Dimensions and characteristics of polystyrene foam

Expanded polystyrene has another more common and well-known name for many - polystyrene foam. Its appearance has also been known for a long time. This is a lightweight material that floats on water because it has air chambers inside its white balls. They are what give the material its unique properties. It has its flaws. It is fragile and flammable.

Expanded polystyrene is a gas-filled material that is made from polystyrene and is used as insulation.

The manufacturer produces it in sheets of different lengths, widths and thicknesses. The last parameter is the main one in choosing this material. The thickness of the product can be from 20 to 100 mm. This material is very popular among builders. It is used to increase thermal insulation during bricklaying with solid bricks. Pieces of foam plastic are placed under plywood, which is used to finish the floor under parquet or laminate. They can be used to insulate walls from the outside while finishing the walls with plasterboard. Most often it is used from the outside.

Foam sheets can be standard or custom sizes.

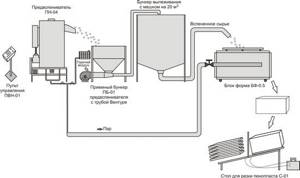

Scheme of production of expanded polystyrene.

The length and width of the standard sheet are 1000, 2000 mm. The manufacturer can cut products into other non-standard sizes. You can often find sheets of 1200x600 that meet the needs of the buyer and are in good demand. This can be a sheet with dimensions of 500x500, 1000x1000, 1000x500 mm. On order, you can receive a batch of expanded polystyrene with sides of 900x500 or 1200x600 and other sizes, which does not contradict the standards. GOST allows cutting products 10 mm smaller if its length is over 2000 and its width is 1000 mm. In thickness for slabs up to 50 mm, a difference of ±2 mm is allowed, and over 50, a difference of ±3 is allowed.

If the length is not suitable for the buyer, then companies selling such products offer individual cutting. Length and width are important only for transporting building materials from the manufacturer to the customer. The main role is given to the thickness of the material.

Features of foam

Recently, foam sheets have been used everywhere.

They are used as protection against heat loss, for protection against mechanical shocks (for example, when transporting fragile items, it is placed in packaging). It has a number of advantages that set it apart from other materials. Their list is as follows:

- Low thermal conductivity;

- Good sound insulation properties;

- Durability;

- Light weight;

- Easy installation;

- Environmental friendliness;

- Low cost.

Material values

This insulation has a high level of thermal insulation, which distinguishes it from other building materials. Thanks to such characteristics, it is possible to ensure long life for houses and structures in any weather. If we compare thermal insulation with others in terms of thermal conductivity, then polystyrene foam, the size of which is 80 mm in thickness, is equivalent to wool 100 mm in thickness, wood - 275 mm, 750 mm of brickwork and 1700 mm of concrete. It should be noted that sheet foam is quite cheap. This allows it to be used in large quantities and for different purposes.

To use it as a finishing material, you need to find out the thickness. It varies from 20 to 500 mm. It is necessary to take into account that the thickness is always a multiple of 0.1 cm. However, you can order sheets with a multiple of 5 mm, but their cost will be much higher compared to analogues of the standard value. Sheet sizes may vary. With standard foam sizes ranging from 1000 to 2000 mm in length and from 1000 to 2000 mm in width, the price may fluctuate depending on several factors.

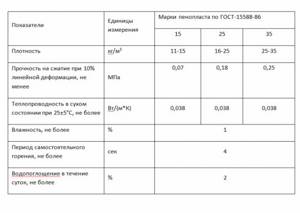

You should pay attention to the density indicator. According to this indicator, there are materials of 15, 25, 35 grades. Density plays an important role when choosing foam. A sheet with a thickness of 500 mm and a 35 grade is similar to the same with a thickness of 100 mm and a density of 25. The denser the sheets are, the higher their cost.

Expanded polystyrene 100 mm: decoration of the structure and its reliable thermal protection

Expanded polystyrene is created from polystyrene granules. They are filled with pentane and heated with steam. After this, the granules increase in volume by 20-50 times. They are very elastic and consist of 98% water. Next, the granules are exposed to hot steam, as a result of which the balls adhere and a soft, durable material is obtained, used as insulation.

Expanded polystyrene is a durable material that provides a high degree of insulation. It is suitable for use in all areas.

In 1952, BASF developed polystyrene foam. Since then, it has conquered the construction market and its popularity is constantly growing. Expanded polystyrene is easy to transport and is light in weight.

Expanded polystyrene is used for insulation:

- Foundation;

- Sexes;

- Sten;

- Roofs.

The price of this material per 1 cubic meter is the lowest compared to other insulation materials. This type of insulating material will protect your walls and floors from moisture all year round and keep your room warm.

Technological methods and release form

It is customary to distinguish three types of expanded polystyrene with their own unique properties, which are determined by the manufacturing method of a particular insulation.

The first category includes polymer produced using the non-press method. The structure of this material is replete with pores and granules measuring 5 mm - 10 mm. This type of insulation has a high level of moisture absorption. There are material grades on sale: S-15, S-25 and so on. The number indicated in the marking of the material indicates its density.

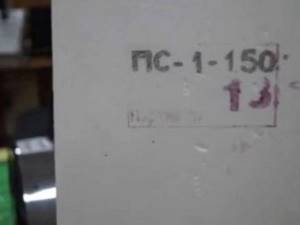

Expanded polystyrene, obtained by manufacturing under pressure, is a material with hermetically sealed internal pores. Thanks to this, such a pressed heat insulator has good thermal insulation properties, high density and mechanical strength. The brand is designated by the letters PS.

Extruded polystyrene foam is the third type of this polymer. Designated EPS, it is structurally similar to extruded materials, but its pores are significantly smaller in size, not exceeding 0.2 mm. This insulation is most often used in construction. The material has different densities, which are indicated on the packaging, for example, EPS 25, EPS 30, and so on.

Foreign autoclave and autoclave-extrusion varieties of insulation are also known. Due to their very expensive production, they are rarely used in domestic construction.

The dimensions of the sheet of this material, the thickness of which is about 20 mm, 50 mm, 100 mm, as well as 30 and 40 mm, are 1000x1000, 1000x1200, 2000x1000 and 2000x1200 millimeters. Based on these indicators, the consumer can choose a block of PPS sheets both for insulating fairly large surfaces, for example, as a substrate for a laminate for a heated floor, and for relatively small insulated areas.

Characteristics of foam plastic 100 mm (video)

Polystyrene foam 100 mm, with its excellent technical characteristics, has long won the trust of consumers and occupies a leading position in the construction market.

Comments

0 Daniil 01/12/2018 21:24 I insulated my garage with polystyrene foam, it took me a long time, but I finally did it, but the garage is warm.

It is also convenient to work with polystyrene foam, it is easy to cut, there are no problems attaching it either, and besides, it is quite cheap. Quote

Update list of comments RSS feed of comments for this entry

Foam insulation - what do the dimensions say?

Just 8 cm of polystyrene foam is equal in its thermal insulation properties to a concrete wall two meters thick! However, our house doesn’t even need such thermal insulation - we still ventilate the rooms, one way or another letting cold air inside. First, decide on the width and length of the slabs - the correct choice of sizes will save a lot of time on adjustment. Indeed, why cut if you can choose the size of a sheet of finished foam that will fit perfectly into the space.

Most often, the standard sizes of foam plastic slabs are a square with a side of 1 m. The 2 m * 1 m option is also popular. There are also narrow slabs, half a meter wide and a meter long. To insulate the outside, choose the middle option - it is quite convenient and quick to work with. How thick is the foam produced? The thickness of expanded polystyrene starts from 10 mm and ends at a huge 500 mm. True, most often especially thick slabs are made to order, and the most common sizes are made on the production line, which range from 20 to 80 mm. Thickness increments are usually 10 mm (20 mm, 30 mm, 40 mm, etc.), although there are also options with 5 mm increments. Watch the price - sometimes the manufacturer deliberately reduces the thickness by 5 mm, pricing the slabs more expensive than they actually cost.

What sheet thickness should I choose? It all depends on the type of insulation. If you are determined to thermally insulate the room from the inside, then 20–50 mm of material thickness for the walls will be sufficient - keep in mind that the walls on the outside also have a thermal insulation coefficient, which is added to the parameters of the foam itself. Thin insulation takes up much less internal space - the foam will take at least 5 cm from each wall, along with a layer of plaster and putty.

For the ceiling, a sheet thickness of up to 50 mm is also sufficient. Foam plastic is laid in two layers on the floor under the concrete screed, so that the total thickness can reach 10 cm. This is justified, because the floor is subject to constant loads. The external walls are insulated with polystyrene foam of 50 mm and above - they are oriented towards the climate of the region. For example, for the Kursk region, the optimal choice for a wall made of two bricks is polystyrene foam slabs 70 mm thick.

Properties and characteristics of the material

Foam plastic can withstand temperature fluctuations from -50 to +75 o C without changing technical characteristics. A detailed description of its properties will help you get acquainted with the technical characteristics of polystyrene foam:

- Thermal conductivity. A special production technology provides foam boards with high thermal insulation properties. Cells in the form of closed polyhedra, the size of which does not exceed 0.5 mm, prevent the penetration of cold air and significantly reduce heat transfer. As the density of the material increases, this indicator changes.

- Sound insulation and wind protection. The walls of the room, in the decoration of which foam boards are used, are reliably protected from the wind. Among the technical characteristics, noteworthy is the high degree of sound insulation, which is also ensured due to the cellular structure of the material.

- Moisture resistance. Expanded polystyrene is valued by builders for its low hygroscopicity relative to other materials. Water is not able to penetrate the walls of the cells, but only seeps through the channels.

- Durability and strength. Foam plastic retains its original technical characteristics for a long time. The plates are able to withstand significant pressure without deformation or destruction. A clear example is the use of polystyrene foam in the construction of runways. The thickness of the polystyrene foam board directly affects the strength of the material, and the correct installation is also important.

- cement;

- gypsum;

- bitumen;

- acids, alkalis and salt solutions;

- sea water;

- not susceptible to water-soluble and acrylic paints.

The resistance of foam plastic to aggressive environments deserves careful study. The stability indicators of polystyrene foam boards directly depend on the composition of the active substance. Polystyrene foam slabs are resistant to solutions:

Prolonged contact with substances that contain oils of plant and animal origin, diesel fuel and gasoline can negatively affect the technical characteristics of the foam.

When expanded polystyrene boards are used in the construction of objects, contact with compounds that aggressively affect the structure of the material should be avoided. Among them:

- turpentine;

- acetone;

- organic paint solvents;

- ether with acetic-ethyl base;

- all kinds of saturated hydrocarbons and substances obtained by petroleum refining.

This includes fuel oil, diesel fuel, kerosene and gasoline. Contact with the above components leads to disruption of the structure and loss of qualities specified in the technical characteristics, and can also provoke complete dissolution.

Among the positive qualities of foam plastic boards, which are not reflected in the technical characteristics, are ease of use and simple installation. Light weight ensures ease of work; the structure does not create difficulties when cutting and subsequent installation is necessary.

Expanded polystyrene is included in the category of environmentally friendly building materials; during operation it does not emit toxic substances. When working with it, the use of personal protective equipment is not required. Numerous summary tables of technical characteristics do not reflect the many positive qualities of the building material. It does not generate dust when cutting, is valued for its lack of odor, does not irritate mucous membranes and skin, and is not toxic.

Fire safety is an important quality characteristic of foam plastic. When choosing a building material, special attention is paid to this indicator. High-quality products must be resistant to open fire. Expanded polystyrene boards belong to flammability class 3-4. This material does not support the combustion process. The temperature at which it can ignite is 2 times higher than that of wood (+491 o C compared to +230 o C).

If a fire retardant is present in the composition of expanded polystyrene, the flammability class of such material is reduced to G2-G1. In the marking, this feature is expressed by the letter C. Ignition of a foam board can occur as a result of prolonged contact with an open fire. Termination of exposure to fire leads to its attenuation on the surface of the polystyrene foam plate within 4 seconds.

Individual technical characteristics of polystyrene foam boards are presented in the summary table:

Definition and properties

Polystyrene foam is an insulating material that has excellent heat and sound insulation properties.

The cost expression of polystyrene foam boards is much lower than for other insulation materials. The use of expanded polystyrene slabs in construction work helps reduce operating costs for heating or cooling residential or commercial buildings by tens of times.

There are several points of view that are associated with the concept of density. The unit of measurement for this parameter is kilogram per cubic meter. This value is calculated from the ratio of weight to volume. It is impossible to measure with one hundred percent accuracy the qualitative properties of polystyrene foam, which are associated with its impermeability and density. Even the weight of this insulation does not affect its thermal insulation capabilities.

When thinking about the question of which insulation to buy, customers are always interested in its density. Through this data, it is possible to evaluate the strength of the material, its weight and thermal conductivity. The density value always refers to a specific range.

When producing expanded polystyrene boards, the manufacturer sets the cost of the products. Based on the formula for finding density, the mass of the insulation will affect the indicated value. The greater the mass of the material, the more dense it is, and therefore its sum is higher. This happens because polystyrene foam as a raw material for heat insulation boards is important. It is approximately 80% of the total cost of finished products.

Insulation of building structures

If you decide to insulate the walls of your house or flooring, then the optimal product measurements are 1000x1000 and 1000x500 mm. It is much easier and more convenient to work with such volumes; when using them, fewer joints are formed that need to be sealed. To insulate a smaller area, the foam is cut into the required pieces. It is recommended in all situations to use large volumes of insulation, this makes it easier to carry out configurations. During installation, adjust to the required measurements by cutting into pieces. Expanded polystyrene with a width of 2000x1000 mm is more difficult to install. If you work alone, then it will be easier for you to lay two products with a volume of 1000x1000 mm than one 2000x1000 mm.

Foam plastic 20 mm

This type of finishing material is used for insulation and soundproofing of buildings, for external and internal insulation of walls, and masonry of floors. The thermal insulation effect of this product manifests itself in the cold season.

Foam plastic 30 mm

In most cases, material with this thickness is used for laying floors, insulating roofs and facades. Does not allow moisture to pass through, even in the rainiest and dampest weather your walls will remain dry.

Foam plastic 40 mm

If you want to insulate your home using this material, then sheets with this thickness are ideal for you. The size can be any, its standard measurements are approximately 1000, 2000 mm in length, 1000-2000 mm in width.

Foam plastic 50 mm

This is a universal size for finishing work. This facade foam is capable of fully protecting the house from dampness and freezing.

Foam plastic 100 mm

A sheet of this thickness is recommended to be used for insulating floors, basements, basement areas and ceilings. Its cost is a little more expensive than conventional ones, so it is worthwhile to use the material wisely.

Foam plastic 200 mm

This type of material can withstand heavy mechanical loads. It is very often used in the construction of heating mains to prevent soil freezing and heaving. It is not recommended to use polystyrene with this thickness for wall insulation and sound insulation, since cracks may form at its joints. It is difficult to say exactly how much repair and construction work with this material will cost. One thing is clear: if you turn to industrial climbers for help, the price for the work will be higher. The larger the footage, the more expensive it is in price.

Technical characteristics of polystyrene foam: savings and durability

100 mm polystyrene foam is equivalent in thermal insulation to 1200 mm of concrete. If instead of concrete you use foam plastic with a thickness of 100 millimeters, you will get significant cost savings, and the efficiency of heat and sound insulation will be even better.

Polystyrene foam is an excellent insulation material, it has good technical characteristics, but it is not recommended to use it inside residential premises.

There is air inside the foam, which provides it with excellent thermal insulation. This material has no expiration date, it does not decompose or deform. Polystyrene foam is fireproof, it does not support combustion and has self-extinguishing property. Another positive characteristic of insulation is the low weight of the slabs, which does not make the structure heavier and does not require reinforcement of the foundation.

Polyfoam has excellent technical characteristics:

- Thermal insulation;

- Soundproofing;

- Resistance to aggressive air environments;

- Moisture resistance;

- Resistance to deformation;

- Fire safety;

- Ease of installation;

- Light weight of slabs.

Along with excellent characteristics, polystyrene foam also has disadvantages. Upon contact with aggressive chemical compounds such as gasoline, kerosene, turpentine, paint solvents, etc., its structure may be disrupted or it may even completely dissolve. Polystyrene foam practically does not allow air to pass through and has poor mechanical strength. A layer of plaster will increase its strength and also help protect it from damage by rodents.

Dimensions, thickness, brands, density

Polystyrene foam is available in the form of white sheets, which can have different thicknesses, widths and lengths. In this case, the main parameter when choosing it is the thickness of this insulation, ranging from 20 to 100 mm.

Note: Expanded polystyrene sheets can have standard factory sizes or be produced to order.

The standard dimensions of a foam sheet are 1000 mm in length and 2000 mm in width. However, manufacturers produce slabs in other sizes. The most common option: 1200x600 mm. Foam sheets with parameters 1000x1000 are also available for sale; 500x500; 1000x500 mm. In addition, upon individual request, you can order polystyrene foam, the sheet dimensions of which are 900x500 mm, etc., as well as purchase individually cut material that best suits the customer’s needs.

In accordance with the density of polystyrene foam, it is usually divided into several main grades, differing in strength and thermal conductivity. The material marked PSB-S 15 has the lowest density, 15 kg/m3. It has minimal weight and is usually used for insulating places where people are temporarily located (in cabins, construction cars, etc.).

The more popular brand is PSB-S 25, with a sheet density of 25 kg/m 3. This type of foam is used for exterior finishing of structures and structures of various types, including thermal insulation of roofs, floors and building facades.

Very dense expanded polystyrene grade PSB-S 35 is used in the manufacture of sandwich panels and reinforced concrete structures constructed using permanent formwork, and foam labeled PSB-S 50, the density of which is 50 kg/m 3, is used in road construction and refrigeration floors. warehouses, etc.

The main advantages of polyplast 100 mm thick

The main characteristic due to which polystyrene foam has become so popular is its thermal conductivity. And it is only 0.037-0.041 W/Mk. A sheet of foam plastic with a thickness of 100 millimeters can be compared to a layer of mineral wool with a thickness of 127 millimeters, a wall of wood with a thickness of 667 millimeters, and brickwork with a thickness of 1233 millimeters. These numbers speak for themselves. There is no doubt about the thermal insulation ability of polystyrene foam.

It is worth mentioning the ability of 100 mm thick foam to pass air. At the same time, it has excellent water-repellent properties. Over the course of a year, it absorbs no more than 1.5-3.5%. This is a very good indicator that speaks in favor of this material. For example, the same mineral wool is not able to maintain its properties without an additional waterproofing layer that protects it from moisture.

Polystyrene foam is an insulating material that consists of 98% air. The rest is polystyrene. This is where one of the advantages comes in – weight. Polystyrene foam is very light. This makes him a pleasure to work with. In addition, polystyrene foam is easy to cut and process. Its surface has good adhesion. Finishing materials adhere well and reliably to it. All this greatly simplifies the installation process.