The gas heating system chosen for heating a home has a large number of parameters. Choosing the right boiler among the offered models, taking into account the climatic characteristics of the area where you live, is quite a complex engineering task. First of all, it is necessary to distinguish among the selected equipment groups that are fundamentally different from each other in parameters. Among them, two large groups of boilers stand out:

…

- With an open combustion chamber,

- With a closed combustion chamber.

Each of these groups has its own pros and cons, and certain requirements for placement.

Let's look at the advantages and disadvantages of boilers with a closed combustion chamber.

Pros and cons of boilers with a closed combustion chamber

Such boilers are very convenient equipment that require a minimum of attention from the owner during everyday use.

Pros:

- To install a wall-mounted or floor-standing boiler, a separate room is not required. They are compact, aesthetic, easy to maintain, and inexpensive. They can be installed in the bathroom, kitchen, even in the hallway. An area of several square meters (and even less for wall-mounted boilers) is quite enough to place equipment that will provide heat in the house and hot water in the taps.

This quality is very valuable for small apartments and houses where living space is limited. Naturally, there are minimum fire safety requirements for premises for placing such boilers.

…

- A vertical chimney is not needed to remove exhaust gases. A horizontal coaxial pipe is sufficient. The boiler is equipped with a fan powered by electricity. The fan creates forced draft, removes combustion results and brings in fresh air.

Air is taken from the street from the room through a coaxial pipe, the exhaust gases are removed by a fan to the street through the same pipe and, at the same time, begin to cool in the pipe. Therefore, no additional ventilation equipment is required. Using boilers of this type is absolutely safe.

- Due to the intake of combustion air from the street, boilers with a closed system have a higher efficiency and use fuel more economically than open systems.

Note! The only drawback of boilers with a closed system is their dependence on electricity, since ventilation and ignition of the burner flame work from it.

If there is a power outage or malfunction, there is a danger of quickly freezing the house if it is severely cold outside. There are two ways to get rid of this drawback:

- provide for the possibility of heating with wood during a lack of electricity using a stove or fireplace, which can quickly heat up a small room;

- buy a gas generator or UPS;

Varieties

Single-circuit gas units have many varieties, among which everyone is sure to find one that is perfect for a particular home.

Depending on whether the boiler is connected to electricity or not, there are two types of boilers.

- Energy independent devices. Experts call a boiler selected for a private building and operating according to an independent circuit an ideal device. The lights often go out because the wires may break, and emergencies constantly occur at substations. Gas is supplied to the house more consistently; outages can only occur as planned - and then in the summer, and not in the winter season of the year. Therefore, devices independent of electricity are in great demand among the population.

- Energy-dependent products. A boiler that is connected to the network has a number of advantages - better fuel combustion (it can be in products with any combustion chambers), fast ignition, comfortable and easy control, which can be done using a remote control. You can select electric or manual ignition.

Depending on the type of combustion chambers, two more types are distinguished.

- The most uncomplicated gas devices for heating a house are open-type combustion chambers (with a special burner). The flame burns due to the normal oxygen flow that comes from the room. The device is placed in rooms with excellent ventilation - this could even be an ordinary boiler room with a window. These products can safely function without electricity.

- A gas boiler with a closed combustion chamber (also called turbocharged) has such advantages as: temperature control, which ensures gas savings;

- smooth ignition and adjustment of the flame force reduces the serious load on the device;

- high efficiency;

- there is no need to equip a separate room to accommodate a turbocharged boiler;

- turbocharged products are the most efficient, but they can be very noisy, since they have built-in fans that are responsible for weathering combustion products and providing a flow of clean air.

According to the efficiency of fuel combustion, gas boilers are divided into two more types.

- Condensation type devices. The efficiency of condensing boilers can reach parameters of 90% and even much more. There may be enough heat left in the combustion products, which is best transferred to the home heating system. It is for this process that condensation products were invented, which allow almost all of the heat wave created by the burner to be taken into the home heating system. They are used only when connected to the mains.

- Convection products. Traditional floor-standing boilers with one circuit are produced according to the convection principle - there is only a heat exchanger and the burner itself. Their efficiency is not very high, like other units, but they are much easier to operate and they cost less.

Depending on the types of heat exchanger, boilers are divided into several types. The duration of operation of the boiler directly depends on the type of its heat exchanger.

It, in turn, can be made from any modern materials.

- Copper structures are extremely rare to see. Despite its high thermal conductivity, copper is an expensive material that wears out quite quickly in serious devices with high power.

- Gas boilers with a cast iron heat exchanger design last as long as possible, which is why they are quite popular. Cast iron is not afraid of corrosion, acid attacks and temperature shocks. The service life of high-quality cast iron products can be even 30 years. Cast iron has only one drawback - it is fragility, which will have to be taken into account when choosing and to prevent temperature differences between supplies of more than +45 degrees. After purchasing a cast iron gas product and bringing it to the site, experts advise carefully checking the heat exchanger for cracks.

- Steel structures are crack resistant and much lighter in weight. But they can quickly rust or burn out, which will reduce their service life to 15 years.

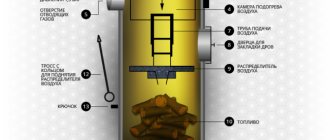

Design of a coaxial chimney

For the normal functioning of a boiler with a closed combustion system, a coaxial chimney is required. Such a chimney consists of pipes of different diameters inserted into one another, and is called a “pipe within a pipe.” Through a large pipe, fresh air enters the boiler from the street, and through a pipe of a smaller diameter, exhaust gases are discharged to the street. Hot gases, surrounded by low-temperature outdoor air, cool quickly.

A successful engineering solution made it possible to avoid installing additional ventilation in the room where the boiler is located. Since air is not taken from the room for fuel combustion, and exhaust gases are immediately removed, combustion products do not spoil the atmosphere in the house, and efficient combustion of fuel is ensured.

…

Criterias of choice

The efficiency of the heating system depends, first of all, on the operational characteristics of the boiler, therefore, when choosing a heat generator, it is necessary to evaluate first of all:

- Thermal power of the device. It is generally accepted that 1 kW is enough to heat an area of 10 m2, with a ceiling height of 2.8 m. 15 - 20% should be added to the resulting value.

- Installation efficiency. It is this parameter that determines the fuel consumption and the efficiency of the heating system. Modern floor-standing gas boilers have an efficiency of 90 to 97%;

- The heating temperature of running water in the DHW circuit is usually in the range of 50 - 55 C;

- The maximum possible coolant temperature in the heating circuit. Most models heat the coolant to 85 - 90 C;

- Combustion chamber type. If there is a closed combustion chamber, it is necessary to use a coaxial chimney;

Number of heat exchangers. Boilers with a bithermal heat exchanger are cheaper, but there is a high probability of scale formation and tube clogging. In addition, if such a heat exchanger fails, its restoration is almost impossible;

- Unit automation level;

- Possibility of connecting additional temperature sensors.

Since double-circuit floor-standing boilers are not cheap, before buying a unit, it is advisable to get specialist advice and read reviews from owners of such equipment. Below is a rating of the most popular models, based on user reviews and expert statements.

Heat exchangers

The main element of heating boilers are heat exchangers. It is the heat exchangers that are designed to transfer energy from the burned fuel to the coolant. Naturally, metal is used to perform this function:

- Steel – Steel heat exchangers are easy to manufacture and therefore inexpensive. However, steel rusts, so the service life of steel products is short and the weight is high. The efficiency is inferior to all other materials. Steel products are preferred by domestic boiler manufacturers;

- Copper is a very convenient material for a heat exchanger, it does not corrode, heats up and cools down quickly. Copper heat exchangers are most often used in imported boilers;

- Cast iron is also not susceptible to corrosion, but due to its fragility and insufficiently careful use, cracks appear on it. Cracks can also appear due to uneven heating during scale formation during long-term operation.

Optimal operation of a gas boiler Find out how to install autonomous gas heating in an apartment, how big the savings are when installing a gas boiler

IMPORTANT! Mandatory flushing of the coolant. If the carrier is water, then once a year. If antifreeze, then once every two years.

Place for installing a gas boiler

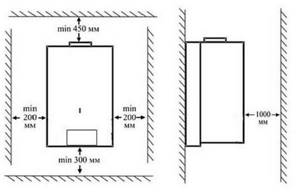

If we talk specifically about apartments, then gas boilers are installed in them, mostly in the kitchens. There are all the necessary communications: running water, gas, a window and an exhaust hood. All that remains is to determine a suitable location for the boiler. For this installation, wall-mounted (mounted) boilers are used. They are installed on several hooks fixed to the walls (usually included in the kit).

As for installation in other areas of the apartment or house, as a rule, none of them meet the requirements. For example, in the bathroom there is no window with natural light, the corridor is usually not suitable in size - there is not enough tolerance from the corners or to the opposite wall, there is usually no ventilation at all or it is insufficient. The problem with storage rooms is the same - there is no ventilation and windows, there is not enough volume.

The exact distance from walls and other objects is indicated in the boiler operating instructions

If there is a staircase in the house to the second floor, the owners often want to place the boiler under the stairs or in this room. In terms of volume, it usually passes, but in terms of ventilation it will have to be very powerful - the volume is considered to be at two levels and it is necessary to ensure its threefold exchange. This will require several pipes (three or more) of a very large cross-section (at least 200 mm).

Once you have decided on the location for installing the gas boiler, all that remains is to find a place for it. It is selected based on the type of boiler (wall-mounted or floor-standing) and the manufacturer’s requirements. The technical data sheet usually specifies in detail the distances from the wall on the right/left, the installation height relative to the floor and ceiling, as well as the distance from the front surface to the opposite wall. These may vary from manufacturer to manufacturer, so it is worth reading the manual carefully.

Installation standards according to SNiP

In the absence of such recommendations in the equipment passport, the installation of a gas boiler can be carried out according to the recommendations of SNiP 42-101-2003 p 6.23. It says:

- Gas boilers can be installed on fireproof walls at a distance of at least 2 cm from it.

- If the wall is fire-resistant or combustible (wooden, frame, etc.), it must be protected with fireproof material. This can be a three-millimeter sheet of asbestos, on top of which a sheet of metal is fixed. Plastering with a layer of at least 3 cm is also considered as protection. In this case, the boiler must be hung at a distance of 3 cm. The dimensions of the fireproof material must exceed the dimensions of the boiler by 10 cm from the sides and bottom, and from the top must be 70 cm larger.

Questions may arise regarding asbestos sheet: today it is recognized as a material hazardous to health. It can be replaced with a layer of mineral wool cardboard. And also keep in mind that ceramic tiles are also considered a fireproof base, even if they are laid on wooden walls: a layer of glue and ceramics provide the required fire resistance.

A gas boiler can be hung on wooden walls only if there is a fireproof substrate

The installation of a gas boiler relative to the side walls is also regulated. If the wall is non-flammable, the distance cannot be less than 10 cm. For flammable and non-combustible walls, this distance is 25 cm (without additional protection).

If a floor-standing gas boiler is installed, the base must be non-flammable. A non-flammable stand is made on the wooden floor. It must provide a fire resistance rating of 0.75 hours (45 minutes). These are either bricks laid on spoons (1/4 brick size) or thick ceramic floor tiles laid on top of an asbestos sheet fixed to a metal sheet. The dimensions of the non-combustible base are 10 cm larger than the dimensions of the installed boiler.

Single-circuit and double-circuit boilers

Single-circuit models have one function - heating the house. The double-circuit model supplies the household with hot water in addition to heating. The main advantage of single-circuit boilers is their significantly lower price. You can purchase additional equipment to obtain hot water, but in this case the cost of additional equipment and the boiler, the complexity of installation, balances or even exceeds the cost of double-circuit boilers. Additional equipment is included in the harness and becomes part of it.

Single-circuit boiler:

Pros:

- Independence from water pressure;

- Constant supply of hot water;

- There are no restrictions on the amount of hot water consumed in all taps.

Double-circuit boiler

Pros:

- The cost of a double-circuit one is lower than a single-circuit one with a boiler;

- Takes up very little space, compact;

- There is no need to purchase additional equipment;

- Easy installation;

- Economical - only the amount of water required is heated.

Minuses:

- Inconsistency of hot water temperature. When the valve opens, the water begins to heat up. Since the water is running, heating occurs gradually from cold to hot. The water temperature is affected by the pressure in the water pipes. The lower it is, the colder the water flows from the tap;

- The water temperature immediately drops if several taps are open at the same time;

- The farther the tap is from the boiler, the longer you have to wait for the water to get hot. Consequently, flowing water is simply poured down the drain until it is heated to the desired temperature;

- The second circuit is turned on only when the water flow is significant. Otherwise, the second circuit may not turn on with a small stream. Because of this feature of dual-circuit modules, it is difficult to save water.

Devices with a storage tank of up to 60 liters or a layer-by-layer heating boiler do not have this disadvantage. They supply water at a constant temperature regardless of the pressure in the water supply.

What are wall-mounted double-circuit gas boilers?

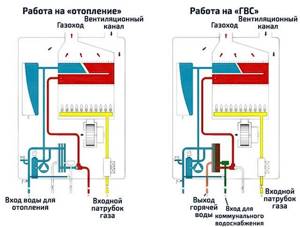

Gas mounted double-circuit models with the same dimensions and heating technical characteristics combine the functionality of two devices at once - the boiler itself and a flow-through (less often storage) water heater. The coolant from the heating circuit in dual-circuit models does not mix with sanitary water from the hot water supply (DHW) circuit.

Another important point is the number of people living in the house, or rather the number of points of simultaneous consumption of hot water. Most dual-circuit models operate on the principle of DHW priority, i.e. when the consumption point opens, the heating circuit is preheated. Less often, usually in more expensive models, where the distribution of performance is implemented using a three-way valve, the heating of the heating circuit does not stop completely, but the performance is still reduced.

In practice, this means that if you use several hot water consumption points at the same time, the performance of the DHW circuit may not be enough, not to mention the heating circuit. Therefore, the total number of rooms with hot water consumption points (bathroom, guest bathroom, kitchen, etc.) should not exceed three.

Design and principle of operation

Double-circuit wall-mounted boilers differ from single-circuit boilers only in the presence of an additional heat exchanger and devices for distributing productivity between the circuits. The technical device may vary from model to model, but the standard design is simple and clear: a burner to which gas is supplied and its igniters → a primary heat exchanger, inside of which there is a heating circuit coolant and a secondary heat exchanger, inside of which sanitary water from the DHW circuit circulates → product removal system combustion into the chimney.

All well-known and common models are already equipped from the factory with all the elements and components necessary for the heating system: expansion tank, circulation pump, automatic air vent, safety valve, pressure gauge, set of sensors, etc. This means that for a standard heating scheme it is enough to just connect the supply and return lines to the boiler, as well as a water source for the DHW circuit (for example, a water supply).

To clearly understand the operating principle of dual-circuit models, let’s consider the functionality of each circuit separately:

- heating - a basic circuit in which the coolant continuously circulates, heating up in the heat exchanger and releasing heat through radiators in heated rooms;

- water heating - activated only when the hot water consumption point is opened, redirects all or a certain part of the heating circuit coolant to water heating.

After closing the consumption tap, the boiler switches back to the heating circuit and heats it up if the coolant has cooled down, or goes into standby mode (background heating) if everything is fine with the temperature.

Traditional double-circuit boilers are always characterized by a delay in the supply of already heated water (from 5 to 15 seconds), but there are models without such a delay, with a built-in boiler, operating on the principle of a storage heater, which we will talk about when describing the selection criteria. In any case, there is also a delay in the supply of hot water, independent of the boiler, associated with the length of the pipeline between the boiler and the point of consumption, where the cooled water is located.

The device is based on the example of the famous dual-circuit BAXI ECO-4s 24F: compact classic layout, optimal materials, all modules are placed down for convenience.

Floor standing boilers

Additional space may be required to accommodate floor-standing boilers, as they have greater power and are larger in size than wall-mounted ones.

Floor-standing boilers, advantages:

- The heat exchangers in them are made of cast iron, which increases the weight of the product, but has a long service life - up to 30 years. Other inexpensive parts are easy to replace during operation;

- A chimney with increased draft is not required.

Minuses:

- Due to the cast iron heat exchanger, it takes up a lot of space on the floor, since the weight and dimensions do not allow the boiler to be hung on the wall;

- It is necessary to purchase and install an expansion tank, the heater is connected;

Operating principle of gas boilers

All existing models can be divided into two main groups:

Convection boilers have a simpler design and low cost. You can find such models everywhere. Heating of the coolant occurs solely due to the influence of the open flame of the burner. In this case, most of the thermal energy is transferred to the heat exchanger, but some (sometimes quite significant) part of it is lost along with the exhaust gas combustion products. The most important drawback is that the latent energy of water vapor that is part of the smoke being removed is not used.

Convection boiler Gaz 6000 W

The advantages of such models include a fairly simple design, the ability to remove combustion products due to natural draft (if there are chimneys that meet the requirements).

The second group is convection gas boilers. Their peculiarity is as follows - convection equipment cannot use the energy of water vapor removed with smoke. It is this drawback that allows the condensation circuit of a gas boiler to be eliminated.

Gas boiler Bosch Gaz 3000 W ZW 24-2KE

The essence of the operation of such devices is that combustion products, which have a sufficiently high temperature, pass through a special heat exchanger, into which water flows from the return of the heating system. Provided that the temperature of such a coolant is below the dew point for water (about 40 degrees), steam begins to condense on the outer walls of the heat exchanger. In this case, a sufficiently large amount of thermal energy is released (condensation energy), which provides preheating of the coolant.

But there are also some negative aspects that characterize condensation technology:

To operate in condensation mode, it is necessary to ensure a return temperature of no more than 30-35 degrees. Therefore, such units are mainly used for low-temperature (no more than 50 degrees) heating systems. Also, boilers of this type can be used in systems with high heat transfer, for example, in underfloor heating systems. Boilers in which a condensing heat exchanger is used to provide hot water supply have proven themselves quite well.

Maintenance and setting the optimal operating mode of the boiler can only be performed by a competent specialist. In the regions, there are not too many craftsmen who can understand condensing boilers. Therefore, servicing the device can be quite expensive.

In addition, the very cost of equipment of this class is high; it will not be possible to classify such equipment as a budget option even with a strong desire.

But is it really worth giving up the opportunity to save more than 30% of energy because of such shortcomings? It is precisely these savings and the short payback period of condensing boilers that make their purchase expedient from an economic point of view.

Boilers with open and closed combustion chamber

Such boilers differ significantly in their technical capabilities, and the conditions for their use also differ.

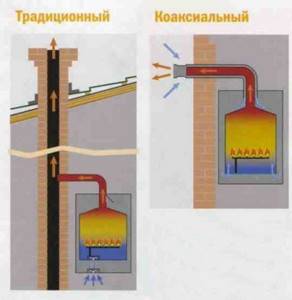

Atmospheric boilers are equipped with an open combustion chamber. The air necessary for gas combustion enters the chamber directly from the room. Therefore, when choosing such boilers, it is necessary to strictly monitor compliance with regulatory requirements for air exchange in the room. The room must have an effective ventilation system; in addition, removal of combustion products in natural draft mode is possible only with the installation of high chimneys (smoke removal above the level of the building roof).

Wall-mounted gas boiler Logamax U054-24K atmospheric double-circuit

The advantages of such boilers include a fairly reasonable cost and simplicity of design. But it is worth considering that the efficiency of such units is most often not very high (compared to more advanced models).

The turbocharged wall-mounted double-circuit boiler is equipped with a closed combustion chamber. Such units are connected mainly to coaxial chimneys, which provide not only the removal of combustion products, but also the supply of fresh air into the combustion chamber from the street. For this purpose, a low-power electric fan is built into the boiler design.

Gas boiler FERROLI DOMIproject F24 wall-mounted double-circuit turbocharged

The main advantage of a turbocharged boiler is increased productivity, while the efficiency of the device reaches 90-95%. This makes it possible to reduce fuel consumption. But it is worth considering that the cost of such boilers is quite high.

Organizing the chimney of a floor-standing gas boiler

To implement chimneys in floor-standing gas boilers, traditional and coaxial smokers are used. The choice of a specific type depends on the combustion chamber used and where the air is supplied to support the combustion process.

Features of the construction of a traditional chimney for a floor-standing gas boiler

As a rule, the construction of a traditional smoker is necessary if the boiler has an atmospheric burner with an open combustion chamber. The presence of natural draft here is a prerequisite for ensuring the normal operation of a floor-standing gas boiler.

Basic requirements for installing traditional smokers:

- the diameter of the outlet pipe must correspond to the diameter at the top point of the chimney;

- the straight section of the pipe from the boiler to the first bend must be at least 1 m;

- to ensure fire safety, at least 50 cm of the wall in all directions from the chimney is treated with non-combustible sealing;

- the distance from the axis of the boiler to the axis of the smoker coming out should be no more than 2 m;

- the outer chimney pipe must be completely covered with thermal insulation;

- the presence of a point for cleaning the chimney and discharging condensate;

- The material of the smoker pipe is stainless, acid-resistant steel.

Features of installing a coaxial chimney for a floor-standing gas boiler

Coaxial chimneys are used in cases where the air supply to the burner is forced - by a fan. In this case, artificial draft of flue gases is provided.

For efficient operation of the system, the installation of a “pipe-in-pipe” smoker is carried out according to the following rules:

for boilers with a power of up to 40 kW, the diameter of the coaxial pipe corresponds to 100/60 mm;

- if you buy a floor-standing gas boiler in Moscow for a private house that is not condensing, then the pipe tilts towards the street;

- for condensing boilers, the slope of the chimney is at least 50 mm per meter and is directed towards the boiler;

- the total length of the horizontal pipe is no more than 3 m;

- height from ground level to exhaust pipe - at least 2-2.5 m;

- the length of the pipe protruding from the wall onto the street is at least 30 cm.