Mulwatt

14960 0 8

Mullvatt September 7, 2016Specialization: Capital construction work (laying a foundation, erecting walls, constructing a roof, etc.). Internal construction work (laying internal communications, rough and fine finishing). Hobbies: mobile communications, high technology, computer equipment, programming.

Only thanks to insulation, a comfortable microclimate for living is formed in the attic.

Some time ago I completed an order to insulate the attic for winter living. While doing the work, I thought that the technology I used was quite simple and even an untrained person could make thermal insulation from the inside with his own hands.

In today’s material I will tell you what is better and how to properly insulate an attic from the inside with your own hands. This instruction will help you avoid making mistakes that I had to face at the beginning of my construction career.

I assure you, upon completion of the work, the attic floor of a wooden house will turn from a useless storage of rubbish into a cozy and comfortable room in which all your household members will fight to live.

General requirements for the thermal insulation system

For thermal insulation to work effectively, the following is necessary:

- The insulation must cover all surfaces without gaps, as a continuous “carpet”.

- Thermal insulation material is protected from condensation that forms under the roof as a result of the interaction of warm, moist air from the inside and cold air from the outside.

- The resulting condensate must be removed through ventilation ducts.

- The insulation must be equipped with a windproof layer that protects it from blowing out heat.

- The selected material must comply with all sanitary and construction standards.

Proper insulation of the attic

*

Do-it-yourself attic insulation

The main heat loss in a country house occurs through an uninsulated roof. The share of losses during the cold period is up to 30% of the total amount of heat generated by the heating system. On the other hand, in the hot season, the under-roof space is a real oven. Therefore, insulating the attic should be considered as a necessary measure that increases the comfort of living in a country house. In addition, this is a good investment, since a well-insulated roof space will generate income annually in the form of savings on heating costs.

Work on reliable insulation is carried out from the inside under the finished roof

Material selection

*

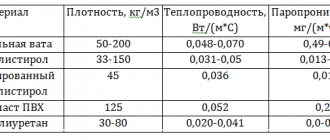

Let's consider the most popular options for insulating attic walls with your own hands from the inside:

- Mineral wool. Inexpensive material, convenient for work. It insulates rooms well and does not accumulate moisture during operation. To lay it between the rafters, it is cut into sheets 1-2 cm wider than the distance between them. The material is inserted into the rafter spaces and, due to elasticity, is tightly held in them.

- Styrofoam. This insulation is one of the budget and practical methods of insulation. It is safe for health, does not rot or decompose. But the complete lack of steam conductivity and vulnerability to rodents reduces its effectiveness. Loose joints between slabs also negatively affect heat retention.

- Polyurethane foam. Insulation that can be easily applied by spraying onto any surface using a portable unit. The applied layer has no breaks or pores, which has a positive effect on the quality of insulation. The material is not sufficiently resistant to high temperatures.

- Ecowool. The cellulose-based material is applied using a spray machine or by hand, resulting in a seamless coating over the entire surface. Requires protection of the resulting surface from moisture with a vapor barrier material.

- Foil materials. Compared to traditional thermal insulation, these insulation materials have better properties due to the mirror layer applied to them. This layer reflects the heat coming out of the room back, increasing its thermal protection. Due to the small thickness, savings are created in the occupied volume of the room.

Materials for attic insulation

Preparing the under-roof space for insulation

You should know that, according to GOST standards, the height of ceilings in the attic cannot be less than 2.5 meters. But this does not apply to the entire area of the attic, but only to half of it, that is, in the remaining 50 percent, the height of the room may be slightly less.

What factors influence heat loss in the attic floor:

- type of main building material of the house;

- the presence of common communications with other rooms of the house;

- features of roof geometry, number and shape of slopes;

- type of load-bearing roof materials;

- placement of the attic relative to the main building (with access beyond its boundaries or not).

All these factors must be taken into account before you begin to insulate the roof from the inside with your own hands. Building regulations dictate that insulation of a house must be carried out from the outside so that the freezing point moves to its outer part. But this rule does not apply to attic floors. Here, the specifics of construction require internal insulation, since roofing material must be placed outside.

The only surface that can be insulated from the outside is the roof gable

In terms of preparation for insulation work, you need to carefully study the options for thermal insulation coating and select a high-quality waterproofing film.

What does proper thermal insulation consist of?

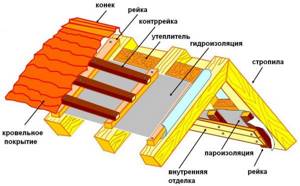

Correctly done insulation of the walls of the attic floor should consist of several layers (in order):

- Windproof vapor barrier. It is fixed under the roofing above the rafters using slats.

- Counter-lattice. It is necessary to create a ventilated space between the roof and waterproofing and remove condensate accumulating there.

- Waterproofing that prevents the insulation from getting wet, in order to avoid loss of its thermal insulation properties.

- Insulation. The material is fixed between the rafters and is the main element of the “constructive cake”. It is necessary to leave a ventilation gap between it and the waterproofing film.

- Lathing. The slats placed across the rafters hold the insulation and serve as the basis for attaching the vapor barrier.

- Vapor barrier. The membrane film is fixed overlapping with a gap of 10-15 cm. All sections are fastened together with adhesive tape to form a solid coating without gaps.

- Interior finishing – plasterboard, OSB, GVL, etc.

Insulation device diagram

*

Procedure for insulating with mineral wool

Purchasing material

First of all, it is necessary to put all the components of the rafter system in order, since after insulation it will be impossible to approach them.

Then you need to measure the dimensions of the roof, walls and floor and calculate the required amount of insulation. The calculated coverage area must be increased by 10%, which will make it possible to slightly compress it during installation and will protect it in case of a slight error in the calculations.

Mineral wool is produced in the form of mats or rolls with a thickness of 5 and 10 cm. Effective insulation of external walls and roofs must be at least 15 cm, based on this value and you need to purchase insulation.

Mineral wool in rolls is more preferable for work in the sense that it can be used to create a coating with a minimum of joints, reducing possible heat losses.

Mineral wool is available in the form of mats or rolls

Cutting the insulation

It is necessary to cut sheets of mineral wool each time, first measuring the distance between the rafters or joists where it should be placed. During the construction process, it is not always possible to keep these distances exactly the same, and the insulation must be placed there with light effort.

To do this, the width of the laid mat is made 1-2 cm wider than the distance between the rafters. Many builders take into account the need to insulate the attic and immediately place the rafters at the required distance from each other.

It is convenient to use a special knife to cut mineral wool.

Effective insulation

Next, we will consider the most effective materials that do not require serious equipment in order to efficiently insulate the attic.

Stone wool

Due to their elasticity, the mats adhere well between the rafters and allow installation without additional fastening. And the relatively dense structure of stone wool prevents its shrinkage over time. Therefore, it has proven itself well on vertical surfaces.

Stone wool mats come in different thicknesses, and you can choose the one you need based on climatic conditions and other materials used Source pallazzo.su

To further reduce the risks, every 3 meters of height it is necessary to arrange supports for the insulation - add a horizontal frame element.

Work procedure for foam insulation

*

The thickness of the foam is selected based on the temperature conditions in the place of residence. For average Russian conditions, a thickness of 15 cm is sufficient.

Fastening foam sheets can be done in two ways:

- Nails with wide heads;

- Construction foam.

The nailing technology is similar to that used when installing mineral wool.

Foam installation is more expensive, but gives better results. To use it, you need a professional foam mounting gun. You should not buy cheap household foam. It comes with a plastic tube for supplying foam, which is very inconvenient to use to fill narrow cracks. The tube bends, it must be guided with a free hand, and the result is a very poor quality glue line. If the cylinder is not completely used up, the foam hardens in the tube, making it unsuitable for further use. A professional foam gun does not have these disadvantages.

In addition, the material of professional foam itself is of higher quality than that of household foam.

Cutting foam

The distance between the rafters is measured and transferred to a sheet of foam plastic. For each sheet, measurements are taken locally. When cutting, it is necessary to increase the dimensions of the workpiece by 1-2 mm, this will increase the strength of its pressing against the rafters.

For work it is convenient to use a hand saw or a stationery knife. For a large volume of work, you can make a special cutter from nichrome wire.

Foam cutting device

Detailed article - how to cut polystyrene foam with a knife or using a machine.

Applying an adhesive layer

Using a gun, a continuous layer of foam is applied to the junctions with the rafters and adjacent sheets. For better adhesion, the foam needs to dry for 3-5 minutes.

Laying insulation

The prepared foam sheet is inserted into place. The insulation must be placed in such a way that it does not touch the waterproofing film anywhere. In such places, dew can collect and flow onto the wooden elements of the roof. The foam around the perimeter of the sheet is additionally foamed if necessary.

Polystyrene foam is fixed between the rafters

Vapor barrier installation

After the foam has hardened, the protruding excess is cut off and the insulation is covered with a vapor barrier film. The principle of its installation is the same as when insulating with mineral wool - gradually increasing the surface from bottom to top with complete sealing of all joints.

Attaching the sheathing.

Sheathing bars are attached on top of the vapor barrier film for subsequent installation of interior finishing.

Recommendations

There are several recommendations that it is advisable to follow when arranging the floor:

- Sealing plays an important role. Therefore, it is necessary to process all joints, corners, and crevices. Lubricants-sealants or electrical tape are used as processing materials.

- If your plans include installing a self-leveling floor, then preliminary priming of the surface is carried out. To create a perfectly level floor, use a self-leveling mixture. The substance is diluted with water in the correct proportions. The floor is laid with tiles, carpet, laminate and so on.

Laminate

- The space between the joists should not be empty. If this space is not filled, it will produce a loud booming sound. To fill the empty space, you can use bulk heat insulation, expanded polystyrene granules or expanded clay chips. This procedure combines thermal insulation and sound insulation.

- When insulating the floor, use the two-layer method. The sutures and beams must also be bandaged. The thickness should be 150 mm or more.

To carry out proper vapor barrier, use rolls of a specially designed product. Rolls must be laid tightly over the entire surface area. The seams are glued together using specially designed waterproofing tape. To ensure a high level of reliability, it is better to create a vapor barrier consisting of two layers.

Installation of thermal insulation material should not cause any difficulties. Mineral wool or polystyrene foam is placed in the cavity between the beams. If expanded clay is used as a thermal insulation material, then the vapor barrier is simply backfilled on top of the product. Next, the insulating layer is covered with another layer of vapor barrier.

In general, the most difficult stage in the entire thermal insulation process is the floor screed. For this procedure, a mesh or reinforced structure must be used. The mesh is laid on top of the beams. Constantly check the evenness of the screed. An uneven screed may have negative consequences in the future.

The process of arranging the lower plane of the attic depends on the product from which the floors are made. The ceilings between rooms can be wooden beams. They can be made of reinforced concrete.

When insulating, not only the selected materials play an important role, but also safety precautions. Having studied the detailed procedure for thermal insulation of the floor in the attic, you can do all the work yourself with your own hands. But the result will not be of such quality; it is better to use the services of specialists. An insulated attic is the key to comfort and coziness.

Insulation of the gable

Installing insulation on gable walls is no different from installing it on side walls or a roof. To install protection, it is necessary to make partitions from boards measuring 5x150 mm. Their arrangement should resemble the structure of the rafter system:

- The thickness should correspond to the thickness of the insulation.

- The distance between them should ensure tight retention of the thermal protection sheets.

To insulate the pediment, it is necessary to install partitions

General points

Let's start with the fact that the attic is a bit of a special room. Its overall structure requires a careful, meticulous approach. And the insulation of the attic roof is even more so:

- Mostly vertical or inclined surfaces . Therefore, it is better to immediately exclude all soft “pliable” materials, namely mineral wool rolls.

- It is advisable to focus on materials with low dead weight . Since the rafter system is already experiencing significant loads from wind and snow. In addition, the load on load-bearing walls will not increase much.

- Often insulation is required for gables . They are not always made by analogy with a main wall. May be made of facing material. Or the frame is simply built for insulation.

- It happens that the area of the attic significantly exceeds the size of the house itself , while part of it rests on columns. In this case, you will also have to insulate the ceiling in contact with the street.

It should be understood that the thickness of the insulation must correspond to the weather conditions of a particular climate zone, while having a small margin. To gain the required thickness, the insulation is installed in several layers, and the relatively small dimensions require joining.

Important: splicing any insulation requires a careful approach. The joints of different layers should not be concentrated in one place. To prevent freezing, they should be spaced as far apart as possible. It is important to constantly remember this so as not to spoil the material, especially when insulating a sloping roof.

Basic mistakes

All the positive aspects of insulation can be negated by errors in their installation:

- Carrying out work at low temperatures. This leads to insufficient drying of the glue and loss of strength of the insulating layer.

- Wrong choice of material thickness. Insulation of insufficient thickness will not give the desired effect, and a layer that is too thick will lead to unnecessary material costs.

- Sliding of thermal insulation due to insufficient fastening. This leads to the appearance of unprotected places and intense penetration of cold through them.

- Lack of vapor and waterproofing. In this case, the insulation will get wet, absorbing moisture, and will quickly lose its properties.

- Installation of steam and waterproofing films with sagging. These materials should be attached with slight tension.

- Lack of ventilation. In an unventilated attic, condensation forms on and inside the walls, damaging the insulation.

When carrying out work on thermal insulation of the attic yourself, it is necessary to take a responsible approach to all stages - from developing the project to attaching the final finish. In this case, a room created with your own hands will delight the owners with comfort for a long time.

Problems with arranging insulation in the attic space

According to statistics, after the first winter in 30% of attics the thermal insulation has to be redone. In this case, there is a need to dismantle the roof covering, and the insulation needs to be dried, and a significant part of the previously used building materials is not subject to further use. This means you need to purchase them again, which leads to unplanned costs.

Often, such troubles arise if the insulation of the attic inside was carried out without taking into account the climatic characteristics of the region where the house was built.

In Russia, cold, dampness, and weather with negative air temperatures are not uncommon. It is known that the lower the ambient temperature drops, the greater will be the volume of steam that is able to penetrate through the vapor barrier layer due to increased partial pressure differences.

As a result, the movement of moisture through the cold membrane slows down significantly. For this reason, the results of testing the vapor permeability of roofing pie, carried out under European climate conditions and severe Siberian frosts, vary. You can't expect the same results.

It should be noted that it is in the residential attic that the maximum value of water vapor pressure exerted on the roofing pie is observed. The fact is that in the attic, the pressure of warm air is added to the steam pressure, and the insulation, which has become damp, begins to quickly lose its properties.

The higher the humidity of the air in contact with the heat-insulating material, the more its insulating characteristics decrease. For example, basalt insulation in conditions of 5% humidity loses heat 20% more than dry insulation.

So one cubic meter of air space at a relative humidity of 100%, at a temperature of plus 20 degrees contains 17.3 grams of water in the form of steam. The lower the temperature, the more difficult it becomes for air to hold water in a bound state.

When the temperature decreases to + 16 degrees, water vapor will become 13.6 grams, and the remaining amount will settle in the heat-insulating material in the form of water. Therefore, we can draw the following conclusion: when the temperature drops, moisture in the insulation appears as a result of condensation of excess water vapor present in the air.