With a thorough and correct study of the drawings of solid fuel boilers, it is quite possible to make a long-burning boiler with your own hands, reliable and economical.

Solid fuel boilers have been very popular for decades, although they have one significant drawback - they require constant loading of fuel (coal, firewood, etc.). Because of this drawback, they are often abandoned when arranging a heating system, but it is easy to get rid of it - make a long-burning boiler with your own hands, operating on almost all types of fuel (exceptionally solid, of course).

Do-it-yourself long-burning boiler

You can use coal to light the boiler.

How a homemade long-burning boiler works

Principle of operation

The operation scheme of such boilers is based on the ability of solid fuel to smolder for several hours, while producing a large amount of thermal energy. It is typical that in this case the fuel is burned more completely, and the amount of waste, as a result, is noticeably reduced.

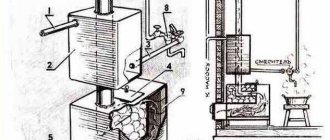

Boiler drawing

Note! Replacing active combustion with smoldering is possible due to the special design of the heating boiler.

The main element of the boiler is the firebox, where combustion is limited and the intensity of the air supply is controlled using special devices. The fuel is loaded twice a day in large portions, after which it slowly smolders (the limited amount of oxygen does not allow it to burn fully).

The pipe through which the smoke is removed is passed through heat exchangers and heats the liquid in the heating system. It turns out that all you need to do is load fuel every 12 hours for uninterrupted heating of the house.

Boiler diagram

Main advantages

Long-burning boilers stand out from other types of heating systems. Of course, the main advantage is the duration of the work, but there are other important points:

- low fuel cost;

- autonomy;

- the ability to heat large areas at minimal costs;

- ease of installation and operation;

- safety;

- Possibility of making it at home.

Types of solid fuel boilers

Device structure

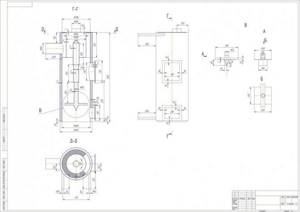

To make a boiler, it is more convenient to use a metal pipe ø30 cm or larger with a wall thickness of at least 5 mm (otherwise the latter will soon burn out due to the high temperature inside the device). The height of the structure can vary between 80 cm and 100 cm, it all depends on the area of the room.

Housing pipe

Regardless of the modification, the boiler consists of three main zones:

- loading area;

- zones of smoldering and heat generation;

- final combustion zones where ash burns and smoke gases are removed.

Note! The device that limits the loading zone and, accordingly, the smoldering time is called an air distributor.

This element is made in the form of a metal circle 5-6 mm thick with a hole in the middle, through which oxygen is supplied to the firebox using a telescopic pipe. The diameter of the product should be slightly smaller than the diameter of the body. The height is adjusted using a special impeller.

Long burning wood boiler

Long burning wood boiler Expert opinion:

Masalsky A.V.

Editor of the “construction” category on the Stroyday.ru portal. Specialist in engineering systems and drainage.

Typically, the combustion zone does not exceed 5 cm in height - if it is larger, the fuel will burn too quickly. By the way, the oxygen pipe can be not only telescopic, but also solid. Its diameter is usually 6 cm, while the size of the hole in the air distributor does not exceed 2 cm, so as not to saturate the area with oxygen.

Long burning boiler

Air can be supplied in one of two ways:

- straight from the atmosphere;

- from a special heating chamber (it is located in the upper part of the structure), which ensures more efficient operation of the boiler.

A special air damper is used for adjustment.

The chimney pipe is welded on top. It must be perpendicular to the body for at least 0.5 m, otherwise excessive draft will be formed.

A door is equipped at the bottom to remove combustion products. Cleaning should be done infrequently, because the fuel will burn more completely.

There are two ways to heat the coolant, each has its own strengths and weaknesses.

Long burning boiler

Long burning boiler

Method No. 1. A coil is connected to the heat exchanger pipe passing through the combustion zone, through which the water in the tank is heated.

Method No. 2. A separate metal tank is formed, through which the chimney pipe is passed. The hot smoke heats the liquid.

The first method is more effective, but at the same time more difficult to implement. The second one is easier to do, but it is only practical in small houses.

Prices for the range of solid fuel boilers

Solid fuel boilers

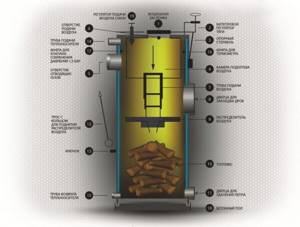

Pyrolysis boilers

The operating principle of these heat generators is based on separate combustion in two chambers communicating with each other through a nozzle made of refractory bricks. In the primary chamber, located on top, firewood smolders with limited air supply from the fan. As a result, a process of pyrolysis occurs, otherwise known as gasification, during which a mixture of flammable gases is released. It moves to the second chamber, where it is burned when secondary air enters. The working diagram of a pyrolysis boiler operating on solid fuel is as follows:

Flue gases from the secondary furnace enter the fire tube heat exchanger in the form of vertical flues surrounded by a water jacket. There they cool, transferring heat to the water, and leave the boiler through the chimney pipe. The performance of the fan is controlled by an electronic unit - controller, based on the readings of pressure and temperature sensors.

In general, the heat generator has good efficiency indicators - about 80%, but the unit is significantly more expensive than a classic one. In addition, the boiler shows high efficiency only when operating on dry wood, although this statement is also true for other solid fuel units.

Manufacturing a long-burning boiler

Boiler

It is not difficult to make such a design at home, but this will require skills in working with a welding machine and clear instructions.

Stage 1. Preparing everything you need

To make a boiler you will need:

- metal pipe ø30 cm or more with a wall thickness of 4-5 mm;

The body can be made from sheet steel by welding - welding machine;

- sheet steel 5 mm thick (for the distributor);

- Bulgarian;

- pipe ø6 cm for oxygen supply;

- pipe ø10 cm for removing smoke gases from the structure.

After preparing the equipment and consumables, you can begin to work.

Stage 2. Assembling the structure

Note! The boiler must be installed on a flat surface. If required, a concrete base is equipped (here everything depends on the total weight of the structure).

The assembly sequence is as follows.

Step 1. The pipe, which will serve as the body of the structure, is cut in accordance with the selected length (from 0.8 to 1 m). If the length is longer, it will make it difficult to load fuel during operation. A bottom made of sheet steel and (if required) legs made of channel steel are welded.

Pipe

Step 2. An air distributor is formed. To do this, a circle is cut out of a sheet of steel, the diameter of which is 2 cm less than the diameter of the structure. A hole ø2 cm is made in the center of the circle.

An impeller with 5-centimeter blades fixed to it, made of the same steel, is welded to the distributor. A ø6 cm pipe is welded on top so that the previously made hole is in the middle.

Boiler body and air distributor

Air distributor

Air distributor

Double wall boiler

Double wall boiler

Boiler

Note! This pipe should be equal in height to the boiler body (more is possible).

The pipe is equipped with a damper on top to regulate the oxygen supply.

Step 3. A door is installed near the bottom of the boiler to remove combustion products. Using a grinder, a rectangle is cut out of a steel sheet, and the hinges with a locking handle are fixed. The rectangle will serve as the door.

Ash pan

Fuel loading hatch

Step 4. A chimney pipe ø10 cm is attached to the top of the boiler. The first 40-45 cm of the pipe should run strictly horizontally, after which it is passed through a heat exchanger (the latter is made in the form of a metal container with water).

Chimney pipe

Step 5. The lid for the boiler is cut out and a hole is made in it for the air distributor. It is important that the lid fits as tightly as possible to the body, otherwise smoke will escape through the cracks.

Boiler cover

Boiler lid (another option)

That's it, the long-burning heat generator is ready for use.

Manufacturers of wood boilers in Europe

Wood-burning boilers are produced by more than twenty different manufacturers, whose factories are located in Germany, the Czech Republic, Poland, Austria and the Baltic states. The products of the most famous brands, which are in constant demand and popularity among domestic consumers, are described in this article.

Wood boilers from Germany

Products from German manufacturers are consistently associated with quality, reliability, thoughtfulness of design, construction, and internal structure. The boilers we offer are economical and have a long service life.

All equipment is covered by a factory warranty, which, as practice shows, is used extremely rarely, since breakdowns are practically excluded.

The following two manufacturers are the most popular:

Buderus is a German company that began its activities back in 1731. The first wood-burning boilers came off the assembly line at the end of the 19th century. At the moment, the company has become part of another famous German brand Bosh. Long-burning wood-burning boilers Buderus are produced in the Logano series. The models are distinguished by an increased volume of the combustion chamber and ash pan. The design includes automation that regulates the air supply and removal of smoke residues, and a safety system that prevents boiling of the coolant.

Viessmann - the company was founded in 1917. At the moment, Viessmann, from a family production, has turned into a global concern, whose enterprises are located in Europe and Asia. Long-burning boilers are presented in the Vitoligno and WBS Ligna series. Models have one heating circuit. To meet the needs for domestic hot water, an indirect heating boiler manufactured by Viessmann is used. Domestic boilers are offered in power sizes from 20 to 110 kW.

Wood boilers made in Poland

Polish heating equipment is a good alternative to German and Czech units. The pricing policy of the companies is specially maintained at such a level as to make the purchase of a boiler affordable for the majority of Russian consumers.

Products are offered by the following manufacturers:

- SAS – the MI series deserves special attention. The universal units of the line are capable of operating using the principle of upper and lower combustion. The design provides for forced air supply. The microprocessor controller ensures precise heating control, with an error of no more than 1°C. The advantage of the SAS MI series is the ability of the boiler to operate without complex automation. In this case, built-in mechanical regulators are used. The absence of a controller reduces the cost of the boiler by 15-20%.

Galmet is a company operating in the field of heating equipment since 1982. Currently, its products are represented in more than 20 countries around the world. A solid fuel boiler of lower and upper combustion, with an enlarged combustion chamber, is presented in the Zulu series. Suitable for connection to heating systems of any type. Turbocharging and a special heat exchanger design are used to retain exhaust gases and extract the maximum amount of heat. Galmet Zulu operates from one fill, from 4 to 12 hours, depending on the type of combustion used and the quality of the fuel.

Wood boilers from the Czech Republic

- ATMOS - the company was founded at the beginning of the twentieth century, but later nationalized. Activities were resumed in 1989. At the moment, the company's heating equipment is among the TOP best boilers in the world, producing products at the level of such concerns as Buderus and Visman. The main difference between the production is the completely robotic assembly, which eliminates even the slightest errors. ATMOS products are offered in sizes from 15 to 100 kW.

Viadrus - the company's products first saw the light of day back in the 1920s. From the very beginning of its activities, the company focused on the simplicity and reliability of its equipment. The company's wood-burning boilers have several features. Cast iron heat exchanger, increased firebox volume, versatility (the ability, in addition to firewood, to use peat, coal, pellets, gas, etc.), high efficiency - all these characteristics set Viadrus boilers apart from similar equipment.

Wood burning boilers from Austria

Austrian manufacturers of solid fuel heating equipment have focused on the most complete automation of the combustion process and ensuring safe operation. All offered equipment belongs to the “Lux” category, which explains the high cost of the boilers:

- Froling is a company that appeared on the domestic heating equipment market relatively recently. The first impressions (associated with the high cost) of the product were negative, but at the moment, thanks to the high quality and reliability, they have completely changed. The design of Froling boilers provides intelligent control that allows you to change the boiler performance within the range of 20-100% of the specified power. There is a self-cleaning system and forced air supply. There is a function that protects the coolant from boiling.

Hargassner, the first heating equipment, was offered to the sophisticated Austrian consumer back in 1984. Since 1986, the company’s specialists began to travel to install boilers, which made it possible to take into account the needs of consumers and quickly respond to customer complaints and eliminate shortcomings. All Hargassner boilers are distinguished by a high degree of automation, including: a system of automatic ignition and self-cleaning, recognition of fuel quality and changing the operating mode. Separately, it is worth noting the Lambda-Touch-Tronic controller, which is a development of the company. The unique design made it possible to increase the size of the firebox. Firewood longer than 1 m is placed in the loading chamber.

Baltic boilers for burning wood

Long-burning boilers are offered by the following companies:

- Stropuva – the company’s calling card was the round design of the boiler, elongated vertically. Models are made in seven primary colors. Working time from one bookmark, from 12 hours to 2-3 days. The consumer is offered Stropuva boilers with a capacity from 8 to 40 kW, in the S and mini series.

Features of fuel loading and operation

From a simple boiler, where a full air supply is necessary throughout the entire volume of fuel combustion, the long-burning design, as noted earlier, is distinguished by the limitation of this supply. Moreover, the loading volume directly affects the burning time, so in our case the combustion chamber is loaded extremely tightly so that there are no gaps.

Firebox from the inside

Note! You can use not only firewood as fuel, but also sawdust, coal, peat, garbage (exclusively combustible), etc.

Fuel is loaded in this order.

Loading the boiler

Test firing of the boiler

Step 1. Remove the top cover of the structure.

Step 2: Remove the air regulator.

Step 3. The boiler is loaded with fuel up to the level of the chimney pipe.

Step 4. A small amount of lighter fluid (diesel fuel, used oil, etc.) is poured over the top of the fuel.

Step 5. The air regulator is installed back, the cover is put on top.

Step 6. The air damper is opened to its maximum.

Step 7. A piece of paper is set on fire and thrown into the structure. When the fuel begins to smolder, the air damper closes.

Heating system. Harness

Heating system. Harness

The fact that permanent combustion has begun can be judged by the smoke emerging from the chimney. As the fuel burns, a pipe of smaller diameter will lower along with the air regulator - using this kind of indicator, you can determine the amount of remaining fuel.

About the cost of ready-made models for heating with solid fuel

If it is not possible to make a long-burning boiler or there is simply no desire, then you can purchase a ready-made design. It must be recognized that models for heating large rooms will not be cheap. In the table you can see the prices for Stropuva boilers.

You can appreciate the stylish design of the Stropuva boiler

Table 1. Prices for Stropuva boilers

| Model | Power in kilowatts | Cost in rubles |

| S-8U | 8 | 70 000 |

| Stropuva S-8U | ||

| S-15U | 15 | 116 000 |

| Stropuva S-15U | ||

| S-20U | 20 | 123 000 |

| Stropuva S-20U | ||

| S-40U | 40 | 142 000 |

| Stropuva S-40U | ||

Stropuva S-40U

Related article:

Long-burning wood-fired boilers for the home. From this publication you will learn everything about wood-burning boilers, their types and nuances of use.

Although the price of the structures is quite high, with long-term use they are justified. The presented models have a fairly stylish design, so there are no problems with their integration into the overall design of the room.

The main advantages of Stropuva products

Voting: which solid fuel boiler is the best?

What would you choose from solid fuel boilers or would you recommend purchasing?

Stropuva S40U

25.00 % ( 1 )

Candle S-18kW

25.00 % ( 1 )

Buderus Logano S171-50 W

0.00 % ( 0 )

ZOTA Optima 20

0.00 % ( 0 )

Sime SOLIDA EV 5

0.00 % ( 0 )

Protherm Beaver 40 DLO

25.00 % ( 1 )

Bosch Solid 2000 B SFU 27

25.00 % ( 1 )

Kentatsu ELEGANT-03

0.00 % ( 0 )

Kiturami KRM 30R

0.00 % ( 0 )

ZOTA Mix 20

0.00 % ( 0 )

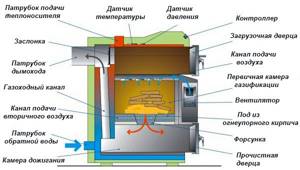

Classic type of unit

This type is used using forced pressurization, which is necessary to avoid smoldering conditions and for economical combustion of solid fuel.

The operating principle is as follows:

- 1. Firewood is placed and set on fire in a firebox with a volume of 112 liters. After this, all the doors are closed tightly, and with the help of automation, the fan is started, pumping air.

- 2. As soon as the temperature reaches the set point, the fan stops and the boiler goes into standby mode. A very small amount of air flows through the channel, closed by a gravity damper, so that the firewood does not go out.

- 3. When the temperature sensor detects that the coolant in the boiler tank has cooled, the fan will automatically turn on and the process will repeat.

With the help of automation, several modes of air injection are carried out in accordance with the wood used, which varies in quality and humidity. The standard type of boiler has the following technical characteristics:

- rated power - 22 kW;

- efficiency - 77%;

- maximum operating pressure - 3 bar;

- firebox depth - 460 mm;

- the size of the opening where the firewood is placed is 36 by 25 cm;

- chamber volume - 112 l;

- Burning time with wood fuel is approximately 8 hours.

The boiler has a simple design: a firebox elongated in height, equipped with grates at the bottom, and at the top - a heat exchanger consisting of 4 pipes and placed inside the tank. The forced air enters the ash chamber through a channel made of a 60 by 40 mm profile. To protect against dirt and dust, the automatic unit and fan are located on top of the boiler.

Long-burning heating boiler using solid fuel

Manufacturing Guide

All the material that you will need during work can be purchased at a hardware store or you can use what is available on your own site.

To make a long-burning coal boiler with your own hands, you need to prepare:

- metal pipe with thick walls with a diameter of 300-400 mm;

- steel sheet 4 mm thick;

- two metal pipes: one FE 60 mm, the other FE 100 mm;

- fittings;

- blower fan;

- welding machine;

- grinding machine.

All actions are performed strictly according to the following scheme:

- At the very beginning, using a grinding machine, cut the pipe into pieces (and one of them should be at least a meter in length) and align the edges. Then a bottom is welded to one side, which is cut out of a prepared steel sheet. Legs made of reinforcing bars are attached to the structure.

- Then they take a sheet of steel and cut a circle in it. Its diameter should be smaller than the body. A hole is drilled in the very center. An impeller is welded to one of the sides using a welding machine and special blades are made; their width should be 50 mm. This will create the lower part of the distributor.

- Next, they work on the upper side: another pipe (FE 60 mm) is welded here, and a damper is installed at the very top, which will serve as an air supply regulator.

- A square hole is cut out from the bottom of the heating boiler and a door is installed.

- A round opening is made on the casing, a threaded coupling is welded, and the finished chimney pipe is attached to it.

At the very end, a special cover is made, an opening is made in the middle and a distribution pipe is inserted there. Actually, the unit is considered ready. As you can see from the master class, it is quite possible to install the boilers yourself.

Installation in the house

The issue of boiler fire safety is a very serious issue. To install it, it is better to provide a separate room or corner, separating it with brickwork. Since the surface of the boiler is metal, there is a high probability of getting burns if you touch it carelessly. It is also important that at the installation site it is possible to conveniently lead the chimney to the street (through the roof or wall). For free access to the device, a space of 50 cm around its circumference is cleared of any objects.

Installation rules:

- Construction of a brick foundation. It should consist of two continuous rows of bricks, and correspond to the dimensions of a long-burning solid fuel boiler.

- The distance from the fire door to the wall is at least 125 cm. The distance between the side parts and the wall must be at least 700 mm.

- A distance of at least 125 cm is maintained between the combustion door and the wall. The space between the sides of the boiler and the wall is at least 70 cm.

- If wood was used to construct the walls, the contact areas between the boiler and the ceiling are additionally decorated with metal or basalt protection. The same applies to areas where the chimney is discharged outside through walls or ceilings.

- The boiler is installed on the foundation strictly level. In this case, the outlet pipe must be located in line with the chimney, otherwise draft disturbances may occur during operation (pro

The best Russian manufacturers

Among Russian manufacturers it is worth highlighting several enterprises:

- Borisoglebsk Boiler and Mechanical Plant. The company produces fire tube equipment operating on solid, liquid fuel and gas. The equipment is equipped with burners and automatic control and safety systems. Devices of our own production. The boilers have three-stage power control, allowing for autonomous operation.

- Industrial group "Generation" (Berezovsky, Sverdlovsk region). The line of fire tube boilers consists of equipment with a capacity of 1 to 2.5 tons/hour. This equipment is used to produce low pressure steam in industry. The boiler circuit is three-pass. The package includes burners that are available in two versions: automated single-fuel and dual-fuel. The advantages of the units are high efficiency - up to 91%, simple design, high repairability.

- JSC "Boiler Equipment Plant" (Belgorod region, Alekseevsky district, Alekseevka). The company produces fire-tube boilers with high efficiency. Steam equipment operates according to a three-pass circuit. The boilers are produced in a wide range with steam production from 2 to 25 t/h, and pressure up to 25 bar.

- Russian power engineering plant JSC Polycraft Energomash. The plant produces boilers with steam output from 0.5 to 5.0 tons/h, have 11 standard sizes and operate on gaseous and diesel fuel. The equipment is equipped with automatic protection.

- JSC Shebekinsky Machine-Building Plant (Shebekino, Belgorod region) manufactures steam fire-tube boilers of the KP and KPa brands with a steam output of 1 to 4 tons/h. Among the advantages: a spiral turbulator, lining the front cover with refractory concrete. The boilers meet the requirements of Rostechnadzor.

Advantages and disadvantages

Boilers with a fire tube design have the following advantages:

- high efficiency, reaching 92-93% due to efficient heat distribution and complete power take-off from the generated heat flow during fuel combustion;

- no heating of the outer surface of the housing due to the use of a water jacket;

- high heat capacity of the boiler and minimal heating inertia during operation;

- stable temperature parameters due to complete control of the fuel combustion process;

- safety during operation: the risk of explosion due to high pressure growth is minimal;

- the ability to make modifications to change technical characteristics;

- simplicity of design, allowing maintenance and repairs without the involvement of specialists;

- compact dimensions compared to other types of boilers with similar characteristics;

- reliability and durability due to the use of heat-resistant steel and a minimum number of welds;

- Possibility of use for heating objects operated in harsh climatic conditions;

- average service life from 20 to 50 years;

- excellent maintainability;

- availability of structures for the use of various types of fuel.

The disadvantages of the fire tube design include:

- if hard water is used, uneven scale forms on the internal surfaces, which can only be removed after disassembly, which is very labor-intensive;

- high water consumption;

- the appearance of stagnant zones of the coolant due to the low speed of its circulation;

- the need for constant condition monitoring and periodic maintenance to prevent emergency situations;

- the difficulty of cleaning passages to remove combustion products from the combustion chamber;

- the presence of unheated areas inside the heat exchangers due to the low circulation rate of the heat flow.

Safety regulations

To achieve good efficiency, durability and efficiency of home-made long-burning boilers, during their operation it is necessary to follow basic fire safety recommendations:

- Make sure that the temperature inside the circuit does not exceed the limit values.

- The supply pipeline must not be equipped with a shut-off valve.

- Flammable materials should not be stored in the immediate vicinity of the boiler.

- Ventilation in the room must be fully operational.

- The device can only be installed in a separate room (boiler room). This point is thought through during the implementation of preparatory activities.

Boiler room equipment is the best option, since TT boilers work slightly differently than conventional wood-burning stoves. In addition, externally the device is not of aesthetic interest, and most likely will disturb the overall interior. Since the use of solid fuel is accompanied by the appearance of dirt, it is best to install the boiler in a non-residential room.

Small devices with a power of no more than 35 kW are allowed to be placed in the main room: for convenience, the installation site can be fenced with a brick wall. The room where the boiler will be located must have good ventilation. It is very important to organize a stable flow of oxygen from the street.

Final assembly and installation

In order to install the ash pan door, you first need to mark and cut a niche on the body for access to the inside of the chamber. Next, a hermetically sealed door is installed in this opening. The cylinder is inserted inside the heat exchanger. Using a welding machine, the tank is thoroughly boiled from above: this makes it possible to achieve absolute tightness of the body, with a round firebox located inside.

When operating a homemade long-burning boiler with a water circuit, it is important to achieve a dosed air supply. The fuel is loaded as tightly as possible: the voids between the layers should be kept to a minimum. It happens that dense packing of logs of different sizes is difficult: in this case, the remaining niches are filled with paper or shavings. The density of the solid fuel filling directly affects the duration of its combustion.

The procedure for loading fuel into the TT boiler:

- First you need to remove the air restrictor.

- Place the firewood through a special hole, having previously lubricated it with liquid for quick ignition.

- Install the limiter in its original place.

- Next, you should light a match and throw it into the firebox.

- After making sure that the fuel begins to gradually flare up, close the door tightly.

As the fuel burns out, there will be a gradual shrinkage of the pipe inside the cylinder. The height of its position gives accurate information about the amount of firewood in the firebox. The layout of a coal-fired boiler is practically no different.

Work on the body drawings

An empty propane cylinder is equipped with markings according to the do-it-yourself drawings of a long-burning solid fuel boiler. A rectangular hole is made for the ash pan door, designed to remove ash. A straight line is drawn along the circumference of the top of the cylinder to cut the cap: trimming is done using a grinder.

In the central part, a niche is marked for the chimney outlet: the dimensions of this hole must exceed the cross-section of the pipe. A hole is made in the lid and a metal ring is welded in, tightly encircling the smoke exhaust channel. A metal ring 4-5 mm thick is used to scald the cylinder inside and out. A lid will subsequently be placed on it.

The chimney at the bottom is equipped with a metal circle that serves as an air distributor. Fastening elements are welded along the cut line of the cylinder on top of a pre-laid asbestos cord. When attaching a cut top, it is important that it can be easily removed. For convenience, it can be equipped with a metal handle.