A situation often arises when it is necessary to organize heating for a dacha or country house that the owner visits from time to time. At the same time, inexpensive bottled or natural gas is available, which is ideal as an energy carrier. Setting up a traditional heating system with a gas boiler is expensive and not practical. In this situation, it makes sense to consider simpler heaters - gas convectors using liquefied gas and methane, which is what we will do in this article.

Operating principle of gas convectors

According to the heating method, these units are designed for direct heat transfer to the air in the room. In this case, the heater burns propane from cylinders or main natural gas. Air masses passing through the cracks at the bottom and top of the housing heat up and thereby force air to circulate in the space of the room. This occurs due to the difference in density between hot and cold environments, a phenomenon called convection.

Heating up inside the unit body from contact with the heat exchanger, the air becomes lighter and is forced out by a heavier cold flow through the upper slots. This is the operating principle of gas convectors, where the heat source is an air heat exchanger heated by a gas burner.

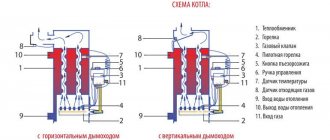

In general, the device is a rectangular body, inside of which there is a closed combustion chamber made of steel or cast iron, which also plays the role of a heat exchanger. The chamber has a built-in burner with a separate igniter and piezo ignition electrode. The gas supply is controlled using an automatic safety valve. It adjusts the gas flow depending on the ambient temperature or completely shuts it off when the following emergency situations occur:

Additionally read:

- How to choose the right double-circuit gas boiler

- What is important to know about Kuznetsov furnaces

- lack of draft in the chimney;

- burner goes out;

- drop in gas pressure in the pipeline.

For reference. Household convectors running on natural gas or propane are equipped with valves from Italian EUROSIT or American HONEYWELL.

The supply of combustion air, as well as the removal of flue gases, is organized from the street via a double-walled coaxial pipe. Combustion products move along the internal cross-section, and outside air passes towards them between the walls of the pipes. Thus, flue gases do not enter the room. And the last important point: the vast majority of gas convectors do not need to be connected to the electrical network.

Device design and operating principle

Let's start with the definition of a gas convector. This heating device is not an analogue of a gas boiler. It works on a completely different principle - it heats not the coolant, but the air. installed in relatively small rooms, as they heat the air locally.

The design of this heating device is relatively simple. The gas convector consists of the following parts:

- heat exchanger

in which the air is heated; - programmer

- a device responsible for maintaining a certain temperature in the room; - control panel

, on which indicators are displayed; - gas valve

that controls the gas supply; - fan No. 1

, responsible for supplying air to the heat exchanger and valve; - fan No. 2

, which disperses heated air throughout the room.

How does a gas convector work? Everything is quite simple: it operates on the principle of a gas burner. Cold air from the outside, obeying the laws of physics, enters from below, heats up and exits through the hole at the top of the device. Note that gas models can function due to natural or forced convection. In the second case, air is pumped by fan No. 1.

What else is important to know?

Based on their design, these heating units are divided into two types:

- wall;

- fireplace type floor convectors.

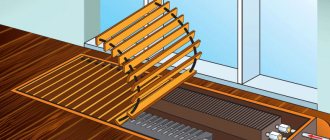

There is no fundamental difference between these types, the only difference is in the installation method. In general, gas convection heaters have considerable dimensions, especially floor-mounted ones. So, when installed under windows, they will protrude more than conventional radiators.

Another important point is the relatively low efficiency of the units. If a conventional gas boiler has an efficiency of about 90%, and a condensing boiler - up to 97%, then a gas heater - no more than 87%. This indicator is a price to pay for the simplicity of the design with undeveloped gas ducts.

Note!

- What is convector heating

Note. At the moment, you can find several improved convectors with a fan on sale. But where one indicator improves, another immediately deteriorates: a continuous annoying noise appears in the room from the operation of the fan.

To provide the convectors with fuel, you will have to install gas pipes from the main line to the installation sites of the units. When working with bottled gas, inevitable difficulties arise with the placement of cylinders, especially when there are several convectors. Then it is necessary to make a gas train and a cabinet for them, where air heating will be provided during severe cold weather. Otherwise, there may be problems with the fuel supply to the burner.

Gas convectors technical characteristics or what they are

Essentially, we have before us a simple heating device consisting of a heat exchanger in an attractive housing and a gas burner.

Construction of a gas heating battery

An excursion into history: back in the 19th century, rooms were heated and illuminated with gas, and even in those days this heating method was cheap, convenient and practical. But then the heating systems and lighting ran on acetylene and were ordinary gas jets, i.e. open burners. Such burners required adjustment to minimize the volume of soot. In addition, combustion products exited the room through a common single ventilation. At the same time, oxygen was consumed to maintain combustion from the volume of the room.

Gas heating convectors have several pleasant innovations, which, ultimately, make them modern heating batteries from rarities:

- The gas flow rate is automatically adjusted, which means more economical gas consumption. A simple thermostat turns off the burner or switches it to maintain the flame when the required temperature is reached. If it becomes 3° less, then the fire lights up again.

- The flame heats the heat exchanger, and not the actual air in the room.

- For most models of modern gas heaters (convectors), air to support combustion comes from the street. And combustion products are removed there too. In this case, it is not a fan that is used, but a pipe in a pipe, the so-called. “coaxial duct”, which is discharged through a different opening.

These are closed-type gas heating convectors. However, there are also so-called open-type gas heating batteries that take air from the room and discharge combustion products into the general ventilation system. Such gas convectors are in great demand due to their easy installation: for heating you just need to connect the battery to the gas source.

Open type gas heating appliance

Fuel for operating a gas heating appliance

You should not think that gas heating radiators can only be placed in places with a natural gas supply from the main gas pipeline. In essence, the operating principle of a gas convector is to use such gas. But manufacturers also produce special adapters that allow the gas convector to operate on liquefied gas, i.e. connect the heating device to a regular cylinder.

Gas convectors using natural gas

Features of a gas heating convector: pros and cons

How convenient and profitable is heating with a gas battery? Does it have any disadvantages? First, let's look at their advantages:

- The cheapest way to heat both an apartment and a house. However, if gas convectors using bottled gas are used, heating costs are almost equal to those of an electric boiler. And less profitable than a solid fuel boiler or heat pump.

- The efficiency of such heating devices can reach up to 97%, i.e. they are economical.

- They can operate at any temperature, even at -50°C.

- There is no combustion of oxygen in the air of the room. Since air is used for combustion, which comes from outside the house.

- Service life - at least 20 years.

- Installation of a gas convector is simple and can be done with your own hands. See below for more details.

- Autonomy: you can easily heat several rooms of the house or just one room.

As with the operation of any gas equipment, batteries (convectors) must be used in compliance with strict safety measures, since the gas is explosive!

When using gas convectors using bottled gas, the saving effect from using such heating batteries is reduced to zero. Gas batteries are only useful when there is no electricity. At the same time, the process of replacing the cylinder with an interval of 1 to 4 days may seem quite tedious.

More cons:

- Gas radiator heating cannot be used to heat water.

- Quite limited thermal conductivity - 2-7 kW (for most models).

- Despite their rather beautiful appearance, they are quite large in size, so they are not easy to disguise.

- Since this equipment runs on gas, its installation and connection requires obtaining permission from a special gas service.

Installation recommendations

It is well known that the installation of a gas convector consuming main methane must be carried out by specialists from companies that have the appropriate permits. It is worth clarifying this somewhat generalized requirement: the issue is not installation, but connection to the gas supply network. This operation can indeed be performed by the above-mentioned workers in accordance with previously completed project documentation. This means that you can put the units in place with your own hands, but without connecting to the gas pipeline.

If you nevertheless decide to take bottled gas as an energy carrier, then the situation is simpler. Connecting propane heaters does not require any permits. However, it is strongly recommended to involve a specialist in this work, at least as a consultant. It will help you check the correctness and quality of the connections and carry out the first start-up of the unit.

Advice. When purchasing a heater, you should make sure that the length of the coaxial channel included with the product will be sufficient to pass through your wall.

Additionally read:

- Gas convectors AKOG

- Reviews about Convector heater ENSTO EPHBE10B

Before installing a gas convector, you need to make a round hole of the appropriate diameter in the wall. Next, attach the device to the wall or floor according to the operating instructions. In this case, in some heater models, the external temperature sensor with a capillary tube must be moved from the transport position to the working position. After this, all that remains is to connect the fuel supply line to the inlet pipe on the device.

Important. Floor and wall convectors must be supplied with gas at a certain pressure specified in the technical data sheet for the product. Therefore, the supply of fuel from the cylinders should be organized through a reducer configured for this pressure.

Installation Rules

Once the convector has been purchased, it can be installed. Before you do this, you will need to have a certain set of tools:

- drill;

- spatula;

- pipe cutter;

- wrenches and adjustable wrench;

- screwdrivers;

- perforator;

- gas tap;

- special silicone;

- self-tapping screws;

- dowels

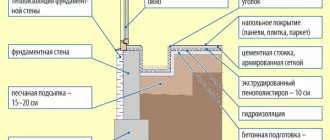

It is necessary to choose a place where it will be located. It is best to do this in accordance with GOST. According to it, installation must be carried out under a window. After this, you should prepare the room. That is, the surrounding space around the installation site must be covered. The installation is done according to this algorithm.

- It is necessary to determine the hole for the gas pipe to enter. It is necessary to leave a gap for the pipe and fitting.

- We make a through hole according to the size of the exhaust pipe using a hammer drill.

- We make holes for the fasteners on which the heater will be mounted, and hammer the dowels in there.

- We connect the device to the exhaust pipe and seal the joint with special silicone.

- We fix the heater to the wall using self-tapping screws.

- We seal all holes using foam to prevent cold air from entering the room.

Cost and quality of gas convector

Prices for gas convectors are determined depending on the manufacturer and power of the device. The cost of the device is also affected by its quality. Thus, a gas convector from one Ukrainian manufacturer, purchased last year for 900 hryvnia, functioned uninterruptedly for a year. There were a total of two such devices in use. One of them failed after working for 5 months. Further repair of the device turned out to be unprofitable. It was more expedient to buy a new gas convector than to repair the old one. The second such device worked for the entire heating season and was turned off. When the next heating season arrived, it was not possible to start the device. Its repair was also extremely unprofitable.

The same cannot be said about two Turkish-made gas convectors. These devices were purchased for 1000 and 1500 hryvnia (200 and 300 dollars at last year's exchange rate). Different in power, but from the same manufacturer, they successfully worked throughout the heating season, were turned off and put back into operation with the onset of cold weather without problems.

Thus, you see a striking difference in quality from different manufacturers.

Note!

- Cast iron electric heating radiators

Installation of a gas convector

Materials and tools:

- Gas convector

- Metal-plastic pipe with metal fittings

- Pipe cutter

- Wrench for tightening threaded connections of fittings

- Plumbing silicone

- Gas tap

- Hammer with crown blade

- Drill with drill

- crosshead screwdriver

- High temperature polyurethane foam

- High temperature silicone

- Plastic dowels and screws for them.

- The first and most important step is choosing a place to install the convector. According to GOST standards, the convector must be installed under the window. To be honest, I don’t know what this is connected with. And, in addition, I saw convectors installed at a great distance from the windows. Perhaps the principle is at work here: for money they will customize any GOST to suit you. We won't go into these details. We are interested in the process itself.

- So, having chosen a place for installation, you should try the convector on the place. This can be done using a tape measure with transferring dimensions, or simply by placing the convector against the wall and marking the holes.

- The next point is important - the gas inlet. If it is located at the bottom of the convector, sufficient distance should be left for connecting a pipe with a clamp fitting to it.

- After this, we use a perforator to punch a through hole in the wall along the diameter of the exhaust pipe. This is the most labor-intensive process. Get ready for dust in the room. Cover everything you can with plastic wrap or rags in advance.

- After this, drill holes for fasteners and hammer dowels into them.

- Insert the exhaust pipe into the hole in the convector. Treat the joint with high temperature silicone. Holding the convector in your hands, insert the pipe into the hole in the wall. Secure the convector to the dowels in the wall with self-tapping screws. This process is also quite difficult. The convector is quite heavy. In general, there are many opinions about the process I described. Here everyone acts as they see fit, but my recommendations have been tested many times in practice and are the most reliable. As a result of the work done, you will receive a convector screwed to the wall and an outlet pipe sticking out onto the street.

- Seal the gaps between the pipe and the wall with high-temperature foam.

- Place the special cap included in the kit on the end of the pipe. It serves to prevent the burner from being blown out by the wind. The cap is attached with self-tapping screws, also included in the kit.

The convector is installed, let's get started with the gas supply.

Required tools and installation diagram

The next step after purchasing the device is preparation for installation. Make sure you have the following materials and tools on hand:

- pipe cutter;

- drill;

- drill;

- adjustable wrench;

- spanners;

- screwdrivers;

- perforator;

- shoulder blade;

- silicone (plumbing, high temperature);

- screws and dowels;

- gas tap.

Now you can move on to the next stage - choosing the installation location.

It is important to act in accordance with GOST! Before you begin installation, take careful measurements, markings and “trying on” the convector. Please note that the room in which you plan to install the heater must be prepared. Remove furniture from the room or cover furnishings with polyethylene, since working with a hammer drill is a rather dusty business.

Installation of a gas convector is carried out according to the following scheme.

- Decide where the hole for the gas pipe entry will be.

- Make a hole in the wall with a hammer drill, focusing on the diameter of the future pipe. This stage is the most labor-intensive.

- The next step is to drill holes for the heater mounts and hammer in the dowels.

- Connect the convector to the exhaust pipe. Be sure to seal the joint with silicone that can withstand high temperatures.

- The heater is attached to the wall with self-tapping screws. At this stage you will need help, because the unit has an impressive weight.

- The final stage of installation is to fill holes and cracks with foam to prevent cold air from entering the room.

We bring to your attention an educational video on editing.

Gas supply to the convector

- GOST requires that the pipe leading to the convector run along the street. We will act in accordance with it. If the gas pipe has a pre-installed threaded connection, then screw a gas valve onto it, shutting off the gas supply to the convector. If the pipe does not have such a branch, you will need to make one. Such work should be carried out by a gas welder. Preferably a specialist from Gorgaz or a similar office.

- When the gas tap is installed, a metal-plastic pipe should be routed to the convector. Using a tape measure, we calculate the length of the pipe and determine the presence of fittings.

- We purchase pipe and fittings. When purchasing pipes and fittings, find out if these pipes and fittings have a certificate of conformity for this type of work.

- Now lay the pipe, attach it to clips every meter. To install the clips, drill holes in the wall.

- When installing fittings, lubricate the pipe and fitting with silicone. This will provide additional sealing. In addition, silicone will serve as a lubricant and will facilitate pipe installation.

The result of the work should be a convector hanging on the wall, an exhaust pipe with a hood and a gas pipe laid and connected to the convector.

Gas connection

Friends, at this stage it is important to be extremely careful! Let's say that you do not have the skills to work with gas appliances - then to perform the following work it is better to turn to specialists.

Installation of a gas heater to a gas supply source proceeds according to the following algorithm.

- Let's imagine that there is a special threaded outlet on the gas pipe. Then you just need to screw a gas valve onto this pipe. If there is no special allotment, then one will need to be made!

- The next step is to bring the gas pipe to the convector and connect them using a fitting. This process cannot be rushed.

- Secure the supplied pipe with special clips. The distance between them is 1 meter. To do this, you will need to drill holes on the outside wall of the building.

- Treat fittings and pipe joints with silicone to ensure a tight seal.

- Be sure to call your gas service representative to ensure proper installation and connections.

Test run of a gas convector

- Before starting, you must open the gas tap and go over all fitting joints and threaded connections with a brush moistened with an aqueous solution of soap or shampoo. If you notice bubbles forming, turn off the faucet immediately and fix the leak.

- After checking the joints, start the convector. To do this, hold down the gas button for about a minute, allowing the gas to pass through the pipes and enter the combustion chamber.

- Click on the piezo igniter. The spark will ignite the gas and a cheerful, blue flame will flare up in the firebox.

- Adjust the operation of the convector to achieve a comfortable temperature.

During the first hours of operation, an unpleasant odor of burning oil may be present. The convector is new, the combustion chamber is burning out. If the smell does not disappear for a long time, you should turn off the gas and carefully inspect the junction of the exhaust pipe with the outlet of the convector.

Attention: It is advisable to carry out all of the above work by a specialist. After all, installing a convector yourself deprives you of the right to warranty repair of the device. In addition, the convector must be accepted by Gorgaz or another similar service. There must be a sidebar project. And all the necessary permits and conclusions of the commission for acceptance of the device into operation.

However, with this knowledge, you will be able to control the installation process of the gas convector by specialists from the operating office.

The connection of the gas convector, as well as the installation, must be carried out by certified specialists who have experience working specifically with gas equipment, or by the gas service itself.

Installation and startup of a gas convector must be carried out with permission, as well as in accordance with the project agreed with the gas service and the manufacturer’s instructions.

Before starting up a gas convector, a representative of a specialized organization is obliged to check and adjust the equipment, as well as conduct training and instruct the consumer.

- Before starting, it is necessary to check the gas pipeline and gas valve for tightness and absence of leaks, make sure that the safety system and automatic control of the convector are in working order.

- If the security system suddenly turns off the device, you should not try to ignite the heater earlier than after 3 minutes.

- It is not recommended to change the factory settings of the device.

Converting the convector to another type of gas must also be carried out by gas workers or an authorized company that provides gas equipment connection services.

When switching off for the summer, it is necessary to shut off the gas supply to the device.

Violation of the rules for installing and starting a gas convector can lead to a gas leak and even cost a human life.

Installation of a heating device

On the wall where it is planned to mount the convector, make a hole corresponding to the parameters of this model. The further actions of the masters are as follows.

- A coaxial telescopic pipe is inserted into the prepared tunnel.

- The wall must be made of material that is not subject to combustion. If the interior is made of wood, drywall or other combustible materials, it must be insulated.

- The pipe is installed perpendicular to the convector with a rigid fastening.

- The back of the device is screwed to it.

- The convector is attached to the wall.

- The telescopic pipe is positioned so that only the fungus is visible from the outside.

- The remaining cracks are sealed with heat-resistant foam and cement mortar.

It is necessary to ensure that emissions from the convector do not fall on footpaths, since the escaping gases have a high temperature.

Preparation for use

Before starting to operate the air heater, you need to check:

- fastening of the gas burner manifold;

- tightness of gas pipeline connections;

- accuracy of thermostat operation;

- security system in the room and the device itself.

Attention! Never attempt to reset factory programmed settings. They are designed for convector operation on natural gas. To carry out the necessary adjustments (for liquefied gas or other types of fuel), contact a specialized service center.

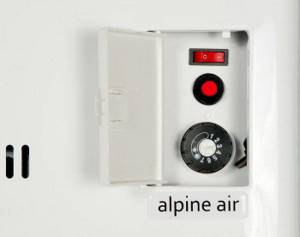

Switching procedure

To ignite the pilot burner, you need to move the main regulator from the “OFF” to “ON” position. Press and hold the control knob for a few seconds until the pilot light comes on. Check to see if the wick lights after you release the control knob. If the light goes out, repeat the operation. To further understand how to turn on and operate the device, watch the video.

Set the temperature control to the desired position - from 13 to 38 degrees. Each of the seven values corresponds to a specific indoor air heating temperature. The gas convector can be left in standby mode when only the wick is lit and the main flame is extinguished. To turn off the device, just press the “OFF” button.

Attention! After the end of the heating season, the gas supply to the device should be completely shut off. To do this, close the valve on the gas pipeline.

Precautionary measures

The use of household appliances requires compliance with safety precautions. Be careful and listen to the advice of manufacturers:

- You cannot use a convector that has a damaged viewing window;

- if the device goes out spontaneously, do not re-ignite it earlier than after 3 minutes;

- To prevent burns, the convector is protected with a protective grille.

It is strictly prohibited:

- dry things on a running appliance;

- turn the device on and off for children and people with limited legal capacity;

- operate the device with the outer casing removed;

- repair the device yourself;

- place flammable objects at a distance of less than 1 m from it;

- leave it on if signs of a gas leak are detected.

If there is an unpleasant odor in your home, take immediate precautions:

- turn off the gas supply;

- extinguish all sources of open fire;

- do not touch switches or mobile phones;

- ventilate the room;

- urgently call the emergency gas service;

- Contact a gas convector service center.

Features of use

The operating principle of the device is based on the physical phenomenon of convection. Streams of cold air penetrate through the lower grilles, heat up from the heat exchanger and rise to the ceiling. Constantly circulating air quickly heats the room. When installing convectors, there is no need to install heating pipes in the apartment.

Several convectors are installed in a large house. A main gas pipeline must be connected to each of them. One device heats a room with a volume of up to 130 cubic meters. It maintains a given temperature regime with a minimum gas flow rate - from 0.22 to 0.48 m3/hour, depending on the model. The efficiency of the devices reaches 88%. In comparison, gas boilers operate with efficiency of up to 98%. The performance is improved for devices with fans, but at the same time the noise level in the room increases. When heating and cooling, steel convectors emit a characteristic crackling sound (the metal expands or contracts). Cast iron casings do not produce any sounds.

Gas appliances come in two types: wall-mounted and floor-mounted, fireplace type. They are fastened in the same way, have a common principle of operation, but the latter are larger in size.

Features of choice

When choosing a gas convector model, you must take into account its operating conditions. Among others, the area of the room and the required temperature for heating should be highlighted. The described heating devices have additional features, including:

- circulation method;

- thermal power;

- drawing method;

- installation option;

- heat exchanger material.

As for the first factor, circulation may be absent or provided by a fan heater

Convectors can be wall-mounted or floor-mounted, sometimes this is important if the room area is limited. The heat exchanger can be based on cast iron or steel

As for the installation location, wall convectors are more practical. They take up little space and are usually installed near the window, creating a thermal curtain between the cold and warm zones. However, such devices should be quite light so as not to create additional load on the wall. Such devices are limited in thermal performance, which does not exceed 10 kW.

If it is necessary to heat a larger area, floor-standing equipment is selected, which usually has large dimensions and significant weight. The cost of wall-mounted and floor-standing units is approximately the same with similar capacities.

LPG convector

The air heater can be converted to operate on bottled (liquefied) gas. For this purpose, special nozzles and a gearbox are purchased. If there are several such convectors in the house, then a special room will be equipped on the outside of the house for storing propane cylinders.

A comfortable temperature in the house is achieved using the built-in thermostat. It prevents the air in the room from overheating, while gas is consumed more efficiently.

Important! Gas combustion products will not enter the airspace of the room if they are vented into the chimney.

Before buying an air heater, calculate the required power to heat the volume of the room in which you plan to install it. Be sure to take into account the height of the ceilings, otherwise the device may not meet your expectations. The best location for convectors is under the windows. In this case, cold air does not have time to penetrate into the room.

Sometimes these devices are used as an additional source of heat in severe frosts. Approximately 0.095 kg of liquefied gas is burned per 1 kW of heat transfer power per day. Keep in mind that a cast iron heat exchanger in a gas convector lasts much longer than a steel one. Its service life can last up to 50 years, but such a device costs much more. Manufacturers provide a factory warranty of up to 5 years. Make sure that when purchasing the device in the store, all documents are filled out, including the warranty card.

Pros and cons of individual gas heating

Please note that the quality of the device, as well as the duration of its successful operation, directly depend on the price of the gas convector. Is it possible to buy a cheap unit and connect it in the house? Yes, but keep in mind that an inexpensive model will last you no more than a year. At the same time, it is unlikely that such a convector will be repaired if it fails.

Let's consider the advantages of gas heating appliances, based on the fact that you did not save money when purchasing and purchased a high-quality unit.

Advantages of gas convectors:

- the room heats up quickly;

- economical use of fuel;

- the device can be easily installed indoors by yourself;

- reasonable price;

- a gas convector does not require installation of a heating system;

- does not destroy oxygen in the room;

- the heater can be mounted to a gas cylinder;

- the device operates in autonomous mode;

- If the convector operates on the principle of natural circulation, then it does not depend on the power supply.

Important: gas convectors with a closed combustion chamber can be installed safely in any room, including the bedroom.

Disadvantages of gas convectors:

- in order to correctly install a gas convector with a connection to a centralized system, it is necessary to obtain permission from the relevant municipal authorities;

- the connection diagram for a gas convector requires punching a through hole in the external wall of the building, in the place where the device is planned to be installed;

- impressive size;

- if you plan to use several gas convectors for heating an apartment or house, then each of them will have to be individually supplied with gas from outside the building.

Important: experts insist on choosing models with a built-in fan. They are more efficient than similar devices with natural convection.

Distinctive features

Convectors operating on liquefied gas have a horizontal or vertical chimney. Vertical systems have more power, but have installation limitations - they cannot be installed everywhere. Models with a fan provide accelerated air circulation in the room.

Installation of the device follows the same principle as in the case of natural gas, but it is necessary to provide an additional hole to connect it to a cylinder located outside the room.

Important! During the first hours of operation of the convector, an unpleasant odor is felt in the room. This burns the lubricating oil. Ventilate the room and the air will be refreshed. To start the device, the operations described above are carried out sequentially. The only difference is that instead of a tap on the gas pipe, they open a valve on the propane tank. An important distinctive feature of liquefied gas appliances is the ability to heat rooms located away from gas pipelines.

How to fix the problem

Malfunctions in the operation of the devices occur very rarely. The main reasons for unstable operation of the device:

- burner contamination;

- clogging of jets;

- dampening of contacts.

Experts advise carrying out preventive measures at least once every 24 months. Craftsmen carry out the necessary repair work:

- weld the damaged body;

- restore the automation system;

- switch the device to liquefied gas.

Attention! Only a certified technician from the gas industry or service center can carry out repairs on gas convectors. The main task of the specialist is to eliminate the cause of the problem. To do this, replace the damaged node or block. Such repairs are done quickly at a low cost. At the final stage, the operation of the equipment is tested in different modes and the functioning of security systems is checked. Experts inspect the gas pipeline to prevent gas leaks.

Main characteristics of the device

Gas convectors have many advantages that allow them to be used in residential buildings, factories and shops. This:

- moderate cost;

- can be turned on only in one room if several devices are installed in the house;

- the device provides significant gas savings;

- uniform distribution of warm air;

- ease of operation;

- reliability and long service life;

- can be used during a power outage;

- no installation of additional sources required;

- affordable installation and maintenance of the convector.

When choosing a heating system for a new apartment, consider installing gas convectors using natural or liquefied gas. Let your home be warm and cozy.

How to turn on a gas convector: basic operating rules

From the author: Hello, friends! Home air heaters create warmth and comfort in the house when there is frost and cold wind outside. After installing a new heating system, apartment owners often do not know how to turn on the gas convector. Of course, you can study the instructions, but the best way is to see everything with your own eyes using a video or get information from experienced users. Additionally, you need to familiarize yourself with the safety precautions and operating rules of the device.

Principle of operation

The Nobo electric convector operates based on air circulation through the device. It has a heating element inside and a thermostat outside to control temperature conditions. Entering the convector, the air exits in the form of a directed heated flow, heating the room. This ensures fast and uniform heating of the air. Thanks to the use of a special alloy for the manufacture of the heating element, it begins to work for heating almost immediately after connection.

The convector can be installed in different rooms and near any surfaces, since fire safety is guaranteed due to the low temperature of the housing. At the same time, with the small size of the heating element, the convector has sufficient power to heat any area.

Thus, this type of heater guarantees efficient operation, reliability, as well as cost-effectiveness and ease of operation.

Switching on and operating modes

Modern convectors have thermostats that regulate the temperature of the heating element and, accordingly, the exhaust air. Electronic installations carry out control with high accuracy (up to 0.1ºС) to achieve a comfortable microclimate. This is suitable for objects where there is a need to maintain a certain temperature regime. You can also adjust the temperature automatically, which also increases efficiency.

The process of turning on an electric convector manually

simple enough. There is a switch on it that supplies voltage to the heating element. In high power convectors there may be several heating elements, and in this case the switch provides several possible positions. Accordingly, when the switch is set to the first position, one heating element will be turned on, in the second - two, and so on until full power. Thus, a high-precision thermostat allows temperature control over large ranges.

In addition to manual, there is the possibility of remote

convector control. Modern technologies allow you to use the Internet and a smartphone to remotely control the heater.

The Norwegian company Nobo offers two systems for remote control of heaters: Orion 700 and Energy Control. Using these systems, you can control convectors (and other electrical appliances) through special receivers, similar to a “smart home”.

This allows the user to remotely control the heating of, for example, a country house so that it does not freeze in cold weather.

The convector operates from the Orion 700 system and the GSM module using SMS commands. A regular SIM card is pre-installed into the module, to which a command is sent from any mobile device, and the module, in turn, communicates with the Orion 700 control unit and configures the operation of the heater via a radio signal.