What is crimping and why is it needed?

After installing the entire heating system, it must be checked for functionality and resistance to high pressure. To do this, high pressure is created inside it using water or air. Most often, when checking, this indicator is exceeded by 2 times the normal operating pressure. This whole process shows what pressure testing of a heating system is.

To carry out this test, special equipment is used that can operate in manual or automatic mode. During the inspection, the performance of pipes, boilers, underfloor heating systems or radiator circuits, as well as their connections and pumps for moving water, is analyzed. If the test was successful and all joints remained sealed, then the system can be handed over for operation and can be used in normal mode for a long time.

Testing heated floors Source stopradiators.ru

Pressure testing - what is it?

Pressure testing of a finished water heating system is a test of tightness and assembly quality. Whether the system can be put into operation or not depends entirely on the results of such a check. This is the first procedure that needs to be carried out after installation and before turning on the heating.

At its core, it is control without destruction. Air or water is pumped into the system, thereby creating increased pressure. If there are no leaks, you can safely put the system into operation.

Pressure testing is also carried out when checking an already operating system. After all, leaks often appear at the places where parts are connected using fittings, soldering or welding. The pipes themselves may also suffer, for example, from mechanical stress or corrosion. High temperature and pressure also cause gradual wear of pipes and parts of the water heating system. To detect and eliminate the location of the flaw, crimping is required.

This is a set of measures through which not only the heating system, but also the hot water supply, sewage system, and pipes in the water well can be checked in a private home.

Pressure testing of a heated floor system

The crimping procedure includes:

- pipeline testing and flushing;

- checking and, if necessary, replacing parts;

- restoration of damaged insulation.

The following are tested under high pressure:

- strength of housings, as well as walls of pipes, radiators, heat exchangers and fittings;

- fastening when connecting the elements that make up the system;

- maintenance of taps, pressure gauges, as well as gate valves.

When is pressure testing carried out?

Hydraulic tests of the heating system are carried out both for new pipes that have just been installed, and for old ones, to check their resistance to pressure changes. The rules for the use of power installations from the Ministry of Energy of the Russian Federation (clause 9.2.12) indicate the standards for conducting inspections and how often they need to be carried out. Flushing and pressure testing of the heating system is done in 3 cases:

- Before the system is handed over for operation or before the heated floor is poured or pipes are installed, the first run is carried out. It is needed to check the system for leaks before it is covered with concrete or other materials, so that after startup they are not damaged by water. It is recommended to carry out an additional (second) check immediately after sealing the system. This will allow you to understand whether damage or pressure points appeared on the pipes during installation.

An example of an open system Source vsks24.ru

- After the end of each heating season, the pipeline should be pressure tested so that there are no problems if it is put into operation unexpectedly. Also, an additional check should be done before the start of cold weather.

- If the system has been repaired or has been idle for a long time, it is necessary to conduct an additional test for stability and leakage. Before doing this, you should drain the old water or liquid that is poured inside the pipes.

All tests are necessary in order to avoid repairs or unnecessary expenses during active use of the system. Most often these are the winter months, when the heating season begins.

Example of a leak Source www.4brothersbuyhouses.com

Why hydrotest?

As you know, the heating system is a closed circuit operating under excess pressure. Any leaks in the threaded connections of the fittings or at the connection points of radiators will lead to water leakage, flooding of premises, damage to building structures, finishing, etc. And since the system operates in winter under pressure and high temperatures of the coolant, accidents may also occur situations that threaten the life and health of people. The consequences of leaking heating systems can be very expensive and problematic in terms of eliminating them, especially in winter.

Therefore, hydraulic tests of heating and heat supply systems are mandatory measures both at the time of commissioning of the facility and at the stage of preparatory work before the heating season.

In some cases, the absence of an act on testing the building’s heat supply systems is a guaranteed refusal of the heat supply organization to release heat into the building before the start of the heating period. Therefore, the organization operating the building must be aware of the procedure for preparing networks and must have the appropriate qualifications to test heating systems. In addition, pressure testing of heating systems connected to the heating networks of a city or town is part of the heat supply contract.

The main preparatory work and testing of heating systems include the following activities:

- system pressure testing,

- flushing of pipelines.

System Test Codes and Regulations

After familiarizing yourself with what “pressure testing of the heating system” is, you should understand the rules and conditions for its implementation:

- The air temperature around the pipes should not be below 0 °C outdoors and +5 °C indoors. If it does not meet the standards, then the test can be carried out only in emergency cases.

- After checking, there should be no condensation on the welds, as well as leaks in all joints or heating equipment.

- The pressure inside the heating circuit should not drop below 0.2 bar within 5 minutes, and for panel systems - 0.1 bar (atmospheres) within 15 minutes.

- During the test, the pressure inside a system that has metal pipes should not drop by more than 0.5 bar within 10 minutes, and for plastic pipes it should not drop by more than 0.6 bar in the initial 30 minutes and 0 .2 bar for 2 hours.

- If the system is tested not with water, but with air, then the pressure drop should not exceed 0.2 bar in the first 5 minutes.

The pressure in pipes and heating devices when pressure testing the system should not be higher than the maximum permissible value for the components and materials of which it consists. Also, the pressure must be higher than 0.6 MPa and exceed the working pressure by no less than 50%. All places that will be hidden after wiring must be checked before finishing activities. If the pressure inside the system begins to drop, then you need to find the leak and seal it. After this, the test should be resumed.

For pipelines with valves, you need to make 2 full turns of the handle before starting the test. Heating devices that consist of sections and are not factory assembled must be crimped on site in the same way as large component parts. All system checks should be carried out before wrapping the pipes with thermal insulation, as this may make it difficult to find a leak.

Pipes with insulation Source ostroymaterialah.ru

If the pipeline and its components have passed all tests, then this must be recorded in the heating system pressure test report. It is also recommended to test it for proper heat distribution and uniform heating of the components. To do this, keep the water temperature inside the system at least +60 °C for 7 hours. If it is not possible to carry out these checks in the summer, then they are postponed until the heating devices are connected or the heating season.

Checking the pressure in the system Source edinayauk.rf

Test Tools

To test the system for resistance to high pressure, a special device is used, which is called a pressure tester. It is a pump capable of creating pressure inside the system up to 60 or 100 atmospheres, depending on the type of mechanism. There are 2 types of pumps: manual and automatic. They differ only in that the second option stops pumping itself if the pressure reaches the desired level.

The pump consists of a tank into which water is poured and a plunger pump with a handle that moves it. On the body of the mechanism there are taps to block the pressure supply and pressure gauges to regulate the pressure. There is also a tap on the tank that allows you to drain the water that remains in the tank.

The principle of operation of such a pump is similar to a conventional piston analogue, which is used to inflate tires. The main difference is the cylindrical piston made of steel. It is fitted tightly inside the housing and a minimum gap is created, which makes it possible to pump up pressure up to 60 atmospheres.

Manual blower Source amazon.com

For hand pumps, the biggest disadvantage is that such pressure testing of pipes will take a very long time due to pumping the system with water. This process can take several hours, since large systems that have radiators will need to be filled manually.

Automatic devices work on a similar principle, but when the pressure limit is reached, they turn off themselves. They also require electricity to operate, so manual ones are more suitable for places where there is no power supply yet. Automatic pumps can pump pressure up to 100 bar, and industrial devices up to 1000 bar.

Electric version of the compressor Source ngenix.net

See also: Catalog of house projects with a boiler room up to 1 million rubles

Pipe crimping

There are 2 different methods of heating heating: water and air. Using the first option, all thermal systems are most often tested. To do this, liquid under pressure is pumped into a special tap, with which you can quickly detect breakouts and leaks.

The air method is a less effective method for checking pipes, but its main advantage is that during frosts water cannot be used, as it may freeze. To find leaks, soapy water is used to lubricate suspicious areas. The main search method is to determine a breakthrough by ear. The pressure in the system is built up using a compressor through a valve into which water must be supplied.

For multi-story buildings, there are certain testing rules that indicate the minimum pressure for the test. In water heating, panel and convector systems it should be 10 atmospheres, and in a circuit with steel or cast iron pipes - 6 bar.

How to pressurize a heating system

There are two main methods of pressure testing of systems:

- Pressure testing with water. The main method for testing heat-transfer circuits, water is pumped into the lower part of the pipeline through the shut-off valve of the drain pipe using an automatic or manual pressure test pump. The advantage of the method is the ease of detecting leaks using water prints.

- Air pressure testing. Not a very effective method due to the difficulty of detecting leaks, it can be used to check the heating circuit in the cold season, when the use of water is difficult due to the possibility of freezing. To pump air, a compressor is used, which is connected to the pipeline through a special adapter. To detect the location of a leak, auditory methods are used; to accurately localize the air-permeable connection, a soap solution is used, similar to checking gas pipes.

Rice. 5 Pressure testing of pipes with a special flushing compressor

Test pressure

The rules for pressure testing of heating systems are regulated by the PTE for heating installations from the Ministry of Energy (clause 9.2.13) in force since October 1, 2003, according to them the test pressure in an apartment building should not be less than:

- 1 mPa (10 bar, atm.) in home hot water supply and heating systems with water heaters;

- 10 bar (atm.) for panel and convector heating circuits;

- 6 bar (atm.) in a circuit with radiators made of cast iron or stamped steel;

- pressure equal to the working pressure with the addition of 5 bar (atm.) but not more than 10 bar for hot water supply;

- pressure, which must exceed the operating pressure (set by the manufacturer and indicated in the technical parameters of the devices) by 1.5 - 2 times for heating air heaters and heating ventilation.

For panel heating in conjunction with heat exchange devices, the test pressure cannot exceed the tolerances for these devices.

Video description

This video shows why pressure testing of the system is needed

To carry out the work, water with a temperature of 42 °C is poured into the heating circuit and air is released through special valves. Within 10 minutes, a test pressure is created, with which the joints are checked for leaks. After this, the pressure is increased to the required standard and a test is carried out for 10 to 30 minutes, depending on the material from which the system is made.

On private plots, the test can be carried out no more often than once every 4-5 years. To do this, you do not need to have a lot of knowledge and skills, and the entire procedure can be done independently, if you have the necessary equipment. In order not to spend a lot of money on purchase, you should rent a compressor or call a special service to check the pipes.

Checking pressure by a specialist Source inkrasnogorsk.ru

In a high-rise building

Pressure testing of heating pipes in multi-storey buildings is most often done in the middle or end of spring, after the heating is turned off. If complaints are received about low water temperature, then the heating company must carry out a calculation of the radiators. Under certain conditions, they can be replaced, removed or new ones added. During the inspection, all risers are checked for blockages and washed under high pressure along with the rest of the system.

Also, during inspections, insulating gaskets, seals on cast iron valves and stuck bolts should be changed. During this, the fittings in elevators and pipes are inspected. This is to check them for rust or damage. After all the tests, the condition of the heat-insulating materials on the line is analyzed.

At the end of the checks, it is necessary to carry out pressure testing of the pipes, taking into account the material from which the system is made and the operating pressure of the system. If the pipes are made of cast iron, then the pressure does not rise above 6 atmospheres, and if they are in the walls - no more than 10 bar, as with panel heating systems.

Example of cast iron radiators Source radiator-home.ru

See also: Catalog of companies that specialize in heating, water supply, sewerage and lighting

Pipe inspection is done in 2 steps. To do this, first the entire heating system is checked, and then its individual sections are tested under higher pressure. To do this, the heating circuit is filled with water, which has a low pH level, which avoids the formation of deposits on the pipes. The pressure is increased using electric pumps, since it is often impossible to manually fill such a volume.

If the pressure has not dropped within 30 minutes, then pressure testing can be completed. If there is a leak, it must be found and removed, and then the test must be repeated. Each node is individually checked in a similar way, only the pressure is increased to 10 atmospheres.

How to carry out crimp testing

The procedure for crimping a heating system largely depends on the type and number of floors of the building (a large multi-story building or a small private house), its complexity (number of circuits, branches, risers), wiring diagram, material and wall thickness of its elements (pipes, radiators, fittings) etc. Most often, such tests are hydraulic, that is, they are carried out by injecting water into the system, but they can also be pneumatic, when excess air pressure is created in it. But hydraulic tests are carried out much more often. So let's look at this option first.

Pressure testing in a multi-apartment high-rise building

As already mentioned, in such buildings, pressure testing of the water heating system is carried out by special services, after installation and before commissioning, after repairs, before the start of each heating season and at its end, using special equipment. Based on the results of such tests, as a rule, a crimping certificate of the appropriate form is drawn up.

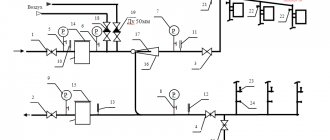

Pressure testing of the heating system of an apartment building

Pressure testing of the heating system of an apartment building

Before carrying out hydraulic tests, the following preparatory work is carried out:

- Visual inspection of the condition of the elevator (supply unit), main pipes, risers and all other elements of the heating system;

- Checking the presence and integrity of thermal insulation on heating mains.

If the system has been in operation for more than 5 years, it is advisable to flush it before pressure testing. To do this, the coolant present in it is drained and it is washed with a special solution. After which you can begin hydraulic tests.

The sequence of work during hydraulic pressure testing is as follows:

- The system is filled with water (if it has just been installed or has been washed);

- Using a special electric or manual pump, excess pressure is created in it;

- The pressure gauge monitors whether the pressure is maintained or not (within 15-30 minutes);

- If the pressure is maintained (the pressure gauge readings do not change), then the tightness is ensured, there are no leaks and all its elements can withstand the pressure of the pressure test;

- If a drop in pressure is detected, all elements (pipes, connections, radiators, additional equipment) are checked to identify water leaks;

- After the location of the leak has been determined, it is sealed or the element is replaced (pipe section, connecting fitting, shut-off valves, radiator, etc.) and the hydraulic tests are repeated.

What should the pressure test be?

The fluid pressure that is created during hydraulic tests of heating systems depends on the operating pressure in them, which, in turn, depends on the material of its pipes and radiators that were used during their installation. For new systems, the pressure testing should exceed the working pressure by 2 times, and for existing systems it should exceed it by 20-50%.

Each type of pipes and radiators is designed for a certain maximum pressure. Taking this into account, the maximum operating pressure in the system is selected and must be taken into account when choosing the pressure test. For example, in apartment buildings with cast iron radiators, the operating pressure, as a rule, does not exceed 5 atm. (bar) and is usually within 3 atm. (bar). Therefore, as a rule, pressure testing of such systems is performed with a pressure of no more than 6 atm. Systems with convector-type radiators (steel, bimetallic) can be pressurized at higher pressures (up to 10 atm).

Crimping of the input unit is performed separately, at a pressure of at least 10 atm. (1 MPa). To create such pressure, special electric pumps are used. The tests are considered successful if the pressure drop within 30 minutes is no more than 0.1 atm.

Electric pump for pressure testing the heating system

Pressure testing in a private house

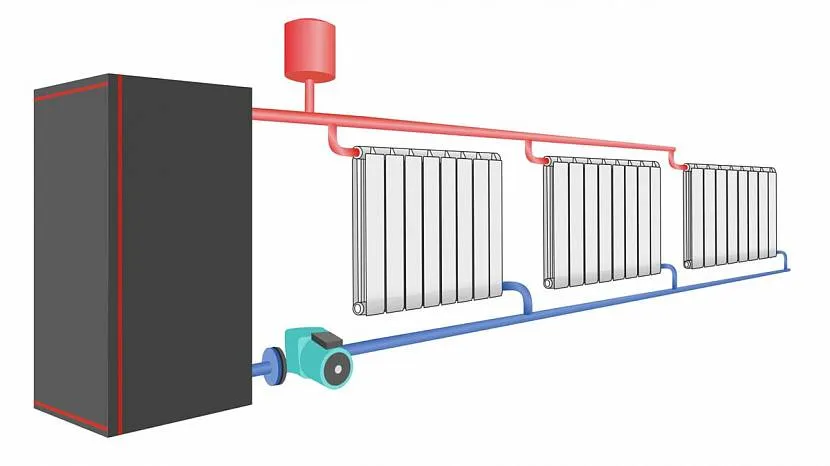

In autonomous closed water heating systems of private houses, the operating pressure rarely exceeds 2.0 atm. (0.2 MPa) and, as a rule, is within 1.5 atm. Therefore, to create pressure (1.8-4 atm.) in such a system, you can use both electric and hand pumps, or connect it to the water supply system at home (usually the water pressure in it is 2-3 atm., which can be quite sufficient for hydraulic testing).

Hand pump for pressure testing the heating system

Filling the system with water must be done from below through a drain or a tap specially designed for this purpose. In this case, the air will be easily pushed out of it by the liquid coming from below upwards and removed through air valves, which should be installed at its highest point, in places where air pockets may form, as well as on each radiator.

It must also be remembered that the temperature of the water used for testing should not be higher than 45° C.

If the system is quite simple, and, moreover, it was installed with your own hands, then you can do the pressure testing yourself, performing the work in the same sequence as in an apartment building.

Pressure testing of the heating system with a hand pump

If, after pressure testing, the pumped water will be used in the future as a coolant, then it is necessary that it be “soft”, that is, have a hardness of no more than 75-95 units (mainly, this is the presence of magnesium and calcium salts) . An example of “soft” water can be rain or melt water, from snow or ice. If you are not sure about the hardness of the water, and an indicator of its increased hardness may be the formation of scale in an electric kettle, heating elements of a washing machine or boiler, then it is better to do an analysis in the laboratory.

In the same case, if the water used for hydraulic tests will not be used as a coolant, then after pressure testing it should be drained and the system should be immediately filled with the appropriate coolant. This is especially important if pipes made of black steel were used during wiring, and cast iron or steel were used as radiators without protecting their inner surface.

Features of air crimping

Air pressure testing is used less frequently, as a rule, for small buildings and private houses, if hydraulic tests cannot be carried out for some reason. For example, if it is necessary to check the tightness of an installed system, but there is no water or equipment for pumping it.

Compressor for pressure testing the heating system

In this case, an electric air compressor or a mechanical (foot, hand) pump with a pressure gauge is connected to the make-up or drain valve and, with the help of it, excess air pressure is created in it. It should not exceed 1.5 atm. (bar), since at higher pressures, in case of depressurization of the connection or rupture of the pipe, injury to the people conducting the tests may occur. Instead of air valves, plugs must be installed.

Pneumatic tests require more time to hold the system under excess pressure. Since, unlike liquid, air is compressed, it takes more time to stabilize and equalize the pressure in the circuit. Initially, the pressure gauge reading may drop slowly even if it is sealed. And only after the air pressure has stabilized, it is necessary to maintain it for at least another 30 minutes.

Pressure testing of open heating systems

In order to carry out pressure testing of an open heating system, it is necessary to seal the connection point of the open expansion tank, for example, using a ball valve installed on the pipe supplying water to it. When pumping water, it can be used as an air valve, and after it is filled, the tap must be closed before creating excess pressure.

The operating pressure in such systems, as a rule, is determined by the height of the expansion tank, on the basis that for every 1 m of its excess above the level of the return inlet into the boiler, there is 0.1 atm of excess pressure in this place. In one-story houses, an open expansion tank is usually located under the ceiling or in the attic. The water column in this case will be 2-3 m high, and the excess pressure, respectively, will be 0.2-0.3 atm. (bar). When the boiler room is located in a basement or in two-story houses, the difference between the level of the expansion tank and the boiler return can be 5-8 m (0.5-0.8 bar, respectively). Consequently, in this case, to carry out hydraulic tests, a lower excess fluid pressure is required (0.3 - 1.6 bar).

Otherwise, the procedure for performing pressure testing of open systems (one-pipe and two-pipe) is the same as for closed ones.

Video description

This video shows a test of a separate system unit using air

On a private plot

For private areas, most often the working pressure does not exceed 2 atmospheres. Therefore, when checking, a pressure of 4 bar is used. Car pumps or small compressors can be used during testing.

Before checking the pipes for leaks and pressure resistance, it is necessary to drain all liquid from the system into a large container for reuse. This is necessary to ensure that coolant with impurities does not enter the system. After this, a special liquid with special additives is poured into the circuit, which helps flush the pipes from excess dirt, scale or rust.

Before flushing the system, it is necessary to clean all water filters and put them back. Cleaning the pipes can be done several times, if necessary, and the water temperature should be from 55 to 60°C. After each run of the purifier, the water filters should be checked. The rinsing can be completed if they remain clean after the test.

Pressure testing with water Source konyademirdokum.com

If the water remains clean after washing, it can be reused to build up pressure during pressure testing. But for this you should let it cool to 40-45 °C. If a manual blower is used, then water must be poured into its tank and the pressure in the system increased using a lever. After it has reached the desired mark, the circuit must be checked within 30 minutes.

Similarly, with multi-storey buildings for private plots, it is also necessary to re-test the system if the pressure drops below normal. To do this, you must first find and repair the leak.

If the pipes are under a concrete covering, and there are no leaks in open areas, then you need to look for wet spots on the surface of the walls or floor, since if depressurization occurs there, the water will wet them. You can also use a thermal imager to detect leaks. If the spots are not visible and the pressure drops, then at high temperatures you can find the problem area using this device.

Video description

This video shows why the pressure in the circuits may drop

Open systems with air

Air testing can be used to test open heating systems. Most often, an expansion tank is used to create pressure in private areas, and the pressure in the system when using it is 1 bar. Therefore, for testing, this parameter will be 2 atmospheres, which can be pumped up using a conventional hand pump.

Before performing the test, all liquid from the system must be drained (preferably into a separate container for reuse) and the pipes must be flushed. After cleaning, all water must be drained and tightly closed all places through which air can be released, for example, Mayevsky taps. It is also necessary to close the inlet pipe that leads to the tank. After this, you should connect the pump to the system through a special fitting using a hose, which is recommended to be secured with clamps, and begin to apply pressure.

Open heating circuit Source izion.pro

Pipe flushing

After familiarizing yourself with the fact that this is pressure testing of the heating system, you should consider one of the important components of this process, namely flushing the pipes. When pouring water into the system, the liquid may contain impurities that, during heating, can leave scale or salts on the walls of heating systems. This reduces the working cross-section of the pipes and can cause blockages, just like rust.

These 2 harmful impurities reduce the rate of heating and cooling of pipes and increase the pressure inside the heating circuits. This can lead to overheating of individual sections of the heat pipe and the formation of fistulas (cracks or holes). If scale or rust has formed a 1 mm layer on the wall, this will degrade the performance of the system by 15-20%, which will lead to a severe loss of thermal efficiency.

Example of a dirty pipe Source restreamsolutions.com

The main indicator of clogged pipes is the speed at which they heat up, the uniformity of this process, as well as increased fluid flow inside the circuits. To clean the system from harmful deposits, the system is pumped with water with special impurities, after which an air compressor is connected. It is needed so that, due to high pressure, turbulence is created in the water flow, which creates additional vibrations in places of deposits.

During such washing, scale and rust are torn off the walls and driven towards the filters. When carrying out this activity, you should close all air valves that should relieve excess pressure. It is also recommended to install a check valve at the junction of the compressor mount in order to avoid water backflow.

Flushing device Source www.lhps.co.uk

Equipment for crimping

Hydraulic tests are carried out using a pressure tester, which is connected to the system to regulate pressure.

Heating in private homes can be checked with a manual pressure tester, since these systems do not require high pressure for testing. Such devices are capable of developing a force of 60 bar and higher; such values make it possible to test water heating systems in multi-storey buildings.

Manual devices have the following advantages:

- A price affordable for most consumers.

- Small weight and dimensions of the device. Thanks to this, they can be used both for personal interests and in the professional sphere.

- Long service life.

- Ability to check medium and small heating appliances.

It is recommended to check systems of multi-storey buildings and industrial facilities using electrical instruments. This equipment supplies water to the system at high pressure, up to 500 bar, which is inaccessible to manual devices.

Electric pumps can be built into or connected to a pipeline. In most cases, the hose is connected to a tap through which water is supplied to the system.

Such work falls into the category of complex technological procedures, so it is important to know and understand how pressure testing of a heating system is carried out. It is best to entrust the inspection to specialists.

Source

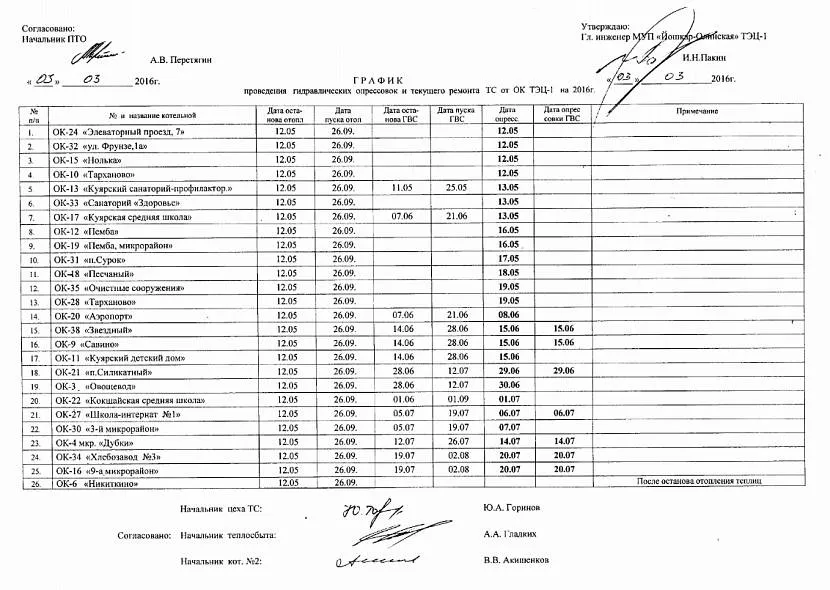

Documents for crimping

To carry out pressure testing of the system, you must have a plan, which is reviewed and signed by the chief engineer of the company that supplies heat. This document determines the sequence in which the inspection will be carried out, as well as what employees should do during the process. Also, after all checks, a pressure testing report must be drawn up, which describes:

- what verification method was used;

- the project for which the heating system was installed;

- the date of the tests, the address of the place of conduct and the names of those people who sign this act;

- what methods were used to fix leaks or problems in the circuit;

- test result;

- the presence of places that violate the tightness of the system and the formation of condensation on fittings or pipes.

After all checks, the act should be checked for errors or inaccuracies, and then signed. There is also a schedule for flushing and pressure testing the heating system, a sample of which can be seen below.

Pressure testing schedule Source yolatec1.ru

Crimping procedure

To check the heating system in this way, hydraulic tests are carried out on the following elements:

If leaks are detected during testing, a conclusion is made about the depressurization of the network.

Immediately before testing, the water supply and heat supply systems are isolated. They also visually determine the strength of the existing connections, check the shut-off valves for operability and evaluate their general condition.

At the next stage, the expansion tank and heating boiler are turned off in order to flush heating devices and pipes from deposits of various natures and remove debris and dust.

If hydraulic tests involve filling the heating system with water, then a compressor is connected to the drain valve to test with air. Gradually, the pressure in the system increases, its indicators are monitored on special pressure gauges. If there are no changes, a conclusion is given about the good tightness of the system and the possibility of putting it into operation. Pressure testing of heated floors with air is carried out in a similar way, including some nuances.

Briefly about the main thing

Pressure testing of the heating system is checking the functionality of the heating circuits and testing them for leaks.

Pipes should be checked after installing the entire heating system, repairing it, and every year before and after the heating season for preventive purposes.

For crimping circuits, manual or electrical equipment will be used. This depends on the size of the system, the funds and time that you plan to spend on testing.

Ratings 0

Pneumatic testing of heating systems

The main limitation of hydraulic tests is carrying out work in rooms with a positive temperature, which is extremely difficult in a building under construction. Therefore, before the main test work, the heating system is often pressurized with air.

The compressor is connected to the drain valve or to the Mayevsky valve at any point in the system, increased air pressure is pumped in, and the system is maintained for a certain time without a drop in pressure.