Beretta gas boilers have proven themselves as a source of thermal energy in autonomous heating systems. The units are equipped with a self-monitoring function for the processes occurring in units and parts during boiler operation. Equipment malfunctions can be identified by light signals.

We will analyze the typical malfunctions of the Beretta gas boiler and their elimination. Let's consider in what cases it will be possible to solve the problem on our own. Let's find out when you will have to call a gas service technician for repair operations.

We will talk about how to identify an error in the operation of the equipment, about which it independently warns the owner. We'll tell you what the combinations of letters and numbers that appear in the event of a problem with the built-in display or indicators mean. With this information, you can decide how best to proceed.

Gas boiler Beretta error 01 what to do?

Beretta boilers, unlike others, have a peculiarity: the same error a01

described in the instruction manual twice:

- lack of flame;

- control board fault

In fact, one of the most common problems that users are looking for information on is the lack of ignition of the boiler burner. In this particular situation, you first need to check which actuators are triggered before the error occurs.

If the pump or fan is working, there are characteristic sparking clicks - most likely, a malfunction of the control board can be ruled out (but not always).

Resuming boiler operation (resetting errors) occurs by moving the switch to the “off” position for 5-6 seconds. If resetting does not help eliminate error a01, you need to start troubleshooting.

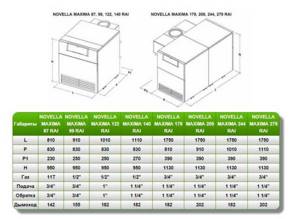

Beretta Novella Maxima

These devices have high performance, which is due to impressive power indicators: from 87.4 kW to 289.9 kW. All units in this series have a heat exchanger made of cast iron. The package includes a two-stage stainless steel burner.

Characteristics of Beretta boilers of Novella Maxima models

Wall models

Among wall-mounted heating boilers, the following models stand out.

CITY Series

The main feature of the wall-mounted boiler of this series is its compact size, which allows installation of the equipment in small city apartments. The attached instructions contain the following technical specifications:

- A good choice of power: from 24 to 50 kW, which will allow you to choose the necessary model for an apartment or country house.

- The series contains both single-circuit models designed for heating premises, and double-circuit models capable of heating running water for domestic needs.

- At the same time, the wall-mounted double-circuit unit has two independent heat exchangers, which reduces the cost of replacing one of them in the event of a malfunction.

Advice! To reduce gas consumption, the most powerful 50-kilowatt installation has a condensing operating principle. This feature increases efficiency and heat transfer, while reducing overall energy consumption.

Series EXCLUSIVE (Exclusive)

This series of Beretta boilers is distinguished by its functionality and comfortable operating process. For rational and economical gas consumption, the instructions advise choosing one of four modes:

- Summer.

- Summer comfort.

- Winter.

- Winter comfort.

Boilers of this series are available with power from 24 to 35 kW and have the following features:

- An automatic system that can, if necessary, independently feed the heating system.

- Possibility of connecting an external sensor, which synchronizes the operating mode of the heating device with the outside temperature.

- A liquid crystal screen on which, in addition to current information about the state of the boiler, error codes are displayed in the event of a malfunction of the equipment.

Another feature that the wall-mounted boiler of the exclusive series has is the presence of a fan in the combustion chamber: it regulates the draft power, depending on the modulation of the flame.

Features of Beretta boilers

Well-known gas boilers are available in floor-mounted and wall-mounted models. Among them there are convection and condensation options. Let's look at the features of each of them.

The most popular wall units: Beretta City 24 CSI, Beretta Super Exclusive. Some models include a useful Winter-Summer mode. It allows you to switch the heating temperature to save fuel.

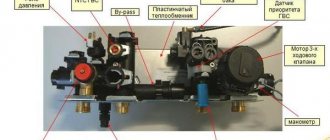

The control can be mechanical with regulators or electronic with a display. It is possible to connect a remote control. Double-circuit boilers are equipped with a secondary plate-type heat exchanger. There is a pressure gauge for pressure control.

A closed combustion chamber takes air from the street and is considered safer to use. A coaxial chimney can be connected both in an apartment and in a private house.

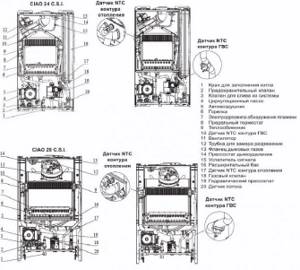

The Novella and Fabula lines represent floor-standing appliances. The control panel is hidden behind a sliding cover. Temperature control, thermometer, protection sensors are available. Burner with two stages of adjustment. The Novella series is equipped with two radiators that operate on different circuits.

Condensing units use combustion energy more efficiently. To the usual efficiency of 90–95%, another 5–10% is added due to the energy of gas combustion. These are the Minute Green and Exclusive Green lines. Among them you can choose options with one and two circuits.

The modulating burner automatically mixes gas and air in equal proportions. It is possible to switch to liquefied fuel. More details on the page “Review of Beretta gas boilers”.

How does the self-diagnosis system work?

In Beretta boilers, the self-diagnosis system consists of a network of monitoring sensors located on the main working units of the units.

After turning on the boiler, the sensors begin to function in continuous mode; they do not require an additional special start. Using the same principle, it is impossible to disable the sensors without stopping or blocking the gas boiler.

All main components of the Beretta gas boiler contain sensors that send signals to the display with an error code when problems are detected

When the monitored parameters change or the operation of a particular unit is disrupted, signals from the sensors are sent to the control module, which blocks the equipment. At the same time, an error code is displayed on the display, allowing the boiler owner to determine the type of problem and take measures to eliminate it.

In addition to the display, malfunctions in Beretta boilers are signaled by special indicators located depending on the design features of different models of heating equipment.

Beretta Novella RAI

This model is a floor-standing gas boiler with automatic control. The power of the units included in this line varies from 24 kW to 71 kW. The equipment operates in closed-type heating systems with forced circulation of coolant (necessarily with a pump in the system).

If desired, you can connect a water heating boiler, which is made in the same style.

The heat exchanger is cast iron.

You can set the priority of hot water, switch the unit to mode with or without heating (winter/summer).

There is a control panel on the case, which is closed with a lid. Automation is responsible for a number of useful functions:

- electronic ignition;

- self-diagnosis, the results of which are displayed on the display.

The security group includes the following elements:

- thermomanometer;

- blocking thermostat;

- smoke removal control;

- cessation of combustion in case of emergency conditions.

The unit can operate at low and high temperatures; the temperature is set by the regulator from 34°C to 82°C.

This is interesting: Izospan A, B, C, D: review, how they differ, characteristics, which one is better to choose

Repair the board or replace it with a new one?

The electronic board of any boiler is an expensive device and replacing it with a new one in case of any malfunction is not advisable, especially since Beretta boards do not have the most complex circuit diagram.

We offer our clients board repair because it is, first of all, profitable, since the cost in most cases does not exceed 30% of the price of a new board. To carry out repairs, we have professional equipment, diagrams, original spare parts and experience.

To carry out diagnostics, special stands have been organized that simulate a real unit, on which the boards are checked after repair.

We don’t just repair boards, but we provide a significant warranty period for the work, because we have already repaired more than one such board and are confident in the result.

How to check sensors

All Beretta boiler sensors are part of the self-diagnosis system. They not only perform control functions, but are themselves objects of observation.

This means that if any sensor fails, short circuits or breaks the wires, the corresponding error code will immediately appear on the display of the boiler control panel. The system polls sensors automatically at the moment of switching on; no special actions are required from the user .

Most of them are thermistors that respond to changes in temperature conditions or when indicators exceed the limits established by the operating mode. The design of the elements is simple; replacement, if necessary, is not difficult and does not take much time.

It is not recommended to change any elements of the boiler yourself; you must call a technician from the service center.

Advantages and disadvantages

The advantages of the Beretta CIAO 24 CSI model include:

- Efficiency, reliability, stability in operation.

- Resistance to external influences, maintaining the specified operating mode.

- The ability to provide the house with thermal energy together with the supply of hot water.

- Automatic operation mode that does not require constant human attention.

- The presence of a self-diagnosis system that notifies the owner of the occurrence of problems.

- Compact, attractive appearance.

The disadvantages of the unit are considered to be:

- Excessive sensitivity of electronics, the need to connect external protection devices (stabilizer).

- Demanding on water quality. A bithermal heat exchanger is extremely difficult to wash, and replacement is expensive, so it is necessary to install softening water filters.

- The need for service, the quality of which is not always at the proper level.

IMPORTANT!

The disadvantages of the Beretta CIAO 24 CSI boiler can be attributed to design features, since they are common to all similar units. This does not reduce their negative effects, but it allows us to take a more correct attitude towards their presence.

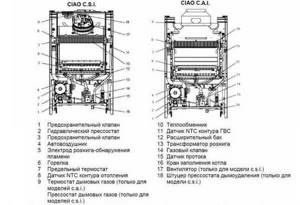

Beretta CIAO CSI

The Beretta brand is the property of one of the leaders in the European heating industry - the Italian company Riello, which is approaching its 100th anniversary.

Beretta boilers are manufactured using modern technologies and fully comply with European requirements for safety, economy and efficiency. The CIAO 24 CSI model is manufactured in accordance with the most advanced technical developments and is capable of meeting the needs of a modern residential building.

The units are manufactured in a wall-mounted design, have a compact and visually attractive body, which allows them to be installed directly in the kitchen and without having to allocate a separate room for the boiler room.

NOTE!

The successful combination of price and quality of the Beretta CIAO 24 CSI model is highly appreciated by specialists and users, which confirms the steady demand and relevance.

Does not start (does not ignite) - reasons and solution

A boiler failure during startup can be caused by various reasons, which can be determined either by the corresponding error code or by independently checking the condition of the boiler. The simplest option is the lack of gas in the main line.

This problem is external and can only be solved by contacting the gas service . The gas supply valve on the unit itself may be closed. There is another reason for ignition failure - reverse polarity of the power wires. It is displayed on the display as code E33.

The solution to the problem is to reconnect the wires . This situation can arise even after some period of normal operation of the boiler, if any work was done on the power supply panel and the phase and neutral were mistakenly swapped.

If you cannot find the reason for the failure to ignite the boiler, you should contact a service workshop.

Popular breakdowns and their elimination

The lower the serial number of the error, the more often it occurs when operating the Beretta boiler.

Let's look at the most common errors and possible ways to eliminate them:

- A01. Blockage due to lack of flame. There are several possible reasons - problems with the gas supply in the main line, the gas supply valve to the boiler is closed, the burner nozzles are severely clogged. Find out if there is gas in the line, clean the burner and nozzles.

- A02. Overheating of the heat exchanger indicates a lack of water. Check the operation of the circulation pump and the coolant pressure, add fluid to the system.

- A03. High pressure in the chimney indicates blockage of the outlet with ice, frost, and soot accumulation. Possible weather conditions - strong gusty winds.

- A 04. A drop in coolant pressure may be caused by a lack of liquid. Check the system for leaks and repair if found.

- A05. Problems with the DHW line thermistor can be eliminated by replacing the sensor.

- A06. A failed heating circuit thermistor must be replaced immediately.

- E33. It is necessary to swap the electrodes in the power plug. Beretta boilers are phase-dependent and do not work if the phase wire is incorrectly connected.

- E46. Exceeding the permissible temperature of the coolant indicates problems in the circulation of the liquid. You should check the operating mode of the circulation pump.

- The bell symbol (bell, p) is flashing. This is a signal from the chimney pressure sensor, indicating that there is an obstacle to the exit of smoke, or the formation of ice or frost at the pipe outlet.

IMPORTANT!

The Beretta boiler error is reset by pressing the shutdown button and turning the boiler back on after 5-6 seconds.

What do the indicator signals mean?

In some models of Beretta gas boilers, for example Beretta City, the occurrence of malfunctions in the operation of the units can be judged by the signals of the red, yellow and green indicators.

The indicators are two or three light diodes located on the central panel, which begin to blink with different intensities when a particular failure occurs.

In some models of Beretta gas boilers, signals about errors and malfunctions are provided by light indicators located on the control panel

A blinking green indicator may mean the following:

- 1 time/3.5 sec – the equipment is switched to standby mode, the fire is extinguished;

- 1 time/0.5 sec – the boiler is stopped due to a breakdown;

- 1 time/0.1 sec – the unit is switched to the auto-regulation system;

- the indicator is on and does not blink - the boiler is working normally, the fire is burning.

Beretta City can stop on its own due to a breakdown if it receives a signal from pressure and smoke sensors.

The boiler may pause operation for 10 minutes, during which the correct parameters must be restored. During this time, the system will automatically scan. A detailed guide on how to check the sensor readings of a Beretta gas boiler should already be included in the self-diagnosis system.

The indicators on the Beretta boiler panel can produce signals in different combinations and with different intensities. The type of light signal depends on what error occurred during the operation of the unit

The red indicator turns on in the following cases:

- the indicator is on and does not blink - if after stopping the boiler operation is not established, the unit goes into emergency mode;

- the indicator is flashing - the limit temperature sensor is triggered. Sometimes you can eliminate the error using the operating mode switch.

Simultaneous flashing of the red and green diodes occurs in the event of a breakdown of the NTC sensor.

The yellow indicator lights up and stays lit when preheating of the coolant in the circuit is turned on.

If you are not confident in your abilities and knowledge, it is strongly recommended to invite a qualified specialist to repair your Beretta gas boiler

To eliminate all the above-described problems with Beretta gas boilers, it is strongly recommended to use the services of specialists from authorized service centers and organizations with which an agreement has been concluded for the maintenance of gas units and the supply of blue fuel.

Independent intervention in the complex design of boilers can lead to an even more serious breakdown, which will result in expensive repairs and a long shutdown of the autonomous heating system.

Error codes on the boiler display

The LCD display, which is equipped with almost all models of Beretta gas boilers, displays information about the operating mode of the equipment, as well as error codes and malfunctions that arise during operation.

Most failures are resolved by rebooting the boiler. But if the problem does not disappear after rebooting, you need to check the parts and components listed below.

The LCD display is located on the control panel of the Beretta gas boiler; in case of failures and malfunctions, error codes are displayed on it, which can be used to determine which unit of the unit has problems

We tried to collect the most complete list of errors.

A01 – there is no flame on the burner, 5 unsuccessful attempts to ignite.

Check:

- presence of gas in the pipeline;

- boiler shut-off valve position;

- adjust the gas valve;

- clean the burner with nozzles;

- ignition electrode, if necessary, clean the contacts;

- ignition relay;

- change the slave board.

A02 – thermostat overheating.

Check:

- thermostat, integrity of wiring to it;

- clean or replace the circulation pump;

- If the pressure in the circuit is low, add fluid.

A03 – violation of smoke removal.

Check:

- presence of traction;

- clean the chimney of the gas boiler, if necessary, chip off the ice at the outlet;

- clean or replace the fan, check the contacts;

- smoke sensor and its contacts.

A04 – decrease in water pressure in the system.

Check:

- presence of leaks;

- pressure sensor, its contacts;

- circulation pump;

- presence of blockages in the system;

- change the slave board.

A05 – failure of the NTC hot water supply temperature sensor.

In order to better understand the reason for the malfunction of the Beretta brand gas boiler, it is advisable to familiarize yourself with the design features of the unit. The device diagram must be in the technical passport

Check:

- NTC sensor, its connections, replace the part if necessary;

- change the slave board.

A06 – failure of the NTC heating temperature sensor.

Check:

- NTC sensor, its connections, replace if necessary;

- change the slave board.

A07 – the thermal relay does not open.

Check:

- change the slave board.

A08-A10 – internal error of the slave board.

Check:

- change the slave board.

A11 – flame simulation (fire on a switched off burner).

Check:

- press Reset, reboot;

- contact service specialists.

A12, A15 – errors on the slave board.

Check:

- change the slave board.

A16, A18 – errors on the main board.

Check:

- replace the main board.

A20 – fire remains after closing the gas valve.

Check:

- gas valve, replace if necessary.

A24 – fan malfunction.

Check:

- fan connection, its contacts;

- if damaged, replace the fan.

ADJ – failure in min and max power settings.

Check:

- configure the necessary parameters.

E02 – NTC1 sensor is not connected.

Check:

- NTC1 sensor and its connections, replace if necessary.

E04 – NTC3 sensor is not connected.

Check:

- NTC3 sensor, its connections, replace if necessary.

E18 – short circuit of NTC1 sensor.

Check:

- NTC1 sensor connector;

- replace the part.

E20 – short circuit of NTC3 sensor.

Check:

- NTC3 sensor connector;

- replace the part.

E23-E26 - errors on the main board.

Check:

- replace the main board.

E32 – no slave (SALVE).

Check:

- position of two-pole switches on individual units, bring them to the ON state.

E33 – phase and neutral are incorrectly connected.

Check:

- reconnect in the correct order.

E34 – Reset button error when pressed more than 7 times within 30 minutes.

Check:

- wait 40 minutes for the error to disappear;

- replace the slave board.

E35 – pressure switch failure.

Check:

- check the water flow in each circuit, bring it to the norm of 2 m3/h;

- replace with a new part with a setting of 500 l/h.

E36 – error on the slave board.

Check:

- change the slave board.

E37 – failure when fire is detected.

Check:

- clean or replace electrodes.

E38 – smoke sensor short circuit.

Check:

- replace element.

E39 - no contact with the smoke sensor.

Check:

- smoke sensor connector;

- replace the part.

E40 – 50 Hz error.

Check:

- frequency in the electrical line;

- connect a voltage stabilizer.

E41 – error on the slave board.

Check:

- change the slave board.

E42 – short circuit of the sensor on the supply pipe.

Check:

- sensor connector on the supply pipe;

- replace the part.

E43 - no contact with the sensor on the supply pipe.

Check:

- sensor connector on the supply pipe;

- replace the part.

E44 – short circuit of the sensor on the return pipe.

Check:

- sensor connector on the return pipe;

- replace the part.

E45 - no contact with the sensor on the return pipe.

Check:

- sensor connector on the return pipe;

- replace the part.

E46 – overheating of the sensor on the supply pipe.

Check:

- measure the water flow in each circuit;

- bring the flow rate to the norm of 2m3.

E47 – overheating of the sensor on the return pipe.

Check:

- measure the water flow in each circuit;

- bring the flow rate to the norm of 2m3.

E48 – smoke sensor overheating.

Check:

- measure the water flow in each circuit;

- clean the heat exchangers on both sides.

Sometimes situations occur when errors are not shown on the display of a Beretta gas boiler, but other signs of equipment malfunctions appear.

Such signs include the appearance of gas or burning odors in the room with the boiler, delayed operation of the boiler burner, as well as a noticeable difference between the heating of the boiler and the temperature of the batteries. These manifestations of problems should be treated with no less attention than the codes on the display.

Start-up and operating instructions

After purchasing and delivering the boiler, you must install it on a load-bearing wall and connect it to a coaxial chimney, for which you will have to make a hole in the outer wall.

Then communications are connected:

- Gas supply.

- Heating circuit forward and return pipelines.

- Water supply for hot water supply and make-up.

- Power supply.

The first start of the boiler is carried out after checking the quality of the connections and filling the system to a pressure of 1-1.5 bar on the pressure gauge.

When the required temperature and operating mode are set, a signal is sent to start the burner, which is produced by the electric ignition system, after which the boiler begins to heat the coolant.

Operation of the unit does not require special measures and consists of periodically cleaning the housing, adjusting the operating mode as necessary and switching the boiler to winter or summer mode at the right time.

All other actions are performed only by specialists from the service center.

Independent intervention in the boiler design is regarded as a refusal of further warranty service at the initiative of the user.

Download instructions

Download instructions for the Beretta CIAO 24 CSI gas boiler.

Series and models related to them

Beretta gas boilers are available in different model ranges and lines.

Floor standing boilers are available in three series:

- Avtonom. A series of energy-independent single-circuit boilers with a massive cast-iron heat exchanger. They have a piezo ignition system and can be connected to a room thermostat and an external boiler. A total of 8 models are offered with power from 18 to 86 kW.

- MAXIMA. A series of powerful energy-independent single-circuit boilers. The line includes 11 models with power from 90 to 279 kW. They have impressive dimensions and are capable of cascading up to 4 units, creating a high-power station.

- NOVELLA E. Single-circuit energy-dependent boilers with a capacity of 18-78 kW (10 models in total). Designed for use in private homes. Can be used in conjunction with an external indirect heating boiler (Novella 55 rai).

There are 4 series of Beretta wall-mounted boilers:

- MYNUTE BOILER. The series consists of three energy-independent models with a power of 24-28 kW. They have a built-in storage boiler with a capacity of up to 60 liters.

- CIAO. The line consists of 6 dual-circuit models with a bithermal heat exchanger. The boiler power is 16, 24 and 28 kW. The combustion chamber is open or closed.

- CITY. Consists of 8 models of single- and double-circuit gas boilers with a separate heat exchanger. The combustion chamber is both open and closed. Power 24, 28 and 35 kW.

- EXCLUSIVE. There are 7 models available with a power of 24-35 kW. There are single- and double-circuit design options, with an open and closed combustion chamber. They have a push-button control panel with an LCD display and a separate heat exchanger.

Condensing boilers:

- CITY GREEN. One model with a power of 25 kW. Double-circuit turbocharged boiler with separate heat exchanger.

- EXCLUSIVE GREEN. 5 models with power 16, 25 and 35 kW. Single- and double-circuit turbocharged boilers with a separate heat exchanger.

The choice of Beretta models is very wide and can satisfy the wishes of any buyer.

Additional Instructions

The Beretta gas boiler, which has only positive reviews, must be connected to gas pipeline pipes that are made exclusively of metal. The use of flexible hoses is permissible only for connecting individual consumers. The chimney must have a cross-section that corresponds to the power parameters of the unit. If it is equal to 30 kilowatts, then the diameter of the chimney should be 130 millimeters. When the power increases to 40 kilowatts, the diameter increases to 170 millimeters. It is impossible to allow the cross-sectional area to be less than the cross-sectional area of the hole for connecting this element.

If you decide to choose a Beretta gas boiler, the installation instructions for which are presented in the article, then it is important to remember that the upper end of the chimney should be 0.5 meters above the ridge. This value is the minimum.

How to choose a boiler

- Define your goal. What do you intend to use the heater for - just to heat the house or also to heat hot water. In the first case, take a single-circuit device, in the second, you need a double-circuit device.

- Determine how much area will be heated. Depending on the area, the power will be selected.

- Which installation option is more convenient for you - wall-mounted or floor-mounted?

- Are additional functions needed?

All models from the Italian brand are compact and silent; they do not bother their owners at all with their work. They have a stylish design, the boilers fit perfectly into modern interiors.

Protective systems

- From freezing. It is possible to operate at low temperatures. If necessary, there is a start to warm up the system.

- From lack of traction. The device turns off when there is a shortage.

- From blocking the pump. Automatic shutdown when left idle for a long time. The shutdown frequency is once a day.

- From improper ignition. There is a built-in flame control device.