rules for performing pressure testing, explanations and references to SNiP.

» Regulatory documentation, rules and SNiP for pressure testing of the heating system Regulatory documentation, rules and SNiP for pressure testing of the heating system Brief excerpts from the regulatory documentation, rules and SNiP for pressure testing of the heating system .

Analyzing the statistics of the questions you ask and understanding that many questions regarding pressure testing of the heating system for the majority of our audience remain incomprehensible to you, we decided to make a selection from the necessary points and Rules for pressure testing, approved by the Ministry of Fuel and Energy of the Russian Federation and SNiP.

All SNiPs and rules contain more than 100 pages of information, which are sometimes difficult to understand, so in order to make the task easier for you, so that you can look at and, if necessary, refer to the desired paragraph of a specific regulatory document, we have processed the applicable regulatory documents and in a brief form posted on the site. Explanations to the Rules and SNiP can be found in the article: “Norms and rules for performing pressure testing of a heating system”

Snip pressure when testing a heating system

To put the heating into operation, it is necessary to flush and pressure test the system. After completing this procedure, a certificate is filled out confirming that the installation of the heating network was done correctly. Employees authorized to perform this work are required to complete all relevant regulations.

SNiP crimping rules

The norms for pressure testing of the heating system are described in documents such as SNiP 41–01-2003, and also 3.05.01–85.

Air conditioning, ventilation and heating - SNiP 41-01-2003

Hydraulic checks of water heating systems can only be carried out at above-zero temperatures in the premises of the house. In addition, they must withstand water pressure of at least 0.6 MPa without damage to the seal and destruction.

During the test, the pressure value should not exceed the limit for the heating devices, pipelines and fittings installed in the system.

Internal sanitary systems - 3.05.01–85

According to this SNiP rule, it is necessary to check water heat supply and heating systems with the expansion vessels and boilers turned off using hydrostatic pressure equal to 1.5 working pressure, but not less than 0.2 MPa in the lower part of the system.

The heating network is considered to have passed the test if it holds the test pressure for 5 minutes and does not drop by more than 0.02 MPa. In addition, there should be no leaks in heating equipment, welds, fittings, threaded connections and pipes.

Conditions for performing crimping

Test work is carried out correctly if all necessary requirements have been met. For example, outside work cannot be carried out on the tested object, and the testing must be supervised by the shift supervisor.

Pressure testing is carried out only according to a program approved by the company’s chief engineer. It defines: the procedure for employees and the technological sequence of verification . They also outline safety measures for ongoing and current work performed at adjacent facilities.

There should be no strangers during pressure testing of the heating system; there should be no turning on or off of testing devices; only employees taking part in the test remain on site.

When work is carried out in adjacent areas, it is imperative to provide reliable fencing and turn off the testing equipment.

Inspection of heating appliances and pipes is permitted only at operating pressure values. When the heating system is pressure tested, reports are filled out to confirm the tightness.

Crimping procedure

This method of checking the heating system involves performing hydraulic tests:

- Heat exchangers;

- Boilers;

- Pipe

This makes it possible to identify leaks that indicate depressurization of the network.

Before testing the heating system with plugs, you should isolate the heating system from the water supply, visually assess the reliability of all connections , and also check the functionality and condition of the shut-off valves.

After this, the expansion tank and boiler are turned off to flush the radiators and pipelines from various deposits, debris and dust.

During the hydraulic test, the heating system is filled with water, but during air tests this is not done, but simply a compressor is connected to the drain valve. Then the pressure is increased to the required value, and its indicators are monitored with a pressure gauge. If there are no changes, then the tightness is good, therefore the system can be put into operation.

When the pressure begins to decrease beyond the permissible value, it means that defects are present . Leaks in a filled system are not difficult to find. But in order to identify damage during an air test, a soap solution should be applied to all joints and joints.

Air pressure testing takes at least 20 hours, and hydraulic testing takes 1 hour.

Having corrected the identified defects, the procedure is repeated again, and this must be done until good tightness is achieved . After carrying out this work, pressure testing certificates for heating systems are filled out.

Checking the heating network with air is usually carried out if it is impossible to fill it with water, or when working in low temperature conditions, because the liquid can simply freeze.

Heating system pressure test certificate

This document displays the following information:

- What type of crimping method was used?

- The project in accordance with which the circuit was installed;

- The date of the inspection, the address where it was carried out, as well as the names of the citizens who sign the act. This is mainly the owner of the house, representatives of the repair and maintenance organization and heating networks;

- How the identified faults were eliminated;

- Test results;

- Are there any signs of leakage or reliability of threaded and welded connections? In addition, it is indicated whether there are drops on the surface of the fittings and pipes.

Permissible test pressure when testing water heating

Many developers are interested in what pressure should be used to check the heating system. In accordance with the SNiP requirements presented above, during pressure testing, pressure is allowed to be 1.5 times higher than the working pressure , but it should not be less than 0.6 MPa.

There is another figure indicated in the “Rules for the technical operation of thermal power plants.” Of course, this method is “softer”; its pressure exceeds the working pressure by 1.25 times.

In private houses equipped with autonomous heating, it does not rise above 2 atmospheres, and it is adjusted artificially: if excess pressure appears , the relief valve immediately turns on. Whereas in public and multi-apartment buildings the working pressure is much higher than these values: five-story buildings - about 3-6 atmospheres, and tall buildings - about 7-10.

Heating system testing equipment

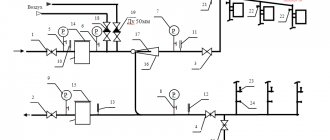

Most often, a pressure tester is used to perform a hydraulic test. It is connected to the circuit to regulate the pressure in the pipes.

A huge number of local heating networks in private buildings do not require high pressure, so a manual pressure tester will be sufficient . In other cases, it is better to use an electric pump.

Hand-held devices for testing heating systems develop a force of up to 60 bar or more. Moreover, this is enough to check the integrity of the system even in a five-story building.

The main advantages of hand pumps:

- Reasonable cost, which makes them accessible to many consumers;

- Light weight and dimensions of hand presses. Such devices are convenient to use not only for personal purposes, but also for professional use;

- Long service life without failures or breakdowns. The device is so simply designed that there is nothing to break in it;

- Suitable for medium and small heating equipment.

Branched and large circuits on large areas, multi-story buildings and production facilities are checked only with electrical devices. They are capable of pumping water under very high pressure , which is unattainable for manual devices. They are equipped with a self-priming pump.

Electric pumps develop a force of up to 500 bar. These units are usually built into the main line or connected to any opening. Basically, the hose is connected to a tap through which the pipe is filled with coolant.

Performing heating pressure testing is a very complex technological procedure. That’s why you shouldn’t do it yourself; it’s better to use the services of professional teams.

- Vadim Nikolaevich Lozinsky

Crimping procedure

To check the heating system in this way, hydraulic tests are carried out on the following elements:

- Pipes.

- Heat exchangers.

- Boilers.

If leaks are detected during testing, a conclusion is made about the depressurization of the network.

Immediately before testing, the water supply and heat supply systems are isolated. They also visually determine the strength of the existing connections, check the shut-off valves for operability and evaluate their general condition.

At the next stage, the expansion tank and heating boiler are turned off in order to flush heating devices and pipes from deposits of various natures and remove debris and dust.

If hydraulic tests involve filling the heating system with water, then a compressor is connected to the drain valve to test with air. Gradually, the pressure in the system increases, its indicators are monitored on special pressure gauges. If there are no changes, a conclusion is given about the good tightness of the system and the possibility of putting it into operation. Pressure testing of heated floors with air is carried out in a similar way, including some nuances.

If an acceptable pressure drop is observed during pressure testing of the heating system, then there are areas with defects in the system. During hydraulic tests, such places leak. If the test was carried out with air under pressure, then the joints and joints are treated with a soap solution.

Pressure testing with air lasts approximately 20 hours, hydraulic tests require only 1 hour.

If defects are detected, repair work is carried out and pressure testing is carried out again. The steps are repeated until good tightness of the system is achieved. Based on the results of the work carried out, a pressure test report for the heating system is drawn up. It is worth noting that the heating system pressure test certificate is a necessary document.

It should be remembered that in most cases the test is carried out hydraulically. Air tests are carried out when it is impossible to fill the circuit with water or at low air temperatures when the liquid simply solidifies.

Rules for crimping heating networks - PPE, standards, instructions

To put the heating into operation, it is necessary to flush and pressure test the system. After completing this procedure, a certificate is filled out confirming that the installation of the heating network was done correctly. Employees authorized to perform this work are required to complete all relevant regulations.

Pressure testing of a heating system in a house according to SNiP: how to check the tightness of pipes and connecting units

To increase the reliability of the functioning of heating systems during their maintenance, periodic checks of the tightness of pipelines are carried out. It allows you to identify connecting elements that have become unusable.

It is also known that the vulnerability of any such system is determined by its weakest link, in the event of a malfunction of which it loses its functionality partially or completely.

To identify potentially dangerous places, a special procedure is provided, called pressure testing of heating equipment.

Hydraulic testing of a heating system: rules - Comfort temperature

To put the heating into operation, it is necessary to flush and pressure test the system. After completing this procedure, a certificate is filled out confirming that the installation of the heating network was done correctly. Employees authorized to perform this work are required to complete all relevant regulations.

Hydraulic testing of the heating system: features of crimping

To provide heat in the house in winter, a reliable and efficient heating system is necessary.

After installing boilers, installing pipes, replacing individual components, and also in preparation for the new season, hydraulic tests of the heating system are carried out.

These tests are aimed at identifying leaks, local damage, leaking connections and other problems that may cause the system to become unusable during operation.

If in apartments hydraulic testing and pressure testing falls on the shoulders of housing and communal services workers, then owners of private houses should turn to specialists or carry out hydraulic tests themselves.

Hydraulic testing of heating system pipelines

Hydraulic testing of the heating system is a prerequisite for ensuring comfortable conditions in a private home. Over time, heating elements wear out and fail; testing your heating system helps prevent damage during the heating season.

Before installing heating elements and pipelines, a hydraulic calculation of the heating system is performed taking into account the material and internal diameter of the pipes, the diameter of fittings and fittings, the thickness of the pipe walls and other technical parameters. If the calculations are incorrect, the efficiency of the system can be significantly reduced, and the operating period can be reduced several times.

Let's consider how the diameter of a heating system pipeline is calculated and the diameter of the pipes is determined depending on the rated load on a particular section.

D = √354∙(0.86∙Q:Δt):V

where D is the diameter of the heating pipe, cm;

Q – load on the design section of the system, kW;

∆t – temperature difference between the falling and return pipes, ᵒС;

This calculation allows you to determine the average diameter of the heating system pipe. Professional heating system calculations use significantly more data. In this case, not only the size of an individual pipe is determined, but also the diameters of narrowed sections, the distance between pipelines, etc.

Why do you need hydraulic testing of a heating system?

Each individual heating system has its own operating pressure, which determines the degree of heating of the room, the quality of coolant circulation, and the level of heat loss. The choice of operating pressure is influenced by a number of factors, including the type of building, number of floors, quality of the main line, etc.

As the coolant moves through pipelines, various hydraulic processes occur, which lead to pressure drops in the system, called water hammer. It is precisely such loads that usually cause the acceleration of the destruction of the heating system, which is why hydraulic tests are carried out under pressure 40% higher than the nominal one.

Hydraulic testing of heating system pipelines is carried out after performing the following work:

- checking valves, serviceability of shut-off valves;

- strengthening the tightness of the system using additional seals (if necessary);

- restoration of pipeline insulation layers, replacement of worn materials;

- cutting off the house from the general system using a blind plug.

When carrying out pressure testing, as well as for further filling the system with coolant, a drain valve is used, which is installed on the return line.

Pressure testing technology for heating systems

During the process of filling the system, liquid is supplied under moderate pressure, which allows it to gradually fill all elements of the system. In this case, air must be released from the system from time to time.

Pressure testing of the heating system

In apartments of multi-storey buildings, leaks are detected by testing with a pressure 20 - 30% higher than the working one.

For this, a special press is used to pressurize the heating system, and the pressure value is controlled by a pressure gauge. After reaching the required pressure, the system is left for 30 minutes.

If the pressure subsequently decreases, it means that there are leaks or leaks in the system.

The most common cause of loss of tightness is damage to gaskets, shut-off valves, joints or bends of pipes, wear of threaded connections or heating radiators.

After eliminating the problems and re-checking, a heating system test report .

A heating system that is ready to start without damage or coolant leaks is considered to be pressurized.

Pressure testing of heated floors, features of implementation

In addition to the heating system, the heated floor also needs regular inspection. Pressure testing of the heated floor is carried out until the pressure in the system stops falling. The required pressure in the system is achieved by using a pressure test pump.

Heating water supply boiler room

LLC DESIGN PRESTIGE > https://resant.ru/

Telephone: 8(495)744-67-74

We provide installation services for heating and water supply systems for private country houses, dachas, and organizations. We supply equipment for work at discounts.

Our services:

Heating:

Installation, design, service repair. Heating by type: autonomous, water, private, wood, individual, gas, natural.

Water supply:

Autonomous water supply from a well and a borehole. Installation of a water supply system for both permanent and temporary residence and use of the house. We provide maintenance of water supply systems: pump replacement, replacement, repair of hydraulic accumulator, setting up automatic pump control.

- Replacing a pump in a well

Boiler room:

For private homes and industrial enterprises. We will install the boiler, distribution modules for heating circuits, and install automation elements for temperature control.

We carry out all work on a turnkey basis. LLC DESIGN PRESTIGE

LLC DESIGN PRESTIGE.

| Repair of apartments , country houses , roofing , foundations , fences , fencing , autonomous gasification , private sewerage , facade finishing water supply systems from wells and boreholes, professional modern boiler rooms for private homes and businesses . |

| Systems: heating , water supply , sewerage . Full construction . |

| Holding company SpetsStroyAlliance |

| Laying , repair and installation of heating networks , turnkey heating mains For private homes and businesses . |

Pressure when testing the heating system of a private house

Before commissioning the heating system, a number of certain measures must be carried out.

The system is flushed and pressure tested; the result of the work performed is a certificate that confirms that the installation work was completed correctly.

This document and other necessary documents are filled out by specialists who are authorized to carry out these activities. In order to carry out verification work yourself, it is important to understand what pressure testing of a heating system means.

How to carry out crimping correctly

Pressure testing of heating systems is carried out in accordance with the requirements of certain documents, which indicate what pressure is used to pressurize the heating system. In particular, we are talking about Sanitary Standards and Rules numbered 41-01-2003 (air conditioning, ventilation and heating) and 3.05.01-85 (Internal sanitary systems).

According to SNIP 41-01-2003, pressure testing of the heating system is carried out only if the room temperature is above 0 0 C. In addition, the system must withstand a pressure of the working medium of at least 0.6 MPa, and damage and leakage are not allowed.

Pressure testing is carried out under pressure, the value of which does not exceed the limit values for heating devices, pipelines and fittings built into the system.

In order not to violate SNIP 3.05.01-85, before checking water heating systems, expansion vessels and boilers should be turned off. According to SNIP, the pressure during pressure testing of the heating system should be 1.5 times higher than the operating pressure, but not less than 0.2 MPa at the lower level of the system.

For a positive test result, the network must last about 5 minutes under the recommended test pressure, and its value should decrease by no more than 0.02 MPa. Also, during a visual inspection of the system elements, no leaks should be detected in threaded connections and welds, pipes and fittings, heating devices and other equipment.

Requirements for crimp testing

A heating system inspection can only be considered completed if certain requirements are met:

- All tests are carried out under the strict supervision of the shift supervisor.

- During control activities, it is prohibited to perform any work at the site.

- The testing program must be approved by the chief engineer of the testing organization. The program strictly regulates the actions of each employee and the sequence of the technological process. In addition, it outlines safety measures when carrying out inspection activities and scheduled work at adjacent facilities.

- The presence of strangers at the site during pressure testing of the heating system is not allowed. Only specialists directly involved in the inspection should be on site.

- It is prohibited to enable or disable the object being checked.

- During testing, adjacent areas must be fenced off with special structures, and the testing equipment must be turned off.

- During the inspection of the equipment being tested, the operating pressure must be maintained in the system; exceeding these values is not allowed.

- To confirm the tightness of the water heating system, the responsible specialist draws up a report on the performance of pressure testing.

How to correctly draw up a pressure test report for a heating system

To draw up an act according to all the rules, it is important to indicate in it the following:

- Test method used.

- The project according to which the installation and installation of the test object was carried out.

- Date and address of testing events.

- List of persons whose signature must be on the document. In most cases, the property owners and representatives of service organizations are indicated.

- Methods for eliminating identified defects.

- Test results.

- Presence of signs of depressurization of the system or violation of threaded connections and welds. It should also be noted that there is condensation on the surface of pipes and fittings.

Similar materials on the company website

Radiator KERMI 11 - 500 x 1400 K KERMI profile radiator with side connection, type 11, height 500mm, length...

OILON GP-50 H - Gas burner Technical characteristics OILON GP-50 H Type: Gas burner Rated heat output,...

URVS-1 (P) - Devices for heating viscous media “Quark” Technical characteristics of URVS-1 (P) Type: Device for heating viscous media “Quark” Operating…

Permissible pressure drop during pressure testing of the heating system

Pressure testing or hydraulic testing is a test of the heating system for leaks. To do this, an excess pressure is created in it, as close as possible to the value of the maximum pressure determined by calculation.

The purpose of heating pressure testing

The main task is to simulate a situation similar to a water hammer, which can occur in an operating heating system at any time.

When is a heating system pressure tested?

The heating system is pressure tested before the start of each heating season, as well as after completion of installation and repair work.

Experience shows that pressure testing of heating system pipelines allows us to identify all defects hidden during installation, and its successful implementation is the best guarantee of trouble-free operation of the equipment in the next heating season.

Experienced building owners who take a responsible approach to heat supply issues conduct hydraulic tests immediately after the end of the heating season, which allows problems to be corrected in a timely manner and then a repeated hydraulic test is performed.

Typically, pressure testing of pipelines and radiators of a heating system is timed to flush the heating system and eliminate various visible problems or carry out scheduled maintenance work.

Pressure testing of the internal heating system consists of several stages

- Filling the system with water;

- Injecting pressure into it;

- Monitoring the readings of instruments measuring pressure in the system;

- Visual inspection of the presence (absence) of a leak;

- Troubleshooting in case of detection;

- Drawing up a certificate of pressure testing of the heating system.

The first stage of hydraulic testing is filling the system with water. If we are talking about a working heating system, it is stopped, cooled, and the coolant is drained.

Water is supplied to the system through a special valve, most often a ball valve, called a “drainer” and located, as a rule, in the elevator unit of the heating system or in the boiler room, on the return pipeline. Water can be supplied directly from the tap.

While filling the system with water, air is released and air pockets are removed. At the same time, they also check for leaks.

Please note that when performing pressure testing of the heating system, water is supplied only from below. If water is poured from above, there is a high probability of air entering the system and forming air pockets in it.

Pressure testing of the heating system of a country house

A characteristic feature of heating systems in private housing construction and cottages is the low level of pressure in them, usually not exceeding 2 atm. This means that to pressurize a country house, it is quite enough to supply water from the water supply to the heating system, where the pressure is exactly 2 or more atm.

In this case, you can do without additional equipment and excess pressure in the system. It is enough to simply check for leaks, fogging of the welds, or their shifts or breaks. After the test, the heating system must be immediately filled with coolant. To do this, you can use chemically purified water or antifreeze.

Features of pressure testing of the heating system of a multi-storey building

Carrying out hydraulic tests of the heating system of multi-storey residential buildings, social facilities, as well as shopping and entertainment centers is regulated by the “Rules for the technical operation of thermal power plants”, as well as the Current Sanitary Norms and Rules.

Crimping pressure

In accordance with them, before starting hydraulic tests, it is necessary to calculate the level of pressure testing . Its value depends on many factors:

- The commissioning period of the heating system (for new heating systems during pressure testing, the operating pressure is increased by 1.5-2 times, and for systems that have been in operation for several years, the operating pressure is increased by 15-50%);

- Type of heating devices installed in the building: if the system uses cast iron radiators, then the pressure test should not exceed 6 atm. For convectors, on the contrary, it is necessary to raise the pressure level to 10 atm;

- Number of floors in the building;

- Purpose of the building.

In most cases, a hydraulic test of a heating system is preceded by flushing, after which the flushing solutions are drained and the system is filled with tap water, the temperature of which should not exceed 45 C. Air must be vented.

After filling the heating system with water, a pump is connected to the drain valve (bleeder) to pressurize the heating system, with the help of which excess pressure is created in the network, the level of which is checked at the highest point of the heating system.

Maximum crimping pressure: what next?

After the system reaches the required level of pressure testing, it is held for at least 15 minutes, during which the readings of the pressure gauges are monitored, and the presence of leaks, shifts in the system or the appearance of ruptures is also visually checked.

During hydraulic tests, each heating device and component must be checked without fail. It does not matter whether the level of pressure testing remains constant or whether it drops. Hidden areas of the heating system, for example, those located in the walls or filled with screed, are especially carefully checked.

If the pressure is stable and no leaks are detected, the hydraulic test of the system is considered complete. After the test is completed, the pressure level is reset to the operating value.

If the test pressure drop exceeds the permissible parameters, a thorough examination of the system is carried out and leaks are identified. Hydraulic testing continues until the damaged area is found.