Instructions

Before starting the boiler, make sure it is installed correctly. The boiler mounting location must comply with fire safety requirements; it must be located at a distance of at least 20 cm from gas appliances and flammable objects. There must be a distance of at least 30 cm between the boiler and the wall. The boiler

near a window to prevent exposure to precipitation. There must be an electrical access point close to the device. The boiler should be positioned evenly on the wall, without distortion. Correct any deficiencies noted before connecting the boiler to the utilities.

Connect the gas boiler

to the water supply, having first removed the plugs from the pipes. Install a special strainer at the inlet, complementing it with a ball valve. Ball valves must be installed on all boiler pipes.

To connect gas equipment to the appropriate gas pipes, invite gas service employees. Connecting on your own is fraught with trouble. Make sure that a gas valve is installed in front of the boiler to shut off gas access if necessary.

Connect a chimney (coaxial pipe with a diameter of 100 mm) to the boiler and lead the pipe outside through a hole specially made in the wall.

Proceed with the final part of the startup procedure. Turn off the boiler

from the mains and slowly fill the system with water.

Make sure that the boiler

does not leak water and gas, and then connect

the boiler

to the mains. Set the thermostat button to the maximum setting. The boiler should automatically ignite using the mode switch. Please note that the very first start-up of a new boiler should still be entrusted to specialists who have a special certificate for performing work of this kind.

Sources:

- Gas boiler installation

- starting a gas boiler

In order for life in the house to be comfortable, it is necessary to connect various communication systems. For example, there is a need to install

heating

system .

This is especially important in the Russian winter with severe frosts and winds. However, it is not enough to simply design this system

; heating must be started.

Instructions

Starting the heating

is an extremely important process that consists of certain actions that must be performed in a strict order. This is the only way that all new purchased equipment will give positive results.

First, fill

heating

system with water.

To do this, take the feed pump and direct it to the return line. In the warm season, the water should be cold; in the cold months, when the temperature drops below 1 degree, the liquid must be heated to +20. This will prevent pipes from freezing. Do not forget to close all drain valves and taps and open the vents, which should be tightened immediately after the first water appears. However, after waiting a few minutes, open them again to release the air. After this, leave heating

system alone for several hours.

Proceed to pressure testing the heating

.

This process means checking all equipment for strength and tightness. This is the only way to detect leaks. To perform pressure testing, increase the pressure in the heating

using compressed air or a column of water. Maintain this pressure for 10-15 minutes, then set the operating pressure. Monitor all changes using a pressure gauge.

- Instructions for preparing for launch

- Features of filling the system with water

- How to remove air pockets?

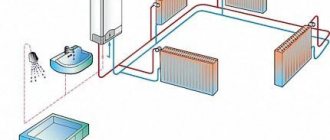

To ensure the operation of the heating system, various heating equipment is used, but the most popular are double-circuit gas boilers. They are not only economical, but also very reliable, provide excellent heating of the entire house, and are able to uninterruptedly supply hot water to the consumer. In order for the gas boiler to work normally, it is necessary to organize its initial start-up, during which the system is filled with water and all air pockets from the radiators and pump are completely removed. For batteries, Mayevsky taps are used to make it more convenient to remove air from the system. They unscrew until water comes out.

To remove air from the pump, the front panel of the boiler is removed and the required adjustments are made.

The air is removed quickly, after which the equipment itself begins to work.

Types of fireplaces with a water circuit

Based on the material used, furnaces are divided into:

Long-burning fireplace stoves with a water circuit, lined with brick, will perfectly complement the interior. It should be taken into account that during the masonry process the heat exchanger is installed. Then the connection to the water circuit is made.

This is what a metal fireplace stove with a water jacket might look like

Metal samples are less attractive and very expensive if you order the device from reliable manufacturers. Devices made of steel or cast iron can heat a room using their surface. But they are not installed in rooms. For this purpose, separate rooms are used with subsequent connection to radiators.

Combined fireplace stoves consist of a metal firebox. The outside is faced with brick. It uses a fireproof glass fuel door. Such fireplace stoves with a water circuit are often used for summer cottages (We recommend studying the material about an effective fireplace for a country house).

Combined stove-fireplace with a metal firebox. External lining of the device with bricks

The fireplace combines the aesthetic properties of a regular fireplace and an excellent heating device. It will significantly reduce heating costs and improve comfortable living in the house.

Owners of country houses where there is no gas main most often install a water heating boiler. Its main advantage is the use of inexpensive raw materials. To correctly install the system, you need to understand the operating principle, design features, installation and operation. Even before purchasing, it is advisable to find out what advantages and disadvantages the unit has.

Instructions for preparing for launch

To use gas, you need to follow simple instructions. The first launch is carried out when the installation of equipment and piping are completed, and the correct installation is checked. All fastenings and location of the boiler must be made in accordance with fire safety rules. A certain distance must be maintained from the boiler to the wall. Which one you need to look at in the instructions for the boiler. For some models of gas boilers, this condition is not necessary. You need to make sure that there are no flammable objects or materials nearby. The boiler should not be placed near windows, as its operation will be disrupted. Great attention must be paid to ensuring that the body is mounted smoothly and there are no distortions.

After this, the equipment is connected to the cold water supply, all plugs are removed from the pipes, and a special filter with a ball valve is installed at the inlet. This helps protect the system from contaminants that could cause breakdowns. Ball valves must be installed on each pipe used for piping.

When solving the problem of how to start a boiler, great attention must be paid to the installation of gas pipes. In this case, it is not recommended to carry out the work yourself; for this purpose, an employee of the relevant service is invited who makes such a connection, sealing, and, if necessary, installs a gas meter.

What else needs to be connected before launch? It is necessary to install a separate power line for the boiler. The equipment is supplied with an electrical cable and plug; during installation, it is necessary to ensure that there is an outlet next to the boiler; it is better to separate it from the others. Next, a connection is made to the chimney pipe, its draft and performance are checked. The pipe itself must go outside; the conditions for its installation depend on what type of chimney is chosen. The last part of the preparation for starting is to disconnect the boiler from the electricity so that it can be filled with cold water. Next, the absence of leaks is checked, the thermostat is turned on to the maximum value so that the mode switch automatically lights up.

Return to contents

Range

Zvezda-Strela Trading House LLC supplies the market with boilers designed for installation in premises for a wide variety of purposes. In addition to household products, this manufacturer also produces industrial models of similar equipment. If desired, today you can also purchase Keber gas boilers, both single- and double-circuit. The first type of equipment is intended exclusively for space heating. Double-circuit boilers are additionally used to heat water.

Who releases

The Keber boilers are produced by the Russian company, which is part of the Tactical Missile Arms OJSC corporation. This company was registered in 2004. That is, it has been operating on the market for about 15 years. This company exclusively supplies heating equipment to specialized stores. Products from this manufacturer have received very good reviews from consumers. Heating units from Zvezda-Strela Trading House LLC are actually very popular among the population.

In addition to the boilers themselves, this manufacturer supplies the market with components for them. It will be absolutely easy for owners of country houses to find spare parts for Keber equipment if necessary.

Components of a solid fuel heating boiler

Firebox

The firebox is a fuel combustion chamber and at the same time a heat exchanger. The firebox includes: a fuel supply portal, an area for removing volatile combustion products, a grate, ash collection containers and air supply openings.

In the firebox, as the fuel burns, its walls heat up, and the water around the firebox in the “water jacket” of the boiler heats up.

Note: For a pyrolysis (gas generator) boiler, an additional firebox compartment is provided for burning wood gas.

Water jacket

In a solid fuel boiler, the firebox has double walls, between which there is a coolant. This is a water jacket . As the fuel burns in the firebox, the coolant in the water jacket heats up, causing convection (heat) currents to form, lifting the hot coolant to the upper part of the jacket. From the water jacket, the hot coolant enters the heat pipe. Having passed through the heating system and given off heat to the house, the cooled coolant returns to the water jacket through the lower pipe. To speed up the circulation of water in the system, special circulation pumps are used.

Smoke extraction system

As a result of burning solid fuel in the boiler, a large amount of smoke is generated. A mandatory element of a solid fuel boiler is a smoke removal system . Smoke removal is carried out by heat-insulated pipes leading from the boiler to the street. Some boilers are equipped with forced ventilation units.

Features of filling the system with water

To turn on the heating system, you must first fill it with coolant, i.e. water, which, after heating, will begin to circulate. A feature of modern equipment is that special manual recharge is not needed. During the first launch, you need to carefully check everything so that further work proceeds smoothly and accurately. Not only a pump is built into the boiler body, but a special tap near the pipe for supplying cold water to the system. When cold water is supplied, noise is heard, this is quite normal, there is no need to panic.

During filling, you need to monitor the pressure in the system; special sensors and pressure gauges are provided for this. Modern equipment necessarily has such additional elements, so there is no need to purchase them separately. As the gas boiler fills, the mark on the sensor rises. When it reaches 1.5-2 atmospheres, it is necessary to stop the supply of cold water, i.e., filling is completed. The pressure parameter may be different, since everything depends on the equipment manufacturer and its requirements for the operating pressure in the system. But this is not the final filling; replenishment is necessary as the heating system is freed from air pockets.

Return to contents

Boiler automation

Of course, modern heating equipment should not only be economical and easy to use, but also safe. After all, natural gas is a fuel that, unfortunately, explodes. In this regard, Keber boilers have also earned relatively good reviews from consumers.

LLC Trading House Zvezda-Strela equips boilers supplied to the market with time-tested Arbat automatics. In total, the units of this brand provide five levels of protection. So, for example, in the event of a drop in pressure in the gas pipeline, Keber boilers automatically turn off.

If desired, consumers can also order from the manufacturer of this equipment its equipment with even more reliable and expensive Italian automation EUROSIT. Units of this type can be operated practically without any intervention from home owners or production personnel.

Specifications

Characteristics of boilers

In some models, the temperature is regulated by a traction gearbox. The automation kit includes a supply fan and an operating mode controller.

Characteristics of coal-gas boilers:

Gas units consume from 2 to 6 m3/hour depending on productivity. The combustion products removed contain carbon monoxide (no more than 119 mg/m3) and nitrogen oxide (less than 240 mg/m3).

The mass of the boilers ranges from 140 to 270 kg.

Weight of some models:

The weight of the boiler depends on the dimensions, the number of plates in the heat exchanger and productivity.

Varieties

Today, several types are involved in the production of Zhytomyr boilers - parapet (wall-mounted) and floor-mounted. In turn, floor products also have divisions into single-circuit and double-circuit.

Floor-standing

If a gas boiler is needed only for heating purposes, attention should be paid to single-circuit models. They are unpretentious, practical and economical

The equipment of the single-circuit boiler “Zhitomir” primarily involves imported components. Thanks to them, the device can be turned on and off if necessary. And if there is a need, in addition to heating, to have hot water in direct access, you will need to choose from dual-circuit options.

In terms of their technical characteristics, floor-standing boilers mostly have the following similarities:

- the maximum temperature limit is +90 degrees;

- efficiency is 92%;

- gas pressure – 635 Pa.

But when choosing a model you definitely like, you need to consider its specific characteristics and capabilities.

Wall mounted

The same separation as in floor-standing boilers is also present in wall-mounted boiler models. They can also be single-circuit or double-circuit. The efficiency of all devices is the same. The same applies to gas pressure.

But it’s still worth considering their characteristics p>

- the power of parapet boilers must be no less than 5 kW and no more than 20 kW;

- the coolant in the device is no more than 17.5 liters;

- depending on the chosen model, natural gas consumption is considered; according to the standard - 0.56–1.67 cubic meters per hour;

- profitability due to imported automation.

For its part, the manufacturer provides a wide range of boilers to choose from, but the Zhitomir-3 KS-G-020 SN model is still in great demand. This device differs from its counterparts not only in terms of availability in terms of price, but also has clear technical data. The design of the device is designed in a minimalist style; the appearance of the boiler looks like a cabinet. It should only be placed on the floor. On the front of the model there is a small door behind which hides a button for turning on and adjusting the device settings. In the same part there is a control window, with the help of which you need to monitor the performance indicators of the boiler.

The basic package includes a housing, which also includes heat exchanger elements. On the outside, it is covered with heat-insulating material and a casing made of steel. The burners are presented in two pieces: one is the main one, and the second is the ignition one. The package includes a gas duct and an automatic gas valve, which is responsible for safety during operation.

Consumer Opinion

Despite the fact that Keber boilers are one of the cheapest brands of heating equipment in Russia today, they have earned quite good reviews from consumers. Owners of houses and apartments attribute, first of all, their impeccable operation to the poles of these units. For the first few years, boilers of this brand usually do not require any special maintenance at all. Some problems with their operation may begin to arise for owners of country houses, judging by reviews, only approximately 5-7 years after installation. At this time, it is recommended to clean the previously purchased Keber boiler from limescale. This is due primarily to the fact that the water in Russia in most regions, unfortunately, is quite hard.

Reviews about Keber gas boilers on the Internet are therefore mostly positive. The only thing is that sometimes owners of country houses still criticize the work of domestic automation of these models. It happens that after several years of operation, Keber boilers, for example, deteriorate in the operation of the switching function. The burners in them light up only some time after pressing the “Start” button.

Models

Let's look at the most popular models of Vulcan gas boilers.

Volcano AOGV 10 E

This unit has one circuit and, accordingly, is intended exclusively for heating; the chimney here is traditional. The boiler is used in heating systems with forced or natural circulation of water and other types of coolant.

As already mentioned, there is no second circuit; small-volume “indirect” boilers are used to prepare hot water.

The Vulcan AOGV 10 E boiler is connected to the gas mains, but it can also operate from liquefied gas. The control system here is mechanical, with a similar protection system. The heat exchanger is made of steel with additional corrosion protection.

Vulcan AOGV 12 VE

This model is the best option for supplying heat to houses and other premises with an area of up to 120 m². The power of the device is 12 kW. The boiler is a double-circuit boiler, and the package includes Italian automatic equipment, as is common in similar units from alternative brands. A traditional chimney is used to remove combustion products.

The operating temperature of the coolant varies from +50 to +90 degrees, the volume of boiler water is 19.3 liters.

Volcano AOGV 9 VPE

This model is parapet. Vulcan differs from traditional boilers in that for their operation there is no need for traditional chimneys. Instead, double chimneys of the “pipe-in-pipe” (coaxial) system are used, exiting from the rear and extending behind the wall.

The gas boiler Vulcan AOGV 9 VPE is double-circuit and non-volatile. It can be installed in new households, where conventional chimneys are rarely built.

Externally, the unit looks exactly the same as its counterparts with open combustion chambers. The heat exchanger of the device is made of durable steel, which is protected from corrosion by means of a special coating. Italian mechanical automation is responsible for controlling the temperature in the pipes and the second circuit.

Vulcan AOGV 16 PE

This model is considered one of the most powerful parapet-type units. The device includes a closed combustion chamber; combustion products are discharged through a coaxial chimney. Air is also taken in through it for the burner to operate.

The power of the device is 16 kW, which is enough to supply heat to rooms with an area of up to 160 m². As in all other models, the heat exchanger here is made of steel and has a special coating that protects against corrosion.

The control system is mechanical, it ensures switching between circuits and maintaining a given temperature regime in the heating system.

Ignition is carried out by a piezoelectric igniter. The device does not need to be connected to the electrical network, so the Vulcan AOGV 16 PE boiler can be used in buildings not connected to electrical mains.

Parapet gas boiler Vulcan AOGV-16PE

Summarizing all of the above, it is worth saying once again that the Vulcan gas boiler deserves attention. This is a high-quality heating device with good technical characteristics. This is confirmed by many positive user reviews.

Gas boilers "Keber": instructions

Heating equipment of this brand, like any other similar one, can only be installed by licensed specialists. Before starting up, all connections in the boiler must be checked for leaks.

The instructions for turning on the Keber ignition head are as follows:

As you can see, the operating instructions for Keber gas boilers are quite simple. If there is no flame after performing the steps described above, all four operations should simply be repeated. In this case, you need to increase the time you hold the handle.

Gas-burners

The efficiency and excellent performance characteristics of boilers of this brand are ensured primarily by the fact that the manufacturer has provided very high-quality Danko burners in their design.

These elements:

- ensure stable combustion of fuel;

- have high anti-corrosion properties;

- ensure the most complete combustion of fuel.

The use of high-quality gas burners allowed the manufacturer, among other things, to reduce the size of the fuel chambers in Keber boilers. The efficient operation of Danko in terms of fuel combustion is, in fact, what made this equipment so economical.

How to troubleshoot a Keber gas boiler

Explain to me how to fix this problem. A Keber KSG floor-standing boiler with an Arbat automation unit was installed at the dacha. If you ignite, the main burner device begins to burn intensely, but after 16-20 seconds it turns off. Repeated action does not bring changes. Has anyone encountered this? First check the functionality of the draft sensor and thermocouple. Perform circuit contact diagnostics. Carefully disassemble the pilot burner and clean it. Adjust the pilot burner to a lower gas pressure. Apparently, the draft has decreased, so the pilot burner does not have enough air during ignition of the main burner. The torch smokes thoroughly and the burner always burns and does not go out. The temperature does not rise above the set level, while the torch continues to burn. A lot of burning. Local gas workers said that the draft was weak. How to fix it? Looks like there's not enough air. You must perform complete prevention. Dismantle the burner device, clean and rinse the burner and jets. The heat exchanger needs to be cleaned from the outside. Can you tell me why the boiler apparatus smokes? What needs to be done to resolve this issue? Apparently, there is a weakening of draft in the firebox. We advise you to clean the smoke exhaust duct. What to do, tell me, if the KSGV Keber boiler does not want to light up? I hold the control handle, press the ignition button, then hold it for about 10 minutes, start pressing, and the device goes out. The igniter tube may be dirty. In this situation, complete maintenance is necessary. Another problem is oxidation of the terminals on the traction sensor. It is recommended to remove the terminals and clean them of oxides. Malfunction of the KSG 12.5 heating boiler with Arbat automation. When you press the ignition button, there is no gas flow to the burner mechanism. What could be the reason? When you press the button, gas fuel flows only into the igniter; it is not allowed to enter the main burner. We have completed the installation of this device. The cycle of transition from the wick to the main burner is a little annoying. Three pops are heard all the time. It should be? Apparently, it is necessary to adjust the automation according to the gas pressure. I use the same device complete with an automatic Sit 820 Nova, which turns off when the temperature rises to approximately 70 degrees. Tell me, how can I fix this problem? Apparently, the traction sensor is turned on. You should have your chimney inspected. A similar unit was installed at the dacha. That week the heating stopped at fifty degrees, but the flame continues to burn continuously. What could be the reason? We assume that the gas supply tube from the automatic control system on the burner has become clogged, as well as the burner nozzle. The house has a Keber 10 gas boiler equipped with Eurosit 630 automation. A week ago it had a breakdown. It began to go out when a wind flow hit the ignition burner. Just recently I replaced the thermocouple, but there was no change. How to fix it? At the moment the main burner starts, this serves to reduce the fuel input to the ignition device, that is, the automation is triggered. You definitely need to increase the fuel supply to the pilot burner. This may occur periodically due to low pressure in the heating system. Another reason may be a weakening of the chimney draft if it is installed incorrectly. Tell me what the problem is if this unit stops, especially if there is a strong wind and bad weather outside. How should I fix the problem? When the pilot burner is turned on, the EMC is forced to operate within twenty seconds. When the ignition device goes out, the EMC valve stops operating after 10 seconds, 0 You will hear a click. Once upon a time a Keber 12.5 boiler was installed at the dacha. The house is small, the space is no more than thirty square meters. As if the consumption is small, and the heating of the water does not exceed 55 degrees. The house has 2 batteries for 12 sections. I can’t figure out how to raise the heating temperature? Installing a circulation pump may help you. Often there is a decrease in pressure in the gas line. Why does the boiler often overheat during use? A significant reason is the lack of circulation in the heating circuit. It is also possible that the filters are clogged or there is an excess of air in the heating system. Yesterday there was a problem. If we close the cold water tap and start opening the hot water supply, all the water disappears from the heating circuit. Why does this happen? Most likely, the heating system make-up valve is not functioning properly. It passes water through both lines. When there is coolant pressure in the system, then passage in the opposite direction cannot happen. What is the reason that the device makes noise, gurgles, and sometimes howls loudly and pops loudly? The liquid in the system is fairly saturated with oxygen. During the heating process, air evaporates, which is why noise is heard. If the unit is not configured correctly, the gas valve or bypass valve howls. Popping noises during startup indicate a problem with the ignition. In October of that year, I installed a Keber 20 floor-standing gas boiler. About a few months later, a failure occurred. I'm trying to adjust the temperature cycle and it won't hold it. Explain what could be? Apparently, the automation failed, and when the temperature rises by 70 degrees, the injectors turn off. It is necessary to adjust the automation for proper operation. Another factor may be that the wrong power of the device is selected in proportion to the heating area. I launched the same device in the middle of this year. It operates on liquefied gas. Almost nine cubic meters were spent in three months. Currently, there is a lot of carbon deposits inside the device, and the main burner also smokes. What is the reason for this phenomenon? Too many soot deposits in the firebox indicate that the gas burner is not adjusted, and as a result, the fuel does not burn to its fullest extent. An unsatisfactory type of gas mixture is also likely. To prevent the burner from smoking, it is necessary to systematically clean it using water. The same device is connected to the system. At the moment of start, the gas burner ignites and immediately goes out. I believe the igniter is faulty. Can you help me fix this problem? It is necessary to check whether the sound of the ignition mechanism sparking is heard when the ignition cable is disconnected. If there is no sound, it is recommended to change the ignition transformer. If there is sound, replace the ignition electrode or ignition burner. Just yesterday a problem emerged with the Keber KS-GV 12.5 boiler. Water flows from it. He was in work for no more than 3 weeks. Perhaps someone can tell me why the water is dripping? Apparently it is dripping due to high pressure in the heating system. Probably the walls of the heat exchanger are burning out. Water hammer also causes leaks in the boiler. At the dacha I would like to implement the connection of this device. Explain what is the standard gas supply pressure (methane/propane) for such models? In this type of device, the nominal gas supply pressure for methane/propane is 150.0/300.0 Pascal. This device was put into operation. Not long ago there was a malfunction. The device turns on, but does not heat in heating mode. What can happen? Perhaps there is an air lock in the batteries or a lot of scale in the heat exchanger. It needs to be washed. We use this device indoors. Until yesterday evening I worked without any questions. But now a problem has arisen with him. It overheats intensely. How to fix this problem? There was probably a blockage with scale, which caused the duct to become clogged. You need to clean the device. Just yesterday a problem with the boiler was discovered. Was in use for only 2 weeks. Then he abruptly stopped raising the adjusted temperature. Maybe someone can tell me why this happened? Your system has lower gas pressure than needed. It is necessary to inspect the gas valve. Most likely, there is too much lubricant inside. The extra one needs to be removed. Explain how you can pump up the expansion tank? The expander tank can be pumped up with any automobile pump to the pressure required according to the instructions. Most often, the approximate interval is from 0.8 to 1.5 bar. Before pumping up the tank, according to the regulations, you need to drain the water from the boiler appliance. This is done through the drain fitting or through the water tap, shutting off the flow of hot water supply. The heating boiler Keber 31.5 cannot start. As long as you keep the start button pressed, the burner lights up. But if you press the key, the device goes out. Explain the cause of the problem? The thermoelectric converter or gas valve is probably faulty. There is also a decrease in gas pressure in the supply pipeline. In some cases, there is a lack of voltage on the electronic board. Remind us what operations need to be carried out in order to change liquefied gas to natural gas? To do this, it is recommended to replace the nozzles of the main burner device. Next, change the modulator supply voltage. And finally set the range of minimum and maximum pressure. How does a safety valve work in a heating system? This valve, adjusted to the operating pressure, protects the heating system. The safety valve must not be used to empty the system. The pressure in the heating system constantly rises. I reduce the pressure of the expansion tank to 2.1-2.3 atm. Can the heating system water come from hot water pipes? The increase in heating system pressure can be explained by the following main reasons. Incorrect pressure settings for the expansion tank. The make-up valve is leaking. There is a problem. The start is very difficult. The pilot burner lights, but the main burner does not fire. I just can’t understand what is the reason? The ignition mechanism may be faulty. We recommend checking the boiler and cleaning the ignition unit. Can anyone please help me troubleshoot the chimney duct? Soon it will be three days since there has been a reverse draft, due to which smoke began to pour straight into the room. I made the chimney myself. It consists of a metal pipe. Perhaps something was wrong. The main factor may be an incorrectly executed chimney design. The pipe may become contaminated with combustion products, which significantly limits its capabilities. In addition, it is recommended to check the ventilation in residential areas.

How to remove air pockets?

Simply connecting the system by filling it with water is not enough. It will not work or its effectiveness will become extremely low. To carry out a full first start-up of the equipment, it is necessary to bleed all the air that has accumulated in it from the system. A modern gas boiler may have a special system for automatically releasing air when filling, but the efficiency of such systems is low. This means that manual bleeding of the main and other systems is required during connection. Only after this can you start.

Removing air pockets during connection is carried out not only in the circulation pump, boiler, but also in all heating radiators. In this case, it is recommended to start the process with radiators. Especially for this purpose, they are equipped with so-called Mayevsky taps, which you simply need to open by placing a basin under them. At first, a slight whistle will be heard - this is the air gradually leaving the system. If the plugs are removed, water begins to flow. If the batteries are free of air masses, then the taps must be closed. This simplest procedure is carried out with each radiator; it must be checked and cleared of plugs. When air has been removed from all radiators, the pressure gauge needle will be set to the desired value. Before turning on the gas boiler, you need to add coolant to the system, that is, feed it with liquid.

Next, you need to completely remove all air pockets from the circulation pump, which requires disassembling some parts of the boiler. This work is simple, you just need to remove the front panel of the boiler, and then find a cylindrical part that has a lid in the middle of the body, it has a slot for a screwdriver. The boiler must be started, that is, power must be supplied, and the heating regulator must be set to the required operating position. After this, a faint hum will be heard - this will start the circulation pump. You can hear gurgling and other sounds. Using a screwdriver, you need to slightly unscrew the lid of the found part; this should be done until water flows out. As soon as the liquid begins to seep out, the lid must be screwed back on. This procedure needs to be carried out 2-3 times, after which the air pockets will completely leave the system, the sounds and gurgling will disappear, and the pump will begin to operate quietly. Immediately after this, the electrical ignition of the equipment will work, and the gas boiler will begin to operate independently.

The pressure in the heating system must be equalized by adding water to the required level. The system gradually warms up and begins to enter normal operating mode. Connection and first start-up for any heating equipment is a complex and demanding process. How effective the heating will be depends on proper preparation, startup, and adjustment of the system.

In the last article we talked about it, but besides this, an important point is its launch. In order to perform the first start-up of the boiler, it is not necessary to invite specialists from the service center. Judge for yourself, this condition under which a brand new boiler is put under “free” warranty service is not worth a penny - anyway, in the future, if a breakdown occurs, you will have to pay for both spare parts and the work of the technician.

So what kind of free warranty repair can we talk about? Moreover, for the first start of the boiler

They will also charge you a fee, a considerable one at that, motivating it for commissioning work. Don't want to waste money? Then read on and learn how to start the boiler yourself and debug the heating system, especially since it’s not difficult.

The initial stage, which involves the first start-up of the boiler, is filling it with water. I think you can definitely cope with this task without outside help. We look under the boiler, where all the communication pipes are connected, and look for something resembling a faucet there - it can be made in the form of a lamb we are familiar with, or it can be a flag or simply a rotating pin. In any case, it is difficult not to recognize it, but if something happens, its location can be determined by looking at the instructions for the boiler equipment.

Found it? We slowly open it, fill the system with water and wait for the pressure indicator on the boiler to reach 3.0 atm, and while the system is filling up, we go and check all the pipes and batteries for leaks. And along the way, we immediately eliminate them - tighten the nuts and close the open Mayevsky taps.

After the pressure in the system has reached 3 atm, we turn off the make-up tap, go through all the batteries one by one and use the Mayevsky tap to bleed the air from them. We return to the boiler again and add water to the system until the pressure indicator on the boiler shows 2-2.5 atm.

Well, the system is dialed up, you can directly start the gas or electric boiler, in principle, there is no difference in the process of starting them. To do this, you will have to disassemble the boiler a little - don’t be afraid, we won’t go anywhere where something can be broken. Our task is to get to the circulation pump - it is it, or rather the air accumulated in it, that is the reason for the boiler equipment not turning on when first started.

The location of this pump is easy to see - it is a cylinder, located with its end facing us, in the center of which there is a wide screw with a slot for a screwdriver. This is exactly the screw we need.

Found this stumbling block? Then you can turn on the boiler and set the necessary levers to the operating position - from this moment the first start of the boiler

. Immediately after the boiler receives its energy supply, the circulation pump will turn on and the electronics will make futile attempts to turn on the rest of the equipment. It is at this moment that there is no need to rush; slowly unscrew the central screw of the circulation pump and release the air from it.

As soon as water flows from under the screw, quickly close it and calmly watch the noisy operation of the boiler. Now the electronic gas supply valve will open, the electronic ignition will work and the boiler will start. It will gurgle, grunt, and make some strange sounds, but this is normal - the boiler is simply expelling air that is stuck in some places from the heating system. The design of the boiler equipment includes a so-called expansion tank, which is equipped with an automatic air release valve - it is through this that the remaining air is removed.

After a few minutes, when the operation of the boiler has stabilized and the gurgling sounds have subsided, we check the pressure in the system and, if necessary, bring its value to 2-2.5 atm by opening the water supply tap to the system. At first, while the heating operation is just getting better, the system can be refilled with water several times - you will have to periodically check the pressure gauge readings and, if necessary, replenish the volume of water in the system.

Well, we figured out how to start the heating boiler, the equipment is working normally, the batteries are starting to get warm - it’s time to start debugging the operation of the entire system.

Gas boiler Keber - a reliable Russian heater

LLC Trading House Zvezda-Strela has been producing heating equipment under the Keber brand since 2006. A responsible approach to the development of each model has made this technology very popular in the domestic market. Today, many experts emphasize the special adaptability of Keber gas boilers to the very difficult Russian conditions.

Units produced in our country have always been considered more adapted to the climatic difficulties of the far north. And in this context, the Keber gas boiler can rightfully be considered one of the leading developments of Russian engineers.

The equipment supplied to the domestic market under the Keber brand is designed for complete heat supply to premises for various purposes. Some units have a double-circuit design, which makes it possible not only to maintain the optimal temperature in a house or apartment, but also to provide residents with hot water year-round.

Natural gas as a universal fuel is an ideal solution for the Russian consumer. And that is why the manufacturing company has focused its attention on this category of heating products.

Each Keber gas boiler is a tandem of reliability and durability. The minimum service life of the system is 15 years. Naturally, with proper maintenance and careful treatment of the main components of the structure, the actual service life is significantly extended. Keber equipment meets Russian quality standards, which is an additional guarantee of its long service life.

The boilers are equipped with special burners that ensure stable heating of the coolant. We are talking about a special Danko mechanism, consisting of a so-called pipe nozzle. The latter has high anti-corrosion properties. The special design of Danko ensures the most efficient combustion of fuel, even if the flame height reaches seven centimeters. It is important to note that the Danko nozzle is a certified design, which in terms of quality is fully consistent with foreign-made analogues.

How to set up the heating system after starting the boiler

To set up the heating system, we will need to carry out minor manipulations with the control valves. The fact is that almost all schemes have one small drawback - the batteries last from the boiler, as a rule, do not have enough thermal energy. It simply does not reach there in the required volume and we will need to eliminate this deficiency by evenly distributing the supply of hot water between all heating devices.

This is not difficult - the control taps of the first two or three batteries need to be tightened a little. If you go from the boiler, then the tap of the first battery is turned halfway, the second a little less, and the third even less. Here you will have to experiment - it may take several days to achieve uniform heating of all batteries. But this no longer matters, because in general the heating system works normally, and the house is warm.

This is how, without any effort, the boiler is started for the first time and the heating system is set up. As you can see, there is nothing complicated about it, and it is not worth the money that service center representatives charge for it. Better spend it on purchasing an electronic room temperature control system - this programmer will reduce the energy consumption of a wall-mounted heating boiler!

Yes, yes, this is exactly what you thought... A wonderful series of computer (and later not only...) books, Simple and understandable, which was very useful to many.

Your new home has taken good care of you all winter. Saved from bad weather, protected from precipitation, wind, cold... But the sun warmed up, and the winter snowdrifts had long since disappeared. May. It's time to turn off the heating in the house. But as? Here in the boiler room there is so much stuff that can be opened, closed, switched, turned off... It’s almost like an airline pilot :-) What to do? Should we quickly look for the phone numbers of “those guys” who installed the boiler and call them for help? Oh no. This is not our choice. If part of your life is your own home, and if your home is not part of a cottage community, you will have to be an electrician and a plumber and many many others... Well, if you are not a “pro,” then at least be a “teapot”, but one that you can manage yourself with your own home. So let's get back to our problem. Summer is knocking on the door. It's hot outside. It is necessary to turn off the heating in a private house. But as? First of all, we determine what kind of boiler we have in our house. This can be done, for example, by simply looking at the documents that exist for this boiler. If the boiler is double-circuit, then everything will be quite simple - you just need to switch it to the “summer” position. What exactly needs to be pressed and turned for this - read the instructions for your boiler - everything is written there simply and clearly. (For reference. A double-circuit boiler works something like this - the coolant circulates in a circle through the pipes and radiators and “looks” at the temperature of the coolant - if it becomes less than what the owner (or the temperature sensor) set, it ignites the gas and heats it. If the owner of a double-circuit boiler turned on hot water - the boiler “stops” caring about the temperature of the coolant in your heating system and devotes all its efforts to only one task - heating cold water in order to make it hot and give it to the owner. Well, that is, if we take it to the extreme - if It’s frosty outside, and the owner of a double-circuit boiler is actively draining hot water from the tap hour after hour - he risks freezing the whole family. Priority of hot water supply - this is the clever name for this behavior of a double-circuit boiler.) It’s a completely different matter for those owners who have a single-circuit boiler. I’ll tell you a terrible secret - a single-circuit boiler has only one circuit :-) Inside a single-circuit boiler there is simply no separate circuit that would be occupied only with heating and which could simply be turned off for the summer. But how is it possible that a single-circuit boiler, having inside itself only one coolant circulation circuit, still manages (and is much more effective than a double-circuit boiler, with its misanthropic “priority of hot water supply”) to drive hot coolant both through the radiator system and through the hot water supply system ? It's simple. Yes, inside a single-circuit boiler there is one single circuit, but outside the boiler, with a system of external pipes, valves, circulation pumps, etc., from this single circuit you can create as many different circuits as you like. Well, that's just it. Imagine: here the coolant, heated by the flame of the boiler, runs through the pipes - along the only circle that a single-circuit boiler has. The hot one ran up the pipes, ran around all the heating radiators, gave all its heat to the house, the cold one ran back into its single-circuit boiler, warmed up, ran up again... He was bored. He runs and runs in the same circle... How to “pinch off” a piece of this flow circulating through the heating system, in order to not only heat the house but also heat the water, with this “pinch off flow”? Yes, it’s clear how. Very simple. We cut the tee into the heating circuit. That's it, now the coolant, having reached the tee, will split into two directions - one flow, as before, will run through the heating radiators - giving off its heat to the house, and the second flow will run into the hot water supply system. Ugh. Well, we finally got to the hot water supply system of a single-circuit boiler. But in fact, there is almost nothing to tell about it... A hefty barrel into which cold water flows through pipes, and inside this barrel there is a “spiral-coil” pipe through which runs the part of the hot coolant flow that we have “pinched off”. That's all. The hot coolant, running again and again inside a barrel of water, each time gives up and gives up its heat to this water - trying to heat the water to the temperature of the coolant. This “magic barrel” in the hot water supply system is called an indirect heating boiler (or, more simply, “water-water boiler”). And that’s all, the heating system, the hot water supply system... The boiler, the pipes, the radiators, and now there’s this “water-to-water” boiler. The whole system, or what? Well, almost... Here, at home with you and me, how can I say this..., well, “they are not small.” It’s usually hard for the coolant to rush around these endless and, as a rule, long circles - until you run from the boiler room to the farthest room... and you still have to run back to the boiler to “warm up”... but you don’t have the strength... Here. To help the coolant move, electric circulation pumps are installed into the pipes. I turned on such a pump and it “like a taxi” moves the coolant through the pipe. Such a circulation pump is located in the same heating circuit (where, until the tee was cut in, the coolant was running alone) and such a circulation pump is located in the pipe of that “pinched off” flow that runs in the boiler. In addition, in these heating and hot water supply systems there are “safety groups”, expansion tanks, many many (often depends on the flight of fancy of those guys who installed these systems in the house :-) taps, and something else that is not mentioned this topic... So true. So far everything is elementary simple. A single-circuit boiler works and heats the house and heats the water and, most importantly, now we already know how it does it. Having thought a little, we understand that there is no way to turn off the boiler itself for the summer - it is necessary to heat the coolant in the “pinched off” flow, otherwise the water in the boiler cannot be heated. This means that in order to turn off only the circulation of coolant through the pipes and radiators of the heating system for the summer, you just need to turn off their valve - so look for and turn off such a valve on the main thick pipe going up from the boiler - look somewhere above the “pinch off into the boiler” "tee), while the valve that you will find standing immediately after the "pinch off tee, but not on the main thick pipe going up, but on its side branch (this valve determines how much or little to "pinch off" into the boiler) - on the contrary, We need to open it completely for the summer. All. Now the circulation through your heating circuit is turned off and the house is no longer heated. The circulation along the hot water supply circuit is completely open, which means there is hot water in the house in the summer. Once you have determined where and what kind of valve you have installed and once you have switched from winter to summer, don’t be lazy, write it down in detail in your own “house book” - believe me, you will use it more than once..

There are some important nuances of the operation of a single-circuit boiler on a usually “short” hot water supply circuit, but I’ll talk about this in my next post.

There are a huge number of options for heating residential and non-residential premises. In particular, gas boilers are also used due to their reasonable price, high level of safety, and large number of types. However, the rules must be followed. Especially know how to turn on a gas boiler the first time you use it.

Keber boilers: possible malfunctions

Of course, there is no engineering design that is perfect in all respects. And if we are talking about domestic units, then the consumer even more needs to be prepared for a variety of “surprises”. This trend does not bypass heating equipment either. For Keber gas boilers, malfunctions are quite common. That is why it makes sense to list the main ones:

Of course, it will not be possible to list all possible problems that arise during the operation of Keber boilers in one article. However, we were able to consider the most common ones. At the same time, we strongly recommend not to do any repairs yourself if you are not confident in your own skills and professionalism.

Source