Commissioning works

After the assembly of the pyrolysis boiler is completed, it is necessary to check the tightness of the welded joints. The water jacket is filled with water, then air is pumped into it, creating excess pressure. Poorly welded seams will make themselves felt by leaks. Now you can carry out tests, it is better to do this outside, supplying running water from a hose. If a safety group is installed on the unit, then you can fill the boiler tank with water and check its operation at a critical pressure of 2-2.5 Bar. The test order is as follows:

- Attach a temporary chimney, load fuel into the chamber and open the direct draft damper.

- Stop the flow of running water by providing a temporary tap.

- Ignite and start the pyrolysis boiler. As soon as the firewood flares up, the direct draft damper must be closed so that the pyrolysis process can begin.

- Open the secondary chamber door and make sure there is a flame. This requires adjustment of the pyrolysis boiler; you need to achieve an even and stable flame by opening or closing the air damper.

- Close the door and observe the readings of the thermometer and pressure gauge. In a closed water jacket, the process of vaporization can begin when the pressure reaches 1.5 Bar, at which time the temperature must be carefully monitored.

- High-quality welded pyrolysis heating boilers can withstand pressures of up to 3 Bar, but there is no need to set records. It is enough if the safety valve set to a pressure of 2 or 2.5 Bar begins to release steam, then you can open the tap and resume water circulation. The air supply damper must be closed for the fuel to begin to fade.

Scheme and drawings of a pyrolysis boiler

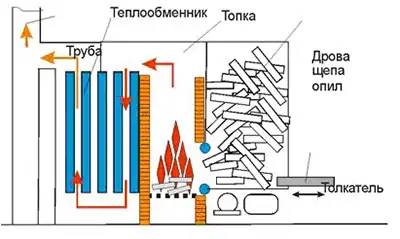

To better understand the operating principle of this equipment, it makes sense to understand how such a boiler works and disassemble its circuit diagram.

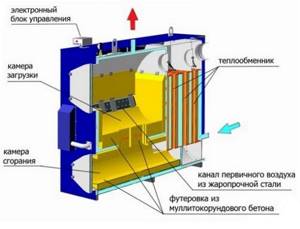

The pyrolysis furnace consists of the following parts.

- Gasification chambers.

- Afterburners.

- Air supply systems (primary, secondary).

- Water shirt.

- Grate.

In addition, the design of a pyrolysis boiler includes pipes for water supply, a combustion chamber, control equipment, a fan and some other components.

A pyrolysis boiler is a rather complex technical device. When producing it yourself, you must strictly comply with all the requirements of the working documentation.

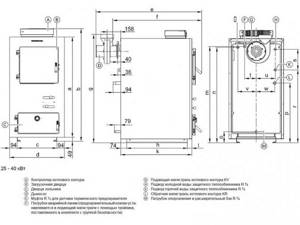

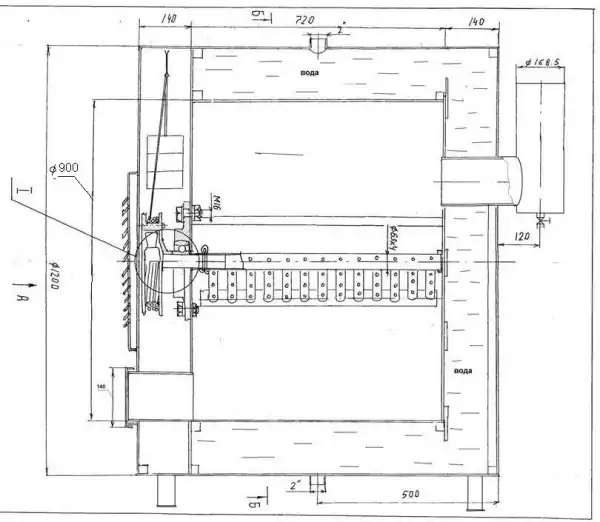

We offer a drawing of the boiler, which will be useful during manufacture.

The following diagram will help you understand the internal structure of the boiler.

As a rule, a boiler with a capacity of 40 kW is sufficient to heat a country house. If this indicator needs adjustment, then you can change some oven parameters.

In order to make a boiler, it is necessary to prepare its main structural elements.

Safety precautions

When installing a homemade boiler, we follow the following important rules:

- to install the heating unit, you need to allocate a separate boiler room;

- The boiler room must be equipped with an effective ventilation system. The minimum area of the air duct opening is 100 cm2;

- the distance between the unit and any other surfaces and objects must be more than 20 cm;

- Before firing the boiler, we lay a steel sheet with a thickness of at least 3 mm on the floor;

- we install the boiler on a pre-equipped brick or concrete base;

- The chimney must be properly insulated. Without thermal insulation, the formation of condensation, soot and other troubles will be more intense. This will negatively affect the efficiency of the equipment and its service life.

Finally, the boiler efficiency is checked. To do this, just do a test load of fuel. If the smoke coming out does not have a carbon monoxide smell, then everything is in order with the efficiency of the boiler and it can be used to heat the house without any fear.

Optional equipment

Unfortunately, pyrolysis boilers are not energy independent. Due to the reverse flow of gases, forced charging is required. For models with a power of up to 15 kW, it is implemented by a blower fan, which is mounted on the bottom door. In this case, replenishing the load during the combustion process is impossible.

More powerful boilers are equipped with a smoke exhaust fan, which is installed on the upper wall of the housing at the outlet of the chimney duct. In this case, the appearance of reverse draft is eliminated and the door of the gasification chamber can be opened without consequences even during the combustion process.

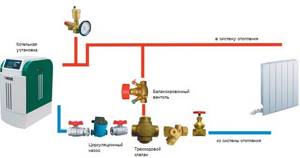

Particular attention should be paid to the temperature of the coolant inside the jacket. After the boiler returns to operating mode, it should not be less than 60 °C to prevent the formation of condensation. This problem is solved by installing an automatic recirculation unit that mixes water from the supply to the return

Installation of a safety group for closed heating systems and the main circulation pump is also required. published econet.ru

This problem is solved by installing an automatic recirculation unit that mixes water from the supply to the return. Installation of a safety group for closed heating systems and the main circulation pump is also required. published econet.ru

Advantages of gas generating equipment

Now that we know how a pyrolysis boiler works and what types of fuel can be used for it, it should be noted that among solid fuel models this is the most economical type. The functioning of such equipment is characterized by:

— rapid transition to energy efficiency mode;

— stable temperature in the heating system, provided that there is fuel in the firebox;

— no need for frequent cleaning;

— the boiler is appropriate to use in conjunction with any system;

- does not require installation of a chimney;

— made of corrosion-resistant, heat-resistant materials.

This list of parameters indicates the operating efficiency of pyrolysis boilers in comparison with traditional solid fuel models, so they can be used for work in any room. High cost is the only drawback of such equipment, however, if it is impossible to use alternative devices other than solid fuel ones, the choice will be in favor of the former.

What does a pyrolysis boiler consist of?

The principle of fuel decomposition and combustion of the resulting gases is used in pyrolysis boilers. Combustion occurs at high temperature and completely.

The design of such boilers is more complex than conventional grate boilers, they are more expensive, but much more efficient.

The pyrolysis boiler consists of:

- From the primary chamber. It resembles the furnace of a conventional boiler into which fuel is loaded. Depending on the design, combustion can occur either at the bottom of the fuel chamber or from top to bottom.

- Secondary camera. It mixes pyrolysis gases with secondary heated air and hot combustion of the resulting mixture. Due to the high temperature, carbon is completely oxidized to carbon dioxide.

- Air supply, separation and heating systems. There are boilers with natural draft or with forced air supply.

- Heat exchange and smoke removal systems.

- Automatic control.

Design and layout of installation elements

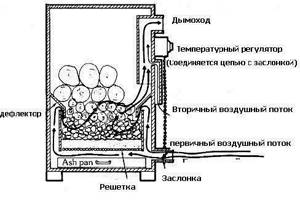

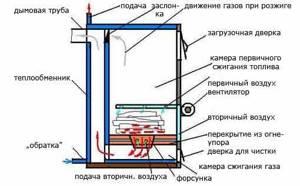

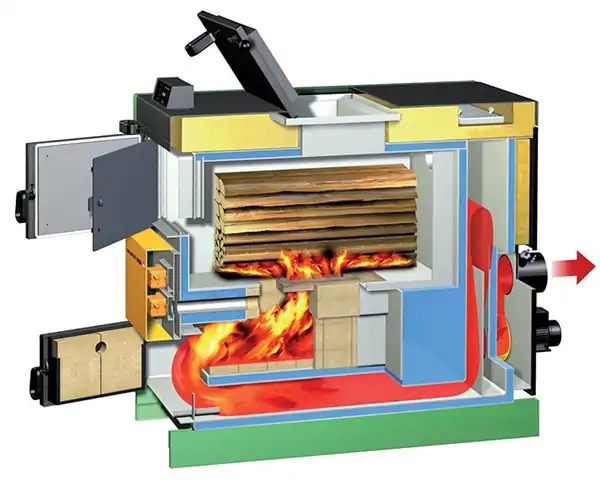

Unlike classic solid fuel installations, long-burning pyrolysis boilers provide two combustion chambers instead of a traditional firebox. In the first chamber, slow combustion occurs due to insufficient air. In this case, the fuel begins to release so-called pyrolysis gas, which flows into the secondary chamber along with combustion products. A sufficient amount of air is supplied there, as a result of which the gas ignites and burns, heating the water jacket of the unit.

The location of the two chambers may be different, since pyrolysis-type heating boilers can operate either using natural chimney draft or using forced air supply from a fan. In installations using natural draft, the secondary chamber is located above the primary and air passes through the fuel from the bottom up. With artificially created draft, the main firebox, on the contrary, is located above the afterburning chamber and the air flow is directed from top to bottom. This is reflected in the diagrams below for the design of pyrolysis boilers with different chamber layouts.

Principle of operation

A certain amount of firewood, which is determined by the volume of the loading chamber, is loaded into it and pre-ignited when primary air is supplied. When the fuel ignites, conditions are artificially created with insufficient oxygen content, due to which flammable gas is released from the wood. It is a mixture of carbon monoxide and volatile hydrocarbons. As the pressure in the loading chamber increases, it flows through the nozzle into the combustion chamber. Secondary air is also supplied here. Its mixing with pyrolysis gas, as well as high-temperature conditions, ensure ignition and combustion of the gas mixture.

During combustion, heat, carbon dioxide and water are released - in most cases, they speak of complete combustion of the fuel with the release of “clean” combustion products listed above. Heat through the walls of the heat exchanger is transferred to the coolant, which is water circulating in the water heating system. Cooled combustion products are discharged through the chimney.

With your own hands

Below is a 25-minute video of designing and making your own pyrolysis boiler. The author describes the assembly process step by step and also talks about the difficulties encountered.

Wrong alloy. The most common mistake, which, by the way, is typical not only for home-made models, is the use of the cheapest materials from ferrous metals. They do not belong to the category of heat-resistant materials, which ultimately leads to burnout of the structure and difficult, or even simply impossible, repairs

It is necessary to carefully select the steel grade and use special heat-resistant alloys. For example, 20Х23Н18 and the like.

Thin steel

Another mistake is the incorrectly selected thickness of the steel sheet. This parameter is determined based on the temperature distribution throughout the boiler, but the minimum value is about 5 mm. The thicker it is, the more expensive it is, but then the boiler will work longer.

Blueprints

An attraction of unheard of generosity – there’s no other way to describe it! From us you can download drawings of pyrolysis boilers completely free of charge. This will allow you to assemble the heart of the heating system in your backyard or garage if you wish.

See examples of graphic materials in the images below.

You also have a unique opportunity to order a set of drawings for one of the models at a very attractive price. Of course, this is an option for those who are going to make a boiler with their own hands, not only for themselves, but also to order. To contact, use the form below.

Difficulties

Tightness is one of the main difficulties that arises when building a pyrolysis boiler with your own hands. That's why they check it twice.

The first time this happens is when all the main components of the boiler are welded, but its interior is still open. The holes for the coolant are blocked tightly with plugs and water is drawn into the boiler. A mark is made at the location where the leak is detected. This part is then digested again.

The boiler is checked the second time when the entire system is completely assembled. To do this, along with water, a pressure tester is used, which pumps up a pressure of 3-4 bar, which should not drop sharply. If it remains at a stable level, then the unit is sealed.

Some features

The boiler configuration, its characteristics, drawings will depend on many factors:

- Material. Regular steel (sheet) will do, but heat-resistant stainless steel or cast iron is best.

- Possibility of good processing of steel, reliable connection of structural parts. Usually, a grinder, a gas cutter and electric welding are used for this.

- Type and characteristics of fuel (liquid or solid). Steel must withstand high temperatures, not deform, and not melt under their influence. Withstand internal pressure of vapors and gases without ruptures or cracks.

- Correct calculation of the coolant circulation method. Will it be natural (due to correct manipulation of pipe diameters, their slope, tank height, etc.) or forced (using a pump in the circuit).

- Taking into account vapor pressure, using valves to discharge excess gases and condensate (installation of return lines).

General principles and possibilities for implementing the idea

Any boiler, no matter whether it is a home-made water heating boiler, or a home-made heating boiler for a furnace, requires the following design: there is a fuel that, when burned, transfers its heat to a heat exchanger, which then heats the coolant (usually ordinary water). The effectiveness of such a simple design depends on two main factors:. The effectiveness of such a simple design depends on two main factors:

The effectiveness of such a simple design depends on two main factors:

- The structure of the heat exchanger. With an increased contact area between the heat exchanger and the fuel tank, heat is transferred faster and the coolant is used more efficiently

- Fuel combustion quality. The high-quality design of a homemade boiler for water heating provides a good flow of oxygen into the tank with burning fuel. If heated gases or fuel vapors evaporate, the design must be modified

In order to assemble the boiler, it is necessary to take into account two important nuances:

- Availability of raw materials. Of course, for homemade wood heating boilers it is better to use heat-resistant types of steel, but in practice ordinary steel sheets are used - they are much easier to get, and they cost an order of magnitude cheaper

- Methods of processing materials. Assembling a cast structure for a homemade wood-burning heating boiler from fire-resistant materials at home simply will not work due to the lack of technical base. And purchasing such a base is more expensive than creating several heating boilers

Installation

Quite a lot of people do not have sufficient knowledge and do not have special tools or skills to use them. But even the lack of a welding machine and the ability to use it is not scary. Step-by-step instructions for installing and piping a finished pyrolysis boiler will help fix the problem. Knowing it is useful, of course, when using self-made equipment. It’s worth clarifying right away that the decisive factor when choosing a connection scheme is the priority of simplicity or functionality.

Thus, the most advanced options allow the use of heat-accumulating containers that help maintain a stable temperature for up to 48 hours even when the boiler is not working.

Before installation, you should purchase specially selected:

- fitting;

- pipes;

- bends;

- filters;

- check valves and other devices.

Experts believe that the best circulation pumps are made in Germany. They may be a little more expensive than models from other countries, but the durability and increased performance make the difference worth it. But you can choose the manufacturer of other components at your own discretion. Since inside the pyrolysis boiler there are circuits with very strong heating, as in metallurgy, fire safety standards must be scrupulously observed. The boiler room should be located in a separate room.

Normal ventilation will be achieved only through an opening measuring 100 square meters. see. The boiler must be placed exclusively on concrete or brickwork. The space in front of the chambers is covered with a steel sheet measuring 1x1 m and at least 0.2 cm thick. It is unacceptable to install the boiler where firewood is stored. The elevation of the chimney above the roof must be at least 0.4 m, and it is prohibited to install unsealed structures for smoke removal.

The minimum approach to walls, even those made of non-combustible materials, is 0.7 m. It is advisable to level the boiler, since the slightest tilt to the side will have a bad effect on its characteristics. Experts and experts recommend insulating the chimney from the inside. This helps to accurately avoid the occurrence of condensation and associated negative phenomena. All these tips can be implemented without turning to specialists, that is, at minimal expense.

The chimney pipe must reach a height that supports the desired draft. The minimum value is 50 cm above the ridge of the tallest building located within a radius of 10 m. Installation of chimneys whose diameter differs from the diameter of the dampers or chokes of the gas passage is not allowed. After these gates, a straight vertical with a length of 2 m should be installed; only in the next section is a rotation of 45 degrees possible, strictly up to 100 cm.

For modular chimneys, “condensate” assembly is practiced, when the upper bends are inserted into the lower segments. The chimneys must not put even a little pressure on the dampers. A gap of at least 15 cm is left from the top line of the head to the top of the pipe. Thermometers are placed strictly on the return lines of heating systems, at least 1 m from the boiler. It is advisable to use a thermometer with scale markings up to 120 degrees.

It is better to form the initial section (1 m of coolant outlet) and the same segment at the beginning of the return stroke from metal. The first turns are made in the half-bend format. You cannot use right angle turns instead. In general, it is recommended to reduce the number of turns. There must be at least 2 m of free space between the front of the boiler and fences or walls.

Do-it-yourself solid fuel boiler is a reality

Anyone who knows how to operate a welding machine and an angle grinder can make a solid fuel boiler with their own hands. Before starting work, you need to choose the optimal type of heating element, perform the correct calculation of the power of a solid fuel heating boiler, select the required construction material, and decide on the type of heat exchanger.

During the work, it is imperative that you follow state standards regarding the safety and efficiency of heating equipment. The boiler must be built according to a pre-created drawing, for the creation of which you can hire a specialist.

Expert advice on boiler combustion

Let's see what the professionals say regarding choosing the optimal type of fuel.

So, when burning wood, a lot of smoke will be generated. To get rid of the inconvenience associated with this, you need to place larger logs along the edges of the load, and put small kindling in the center.

In densely populated areas, it is recommended to refrain from using peat, because... during its combustion, a large amount of carbon dioxide is released and various large particles are released into the atmosphere, which is unlikely to please the neighbors.

To effectively use anthracite, you need a strong hearth. The power of a pyrolysis boiler is usually not enough to completely burn such fuel. To reduce costs, sift out large surviving fragments from the ashes and reuse them.

Thus, having mastered welding skills and following the recommendations given, you will be able to independently make an effective, reliable, safe and economical pyrolysis boiler.

Boiler operation

Good luck!

Video - DIY pyrolysis boiler

Prices for the range of solid fuel boilers

Solid fuel boilers

Operating principle

Before considering the diagrams and drawings of pyrolysis boilers, it is necessary to understand the principle of their operation. So, in the process of burning fuel (in other words - dry distillation) under the influence of high temperatures (about 200-800 ° C) and insufficient oxygen, wood decomposes into two parts: the volatile part (pyrolysis gas) and solid sediment ( charcoal).

The design of the pyrolysis boiler assumes that pyrolysis gas will accumulate at the top of the chamber, which, with the air flow created by the smoke exhauster, will be sent for afterburning to another chamber. This is an exoteric process, accompanied by the release of heat, which improves heating, dries the fuel in the boiler, and also heats the air entering the combustion zone. The mixing of pyrolysis gas released at high temperature with atmospheric oxygen causes the combustion process of the former, which is subsequently used to produce thermal energy.

Manufacturing nuances

From the above, it becomes clear that many complex chemical processes will take place inside the future home-made boiler, and the efficiency and safety of the unit will depend on how correctly they are carried out. Therefore, if a choice has been made in favor of developing the circuit and assembling a home-made unit, this process must be taken with great responsibility.

The situation is complicated by the fact that open sources do not have many drawings, as well as detailed photos of boiler designs. Most of them are generic and lack step-by-step instructions as well as details.

There are two options to solve this situation:

- Buy drawings with step-by-step assembly instructions from manufacturers or people who have good experience in the design, manufacture and testing of gas-generating boilers.

- Take up books and modeling programs yourself to develop a design and drawings for a pyrolysis boiler.

When designing, working out step-by-step instructions, as well as manufacturing, you need to take into account the following features:

- The material from which the gasification, combustion and post-combustion chambers will be made must be steel with a heat-resistant lining. The reason for this is 1000 °C inside the combustion chamber. If you use standard sheet steel, it will burn out in two or three seasons. According to many videos, it most often burns out under the combustion and afterburning chambers.

- It is better to make a water heat exchanger. Although it is more complex because it requires the manufacture of two containers that are connected by a system of pipes, it is more reliable and lasts longer. As for the fire tube heat exchanger, it lasts less, because the pipes must be heated to a temperature of more than 600 ° C. Such heating leads to rapid burnout. People choose such heat exchangers because they are easier to manufacture, because they represent one water container with a small number of vertical tubes placed inside it.

- The heat exchanger is placed only in the rear chamber. It should not be placed in chambers where fuel burns. This is because it will absorb heat, which will disrupt the processes of pyrolysis and combustion of gases. The efficiency will become less.

- Cameras should be made round or rounded. If the design of the pyrolysis boiler includes rectangular containers, then the efficiency will be lower, because that part of the heat that disperses to the corners will simply disappear without giving any benefit. Moreover, such a leak will reduce the temperature in all chambers and disrupt the processes that occur in them. The ideal cameras are round. They look like a barrel placed on its side.

- The nozzles also need to be made round. Ideally, they should be in the shape of a circle. However, such holes quickly become contaminated with ash and need to be cleaned. The latter process damages the lining. Therefore, it is worth choosing a nozzle with a slit that runs through the entire length of the bottom. Due to this solution, the efficiency does not drop very much - up to 3%.

DIY pyrolysis boiler: rules and nuances

In order to install a pyrolysis boiler with your own hands, while maintaining all its working qualities, it is necessary to rely on accurate drawings and calculations. An incorrectly assembled boiler, installed according to an incompetent design, will not only perform its functions poorly, but will also pose a safety threat to the environment and to you in the first place.

Rules for assembling a pyrolysis boiler with your own hands:

- Your first priority, before starting assembly, is to familiarize yourself with the drawings, plans and diagrams. They will help determine the amount of material needed for work, and will also protect you from possible emergency situations;

- Check the presence of fundamental elements, without which it is impossible to assemble the pyrolysis boiler yourself. These are: regulators, air holes, smoke channels, water drainage pipes, combustion chamber, water supply pipes, and a fan;

- Please note that if you plan to heat a standard country house, a 40 kW pyrolysis boiler is quite suitable for you, and if you are the owner of a very small cottage, then a 30 kW boiler will be enough. There is no point in installing super powerful boilers, since a small device will perfectly insulate the premises, while huge units will cost a lot of money and require significant expenses;

- It will not be superfluous to prepare the necessary tools for installing the boiler. So that you don’t have to run to the hardware store one more time, prepare everything you need right away. To install a pyrolysis boiler with your own hands, you will need the following tools: grinder, grinding wheels, welding machine, electric drill, pipes of various diameters, electrodes, fan, steel strips, temperature sensor, metal sheets

Please note that assembling a pyrolysis boiler with your own hands is a long and painstaking process, so be prepared for possible difficulties. However, by carefully preparing for the process, you significantly reduce the risk of unexpected problems.

After all the rules have been followed, the desired circuit has been selected, it’s time to begin the actual assembly. When assembling the device step by step, make sure to comply with the following nuances:

- Unlike conventional boilers, the hole for placing firewood in the firebox should be located slightly higher;

- Be sure to check the presence of a restrictor that fixes the air supply to the boiler. Its optimal dimensions are 70 ml in cross-section and a length exceeding the dimensions of the body;

- The disk welded to the limiter must be made of stainless steel and located at the bottom of the entire structure;

- It is best to have a rectangular shape for the hole for supplying solid fuel. For a pyrolysis boiler, this shape is optimal;

- The door must close tightly and securely; a special lining is required that will tightly secure the closure;

- Provide in advance and then do not forget to make a special hole with which you will remove accumulated ash;

- The coolant pipe should not be straight, but slightly curved. This shape is necessary to increase heat transfer;

- The location of the valve should be convenient and accessible. Thanks to it, you will control the process of air entering the firebox;

- First start. After you have completed assembling and installing the pyrolysis boiler yourself, conduct a test run of the device. Using special equipment, check the correct operation at all stages and make sure that carbon monoxide does not accumulate in the boiler. Only after this can the boiler be fully put into operation.

Design of a homemade unit and calculation of materials

A do-it-yourself pyrolysis boiler is made mainly with an upper loading firebox, under which there is a gasification chamber. It is easier to manufacture and has good efficiency. If you have some engineering skills, you can make changes to the finished drawing, but the internal dimensions are left the same or with minor adjustments. It is better to make the fireboxes the same in width and length, the only differences being in height.

To calculate whether the device is suitable in terms of power, we proceed from the following rule: every 10 m2 of room requires 1 kW of energy. The value is multiplied by a factor of 1.2, but in practice it is increased to 1.5, since high-quality fuel is not always available. If, for example, we assume that the device produces 20 kW, then it is capable of heating 200 m2 of area, but taking into account the reserve - 130 m2. A boiler of this performance is available for self-production; with higher power, the use of special heat-resistant steel of large thickness is required. It is difficult to cook it at home.

It is recommended to use heat-resistant alloy steel for cameras, but its cost is significant, so it is replaced with simple carbon steel 5 mm thick. The burning gas creates a high temperature in the working area of the compartment. To protect the metal, a cast iron grate is installed at the bottom of the filling chamber, and the bottoms of both fireboxes are lined with refractory bricks.

The water jacket operates under pressure, which requires high quality seams. The main factor preventing this is hot and cold cracks, which are formed due to a high temperature difference over a relatively short length of the product. To reduce the negative consequences, several technological techniques are used:

- the metal is cut by smoothly feeding the cutting tool to protect the edges from overheating;

- welding is carried out in a soft mode, reducing the required current by 20–25%;

- the seam passes without lateral vibrations at high speed;

- They line it with thick metal for faster cooling.

The designs of many pyrolysis boilers do not provide for the use of water as a coolant. Then the exchanger is not sealed; hot air enters the room through its pipes, and the influx of cold air comes from the floor. This solution has its advantages, especially for summer residents who occasionally visit their country house. Then there is no risk of the system defrosting.

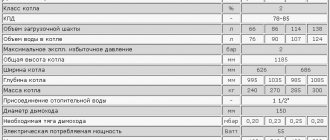

You can significantly reduce the cost of a homemade installation by choosing the right metal and equipment. The required materials and their characteristics are given in the table:

| Name | Dimensions, mm | Consumption |

| Round pipes | 57×3,5 | 8 m |

| 159×4,5 | 1m | |

| 32×3,2 | 1m | |

| Profile pipes | 60×30×2 | 1.5 m |

| 80×40×2 | 1m | |

| 20×20×2 | ||

| Steel strips | 20×4 | 7.5 m |

| 30×4 | 1.5 m | |

| 80×5 | 1m | |

| Fire brick | 15 pieces | |

| Sheet metal | 3 and 5 mm | 10 m2 |

As for the tools, in addition to the welding machine, you will need grinders with the ability to install disks with a diameter of 230 and 125 mm. Circles require 10 large and 5 small. The use of an angle grinder for cutting metal does not provide accuracy, which then affects the quality of the seams. It is better to order production using a guillotine in a workshop. An electric drill will come in handy. Perhaps during work there will be a need to buy some more material, but this can be solved.

Manufacturing instructions

When you have everything you need (material and tools), all that remains is to assemble the boiler in the following sequence:

- We take 2 barrels with different diameters, wall thickness of at least 4 mm;

- Use a grinder to cut out holes for the ash pan and water container;

- We install one cylinder of smaller diameter inside the other;

- We weld the lid over them, the ash pan, and the firebox;

- Close the door;

- We weld water pipes, a pipe for a check valve (pressure relief);

- We install a grate inside the oven;

- We make a hole for the chimney;

- Install the pipe;

- We check the tightness.

When there are no leaks in the boiler, it is connected to the heating system and water supply network.

After installing the boiler into the heating system with your own hands, you need to check that it is working correctly. A properly assembled device will heat the coolant (water or oil) during the combustion process. If he does this poorly, then you should check for air pockets in the heating network and reduce the vapor pressure by releasing them.

In any case, you need to understand the operating principle of this type of boiler so that there are no excesses or problems during its operation.

Connecting the boiler to the heating system

The last stage is connecting the pyrolysis boiler and piping it. As with all solid fuel installations, it is necessary to prevent the formation of condensation on the internal walls of the firebox during heating. This phenomenon shortens the service life of the furnace body, since the condensate contains sulfur inclusions and will cause intense corrosion of the metal. For this reason, the piping of the heating boiler must be done according to a scheme that does not allow cold water to enter the jacket during heating.

Below is a classic diagram for connecting a pyrolysis boiler to a heating system with a balancing valve between the supply and return pipelines.

The jumper forms a small circuit in which the coolant is driven by a circulation pump. The piping of a pyrolysis heating boiler shown in the diagram allows water to circulate through a small circuit, warming up along with the unit. The thermostatic three-way valve will begin to add cold water from the system at the moment when the water temperature in the small circuit reaches the set value, usually 45-50 ºС.

The operating temperature in the heating system is in the range of 60-80 ºС; it is rarely necessary to raise it higher. If your home is cool when operating in this temperature range, then you need to look for the reason in the system itself. It makes no sense to increase the temperature; this will only increase the consumption of firewood in the pyrolysis boiler.

Selecting the type of solid fuel heating element

The most economical solid fuel heating boiler is a pyrolysis type or top-burning device. For self-production, the first option is difficult. An upper combustion device is somewhat easier to design, but here the drawings and calculations must be carried out by a specialist, which costs a lot of money

That is why people who want inexpensive solid fuel heating boilers should pay attention to the designs of the traditional structure

Before starting design, you also need to consider what type of energy carrier in the region is considered the most accessible. If it is firewood, then the combustion chamber must be large. After all, only a large volume of wood can ensure normal temperature conditions in the house. In the case of a small firebox, energy will need to be constantly supplied, which is not very convenient.

If it is planned to use coal as the main fuel, then the firebox can be made small, thus saving on structural materials. Coal is energy efficient and a large amount of it in the firebox can increase the temperature of the coolant to a critical level, which can lead to an accident.

Installation specifications

Industrial pyrolysis equipment allows you to process tens of tons of material per day, but its disadvantage is its large size.

Main parameters of the units:

- productivity (kg/hour or cubic meters per day);

- installation weight (mobile units weigh 3-8 tons, stationary units weigh more than 10 tons);

- dimensions;

- power;

- type of power supply (required fuel/electrical network parameters);

- mobility (is disassembly required for transportation);

- number of floors of the installation (number of levels).

Sometimes the manufacturer of pyrolysis plants indicates additional parameters: payback, reactor volume, etc.

Classification

The boilers differ in the location of the combustion chambers:

- with top position;

- with a lower location.

Boilers with an upper chamber are more bulky and require more material to assemble the chimney. But they will have to be cleaned much less often, because particles from burnt fuel do not enter the chamber for afterburning gases.

In boilers with a lower section, the fuel is located in the upper part, and the gases are discharged to the lower part and burn out there. This is convenient, but you will have to frequently remove small wood particles from the gas recovery chamber.

According to energy dependence, boilers are:

- without the use of electricity: boilers with natural draft;

- with forced draft.

Non-volatile boilers require the inclusion of a high chimney (at least 5–6 meters) in the design to increase draft and ensure sufficient vacuum in the combustion compartment.

The heating efficiency of such boilers will be slightly lower than that of forced draft boilers.

Devices with forced air supply are equipped with one or two fans that can operate in the mode of pumping air or pumping out burnt gases.

Some boiler models use a combined method involving gas injection and suction devices to increase power.

Reference! Mechanisms that pump out exhaust gases are made of special heat-resistant (austenitic) alloys; their cost is much higher than that of blower fans.

By heating method:

- Water heating - water pipelines are connected to the boiler heat exchanger, through which the heated working fluid is distributed to various rooms.

- Air heating - instead of water, air is used, receiving heat through the same heat exchanger and distributed through air ducts. The efficiency is lower than that of the water method; it is used at production sites and warehouses.

Photo 1. Pyrolysis boiler with a heat exchanger, designed for water heating, runs on wood.

Drawing: general view, workflow

There are many design options for a pyrolysis boiler. The simplest view according to the drawing is arranged in this way.

- Boiler combustion chamber.

- Gasification compartment.

- Gas afterburning section.

- Grate grates.

- Heat exchanger (inlet/outlet pipes).

- Gas exhaust pipe (chimney).

- Ventilation holes.

- Door to the compartment for storing fuel.

The boiler may include temperature sensors and instruments to monitor and maintain normal operating conditions.

As well as the boiler hardware for automating the functioning of the entire heating complex.

The essence of what is happening inside the pyrolysis boiler is characterized by the following processes:

- An air flow from outside enters the gasification compartment with the fuel located there.

- Some of the oxygen will support the combustion process (smoldering). Gases, which are combustion products, enter the combustion chamber of the boiler through the nozzle and are oxidized there in the presence of secondary oxygen, which enters along with the air from outside.

- Part of the pyrolysis gases is reduced in the presence of carbon from the fuel to carbon monoxide and nitrogen oxide, while consuming part of the energy. The mixture passes into the gas afterburning section and is oxidized there, returning the energy it took away.

Photo 2. Drawing of a long-burning pyrolysis boiler; a device assembled from it can heat a large house.

The gas mixtures participating in the pyrolysis reaction are discharged outside through the chimney, bypassing the boiler heat exchanger.

Attention! Since the operation of pyrolysis boilers is associated with a large amount of energy generated inside the equipment and the possible release of various types of harmful gases, it is recommended to independently build boilers only with a full understanding of all the physical and chemical processes that occur during its operation. Temperature phases:

Temperature phases:

- drying, pyrolysis of wood - 450 °C;

- combustion of wood gas and secondary air - 560 °C;

- flame blowing and heat recovery - 1200 °C;

- removal of remaining combustion products - 160 °C.

Differences between the device and conventional boilers

Including wood (firewood), special fuel briquettes (pellets) and waste generated in production. One of the main differences between boilers is the use of different types of solid fuel, almost any substance that can burn.

The duration of the fuel combustion process is much longer than that of conventional boilers. From 8–10 hours and above. There are models of boilers with a large compartment for firewood, the duration of continuous operation is up to 24 hours. This means that the combustion chamber is replenished with new portions of fuel 1–2 times a day.

Important! Due to the fact that solid materials are almost completely decomposed, pyroboilers are less harmful to the environment

Features of the device and principle of operation

The pyrolysis boiler optimizes the combustion process, increases its duration, and maximizes efficiency. It has two chambers - gasification and afterburning. There are main types of installations: with forced air and natural, the location of the fireboxes depends on this.

In devices with natural draft, firewood is loaded from above, with mechanical draft - from below. Firewood and solid residues smolder in the loading firebox. In the second chamber, the resulting gases are burned. The table will help you compare the pros and cons of both designs:

| Location of the fuel | Advantages | Flaws |

| Upper | Convenient to load firewood | Both fireboxes need to be cleaned of ash. |

| Natural removal of smoke and combustion products | It is difficult to regulate traction, which depends on the weather | |

| Non-volatile boiler | ||

| Lower | Natural circulation of wood gas | Consumes electricity |

| Fireboxes are cleaned much less frequently | Additional equipment required: fan, uninterruptible power supply |

Forced air units have their advantages. They begin pyrolysis and heating of the heating system much faster. Combustion products are immediately removed without lingering inside. It is possible to automatically regulate the process. A significant disadvantage is the constant dependence on electricity. A boiler with natural draft is unpretentious and reliable, rarely breaks down.

Differences in the device do not affect the principle of operation; they have it in common. Oxygen is supplied to the firebox in such a volume that the wood only smolders. Prolonged combustion occurs, resulting in the formation of wood gas. Compared to natural materials, it has a low calorific value, but is capable of burning and releasing a sufficient amount of additional heat.

The fuel decomposes into its constituent parts with a minimum volume of incoming oxygen. Firewood in a regular boiler burns at an average temperature of 1000° in 3–4 hours, releasing about 5 kilocalories of heat. In pyrolysis, this occurs at 300–800° for half a day. The efficiency increases to 90% compared to the usual 70%.

The unit starts and operates in the following sequence:

- firewood is loaded into the firebox, set on fire and the door is closed;

- open the chimney damper - a pressure difference occurs, oxygen flows into the upper chamber;

- The CO gas released during fuel smoldering is heavier than air, so it sinks and ignites;

- There is a constant circulation of the mixture - it burns in both chambers, the process stabilizes.

The boiler operation consists of three stages:

- Ignition. The forward flow damper is in the open position, smoke is removed unhindered.

- Work mode. The gate is closed and pyrolysis begins. The draft is provided by a fan or a natural process.

- Additional fuel loading. Open the throttle and quickly fill the firebox with wood.

A large amount of thermal energy constantly circulates in the pyroboiler. A significant part of it is used for self-sustaining work cycle. Only those that are not required for these purposes are available for selection. If you install a heat exchanger in any chamber, this will sharply deteriorate the efficiency of the unit, possibly causing the formation of harmful fumes that do not have time to burn. The hot water register is located in the path of the flue gases.

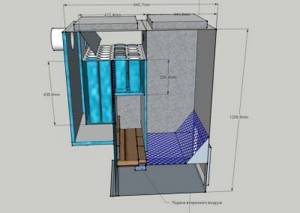

Pyrolysis boiler from a barrel

We will need a 200 liter metal barrel. You can take a ready-made one, or you can bend and weld a sheet of steel 3-4 mm thick. We cut off its upper end and make a lid out of it, welding a strip of metal around the circumference. We drill a hole in the center for the air duct pipe. We drill a hole in the side of the upper part of the barrel for the chimney and weld the chimney pipe into it.

Next we make the piston. It is a circle, slightly smaller in diameter than the lid of the barrel, so that it can fit into it. A hole is drilled in the center and an air duct pipe is welded to it, through which oxygen will flow into the firebox.

Pyrolysis boiler from a barrel

In the upper part we make a damper that will regulate the amount of air entering inside. To do this, we drill a through hole, insert a thick pin into it and weld a small plate inside it. By rotating it, we change the area of the hole.

The bottom of the steel sheet must be weighted so that during combustion the piston, under its own weight, lowers and crushes the burnt fuel

It is important that all welds are sealed. If this is not the case, the boiler will not be able to operate efficiently enough.

Using such a homemade boiler is easy. Fuel is poured into the bottom and set on fire. When it is hot enough, the piston is installed on top and the lid is closed. As it burns, the piston will gradually lower.

The process of smoldering will take place under it, and the gases released will burn on top of it. This design is also called a pyrolysis head and can operate on wood or related fuels made from wood waste.

Pyrolysis boiler in the house: features of operation

In general, if you live in a place where gas mains are available, then the simplest solution is to install a standard gas boiler. However, despite their convenience, gas boilers are still not suitable for everyone. Firstly, installation will require a connection to the gas network, and if there is none, then you are left without heating. Secondly, gas boilers are far from the most economical. Burning gas, of course, is easier than wood or other solid fuel, but it is very wasteful, especially when it comes to a large house.

In other words, a pyrolysis boiler is an excellent alternative to standard equipment. Installing the boiler is possible with your own hands, setting it up is not a problem, and the use of such equipment has many advantages. How does such a boiler work? The corresponding equipment is called a gas generator boiler, but it still belongs to solid fuel equipment, how did this happen?

The fact is that the pyrolysis boiler has a special cunning device, thanks to which gas is extracted directly from the wood that is burned. You put firewood into the boiler, it burns it, and at the same time produces gas, which is also used for heating. Thus, the boiler generates gas, which became the basis for its name.

To obtain gas from wood, difficult conditions must be met:

- High internal temperature;

- Boiler tightness;

- Lack of oxygen inside.

In other words, it’s not so easy to immediately take and burn gas; the boiler must be heated, some of the wood burned, during which all the oxygen will be absorbed and, provided it is sealed, the process of gas generation will begin.

Types of heating boilers

The range of heating units allows you to select the installation according to the financial capabilities and personal preferences of the owners

When choosing a device, it is advisable to pay attention to the type of fuel

Specifics of solid fuel models

In rural areas or if you want to save on fuel, you can install a wood-burning, briquette, or coal unit. The line of solid fuel models also includes sawdust and coke boilers. All devices are environmentally friendly and safe. According to the principle of operation there are:

- Classic - heat the room through direct combustion of fuel materials. Bookmarking is done after 5-6 hours.

- Pyrolysis - they operate on the principle of afterburning gas released in the combustion chamber. Fuel is loaded once every 12-14 hours.

When making a solid fuel model yourself, you need to organize a chimney with high-quality draft and a place for fuel.

Characteristics of electric boilers

Electric heaters are compact, quiet, and affordable. Products differ according to the type of heating elements:

- On heating elements. Modifications with a tubular heater are suitable for floor and wall installation. The disadvantage is the formation of scale on the heating element.

- On electrodes. Suitable for a system of 1-2 batteries or a large room. The devices are efficient, heat water quickly, but are sensitive to its chemical composition.

- Induction. They quickly heat up any type of coolant, have an efficiency of 100%, and are equipped with an overheating protection system.

Features of gas devices

A gas heater can be selected according to several parameters:

- Number of circuits. Single-circuit options work only for heating; double-circuit options, in addition to heating, are connected to the hot water system.

- Method of heating water. A flow column or a built-in boiler of 150-180 liters is used.

- Number of double-circuit heat exchangers. A single bithermic element heats water for heating and domestic hot water. For units with two heat exchangers, the primary one is used for heating, the secondary one is used for hot water supply.

- Combustion chamber type. A boiler with an open draft is installed in a separate ventilated room and is equipped with a vertical smoke outlet, because takes in air masses in a natural way. Closed equipment is equipped with a coaxial flue pipe located horizontally, and air is supplied into it by a fan or cooler.

- Ignition method. Electric is used for devices that burn intermittently. Modifications with piezo ignition are turned on manually.

Design

A pyrolysis boiler consists of a fuel chamber divided into zones. In one of them, called the gas generator, the fuel is decomposed into ash and pyrolysis gases, in the other, the afterburning zone, these gases are burned.

- Boilers are available in two types:

- with top loading, or shaft;

- with bottom loading.

Top combustion mine boilers

To overcome aerodynamic drag and stabilize the draft, the chamber is equipped with a blower fan installed on top of the boiler - this process is called “top blast”. Some models are equipped with another fan that supplies a stream of air directly to the afterburner, which increases the efficiency of the boiler. After combustion, smoke and steam are discharged into the chimney through the smoke pipe.

Boilers with bottom combustion In this type of heating units, the gas-generating chamber is located at the bottom, and the pyrolysis gases rise upward under the influence of draft. For stable combustion, such boilers require a chimney with a height of at least 5 meters.

The use of a fan for boilers with bottom loading is not necessary, because air is supplied through the damper. The efficiency of bottom combustion boilers is lower than that of mine boilers, but they do not depend on the availability of electricity.

Heat exchanger and connection of the boiler to the heating system

Next to the firebox there is a heat exchanger through which the heating system coolant circulates. The design of the heat exchanger depends on the model of the unit. Fittings are provided for supplying and draining water into the system. The inlet fitting, through which water that has cooled in the heating system enters the boiler, is located in the lower part of the heat exchanger. The outlet fitting is at the top. Water, preferably distilled, or antifreeze can be used as a coolant.

Long-burning gas generators can operate in systems with natural or forced circulation. When choosing a boiler, it is necessary to agree on the volumes of the heat exchanger and the coolant required to fill the heating system. The system is equipped with an expansion tank, and for forced circulation - with a pump, which is installed immediately before entering the boiler.

To stabilize the temperature in the heating system, it is also recommended to install a heat accumulator - a storage tank, which will be an intermediate link between the boiler and heating devices. At the same time, during breaks in the boiler furnace, the system will not cool down by more than 10-15 degrees. The water entering the heat exchanger must have a temperature specified by the manufacturer, usually 60 degrees Celsius. To maintain this temperature, the systems are equipped with a pipe for mixing hot water. In systems with forced circulation, in case of a sudden power outage, it is also necessary to provide a bypass to bypass the circulation pump.

A number of models of pyrolysis gas generators, in addition to heating, can also be connected to a hot water supply circuit; such boilers are called double-circuit boilers. It is convenient if the unit can be operated with the heating system turned off, only for heating water, which will allow it to be used in the summer. Typically, such models are equipped with additional heating elements built into the heat exchanger.

Housing material

Long-burning solid fuel boilers usually have a steel body with a thickness of 3 to 8 mm.

- But some manufacturers offer cast iron boilers, which have a number of advantages:

- cast iron has increased corrosion resistance compared to steel; cast iron boilers are not afraid of low-temperature corrosion;

- cast iron boilers with a forged heat exchanger do not have welds, where the destruction of steel most often begins;

- the thicker walls of cast iron units are not subject to burnout and deformation;

- due to their greater thickness, they do not cool down longer, which allows you to maintain the temperature in the system during a break to clean the boiler.

- Cast iron models also have disadvantages:

- they are much heavier, 2-2.5 times;

- the price is higher than that of steel, by about 50-70%.

Fuel requirements

Most modern models of pyrolysis boilers are equipped with automatic control of the combustion mode. The duration of combustion depends on the type of fuel. As a rule, when fired with dry wood, the gas generator can operate on one load for up to 12 hours, and on coal - for about a day. The use of sawdust, shavings, and woodworking waste somewhat reduces the burning time without additional loading.

Firewood must be dry, with a moisture content of no more than 16%. When using pellets or briquettes, such humidity is guaranteed by the manufacturer; the firewood must be dried in the shade for at least a year.