Types of shut-off and control valves

To begin with, let’s make a reservation that in this topic we are considering only elements of heating circuits of private houses and apartments, since in the general case the range of fittings used is quite wide. It will be difficult to review it within one article.

Types of heating taps

So, shut-off and control valves are elements of a system designed to control the flow of coolant by partially or completely blocking the flow area of pipelines.

By and large, all flow control elements installed in heating systems of private houses can be divided into the following groups:

- constipation;

- shut-off and regulating;

- mixing and regulating.

You should not confuse concepts such as shut-off and control valves and control and measuring instruments (thermometers, pressure gauges). Also, various safety and air vent valves, filters - mud traps and metering devices have nothing to do with the control of the coolant.

Shut-off valves

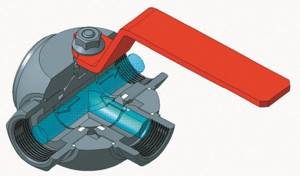

The most common example of a shut-off device is a simple ball valve. It has only 2 working positions: “open” or “closed”. Due to its design, when open, the valve allows a flow of liquid through itself without changing its direction or flow area. It is a brass body with a built-in element in the form of a ball with a hole, rotating a rod with a handle, as shown in the diagram:

Section of shut-off valves

The polished steel ball is sealed with polymer material and can rotate 90º. As can be seen from the diagram, the design of the control valves also allows the flow to be blocked not completely, but this method of control is not used. Firstly, it is too rough, and secondly, the hole of the ball, rotated at some angle, creates high hydraulic resistance to the flow of liquid.

Stopcock with filter

For reference. Modern ball valves are produced in multifunctional versions: with a built-in drain fitting, a Mayevsky valve, a strainer and even an electric drive. In addition, there are three-way ball valves that can switch flows in different directions. The last 2 modifications are used in individual systems quite rarely.

Three way valve

In water heating systems, shut-off ball valves are used in the following places:

- cutting off radiators from the system for the purpose of their periodic maintenance;

- to disconnect branches and risers;

- shutting off the flow to remove or repair heating and pumping equipment, expansion tanks;

- for emptying and refilling the system.

Electric crane

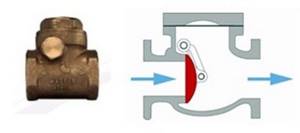

Shut-off devices also include check valves and various shut-off valves with electric drive. It should be noted that in systems of private houses and apartments, shut-off and control valves with an electric drive are very rarely installed, unless in complex and branched circuits controlled by automation.

Valve

As for check valves, their task is to pass the coolant in full in one direction, and to tightly shut it off in the other. Place of installation of elements - boiler piping diagrams and other special cases when it is necessary to avoid the reverse movement of water.

What to consider when installing taps

When installing various taps, it is necessary to take into account, firstly, personal preferences, that is, whether you want to overpay for more precise temperature control, and secondly, the parameters of the room, house, and so on.

The instructions for installing shut-off valves of various types are very similar to each other. It is imperative to check everything for leaks in order to avoid accidents; you also need to take into account the convenience of using such devices. You shouldn’t waste money on a seal; it’s better to choose trusted manufacturers.

If you do not understand anything about installing shut-off valves, then it is better to consult with a professional about what type of faucet you should install in your home.

Shut-off and control elements of systems

These include the following devices:

- balancing valves;

- automatic differential pressure regulators;

- thermostatic radiator valves.

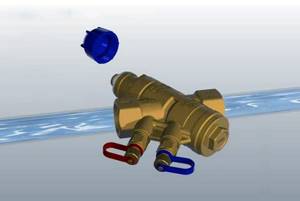

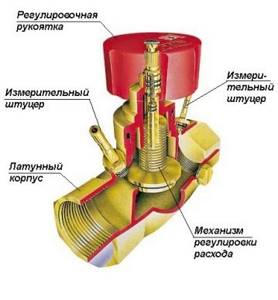

Balancing valve

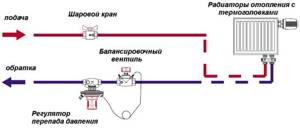

The listed types of shut-off and control valves are designed to carry out quantitative regulation of the coolant. That is, by partially blocking the flow section of the pipeline, these elements provide a certain flow of water entering a section of the system or into a heating device. Balancing valves are installed both at the outlet of the batteries and at the beginning of a branch or riser of the system, as a rule, on the return line.

Valve diagram

With a large number of batteries, the disposition may change and the installation of shut-off and control valves is carried out using automatic differential pressure regulators. They are placed together with valves and connected to them by a capillary tube. The balance valve provides the required coolant flow to the branch or riser, and the regulator adjusts it in accordance with the operation of the radiator thermostats.

Application of automatic valve

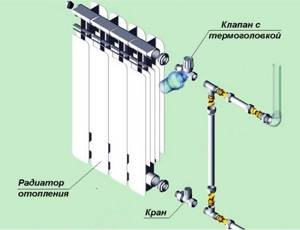

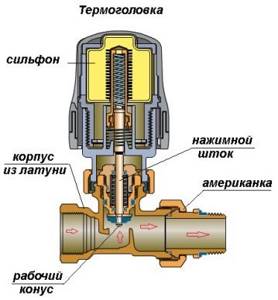

Automatic thermostatic valves are fittings for radiators that reduce or increase the flow of hot water through the radiator depending on the room temperature.

Valves with thermal heads

It is installed on the supply line and can be additionally equipped with a thermal head and a remote thermostat for more precise control of coolant flow. It is considered an integral element of modern schemes and one of the main means of saving energy.

Thermostatic valve

Blitz tips

- It is necessary to consider the type of batteries when installing faucets. That is, if the batteries are old and made of cast iron, then there is a high probability of internal corrosion and severe contamination; in general, in this case, it is better to change the batteries, but if this is not possible, then it is better to install a tap that can be easily removed to clean the insides of the radiator.

- It is better to use as much sealing tape as possible for a better seal.

- When purchasing faucets, you need to find out the material from which the device is made in order to avoid purchasing low-quality materials that may not work well in water.

- If you have the opportunity to buy a thermostatic valve , then it is better to purchase it, as it shows high quality and reliability, and most importantly, durability.

- A quick and easily accessible passage must be provided to the tap in order to quickly turn off the water supply during emergencies. That is, you should never crowd the space in front of the battery with various furniture and other things.

Mixing and control valves

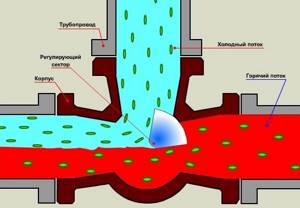

A prominent representative of this group of devices is the thermostatic three-way valve. Its task is high-quality regulation of the coolant, that is, by temperature, and not by flow. A three-way valve does not act like a shut-off valve, it works like a mixing unit. Configured to produce coolant at a certain temperature, the element mixes the two flows in the required proportions.

Heating mixing unit

The device is a brass body with three pipes, inside of which there is a rod controlled by a thermostatic drive. The rod passes through 2 seats, regulating the flow of the required amount of water through them from two pipes, in order to obtain a mixture of the set temperature in the third.

Operating principle of three-way valve

It must be said that not every heating system needs such fittings. The scope of application of mixing devices is maintaining the temperature in underfloor heating circuits, individual radiators or entire groups of heating devices, as well as in small circulation circuits of solid fuel boilers. In general, it is quite difficult to list all the special cases of using mixing valves, since there can be a lot of them in modern water heating schemes.

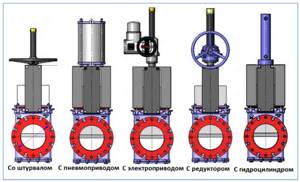

Drives

A valve drive is a device that ensures movement of the locking element, as well as creating the necessary force to ensure sealing of the valve. Drives are used in situations where shut-off valves have large overall dimensions and manual rotation of the flywheels requires the application of too much physical effort, incomparable to human capabilities. Another important function of the drives is the possibility of remote control, which allows you to quickly carry out all work on shutting off or regulating the flow of media in pipeline networks without human presence.

GOST 24856-2014 establishes the following classification of shut-off valves by type of actuator:

- Manual - human physical strength is used to move the actuator.

Rice. 18 Types of drives

- Electric (electric) - to perform its functions, the fittings use electromechanical mechanisms that provide translational or rotational (multiple or partial) movement of the spindle.

- Electromagnetic (solenoid) - the energy conversion of electric current occurs in an electromagnetic coil, which, due to its field, moves a ferromagnetic core connected to the spindle of the device. Based on the method of arrangement of the electromagnetic coil, a distinction is made between those built into the fittings and block units located outside the device body. Based on the type of action of the electromagnet, there are designs of reversible, pulling, pushing, and rotary types.

- Pneumatic - compressed air is used to control the shut-off or control mechanism.

- Hydraulic drive (hydraulic) - the movement of the actuator is carried out using fluid supplied under pressure.

- Pneumatic and hydraulic is a combined design, the actuating element of which moves with the help of compressed air and liquid supplied under pressure.

- Electrohydraulic (electrohydraulic) - the movement of the actuator is realized by supplying the mechanism with electric current and liquid under pressure.

Rice. 19 Materials for manufacturing a household ball valve using the example of the Bugatti model