40 kg/m 3.

| Name of works | Insulation thickness, mm | Cost per 1 m 2, rubles including VAT |

| 50 | 450 | |

| 100 | 650 | |

| 150 | 900 | |

| 200 | 1200 | |

| 30 | 570 | |

| 50 | 950 | |

| 80 | negotiable | |

| 100 | negotiable | |

| from 9500 rub/m 3 | ||

| From 16,000 rub/m 3 |

Spraying of polyurethane foam is carried out using our own installations. Before starting work, the dimensions of the insulated surfaces are assessed, after which a contract for the provision of services is drawn up and the spraying process is carried out directly.

The warranty on the material itself, depending on the brand, can range from 25 to 30 years, even without special care.

Sprayed thermal insulation Ecotermix is a reliable material for ceiling insulation in a private home

- Residential insulation

- Industrial insulation

- House

- Hangars and warehouses

- Wall

- Yachts and ships

- Containers and wagons

- Floor

- Ceiling

- Roof

- Attic and attic

- Foundation and plinth

- Basement

- Gas ducts

- Industrial insulation

- Vans

- Garages

- Residential insulation

- Bath and sauna

- Balcony and loggia

- Rooms (kitchen, bathroom, pantry.)

How to do everything in practice?

There are 3 types of this insulation, with three levels of rigidity. This must be taken into account when choosing technology, which can be classical or complex . When using the first, a material of the same hardness is taken and one or several layers are applied. If the second technology is chosen, then first a layer of high-hardness polyurethane foam (3-5 cm) is applied, then a softer layer (5-8 cm).

If the attic was uninhabited before treatment, before starting work it is necessary to empty it of unnecessary things and clean all surfaces of the remnants of the old coating and dust.

The next step is preparing workwear, tools and material . You will need 2 containers (for liquid insulation and water), a sprayer, a pump with a compressor, hoses, thick clothing, a respirator, goggles, and a tool for cutting off excess frozen material.

The PU foam components should be mixed according to the instructions and mixed thoroughly to maintain the positive characteristics. Attic insulation using polyurethane foam is the application of liquid material between the rafters and on the floor, filling all the cracks and hard-to-reach places. If necessary, application of 2 or more layers is allowed.

Upon completion of the work, the roof and floor form a single whole with the insulation. In winter the attic will be warm, in summer it will be cool. If you cover polyurethane foam with finishing material, it can last up to 30 years.

Increasingly, owners of private houses are using the attic as a living space, significantly expanding the total area of the building.

For many, the attic, which has become a full-fledged room, becomes a way to save the family budget.

The construction of another floor in the house requires a significant investment in its construction, and to build an attic, you only need to prepare a roofing project of a special design.

If the home owners plan to use the attic for living in the winter, then care must be taken to include it in the general heating system of the building. However, the first thing that owners should take care of is the insulation of this room. Only after complete insulation can the attic be included in the number of residential premises.

Disadvantages of polyurethane foam, reviews

Reviews and practice of application most often provide the most objective assessment of insulation. Usually, users are primarily interested in the shortcomings of materials in order to find out what awaits in the future and whether money will be wasted. Each material has its own characteristics, which can also be considered disadvantages; polyurethane foam is no exception.

Which insulation to prefer

Choosing insulation often becomes an overwhelming task for the consumer. There are too many technical nuances that are not obvious at first glance. The heat insulator is specified in the project, but it is difficult to solve the problem on your own.

Every insulation product has disadvantages, which the developer is not aware of or has a false idea due to advertising. For example, the durability of materials, about which very contradictory data are given in different sources, cannot be considered an advantage for many materials.

The eternal question of what to give preference to is best solved by acquiring ready-made reviews, operating experience... Or acting according to the approved documentation...

What is polyurethane foam?

Polyurethane foam is synthesized directly on the construction site by mixing complex components using special equipment. Therefore, insulation services with this material are provided only by organizations with special equipment. Independent use of polyurethane foam is impossible.

As a result of the constant slight expansion of the foamed substance and its hardening, a material with a porous structure is formed, 90 - 95% of the volume consisting of voids in the cells. But the characteristics are unique - the highest degree of thermal insulation among artificial materials. At the same time, the price is moderate. Specific costs for very large volumes are low, i.e. over large areas the material also becomes advantageous.

Individual disadvantage

But the creation of polyurethane foam occurs every time without standards, “like an uncle twisting a pen.” This also entails its big drawback - the characteristics will completely depend on the desire of the creator, his conscientiousness, the quality of the equipment, the quality of the components...

The most important parameter is achieving the design specific gravity - kg/m3. Strength characteristics, thermal insulation coefficient, vapor permeability will depend on this... But the creators want to fill the volume and spend as few components as possible….

Therefore, one of the most important indicators of this material is simply consumer reviews of a particular organization involved in spraying. To avoid negative consequences, independent technical control at the construction site is also important.

Afraid of the sun

The effect of ultraviolet radiation on most synthesized plastics is negative. Irradiation destroys chemical bonds and the structure of the material. Users comment on the shortcoming - “the material turns yellow and shrinks.”

When coating external surfaces, it is not recommended to keep polyurethane foam in the sun without protection. In any case, manufacturers may not focus on this. But reviews of polyurethane foam speak precisely to the need to protect it from radiation.

Can be used under protective putty or paint. True, external use is questionable due to another disadvantage of the material...

No flat surface

A typical area of application for polyurethane foam is in cavities covered by hinged panels. Or in places that do not need aesthetic evaluation. Why panels that are hung on the sheathing?

Because it is not profitable and difficult to apply a plaster and paint layer on top of the material. A too uneven surface is created. Spraying is done individually, as the master can. And the thickness of the layer is determined by the average result, while in some places it can be +- 2 cm.

Vapor barrier - advantage or disadvantage?

Reviews about polyurethane foam say one thing - it is better not to use it on vapor-transparent materials from the outside. The insulation will block the escape of moisture from wood, from aerated concrete, from expanded clay concrete... It is better to use the material strictly in accordance with the design, where the structures are specially designed, for example, vapor barrier membranes are provided.

Doing it on your own can literally lead to disastrous results for the wall (structure) - water will flow from it. Thus, the property of the material to poorly allow water vapor to pass through itself will turn into a major disadvantage if used ineptly...

Destroys and binds

Expansion during the formation of the structure can also be considered as a disadvantage of this heat insulator. Using these criteria, users usually make reviews about polyurethane foam - for example, “this foam brought down half of my wall, I didn’t expect...”

Indeed, in closed cavities the material can cause trouble - it will rupture the shells. For example, when pumping without rules into the cavity of a three-layer wall behind a brick wall, there is a risk of squeezing out the cladding, collapsing...

On the other hand, the material is designed in prefabricated structures on lathing, in panel houses. Here it not only fills the internal cavity of the panels, creates a heat-insulating shell, but also fastens the outer cladding itself, creating a monolith….

What is the downside in case of fire?

The material does not support combustion, but at a high enough temperature it begins to decompose, smolder, and ignite. At the same time, releasing substances that are not at all useful. It is not recommended to use it from the inside in an open form for fire reasons; it is better to cover the polyurethane foam on top with a fire-resistant shell.

Typically, an application in which fireproof walls made of mineral materials, or panels made of gypsum fiber or cement fiber, are located inside the living space.

What reviews say about the durability of polyurethane foam

One of the most important qualities of materials used inside permanent structures, such as walls, is durability. It’s good if the wall can be easily disassembled and the insulation material can be replaced, as for example in a ventilated façade system with hanging panels on the outside. But if the material is bonded to a supporting frame, as polyurethane foam does, and covered with heavy finishing in wet processes, then its low durability is the main drawback.

Pros and cons of polyurethane foam

Advantages

Judging by the reviews and technical properties of polyurethane foam, we can highlight a number of advantages that this insulation material has:

- When treating the surface with polyurethane foam to insulate it, no seams or cracks are formed. As a result, the heat loss coefficient is much lower than that of boards made of extruded polystyrene or other similar material.

- Judging by the reviews of both experts and ordinary owners of buildings with such treatment, polyurethane foam for insulation provides excellent sound insulation.

- In most cases, a 50 mm layer of polyurethane foam is enough to provide high-quality thermal insulation.

- Transporting the substance is much cheaper than slabs. It's all about the compactness of both the installation and the material.

- PU foam can be used at temperatures from -150 to +220 degrees Celsius. Therefore, it can be used in construction anywhere in the world. Moreover, scientists actively use this substance in the creation of aerospace technologies.

- The use of material allows you to significantly strengthen the roof.

- High thermal inertia allows polyurethane foam for insulation to retain heat indoors even in the strongest winds. This is evidenced by numerous reviews from home owners from cold regions.

- Polyurethane foam has a low water absorption coefficient. It is not surprising that it is often used to create reliable waterproofing. Thanks to this property, the substance has found wide use in roofing.

- When applying polyurethane foam, special equipment is used. A significant part of it is the gun, with which you can regulate the spraying speed. This greatly speeds up installation and makes it more economical, at least that’s what reviews say.

- The substance has high heat resistance and biological neutrality. It is safe for both the environment and humans, but spraying must be carried out with a mask and goggles. Otherwise there may be serious consequences. As you can see from the reviews.

- The service life of polyurethane foam for insulation can reach 50 years.

According to reviews and expert opinions, polyurethane foam insulation has many advantages. If we talk about those that gave it a key advantage in the market, then it is the speed of installation and ease of transportation.

Separately, we need to talk about the benefits that industrial facilities receive. Take, for example, grain storage and vegetable storage. These objects are often susceptible to attack by rodents and insects. But the biological properties of polyurethane allow it to be an insurmountable obstacle for the former and the latter.

Flaws

Unfortunately, despite its more than outstanding advantages, polyurethane foam insulation has its drawbacks:

- The material is vulnerable to ultraviolet rays. Under their influence, accelerated destruction of the structure is observed. However, you can find out about this from the reviews.

- It is not recommended to use polyurethane when it is necessary to insulate a roof consisting of corrugated sheets or metal tiles. The fact is that due to the lack of a gap, condensation begins to form. As a result, the roof surface is destroyed. But reviews on this issue largely contradict each other.

- The price of the material itself is not that low. Moreover, to spray it you will need to rent or purchase special equipment.

At first glance, polyurethane foam, which is used for insulation, has much fewer disadvantages than advantages. But it's not that simple. Judging by the reviews, most of the disadvantages of this substance are leveled out or quite easily eliminated.

Take, for example, rapid deterioration under ultraviolet light. It is enough to take paint and apply it to polyurethane for insulation, so that the service life of the substance will be extended for several decades. Moreover, there are other alternative methods of protection. Suffice it to recall at least plaster.

Now regarding the price. If calculated in cubes, then polyurethane foam for insulation requires significantly less than the same extruded polystyrene. On average, savings are about 20 percent. If we remember the reduction in transportation and hiring costs, the level of savings will be even higher.

The fact is that if you use polyurethane foam for insulation, then judging by the reviews, you can handle an area of 400 square meters in about 8 hours. If you process it using extruded polystyrene slabs, you need at least three days. This is taking into account that about seven workers with appropriate qualifications will work for you.

This is exactly how many workers, if you look at the reviews, are needed to complete the work in the shortest possible time. In turn, one person can handle spraying polyurethane foam for insulation. Reviews also testify to this.