The issue of country heating is becoming more acute every year: everything is becoming more expensive, both firewood, coal or peat, and their delivery. Meanwhile, potential fuel is literally “lying” under our feet. We can use shavings and sawdust, dry leaves and straw, the husks of all grain crops, wood chips and branches cut off while tending the garden, unusable boards - all this is quite suitable for making fuel briquettes with your own hands. And if you come to an agreement with the manager of a nearby forestry enterprise or park, or make friends with the owner of a sawmill, you will have plenty of material for briquettes for personal use.

Homemade sawdust briquettes are an excellent fuel

For reference

It is impractical and even pointless to send wood waste in its natural form to a furnace or boiler. Their friability leads to the fact that burnout occurs in the shortest possible time and is accompanied by weak heat transfer. In addition, a significant part of the sawdust spills from the grate into the ash pan, which reduces efficiency and increases consumption. Sawdust fuel briquettes do not have all these disadvantages. From an economic point of view, it is unreasonable not to use waste, which is available in abundance at the dacha, for one’s own purposes.

You can use shavings, straw, hay, and dry leaves as raw materials.

Material selection

The determining factor in the quality of European firewood is the raw material for production. Most briquettes for heating with your own hands are characterized by low heat transfer precisely because of incorrectly selected and prepared manufacturing materials.

The most popular waste products currently used are wood processing industry waste – sawdust, shavings, etc.

Wooden briquettes for heating

In reviews of briquettes for heating, it is about wood models that the most conflicting opinions are expressed. This can be explained by the characteristics of the original manufacturing material. Unlike coal briquettes for heating, European firewood made from wood waste has one significant drawback - moisture absorption.

This can lead to artificial weight gain due to increased water content. Alas, there are no regulatory documents for the production of Euro-firewood. Therefore, manufacturers most often introduce internal standards, which may not always meet customer expectations. If the technology was followed during the production of wood briquettes for heating, then the product must meet the requirements from the table.

| Characteristic | Meaning |

| Bulk mass, kg/m³ | 125 |

| Briquette density, kg/m³ | 1150 |

| Humidity, % | 6-10 |

| Calorific value, MJ/kg | 25 |

| Ash content, % | 0,5-1,3 |

How to distinguish a quality product from a dubious one? The first one must have a number of qualities:

- Uniform surface firing or correct shape of RUF cubes;

- No condensation on the surface or water stains;

- All briquettes from the same batch have the same shape and size.

But besides this, you need to ensure the correct storage location. To do this, it is recommended to use a separate room with normal ventilation and room temperature. When organizing heating with sawdust briquettes, the fuel is most often stored in an adjacent room.

Fuel briquettes have proven themselves best in long-burning fuel boilers.

Peat and coal briquettes for heating

The use of peat and brown coal to make heating briquettes with your own hands is due to large reserves of raw materials. This helps reduce production costs, and as a result, reduce heating costs.

The main problem with peat and coal heating briquettes is the initially high humidity. To solve this problem, it is necessary to perform a drying procedure in special sealed thermal chambers. However, the high cost will not allow most manufacturing enterprises to include them in the technological process.

As a result, peat heating briquettes are characterized by slightly worse parameters than those made from sawdust.

| Characteristic | Meaning |

| Bulk mass, kg/m³ | 280-400 |

| Briquette density, kg/m³ | 500-600 |

| Humidity, % | 12-18 |

| Calorific value, MJ/kg | 16-18 |

| Ash content, % | 3-5 |

Also, unlike European sawdust firewood, ash from peat or coal analogues is practically not used as a fertilizer for the soil. In addition, most often they are made by pressing without additional surface firing. This leads to a decrease in the strength and shelf life of coal heating briquettes.

To preserve the thermal conductivity of the fuel briquette and reduce its humidity, it is recommended to store some of them in the boiler room.

Advantages of do-it-yourself fuel briquettes

Homemade fuel has many advantages.

- Almost any waste, except food and artificial, is suitable as a raw material for fuel briquettes. They can be injected with coal dust, which is considered an inevitable loss.

- Fuel briquettes have an impressive burning time of up to 4 hours. And throughout this entire period heat will be generated.

- It is quite possible to make your own fuel briquettes. Moreover, such production does not require significant initial investments.

- When burning fuel briquettes, virtually no smoke is released.

- Briquettes made from sawdust and other wood waste are extremely environmentally friendly, because only natural ingredients are used to make fuel briquettes.

- Such fuel is practical and economical: its cost when produced independently is several times lower than the same amount of coal or firewood, and the energy output is the same, or even higher. In addition, ash from sawdust briquettes and other wood waste is an excellent fertilizer for cultivated plants.

True, the production of fuel briquettes from sawdust requires some time and physical effort. On the other hand, in a country house there is always free time. And work, as we know, ennobles.

Fuel briquettes are multifunctional

Main advantages

Fuel briquettes are a modern type of alternative fuel. They can be used in any stoves, fireplaces, boilers, grills, barbecues. Eurobriquettes are cylindrical billets resembling firewood, or rectangular bricks. Small dimensions allow them to be placed in fireboxes of any size.

What are briquettes made from? Most often, wood is used (sawdust, shavings, dust), but straw, paper, peat, coal, seed or nut husks, and even manure are also used. The composition of eurobriquettes can vary significantly, depending on what technology is used in production.

At the same time, all types of raw materials from which firewood can be produced are natural, absolutely natural. Making fuel briquettes at home will allow you to create an environmentally friendly product that will burn almost completely in the furnace firebox and at the same time emit a minimum of smoke.

A home-made eurobriquette can be used to light a sauna stove or heat a home. Since the raw material is compressed quite strongly and the amount of moisture is minimal, the fuel briquette burns for a long time, constantly releasing a large amount of heat. An interesting point was noticed by people who are already actively using such fuel: if you heat your barbecue with eco-wood and fry food on it, if fat gets on the briquettes, it will not ignite.

For stoves, boilers and fireplaces that burn solid fuel, sawdust briquettes are an excellent option. They flare up slowly, but then burn for a long time and emit a large amount of heat. This is explained by the high density of the pressed wood product. The heat transfer from briquettes significantly exceeds the level of heat obtained from the combustion of even the driest firewood, the storage and drying of which took at least a year.

The humidity of fuel briquettes is 8-9%, dry firewood, in turn, has an indicator of 20%. It turns out that a briquette made from the same wood burns better than the wood itself. This effect is formed due to the fact that when burning, fuel briquettes do not need to evaporate a large amount of moisture.

The briquette burns with a stable fire, without splashes, sparks, or crackles, and the amount of smoke released during combustion can be described as small. It is extremely convenient to put such fuel into the stove, since all products have the same correct shape.

A little trick: if you want to create an intense fire with high heat transfer, you should place fuel briquettes in the firebox at some distance from each other and, conversely, to maintain smoldering, you need to tightly connect all the eco-wood in the firebox.

Like any product, fuel briquettes are not without their disadvantages:

- First of all, it is worth noting that they are very vulnerable to moisture, so they are sold in cellophane packaging.

- Briquettes are not able to withstand mechanical stress, especially products made using RUF technology that are not fired on the outside.

- If you want to start making such things at home, it will cost you a pretty penny, although there will certainly be benefits in the long run. The fact is that you will have to purchase a grinding installation, a dryer and a pressing machine in order to carry out the entire cycle of work with raw materials. With suitable equipment, it will be possible to set up artisanal production of fuel briquettes even in your own garage.

Scope of application

Sawdust briquettes have a fairly wide functionality. This fuel can be used:

- for heating a residential building. Due to their compactness, briquettes made from wood raw materials are suitable for fireplaces, stoves, and solid fuel boilers;

- when heating baths and saunas, if your main house is heated in some other way. Briquettes ideally suit all environmental conditions;

- on picnics. They are an excellent alternative to coal and firewood. Moreover, they can boast of a remarkable property: when fat gets on a hot briquette, the latter does not ignite and does not smoke.

By the way, sawdust briquettes should probably be recommended for cooking in closed spaces: there is no burning smell, and the dish is fried extremely evenly.

A little theory

Before you start making homemade briquettes, you should familiarize yourself with the stages of their industrial production. This will help you avoid making mistakes when creating your own fuel. The algorithm of actions in production is as follows.

- The raw materials are crushed to approximately the same particle size of the starting material.

- The sawdust is dried; The humidity level should drop to 10 percent.

- Next, either a hydraulic press or an extruder is used, depending on the method of forming the fuel, which is preferred in production.

- At the final stage, the finished product is packaged to prevent it from absorbing moisture from the atmosphere.

In the production of sawdust briquettes, no adhesive material is used. Under pressure from the press, when the raw material spontaneously heats up, lignin is released from the wood, which prevents the disintegration of the finished product, maintaining its given shape.

Features of making briquettes with your own hands

The equipment available for making fuel at home does not allow the press to press the raw material with enough force to cause lignin to begin to be released. Therefore, it will not be possible to make a briquette without binders in handicraft production.

In addition, the costs of drying equipment will make the finished product unprofitable - it will be cheaper to buy traditional coal and firewood. On the other hand, this inconvenience somewhat simplifies the production of briquettes with your own hands: you can skip the drying step while complying with a number of technological requirements. But a new difficulty appears: after you have passed the raw materials through the press for fuel briquettes with your own hands, you need to place the finished product to dry. That is, provide space under a canopy in the summer or a room with low humidity and sufficient temperature in other seasons.

However, real masters of the fuel business are engaged in the production of fuel briquettes exclusively during the summer season - and in winter they are actively consumed.

Necessary equipment

Despite the relative ease of obtaining fuel, you still have to acquire some equipment. Or adapt existing ones to new needs. What you will need:

- Chopper. You can’t do without it, because the finer the raw material, the denser the finished briquette. And when making it with your own hands, materials of various fractions are used. You won’t have to spend money on purchases if your farm has a device that chops vegetation to send it to compost. Inventors with skillful hands adapt an old activator-type washing machine for a shredder - they change the activator itself with knives;

- Any container where the raw materials will be mixed before being placed in the matrix. It would be a good idea to supplement the “trough” with a miniature concrete mixer or construction mixer. In the absence of both, get ready for hard physical work of kneading raw materials;

You can make a briquetting press yourself

- Press for the production of fuel briquettes. It can be manual or hydraulic, wall or floor mounted. In general terms, a press for the production of briquettes from sawdust and other plant waste consists of a solid frame made of steel and what can be called a working part;

- Matrices with which briquettes will be formed. They can be in the form of standard bricks, but it is more convenient to use cylindrical shapes - less fuss. Although warehousing and storing will be somewhat more difficult. The matrix must have perforated walls: moisture squeezed out of the workpiece by the press will be removed through the holes.

Particular attention should be paid to the moment of pressing. Muscular effects are a waste of time and effort with low efficiency. Experienced craftsmen recommend equipping the press for the production of fuel briquettes with a hydraulic jack from a car. It should be fixed upside down on the upper frame of the press.

Briquette manufacturing technology

The raw material for the production of fuel briquettes is wood processing waste - sawdust, the main supplier of which is the sawmill. The type of wood does not matter, but the moisture content of the raw materials should be no more than 12%, size - up to 6 mm. Rotten wood should not be more than 5% of the total mass of waste. First, sawdust is sorted to eliminate large pieces of wood, after which they are fed into a crusher, and then to regrinding, where they are given the desired size.

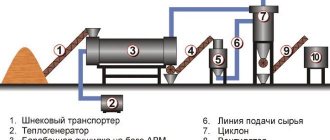

Crushed sawdust is fed into the heat generator and mixed with flue gases, then to the drying drum. From there, the briquette mass enters a cyclone, in which dry waste is separated from gases and settles to the bottom. Next, the material enters the conveyor and presses or extruders to create the necessary pressure. Sawdust briquettes for heating are made in two ways:

- creation using a hydraulic press;

- extrusion method.

The extrusion method consists in the fact that the raw material is poured into the receiving hopper of the device and goes into a tapering working channel, where it is strongly compressed using a press. The result is firewood made from sawdust in the shape of a hexagon. After undergoing heat treatment, they are cut to one size with a special knife.

With both technologies, Euro-firewood is produced by strongly squeezing wood waste, as a result of which lignin, a binding substance, is released from it. Due to strong compression, the raw material heats up , resulting in the formation of rectangular logs. Due to the high pressure, the briquette heats up so much that it chars a little. In some cases, after the press, the blanks are sent to the furnace for even greater heat treatment.

Hydraulic and screw presses facilitate the release of lignin, but maintaining such units is expensive, so they are used only in industrial production.

Algorithm for manufacturing fuel briquettes

Do-it-yourself briquetting is carried out differently than in production. The initial stage is similar: wood waste is shredded. But then there is no drying, but, on the contrary, soaking in water. Or at least good hydration so that you don’t have to express excess moisture later.

Next, a binder is introduced. There are three options here:

- Clay. The cheapest and most widely available filler. The proportions with the base material are 1:10. It perfectly binds the original wood raw materials, however, after using ready-made briquettes, a significant amount of ash waste is obtained: the clay practically does not burn.

- Wallpaper glue. It is devoid of the disadvantages of the previous additive, it is introduced in smaller quantities, but makes production noticeably more expensive.

- Any waste paper, including cardboard, pre-shredded and soaked. No waste, virtually no costs, proportions are the same as in the case of clay. There are two drawbacks. The finer the sawdust fraction, the more paper filler is required - this time. Second: it will take much longer to dry the finished briquettes.

The next step is mixing - manual or mechanized. To make a truly high-quality briquette, you need to bring the mass to the maximum possible homogeneity.

The press can also be wall-mounted

Next, the raw materials are placed in a briquetting mold, and the press is used. The output is briquettes of a given shape, which are sent for drying. They should be laid out loosely enough to allow space for ventilation. To speed up the drying process, it is recommended to periodically turn the fuel. And also - transfer the elements with paper or dry rags - these materials quickly draw excess moisture from the briquettes.

Fuel briquettes should be dried until their humidity reaches at least the level of wet firewood, that is, 25%. In fact, it is desirable to achieve even lower humidity - the heat transfer will then be higher. You are not in a hurry, so in hot weather you can easily afford to keep the fuel briquettes in the sun for a week longer. The warmer your home will be in winter. Please note that rushing is harmful: solid fuel boilers, like hydrolysis boilers, only operate on fuel whose humidity is not higher than 30%. Hurry up - you will pay for expensive repairs or even have to buy new heating equipment.

Well-dried fuel is removed for storage. You can keep briquettes in an unheated and fairly damp place if you pack them in plastic bags, tighten the neck tightly and seal it with several layers of overlapping tape.

There are also reasons to doubt

It's time to think

Before you get excited about sawdust briquetting, decide for yourself how interested you are in it. Despite the apparent simplicity of the process, it also has significant drawbacks.

- Preparing raw materials and pressing them into molds takes a lot of time and requires serious physical stress.

- If you want the drying of finished briquettes not to be affected by the weather, you will have to allocate a spacious, ventilated, dry room for them, which can clearly be used for other purposes.

- Modernization with the introduction of electrical equipment affects the cost of products. As a result, making briquettes with your own hands becomes not a way to save money, but a hobby, and not a cheap one.

- And most importantly: homemade sawdust briquettes are still inferior in quality to factory-made European fuel.

If you are serious about using the waste at your disposal rationally, consider making money from it. That is, about the production of fuel briquettes from sawdust in larger quantities. This could be a good business!

And how to make a press, watch the video:

Equipment and raw materials

You can create fuel briquettes with your own hands from various types of human waste. In principle, you can use any substance that can burn normally. What household waste can become valuable raw materials:

- First of all, wood, sawdust and shavings, wood dust, leaves and tree branches. The type of wood does not play a primary role, but it is better that the sawdust be birch, oak, alder or aspen.

- Straw left over from the harvest of wheat or corn.

- Cardboard and paper. It is much easier to make fuel briquettes from paper yourself than from wood, but the paper version will burn out faster.

- Residues and husks of seeds and nut shells can be good but rare raw materials.

Good to know: What can you use to heat a stove besides wood, consider peat and coal

The composition of briquettes can be different, and hence the different adhesive capabilities of the mixture. Depending on the raw materials used, clay is added to some briquettes to help bind the elements, usually in a ratio of 10 to 1.

Sawdust can be the best raw material

To create homemade fuel briquettes you will need special equipment. You can order an entire line for home production at once by contacting a specific company, or you can assemble the equipment in parts, because the technology for making fuel briquettes is essentially simple.

The whole technology is based on three stages of production:

- The first stage involves the initial preparation of raw materials. The existing waste should be crushed and crushed to the required consistency so that the composition of the mixture is homogeneous.

- The second stage involves bringing the mixture to a ready-made state by drying. The drying machine removes moisture from the raw material.

- The third stage involves the manufacture of products; here fuel briquettes are pressed on a special machine under high pressure and temperature.

Screw press for working with raw materials

Accordingly, for each stage you will need to select a machine suitable for your raw materials: a crusher, a dryer and a press.

By and large, the production of fuel briquettes with your own hands is not much different from industrial production, except that they do not apply inflated criteria to the quality of products and do not pack the finished products in a hermetically sealed shell.

Another difference with home production is that you can, in principle, eliminate the dryer from the line. You can dry raw materials and briquettes naturally under the sun. By the way, if the raw materials are ready-made sawdust or seed husks, then you may not need a crusher.

Particularly skilled craftsmen make the press themselves, based on their needs and capabilities. Nowadays, access to information is not limited, so drawings of any type of device can be found freely available on the Internet. By assembling your press according to the drawings, you can make a unique briquetted product that will burn perfectly in furnace fireboxes.

Good to know: How to properly organize firewood storage, ready-made solutions

Friends who already deal with similar home-made or factory-made equipment can tell you how to make a press machine. You can choose a screw, hydraulic or shock-mechanical option.

Fuel briquette production machine

To install the equipment you will need a decent room. It will have to accommodate all the machines, raw materials and resulting products. It is advisable to provide comfortable conditions for drying so that the humidity of the briquettes is minimal, so take care of ventilation. To connect the machines you will need electricity, and since we produce fuel, we should not forget about fire safety measures.